Abstract

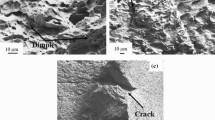

In an effort to optimize the transportation of oil and gas, the pipeline industry is developing large-diameter, thick-walled pipelines that can withstand low temperatures and high pressures. In this study, three X70 steel plates of similar chemistry, ranging in thickness from 13.5 mm to 22 mm, were subjected to drop-weight tear and Charpy V-notch tests to determine the effects of plate thickness and microstructure on the formation of separations and impact behavior. Constraint induced by specimen thickness appears to dictate the location of separations, the three microstructures exhibited different separation behaviors, and microstructural banding was not found to promote separation formation. Separations were most frequent when the primary fracture plane was parallel to the rolling direction. This study also found that standardized empirical relationships between Charpy V-notch and drop-weight tear tests do not estimate to the advanced high-strength and -toughness steels investigated.

Similar content being viewed by others

Change history

13 April 2021

A Correction to this paper has been published: https://doi.org/10.1007/s11837-021-04663-5

References

H. Hillenbrand, M. Graf, and C. Kalwa, Proceedings of the Niobium Science and Technology Conference, 543 (2001).

J. Ding, X. Liang, and S. Jiao, 9, 35 (Baosteel Technical Research, Shanghai, China, 2015)

S.Y. Shin, B. Hwang, S. Kim, and S. Lee, Mater. Sci. Eng. A 429, 196. (2006).

D.B. Rosado, W. De Waele, and D. Vanderschueren, Int. J. Sustain. Construct. Design 4, 1. (2013).

H. M. Al-Jabr, Colorado School of Mines Metallurgical and Materials Engineering, Golden, CO, PhD Thesis 2016.

B. Hwang, Y. Gon Kim, S. Lee, Y. Min Kim, N.J. Kim, and J. Yong Yoo, Metall. Mater. Trans. A 36A, 2107. (2005).

A.P. Coldren, and J.L. Mihelich, Metaltoved. Termichesk. ObrabotkaMetatlov 7, 44. (1977).

S. Li, Z. Jiang, Y. Li, D. Stalheim, Q. Li, and G. Zhang, in Proceedings of the 9th International Pipeline Conference, vol. 293 (2012).

X.L. Yang, Y.-B. Xu, X.-D. Tan, and D. Wu, Mater. Sci. Eng. A 607, 53. (2014).

M.S. Joo, D.W. Suh, J.H. Bae, N. Sanchez Mouriño, R. Petrov, L.A.I. Kestens, and H.K.D.H. Bhadeshia, Mater. Sci. Eng. A 556, 601. (2012).

M.S. Joo, D.-W. Suh, J.H. Bae, and H.K.D.H. Bhadeshia, Mater. Sci. Eng. A 546, 314. (2012).

S.Y. Shin, B. Hwang, S. Lee, N.J. Kim, and S.S. Ahn, Mater. Sci. Eng. A 458, 281. (2007).

A. Gervasyev, I. Pyshmintsev, A. Struin, T. Yesiev, and A. Arabey, in Pipeline Technology Conference, vol. 1 (2013).

W. Guo, H. Dong, M. Lu, and X. Zhao, Int. J. Press. Vessel. Pip. 79, 403. (2002).

ASTM E562, ASTM International, West Conshohocken, PA, (2011).

ASTM E112, ASTM International, West Conshohocken, PA, (2013).

ASTM E23, ASTM International, West Conshohocken, PA, (2018).

API RP 5L3, API, Washington, DC, (1996).

ASTM E436, ASTM International, West Conshohocken, PA, (2014).

B. Davis, University of Wollongong School of Mechanical, Materials, Mechatronic, and Biomedical Engineering, Ph.D. Thesis, (2017).

G. Wilkowski, W. Maxey, and R. Eiber, A.G.A.-EPRG Line Pipe Research Seminar III, 1 (1978).

M. Erdelen-Peppler, R. Gehrmann, G. Junker, G. Knauf, and A. Liessem, in 11th International Conference on Fracture (2005).

B. Hwang, S. Lee, Y.M. Kim, N.J. Kim, J.Y. Yoo, and C.S. Woo, Mater. Sci. Eng. A 368, 18. (2004).

M. Manahan, and C. McCowan, J. ASTM Int. 5, 1. (2008).

Y. Hioe, G. Wilkowski, M. Fishman, and M. Myers, in Proceedings of the 11th International Pipeline Conference, V003T05A015 (2016).

M. Connelly, J. Hammond, and S. Schmidt, White Paper, API SC5/Task Group on Line Pipe and the European Pipeline Research Group, vol. 1 (2011).

B. Hwang, S. Lee, Y. M. Kim, and N. J. Kim, in Proceedings of The Thirteenth International Offshore and Polar Engineering Conference, vol. 129 (2003).

E. B. Mitchell, Colorado School of Mines Metallurgical and Materials Engineering, Golden, CO, MS Thesis, (2019).

G.J. Baczynski, J.J. Jonas, and L.E. Collins, Metall. Mater. Trans. A 30A, 3045. (1999).

Acknowledgements

The author would like to acknowledge SABIC for providing the 13.5-mm and 15.5-mm plates and Baosteel for providing the 22-mm plate. The author would also like to thank EVRAZ North America for performing all DWT testing, and the National Institute of Standards and Technology (NIST) for performing all CVN testing. Finally, the author would like to thank colleagues and sponsors of the Advanced Steel Processing and Products Research Center at the Colorado School of Mines for their support. Commercial equipment, instrument, or materials are identified only in order to adequately specify certain procedures. In no case does such identification imply recommendation or endorsement by NIST. On behalf of all authors, the corresponding author states that there is no conflict of interest.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflicts of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This article was updated to correct duplication of author names in the reference list.

Rights and permissions

About this article

Cite this article

Mitchell, E.B., Lucon, E., Collins, L.E. et al. Microstructure and Thickness Effects on Impact Behavior and Separation Formation in X70 Pipeline Steel. JOM 73, 1966–1977 (2021). https://doi.org/10.1007/s11837-021-04562-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-021-04562-9