Abstract

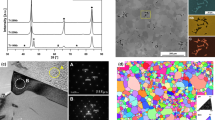

The effect of heat treatment conditions on the microstructure and mechanical properties of Mg-3Nd-3Al and Mg-3Nd-0.5Zr alloys has been comparatively investigated. The experimental results showed that the grain size of Mg-3Nd-3Al and Mg-3Nd-0.5Zr alloys was similar, which was 48 ± 4 μm and 46 ± 4 μm in as-cast condition and 50 ± 3 μm and 50 ± 4 μm in solid solution (T4) and solid solution + peak aging (T6) conditions, respectively. The intermetallic phases in the as-cast Mg-3Nd-3Al alloy were granular Al2Nd and acicular Al11Nd3. The intermetallic phase in the as-cast Mg-3Nd-0.5Zr alloy was Mg12Nd. The Al2Nd phase did not dissolve and the Al11Nd3 phase decomposed into the Al2Nd phase and the Mg12Nd phase completely dissolved into α-Mg during T4 treatment process. After T6 treatment, the amount of precipitation phase of the Mg-3Nd-3Al alloy was less than that of the Mg-3Nd-0.5Zr alloy. Compared with the Mg-3Nd-0.5Zr alloy, the Mg-3Nd-3Al alloy had higher strength and elongation in as-cast condition, lower strength in T6 condition and a weaker age-hardening effect.

Similar content being viewed by others

References

X.B. Zhang, G.Y. Yuan, L. Mao, J.L. Niu, P.H. Fu, and W.J. Ding, J. Mech. Behav. Biomed. 7, 77 (2012).

K. Suresh, K.P. Rao, Y.V.R.K. Prasad, N. Hort, and K.U. Kainer, JOM 66, 322 (2014).

J.H. Zhang, S.J. Liu, R.Z. Wu, L.G. Hou, and M.L. Zhang, J. Magn. Alloy 6, 277 (2018).

S.M. Zhu, M.A. Gibson, J.F. Nie, M.A. Eastona, and T.B. Abbottc, Scripta Mater. 58, 477 (2008).

Y.R. Gao, C.M. Liu, S.L. Fu, J. Jin, X. Shu, and Y.H. Gao, Surf. Coat. Tech. 204, 3629 (2010).

J.W. Chang, X.W. Guo, P.H. Fu, L.M. Peng, and W.J. Ding, Electrochimi. Acta 52, 3160 (2007).

H.H. Yu, Y.C. Xin, M.Y. Wang, and Q. Liu, J. Mater. Sci. Technol. 34, 248 (2018).

H.H. Yu, C.Z. Li, Y.C. Xin, A. Chapuis, X.X. Huang, and Q. Liu, Acta Mater. 128, 313 (2017).

Y. Ali, D. Qiu, B. Jiang, F.S. Pan, and M.X. Zhang, J. Alloys Compd. 619, 639 (2015).

L. Wang, Y.C. Feng, L.P. Wang, Y.H. Chen, and E.J. Guo, J. Mater. Eng. Perform. 27, 2099 (2018).

J.F. Nie, Metall. Mater. Trans. A 43, 3891 (2012).

W.J. Ding, P.H. Fu, L.M. Peng, H.Y. Jiang, and X.Q. Zeng, Mater. Sci. Forum 546, 433 (2007).

P.H. Fu, L.M. Peng, H.Y. Jiang, J.W. Chang, and C.Q. Zhai, Mater. Sci. Eng. A 486, 183 (2008).

D. Liu, J.F. Song, B. Jiang, Y. Zeng, Q.H. Wang, Z.T. Jiang, B. Liu, G.S. Huang, and F.S. Pan, J. Alloys Compd. 737, 263 (2018).

B.R. Powell, V. Rezhets, M.P. Balogh, and A. Waldo, JOM 54, 34 (2002).

Y.F. Jiao, J.H. Zhang, L.L. He, M.L. Zhang, F.C. Jiang, W. Wang, L.M. Han, L.J. Xu, and R.Z. Wu, Adv. Eng. Mater. 18, 148 (2016).

M.L. Su, J.H. Zhang, Y. Feng, Y.J. Bai, W. Wang, Z.W. Zhang, and F.C. Jiang, J. Alloys Compd. 691, 634 (2017).

GB/T 228.1-2010, Metellic materials -Tensile testing- Part 1:Method of test at room temperature. SCA.

P.H. Fu, L.M. Peng, H.Y. Jiang, C.Q. Zhai, X. Gao, and J.F. Nie, Mater. Sci. Forum. 546, 97 (2007).

R. Wilson, C.J. Bettles, B.C. Muddle, and J.F. Nie, Mater. Sci. Forum 419, 267 (2003).

Y.D. Huang, H. Dieringa, N. Hort, P. Maier, K.U. Kainer, and Y.L. Liu, J. Alloys Compd. 463, 238 (2008).

X.W. Zheng, L.D. Wang, J.L. Wang, Y.M. Wu, Z.L. Ning, J.F. Sun, and L.M. Wang, Mater. Sci. Eng. A 515, 98 (2009).

J.H. Zhang, J. Wang, X. Qiu, D.P. Zhang, Z. Tian, X.D. Niu, D.X. Tang, and J. Meng, J. Alloys Compd. 464, 556 (2008).

H.H. Zou, X.Q. Zeng, C.Q. Zhai, and W.J. Ding, Mater. Sci. Eng. A 392, 229 (2005).

D. Qiu and M.X. Zhang, J. Alloys Compd. 586, 39 (2014).

M. Sun, M.A. Easton, D.H. StJohn, G.H. Wu, T.B. Abbott, and W.J. Ding, Adv. Eng. Mater. 15, 373 (2013).

G. Mann, J.R. Griffiths, and C.H. Cáceres, J. Alloys Compd. 378, 188 (2004).

C.L. Wang, J.C. Dai, W.C. Liu, L. Zhang, and G.H. Wu, J. Alloys Compd. 620, 172 (2015).

Acknowledgement

The authors gratefully acknowledge the financial support from the Heilongjiang Province Natural Science Foundation (No. E2018045).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Wang, L., Feng, Y., Guo, E. et al. Comparative Study on Microstructure and Mechanical Properties of Mg-3Nd-3Al and Mg-3Nd-0.5Zr Alloys Under Different Heat Treatment Conditions. JOM 71, 2194–2201 (2019). https://doi.org/10.1007/s11837-019-03493-w

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-019-03493-w