Abstract

The effect of the second-phase morphology on dynamic recrystallisation in a Mg–9Gd–0.8Al alloy during hot extrusion was investigated at a temperature of 400 ℃. Microstructure analysis of the as-cast Mg–9Gd–0.8Al alloy revealed a predominant composition comprising an α-Mg matrix, a petal-like (Mg,Al)3Gd phase, and a lamellar Mg5Gd phase along the grain boundary, along with a small proportion of a square Al2Gd phase within the grain. Upon subjecting the alloy to a solid-solution treatment at 540 ℃, the lamellar phase underwent precipitation, eventually dissolving into the matrix as the treatment time increased. The recrystallisation volume fraction of the alloy showed a positive correlation with the solution time following hot extrusion at 400 ℃. The mechanical properties of the extruded alloy were tested, and the results revealed that the as-cast extruded alloy had the highest tensile strength of 317 MPa among the tested samples, mainly owing to its bimodal structure. Moreover, the broken (Mg,Al)3Gd phase initiated particle-stimulated nucleation. Here, the extruded alloy subjected to 10 h of solution treatment exhibited the highest yield strength of 240 MPa. The increased yield strength was attributed to the presence of the broken (Mg,Al)3Gd phase and the dispersion of lamellar (Mg,Al)2Gd phases at the recrystallised grain boundaries. Notably, the alloy extruded with a treated solution for 50 h exhibited the most favourable plasticity compared to the others, achieving an elongation of 29.7%. These results underscore the significance of the study in understanding the relationship between the second-phase morphology and alloy behaviour after hot extrusion.

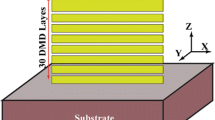

Graphical Abstract

Similar content being viewed by others

References

M. Wu, X. Jiang, J. Chen, H. Yan, W. Xia, B. Su, Y. Deng, High strength-thermal conductivity Mg–Ga–Ca–Ce Sheet by hot-extrusion and rolling. Met. Mater. Int. 30, 13–24 (2024). https://doi.org/10.1007/s12540-023-01481-z

F.H. Gao, B.J. Lv, T.W. Xu, N. Cui, F. Guo, Effects of Sn and Mn addition on the microstructure and mechanical properties of As-extruded Mg–2Al–1Zn alloys. Met. Mater. Int. 29, 3178–3189 (2023). https://doi.org/10.1007/s12540-023-01435-5

L. Yang, Q. Li, X. Chen, W. Mei, N. Zhang, Effect of Ce microalloying on microstructure and mechanical properties of extruded Mg–10Gd–0.5Zr alloy. Met. Mater. Int. 29, 3190–3203 (2023). https://doi.org/10.1007/s12540-023-01438-2

N.B. Tork, S.H. Razavi, H. Saghafian, R. Mahmudi, Microstructural evolution and mechanical properties of the As-cast and extruded Mg-Gd alloys. Adv. Eng. Mater. 18(1), 156–161 (2016). https://doi.org/10.1002/adem.201500189

B. Lei, B. Jiang, H.B. Yang, Z.H. Dong, Q.H. Wang, M. Yuan, G.S. Huang, J.F. Song, D.F. Zhang, F.S. Pan, Effect of Nd addition on the microstructure and mechanical properties of extruded Mg–Gd–Zr alloy. Mater. Sci. Eng. A 816, 141320 (2021). https://doi.org/10.1016/j.msea.2021.141320

J.H. Zhang, S.J. Liu, R.Z. Wu, L.G.M.L. HouZhang, Recent developments in high-strength Mg-RE-based alloys: focusing on Mg–Gd and Mg–Y systems. J. Magn. Alloys 6(3), 277–291 (2018). https://doi.org/10.1016/j.jma.2018.08.001

J.F. Nie, Precipitation and hardening in magnesium alloys. Metall. Mater. Trans. A 43(11), 3891–3939 (2012). https://doi.org/10.1007/s11661-012-1217-2

X. Tong, G.H. Wu, L. Zhang, W.C. Liu, W.J. Ding, Achieving low-temperature Zr alloying for microstructural refinement of sand-cast Mg–Gd–Y alloy by employing zirconium tetrachloride. Mater. Charact. 171, 110727 (2021). https://doi.org/10.1016/j.matchar.2020.110727

S.R. Agnew, R.P. Mulay, F.J. Polesak, C.A. Calhoun, J.J. Bhattacharyya, B. Clausen, In situ neutron diffraction and polycrystal plasticity modeling of a Mg–Y–Nd–Zr alloy: effects of precipitation on individual deformation mechanisms. Acta Mater. 61(10), 3769–3780 (2013). https://doi.org/10.1016/j.actamat.2013.03.010

J.C. Dai, M. Easton, S.M. Zhu, G.H. Wu, W.J. Ding, Grain refinement of Mg–10Gd alloy by Al additions. J. Mater. Res. 27(21), 2790–2797 (2012). https://doi.org/10.1557/jmr.2012.313

X.L. Hou, Z.Y. Cao, L. Zhao, L.D. Wang, Y.M. Wu, L.M. Wang, Microstructure, texture and mechanical properties of a hot rolled Mg-6.5Gd-1.3Nd-0.7Y-0.3Zn alloy. Mater. Des. 34, 776–781 (2012). https://doi.org/10.1016/j.matdes.2011.06.068

J.R. Li, A.Y. Zhang, H.C. Pan, Y.P. Ren, Z.R. Zeng, Q.Y. Huang, C.L. Yang, L.F. Ma, G.W. Qin, Effect of extrusion speed on microstructure and mechanical properties of the Mg–Ca binary alloy. J. Magn. Alloys 9(4), 1297–1303 (2021). https://doi.org/10.1016/j.jma.2020.05.011

X. Liu, H. Yang, B.W. Zhu, Y.Z. Wu, W.H. Liu, C.P. Tang, Unveiling the mechanical response and accommodation mechanism of pre-rolled AZ31 magnesium alloy under high-speed impact loading. J. Magn. Alloys 10(4), 1096–1108 (2022). https://doi.org/10.1016/j.jma.2021.07.030

J.G. Jung, S.H. Park, H. Yu, Y.M. Kim, Y.K. Lee, B.S. You, Improved mechanical properties of Mg-7.6Al-0.4Zn alloy through aging prior to extrusion. Scr. Mater. 93, 8–11 (2014). https://doi.org/10.1016/j.scriptamat.2014.08.017

J. Go, S.C. Jin, H. Kim, H. Yu, S.H. Park, Novel Mg-Bi-Al alloy with extraordinary extrudability and high strength. J. Alloys Compd. 843, 156026 (2020). https://doi.org/10.1016/j.jallcom.2020.156026

L.W. Zheng, X.P. Zhang, H.X. Wang, L.F. Wang, H. Hou, H. Li, S.S. Kwang, Synergistic effect of LPSO and eutectic phase on mechanical properties of Mg–Gd–Nd–Zn–Zr alloy during equal channel angular pressing. J. Mater. Res. Technol. 15, 2459–2470 (2021). https://doi.org/10.1016/j.jmrt.2021.09.058

Y.P. Zhuang, P.W. Zhou, H.X. Wang, K.B. Nie, Y.M. Liu, W. Liang, L.F. Wang, L.W. Zheng, The formation mechanism of the lamellar phase precipitated during solid solution treatment in the Mg–Gd–Al alloy. J. Mater. Res. Technol. 9(5), 11392–11401 (2020). https://doi.org/10.1016/j.jmrt.2020.08.024

X. Wang, W. Du, K. Liu, Z. Wang, S. Li, Microstructure, tensile properties and creep behaviors of as-cast Mg–2Al–1Zn–xGd (x=1, 2, 3, and 4wt.%) alloys. J. Alloys Compd. 522, 78–84 (2012). https://doi.org/10.1016/j.jallcom.2012.01.084

X.-F. Gu, T. Furuhara, Characterization of crystal structure and precipitation crystallography of a new MgxAl2−xGd phase in an Mg97Al1Gd2 alloy. J. Appl. Cryst. 49, 1177–1181 (2016). https://doi.org/10.1107/S1600576716008980

S.H. Park, S.H. Kim, Y.M. Kim, B.S. You, Improving mechanical properties of extruded Mg–Al alloy with a bimodal grain structure through alloying addition. J. Alloys Compd. 646, 932–936 (2015). https://doi.org/10.1016/j.jallcom.2015.06.034

K. Huang, R.E. Loge, A review of dynamic recrystallization phenomena in metallic materials. Mater. Des. 111, 548–574 (2016). https://doi.org/10.1016/j.matdes.2016.09.012

K. Wei, L.R. Xiao, B. Gao, L. Li, Y. Liu, Z.G. Ding, W. Liu, H. Zhou, Y.H. Zhao, Enhancing the strain hardening and ductility of Mg-Y alloy by introducing stacking faults. J. Magn. Alloys 8(4), 1221–1227 (2020). https://doi.org/10.1016/j.jma.2019.09.015

Z. Yang, C. Xu, T. Nakata, S. Kamado, Effect of extrusion ratio and temperature on microstructures and tensile properties of extruded Mg–Gd–Y–Mn–Sc alloy. Metall. Mater. Trans. A 800, 140330 (2021). https://doi.org/10.1016/j.msea.2020.140330

Y.M. Zhu, A.J. Morton, J.F. Nie, The 18R and 14H long-period stacking ordered structures in Mg–Y–Zn alloys. Acta Mater. 58(8), 2936–2947 (2010). https://doi.org/10.1016/j.actamat.2010.01.022

E.A. Ball, P.B. Prangnell, Tensile-compressive yield asymmetries in high strength wrought magnesium alloys. Scr. Metall. Mater. 31(2), 111–116 (1994). https://doi.org/10.1016/0956-716x(94)90159-7

G.W. Lorimer, L.W.F. Mackenzie, F.J. Humphreys, T. Wilks, The recrystallization behavior of AZ31 and WE43. Mater. Sci. Forum 488-489, 99–102 (2005). https://doi.org/10.4028/www.scientific.net/MSF.488-489.99

M. Mabuchi, K. Kubota, K. Higashi, Tensile strength, ductility and fracture of magnesium–silicon alloys. J. Mater. Sci. 31(6), 1529–1535 (1996). https://doi.org/10.1007/bf00357861

W.L. Cheng, S.S. Park, B.S. You, B.H. Koo, Microstructure and mechanical properties of binary Mg–Sn alloys subjected to indirect extrusion. Metall. Mater. Trans. A 527(18–19), 4650–4653 (2010). https://doi.org/10.1016/j.msea.2010.03.031

Z.Z. Jin, M. Zha, Z.Y. Yu, P.K. Ma, Y.K. Li, J.M. Liu, H.L. Jia, H.Y. Wang, Exploring the hall-Petch relation and strengthening mechanism of bimodal-grained Mg–Al–Zn alloys. J. Alloys Compd. 833, 155004 (2020). https://doi.org/10.1016/j.jallcom.2020.155004

Y.K. Li, M. Zha, H.L. Jia, S.Q. Wang, H.M. Zhang, X. Ma, T. Tian, P.K. Ma, H.Y. Wang, Tailoring bimodal grain structure of Mg–9Al–1Zn alloy for strength-ductility synergy: co-regulating effect from coarse Al2Y and submicron Mg17Al12 particles. J. Magn. Alloys 9(5), 1556–1566 (2021). https://doi.org/10.1016/j.jma.2021.01.0082213-9567

H. Zhang, H.Y. Wang, J.G. Wang, J. Rong, M. Zha, C. Wang, P.K. Ma, Q.C. Jiang, The synergy effect of fine and coarse grains on enhanced ductility of bimodal-structured Mg alloys. J. Alloys Compd. 780, 312–317 (2019). https://doi.org/10.1016/j.jallcom.2018.11.229

Z.Z. Jin, M. Zha, S.Q. Wang, S.C. Wang, C. Wang, H.L. Jia, H.Y. Wang, Alloying design and microstructural control strategies towards developing Mg alloys with enhanced ductility. J. Magn. Alloys 10(5), 1191–1206 (2022). https://doi.org/10.1016/j.jma.2022.04.002

M.R. Barnett, H. Wang, T.T. Guo, An Orowan precipitate strengthening equation for mechanical twinning in Mg. Int. J. Plast. 112, 108–122 (2019). https://doi.org/10.1016/j.ijplas.2018.08.010

D.H. Lee, B.G. Moon, Y.M. Kim, S.H. Park, Unusual relationship between extrusion temperature and tensile strength of extruded Mg–Al–Zn–Ca–Y–MM alloy. J. Alloys Compd. 862, 158051 (2021). https://doi.org/10.1016/j.jallcom.2020.158051

Q. Zhang, Q. Li, X. Chen, J. Zhao, J. Bao, Z. Chen, Dynamic precipitation and recrystallization mechanism during hot compression of Mg–Gd–Y–Zr alloy. J Mater Res. Technol. 15, 37–51 (2021). https://doi.org/10.1016/j.jmrt.2021.08.013

C.D. Barrett, A. Imandoust, A.L. Oppedal, K. Inal, M.A. Tschopp, H. El Kadiri, Effect of grain boundaries on texture formation during dynamic recrystallization of magnesium alloys. Acta Mater. 128, 270–283 (2017). https://doi.org/10.1016/j.actamat.2017.01.063

C. He, S.W. Bai, B. Jiang, L.T. Liu, Q.H. Wang, M. Yuan, Z.H. Dong, W. He, G.S. Huang, D.F. Zhang, F.S. Pan, Effect of Gd content on the microstructure, texture and mechanical properties of Mg–xGd–0.5Mn alloys. J. Mater. Res. Technol. 20, 343–358 (2022). https://doi.org/10.1016/j.jmrt.2022.07.034

N. Stanford, D. Atwell, M.R. Barnett, The effect of Gd on the recrystallisation, texture and deformation behaviour of magnesium-based alloys. Acta Mater. 58(20), 6773–6783 (2010). https://doi.org/10.1016/j.actamat.2010.09.003

Acknowledgements

This work was supported by the Natural Science Foundation of Shanxi Province (20210302123135, 20210302123163, 202303021221143), Scientific and Technological Achievements Transformation Guidance Special Project of Shanxi Province (202104021301022, 202204021301009), Central Government Guided Local Science and Technology development projects (YDZJSX20231B003, YDZJSX2021A010) and National Natural Science Foundations of China (52374395). The Ministry of Science and higher Education of the Russian Federation for financial support under the Megagrant (No. 075-15-2022-1133) and the National Research Foundation (NRF) grant funded by the Ministry of Science and ICT (2015R1A2A1A01006795) of Korea through the Research Institute of Advanced Materials. China Postdoctoral Science Foundation (2022M710541), Research Project Supported by Shanxi Scholarship Council of China (2022-038).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Wang, C., Yang, Z., Ren, G. et al. Microstructures and Mechanical Properties of Extruded Mg-Gd-Al Alloys: Influence of Initial Second-Phase Morphology Before Extrusion. Met. Mater. Int. (2024). https://doi.org/10.1007/s12540-024-01665-1

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s12540-024-01665-1