Abstract

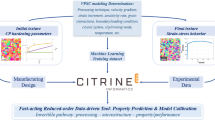

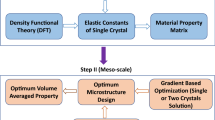

We have developed a machine learning-based crystal plasticity surrogate model (CP-SM) that can directly learn highly nonlinear material behavior during plastic deformation. CP-SM provides fast inference of spatially resolved three-dimensional (3D) microstructure and micromechanical fields and their evolution during plastic deformation, predicting the 22-dimensional material characteristics including a four-dimensional (4D) quaternion-based representation of crystal orientation, six-dimensional (6D) elastic and plastic strain tensors, and 6D stress at each location in the 3D structure. The predictions from CP-SM are orders of magnitude faster than and show good agreement with the deformation fields predicted by performing direct numerical simulations using spectral solvers. The fidelity of the CP-SM is further tested by assessing how well physics-based constraints are satisfied by the predicted 3D fields. We demonstrate our results on numerical simulations of uniaxially loaded copper.

Similar content being viewed by others

References

H.F. Poulsen, Three-dimensional X-ray Diffraction Microscopy: Mapping Polycrystals and their Dynamics (Springer, Berlin, 2004).

R. Pokharel, Materials Discovery and Design (Springer, Cham, 2018).

R. Pokharel, and R.A. Lebensohn, Scr. Mater. 132, 73. (2017).

D. Peirce, R.J. Asaro, and A. Needleman, Acta Metall. 31(12), 1951. (1983).

C.A. Bronkhorst, S.R. Kalidindi, and L. Anand, Philos. Trans. R. Soc. London A 341(1662), 443. (1992).

S.R. Kalidindi, C.A. Bronkhorst, and L. Anand, J. Mech. Phys. Solids 40(3), 537. (1992).

P.R. Dawson, Int. J. Solids Struct. 37(1–2), 115. (2000).

D. Raabe, and F. Roters, Int. J. Plast. 20(3), 339. (2004).

F. Roters, P. Eisenlohr, L. Hantcherli, D.D. Tjahjanto, T.R. Bieler, and D. Raabe, Acta Mater. 58(4), 1152. (2010).

H. Moulinec, and P. Suquet, CR Acad Sci Paris II 318, 1417. (1994).

R.A. Lebensohn, Acta Mater. 49(14), 2723. (2001).

R.A. Lebensohn, A.K. Kanjarla, and P. Eisenlohr, Int. J. Plast. 32, 59. (2012).

J. Segurado, and R.A. Lebensohn, J. Llorca. Adv. Appl. Mech. 51, 1. (2018).

R.A. Lebensohn, and A.D. Rollett, Comput. Mater. Sci. 173, 109336. (2020).

J. Ghaboussi, Soft Computing in Engineering (CRC Press, Boca Raton, 2018).

M. M. Hasan, A. Senthilnathan, and P. Acar (2021) AIAA Scitech 2021 Forum https://doi.org/10.2514/6.2021-1140

D. Reimann, K. Nidadavolu, N. Vajragupta, T. Glasmachers, P. Junker, and A. Hartmaier, Front. Mater. 6, 181. (2019).

R. Saunders, C. Butler, J. Michopoulos, D. Lagoudas, A. Elwany, and A. Bagchi, npj Comput. Mater. 7(1), 1. (2021).

D.M. de Oca Zapiain, and S.R. Kalidindi, Modell. Simul. Mater. Sci. Eng. 27(7), 074008. (2019).

A. Mangal, and E.A. Holm, Int. J. Plast. 111, 122. (2018).

A. Mangal, and E.A. Holm, Int. J. Plast. 114, 1. (2019).

A. Tran, and T. Wildey, JOM 73(1), 72. (2021).

K. Linka, M. Hillgärtner, K.P. Abdolazizi, R.C. Aydin, M. Itskov, and C.J. Cyron, J. Comput. Phys. 429, 110010. (2021).

A. T. Mohan, N. Lubbers, D. Livescu, and M. Chertkov. arXiv preprint https://arxiv.org/abs/2002.00021 (2020)

T. Kirchdoerfer, and M. Ortiz, Comput. Methods Appl. Mech. Eng. 304, 81. (2016).

K. Karapiperis, L. Stainier, M. Ortiz, and J.E. Andrade, J. Mech. Phys. Solids 147, 104239. (2021).

M. Mozaffar, A. Paul, R. Al-Bahrani, S. Wolff, A. Choudhary, A. Agrawal, and K. Ehmann, J. Cao. Manuf. Lett. 18, 35. (2018).

G. Capuano, and J.J. Rimoli, Comput. Methods Appl. Mech. Eng. 345, 363. (2019).

A. Frankel, K. Tachida, and R. Jones, Mach. Learn. Sci. Technol. 1(3), 035005. (2020).

M.J. Cherukara, Y.S. Nashed, and R.J. Harder, Sci. Rep. 8(1), 1. (2018).

Y.F. Shen, R. Pokharel, T.J. Nizolek, A. Kumar, and T. Lookman, Acta Mater. 170, 118. (2019).

A. Scheinker, and R. Pokharel, J. Appl. Phys. 128(18), 184901. (2020).

A. Pandey, and R. Pokharel, Scr. Mater. 193, 1. (2021).

M.A. Groeber, and M.A. Jackson, Integ. Mater. Manuf. Innov. 3(1), 56. (2014).

R. Pokharel, J. Lind, S.F. Li, P. Kenesei, R.A. Lebensohn, R.M. Suter, and A.D. Rollett, Int. J. Plast. 67, 217. (2015).

Z. Ding, E. Pascal, and M. De Graef, Acta Mater. 199, 370. (2020).

G.E. Karniadakis, I.G. Kevrekidis, L. Lu, P. Perdikaris, S. Wang, and L. Yang, Nat. Rev. Phys. 3(6), 422. (2021).

Acknowledgements

This work was supported by the U.S. Department of Energy through Los Alamos National Laboratory. Los Alamos National Laboratory (LANL) is operated by Triad National Security, LLC, for the National Nuclear Security Administration of the US Department of Energy (Contract No. 89233218CNA000001).

Funding

The work was funded by LANL’s LDRD-ECR Project No. 20190571ECR.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Pokharel, R., Pandey, A. & Scheinker, A. Physics-Informed Data-Driven Surrogate Modeling for Full-Field 3D Microstructure and Micromechanical Field Evolution of Polycrystalline Materials. JOM 73, 3371–3382 (2021). https://doi.org/10.1007/s11837-021-04889-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-021-04889-3