Abstract

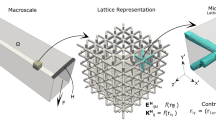

The present work addresses gradient-based and machine learning (ML)-driven design optimization methods to enhance homogenized linear and nonlinear properties of cubic microstructures. The study computes the homogenized properties as a function of underlying microstructures by linking atomistic-scale and meso-scale models. Here, the microstructure is represented by the orientation distribution function that determines the volume densities of crystallographic orientations. The homogenized property matrix in meso-scale is computed using the single-crystal property values that are obtained by density functional theory calculations. The optimum microstructure designs are validated with the available data in the literature. The single-crystal designs, as expected, are found to provide the extreme values of the linear properties, while the optimum values of the nonlinear properties could be provided by single or polycrystalline microstructures. However, polycrystalline designs are advantageous over single crystals in terms of better manufacturability. With this in mind, an ML-based sampling algorithm is presented to identify top optimum polycrystal solutions for both linear and nonlinear properties without compromising the optimum property values. Moreover, an inverse optimization strategy is presented to design microstructures for prescribed values of homogenized properties, such as the stiffness constant (\(C_{11}\)) and in-plane Young’s modulus (\(E_{11}\)). The applications are presented for aluminum (Al), nickel (Ni), and silicon (Si) microstructures.

Similar content being viewed by others

References

Yu Liu M, Greene S, Chen W, Dikin DA, Liu WK (2013) Computational microstructure characterization and reconstruction for stochastic multiscale material design. Comp Aided Des 45(1):65–76

Mohammed B, Park T, Pourboghrat F, Jun H, Esmaeilpour R, Abu-Farha F (2018) Multiscale crystal plasticity modeling of multiphase advanced high strength steel. Int J Solids Struct 151:57–75

Horstemeyer MF (2012) Integrated Computational Materials Engineering (ICME) for metals: using multiscale modeling to invigorate engineering design with science. John Wiley & Sons, Hoboken

Adams Brent L, Surya K, Fullwood David T (2012) Microstructure sensitive design for performance optimization. Butterworth-Heinemann, Oxford

Johnson OK, Kurniawan C (2018) An efficient algorithm for generating diverse microstructure sets and delineating properties closures. Acta Mater 147:313–321

Acar P (2020) A new sampling approach for the multi-scale design of metallic materials. J Mech Des 142(8):081702

Kalidindi SR, Binci M, Fullwood D, Adams BL (2006) Elastic properties closures using second-order homogenization theories: case studies in composites of two isotropic constituents. Acta Mater 54(11):3117–3126

Fullwood DT, Niezgoda SR, Adams BL, Kalidindi SR (2010) Microstructure sensitive design for performance optimization. Progr Mater Sci 55(6):477–562

Sigmund O (1995) Tailoring materials with prescribed elastic properties. Mech Mater 20(4):351–368

Xu H, Yang L, Brinson C, Chen W (2014) A descriptor-based design methodology for developing heterogeneous microstructural materials system. J Mech Des 136(5):051007

Allison J, Backman D, Christodoulou L (2006) Integrated computational materials engineering: a new paradigm for the global materials profession. JOM 58(11):25–27

Cowles BA, Backman DG, Dutton RE (2015) Update to recommended best practice for verification and validation of icme methods and models for aerospace applications. Integr Mater Manuf Innov 4(1):16–20

Venkatesh V, Green R, O’Connell J, Cernatescu I, Goetz R, Wong T, Streich B, Saraf V, Glavicic M, Slavik D et al (2018) An ICME framework for incorporating bulk residual stresses in rotor component design. Integr Mater Manuf Innov 7(4):173–185

Acharjee S, Zabaras N (2003) A proper orthogonal decomposition approach to microstructure model reduction in rodrigues space with applications to optimal control of microstructure-sensitive properties. Acta Mater 51(18):5627–5646

Ganapathysubramanian S, Zabaras N (2004) Design across length scales: a reduced-order model of polycrystal plasticity for the control of microstructure-sensitive material properties. Comp Methods Appl Mech Eng 193(45–47):5017–5034

Adams BL, Henrie A, Henrie B, Lyon M, Kalidindi SR, Garmestani H (2001) Microstructure-sensitive design of a compliant beam. J Mech Phys Solids 49(8):1639–1663

Olaf E, Valerie R (2009) Introduction to texture analysis: macrotexture, microtexture, and orientation mapping. CRC Press, Boca Raton

Kocks UF, Tome CN, Wenk H-R (1998) Texture and anisotropy: preferred orientations in polycrystals and their effect on materials properties. Cambridge University Press, Cambridge

Kalidindi SR, Houskamp JR, Lyons M, Adams BL (2004) Microstructure sensitive design of an orthotropic plate subjected to tensile load. Int J Plast 20(8–9):1561–1575

Fast T, Knezevic M, Kalidindi SR (2008) Application of microstructure sensitive design to structural components produced from hexagonal polycrystalline metals. Comput Mater Sci 43(2):374–383

Zhang X-J, Chen K-Z, Feng X-A (2004) Optimization of material properties needed for material design of components made of multi-heterogeneous materials. Mater Des 25(5):369–378

Du P, Zebrowski A, Zola J, Ganapathysubramanian B, Wodo O (2018) Microstructure design using graphs. npj Comput Mater 4(1):1–7

Sundararaghavan V, Zabaras N (2007) Linear analysis of texture-property relationships using process-based representations of rodrigues space. Acta Mater 55(5):1573–1587

Acar P, Sundararaghavan V (2016) Utilization of a linear solver for multiscale design and optimization of microstructures. AIAA J 54:1751–1759

Acar P, Sundararaghavan V (2016) Linear solution scheme for microstructure design with process constraints. AIAA J 54:4022–4031

Rogl P, Podloucky R, Wolf W (2014) DFT calculations: a powerful tool for materials design. J Phase Equilib Diffus 35:221–222

Hafner J, Wolverton C, Ceder G (2006) Toward computational materials design: the impact of density functional theory on materials research. MRS Bull 31(9):659–668

Neugebauer J, Hickel T (2013) Density functional theory in materials science. Wiley Interdiscip Rev Comput Mol Sci 3(5):438–448

Schleder Gabriel R, Padilha Antonio CM, Mera AC, Marcio C, Adalberto F (2019) From dft to machine learning: recent approaches to materials science-a review. J Phys Mater 2(3):032001

Agrawal A, Deshpande PD, Cecen A, Basavarsu GP, Choudhary AN, Kalidindi SR (2014) Exploration of data science techniques to predict fatigue strength of steel from composition and processing parameters. Integr Mater Manuf Innov 3(8):1–19

Ankit A, Alok C (2016) Perspective: Materials informatics and big data: realization of the “fourth paradigm” of science in materials science. APL Mater 4(053208):1–10

Ramprasad R, Batra R, Pilania G (2017) Arun Mannodi-Kanakkithodi, and Chiho Kim. Machine learning in materials informatics: recent applications and prospects. npj Comput Mater 3(1):1–13

Paul A, Acar P, Ruoqian Liu W, Liao AC, Sundararaghavan V, Agrawal A (2018) Data sampling schemes for microstructure design with vibrational tuning constraints. Am Inst Aeronaut Astronaut (AIAA) J 56(3):1239–1250

Schütt KT, Sauceda HE, Kindermans P-J, Tkatchenko A, Müller K-R (2018) SchNet-a deep learning architecture for molecules and materials. J Chem Phys 148(24):241722

Jha D, Ward L, Paul A, Liao W, Choudhary A, Wolverton C, Agrawal A (2018) Elemnet: Deep learning the chemistry of materials from only elemental composition. Sci Rep 8(1):1–13

Ziletti A, Kumar D, Scheffler M, Ghiringhelli LM (2018) Insightful classification of crystal structures using deep learning. Nature Commun 9(1):1–10

Yang Z, Xiaolin Li L, Brinson C, Choudhary A, Chen W, Agrawal A (2018) Microstructural materials design via deep adversarial learning methodology. J Mech Des 140(11):10

Agrawal A, Choudhary A (2019) Deep materials informatics: applications of deep learning in materials science. MRS Commun 9(3):779–792

Paul A, Acar P, Liao W, Choudhary A, Sundararaghavan V, Agrawal A (2019) Microstructure optimization with constrained design objectives using machine learning-based feedback-aware data-generation. Comput Mater Sci 160:334–351

Jung J, Yoon JI, Park HK, Kim JY, Kim HS (2019) An efficient machine learning approach to establish structure-property linkages. Comput Mater Sci 156:17–25

Jha D, Choudhary K, Tavazza F, Liao WK, Choudhary A, Campbell C, Agrawal A (2019) Enhancing materials property prediction by leveraging computational and experimental data using deep transfer learning. Nature Commun 10(1):5316

Yang Z, Jha D, Arindam P, W Liao, A Choudhary, Agrawal A (2020) A general framework combining generative adversarial networks and mixture density networks for inverse modeling in microstructural materials design. pp 1–8

Liu P, Huang H, Antonov S, Wen C, Xue D, Chen H, Li L, Feng Q, Omori T, Yanjing S (2020) Machine learning assisted design of \(\gamma \)’-strengthened co-base superalloys with multi-performance optimization. Npj Comput Mater 6(1):1–9

D Jha, V Gupta, L Ward, Z Yang, C Wolverton, I Foster, W. Liao, Alok N. Choudhary, Ankit Agrawal (2021) Enabling deeper learning on big data for materials informatics applications. Sci Rep 11:4244

Choudhary K, Cheon G, Reed E, Tavazza F (2018) Elastic properties of bulk and low-dimensional materials using van der waals density functional. Phys Rev B 98(1):014107

Choudhary K, Garrity KF, Reid ACE, DeCost B, Biacchi AJ, Hight AR, Walker ZT, Jason Hattrick-Simpers A, Kusne G, Centrone A et al (2020) The joint automated repository for various integrated simulations (jarvis) for data-driven materials design. npj Comput Mater 6(1):1–13

Mezeix L, Green DJ (2006) Comparison of the mechanical properties of single crystal and polycrystalline yttrium aluminum garnet. Int J Appl Ceram Technol 3(2):166–176

Du X, Zhao JC (2017) Facile measurement of single-crystal elastic constants from polycrystalline samples. npj Comput Mater 3(1):1–8

Kresse G, Furthmüller J (1996) Efficient iterative schemes for ab initio total-energy calculations using a plane-wave basis set. Phys Rev B 54(16):11169

Kresse G, Furthmüller J (1996) Efficiency of ab-initio total energy calculations for metals and semiconductors using a plane-wave basis set. Comput Mater Sci 6(1):15–50

Jiří K, Bowler David R, Angelos M (2009) Chemical accuracy for the van der waals density functional. J Phys Condensed Matter 22(2):022201

Bunge H-J (2013) Texture analysis in materials science: mathematical methods. Elsevier, Amsterdam

Wenk HR (2016) Preferred orientation in deformed metal and rocks: an introduction to modern texture analysis. Elsevier, Amsterdam

Kumar A, Dawson PR (2000) Computational modeling of fcc deformation textures over rodrigues’ space. Acta Mater 48(10):2719–2736

Geoffrey Ingram Taylor (1938) Plastic strain in metals. J Inst Metals 62:307–324

Liu R, Kumar A, Chen Z, Agrawal A, Sundararaghavan V, Choudhary A (2015) A predictive machine learning approach for microstructure optimization and materials design. Sci Rep 5(1):1–12

Liaw A, Wiener M et al (2002) Classification and regression by randomforest. R News 2(3):18–22

Klosek V (2017) Crystallographic textures. EPJ Web Conf. 155:00005

Kunze K, Etter T, Grässlin J, Shklover V (2015) Texture, anisotropy in microstructure and mechanical properties of in738lc alloy processed by selective laser melting (slm). Mater Sci Eng A 620:213–222

Hearmon RFS (1956) The elastic constants of anisotropic materials-ii. Adv Phys 5(19):323–382

Haldipur P, Margetan FJ, Thompson RB (2004) Estimation of single-crystal elastic constants from ultrasonic measurements on polycrystalline specimens, vol 700. American Institute of Physics, College Park, pp 1061–1068

Cantwell Patrick R, Kim H, Schneider Matthew M, Hsu HH, Peroulis D, Stach Eric A, Strachan A (2012) Estimating the in-plane young’s modulus of polycrystalline films in mems. J Microelectromech Syst 21(4):840–849

Ju S-P, Wang C-T, Chien C-H, Huang JC, Jian S-R (2007) The nanoindentation responses of nickel surfaces with different crystal orientations. Molecular Simul 33(11):905–917

Acar P (2019) Eliminating mesh sensitivities in microstructure design with an adjoint algorithm. Finite Elements Anal Design 154:22–29

Acknowledgements

MH, PA, YM, AC, and AA would like to acknowledge the support from the National Science Foundation (NSF) CMMI Grants # 2053840/2053929. YM, AC, and AA also acknowledge partial support from NIST award 70NANB19H005 (CHiMaD).

Author information

Authors and Affiliations

Contributions

MH and PA conducted the research on microstructure modeling with ODF. KC and FT conducted the research on DFT. YM, AC, and AA conducted the machine learning research. All authors contributed to the manuscript preparation.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Hasan, M., Mao, Y., Choudhary, K. et al. Data-Driven Multi-Scale Modeling and Optimization for Elastic Properties of Cubic Microstructures. Integr Mater Manuf Innov 11, 230–240 (2022). https://doi.org/10.1007/s40192-022-00258-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s40192-022-00258-3