Abstract

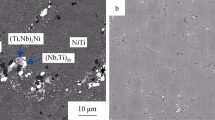

The microstructures and mechanical properties of 66(NixAl)-28Cr-6Mo (x = 1.0, 1.5, 2.0, 2.5, 3.0, and 3.5) alloys were investigated using scanning electron microscopy, energy dispersive spectroscopy, transmission electron microscope, microhardness, and compression tests. The microstructure of NiAl-28Cr-6Mo (Ni1.0) eutectic alloy consists of NiAl and Cr(Mo) phases. With increasing the Ni content to 2.0, the microstructure changes from eutectic (Ni1.0) to eutectic + primary NiAl dendrite (Ni1.5 and Ni2.0), and the morphologies of part of precipitates in primary NiAl dendrite evolve from granular to needle-like. When the Ni content increases further, besides eutectic and primary NiAl dendrite, the gray phase forms and is identified as an ordered FCC (L12) (Ni,Cr)3(Al,Mo) phase. Moreover, the more needle-like precipitates emerge in the primary NiAl dendrite of Ni2.5, Ni3.0, and Ni3.5 alloys, and the precipitate is identified as a bcc Cr(Mo) phase. The deep etching reveals that the three-dimensional morphology of Cr(Mo) precipitate is not needle-like but lath-like. Among the investigated alloys, both Ni2.0 and Ni2.5 alloys possess the higher fracture strength and microhardness. The relevant strengthening mechanisms are discussed.

Similar content being viewed by others

References

D.R. Johnson, X.F. Chen, B.F. Oliver, R.D. Noebe, and J.D. Whittenberger, Intermetallics 3, 99 (1995).

H. Bei and E.P. George, Acta Mater. 53, 69 (2005).

A. Misra and R. Gibala, Intermetallics 8, 1025 (2000).

J.F. Zhang, J. Shen, Z. Shang, Z.R. Feng, L.S. Wang, and H.Z. Fu, Intermetallics 21, 18 (2012).

D. Yu, H. Bei, Y. Chen, E.P. George, and K. An, Scripta Mater. 84–85, 59 (2014).

D. Yu, K. An, X. Chen, and H. Bei, J. Alloys Compd. 656, 481 (2016).

L. Wang, J. Shen, Z. Shang, and H.Z. Fu, Scripta Mater. 89, 1 (2014).

L. Wang, J. Shen, Y.P. Zhang, and H.Z. Fu, Mater. Sci. Eng. A 664, 188 (2016).

L. Wang and J. Shen, J. Alloys Compd. 663, 187 (2016).

C.Y. Cui, J.T. Guo, Y.H. Qi, and H.Q. Ye, Scripta Mater. 44, 2437 (2001).

J.T. Guo, Ordered Intermetallic Compound NiAl Alloy (Beijing: Science Press, 2003), p. 73.

L.Y. Sheng, F. Yang, T.F. Xi, Y.F. Zheng, and J.T. Guo, Intermetallics 27, 14 (2012).

L. Wang and J. Shen, Mater. Mater. Sci. Eng. A 654, 177 (2016).

L. Wang, J. Shen, Z. Shang, J.F. Zhang, J.H. Chen, and H.Z. Fu, Intermetallics 44, 44 (2014).

L.Y. Sheng, F. Yang, T.F. Xi, Y.F. Zheng, and J.T. Guo, Trans. Nonferrous Met. Soc. China 23, 983 (2013).

L.Y. Sheng, W. Zhang, J.T. Guo, and H.Q. Ye, Mater. Charact. 60, 1311 (2009).

L. Wang, J. Shen, Y.P. Zhang, L.L. Guo, H.X. Xu, and H.Z. Fu, Intermetallics 84, 11 (2017).

P.L. Ferrandini, F.L.G.U. Araujo, W.W. Batista, and R. Caram, J. Cryst. Growth 275, e147 (2005).

S. Milenkovic and R. Caram, Metall. Mater. Trans. A 46, 557 (2015).

S. Milenkovic and R. Caram, J. Mater. Process. Technol. 143–144, 629 (2003).

F.J. Wang, Y. Zhang, G.L. Chen, and H.A. Davies, Int. J. Mod. Phys. B 23, 1254 (2009).

F. Otto, A. Dlouhy, Ch. Somsen, H. Bei, G. Eggeler, and E.P. George, Acta Mater. 61, 5743 (2013).

Y.P. Lu, Y. Dong, S. Guo, L. Jiang, H.J. Kang, T.M. Wang, B. Wen, Z.J. Wang, J.C. Jie, Z.Q. Cao, H.H. Ruan, and T.J. Li, Sci. Rep. 4, 1 (2014).

Y.P. Lu, X.Z. Gao, J. Li, Z.G. Chen, T.M. Wang, J.C. Jie, H.J. Kang, Y.B. Zhang, S. Guo, H.H. Ruan, Y.H. Zhao, Z.Q. Cao, and T.J. Li, Acta Mater. 124, 143 (2017).

F. He, Z.J. Wang, P. Cheng, Q. Wang, J.J. Li, Y.Y. Dang, J.C. Wang, and C.T. Liu, J. Alloys Compd. 656, 284 (2016).

F. He, Z.J. Wang, S.Z. Niu, Q.F. Wu, J.J. Li, J.C. Wang, C.T. Liu, and Y.Y. Dang, J. Alloys Compd. 667, 53 (2016).

F. He, Z.J. Wang, Q.F. Wu, D. Chen, T. Yang, J.J. Li, J.C. Wang, C.T. Liu, and J.J. Kai, Scripta Mater. 155, 134 (2018).

Y.L. Chou, J.W. Yeh, and H.C. Shih, Corros. Sci. 52, 2571 (2010).

H.E. Cline, J.L. Walter, E. Lifshin, and R.R. Russell, Met. Trans. 2, 189 (1970).

Y.F. Han, S.H. Li, and M.C. Chaturvedi, Mater. Sci. Eng. A 160, 271 (1993).

P. Perez, P. Gonzalez, G. Garces, G. Caruana, and P. Adeva, J. Alloys Compd. 302, 137 (2000).

S. Singh, N. Wanderka, B.S. Murty, U. Glatzel, and J. Banhart, Acta Mater. 59, 182 (2011).

T.T. Shun, C.H. Hung, and C.F. Lee, J. Alloys Compd. 493, 105 (2010).

J.Y. He, H. Wang, H.L. Huang, X.D. Xu, M.W. Chen, Y. Wu, X.J. Liu, T.G. Nieh, K. An, and Z.P. Lu, Acta Mater. 102, 187 (2016).

C.Y. Geng, C.Y. Wang, and T. Yu, Acta Mater. 52, 5427 (2004).

L. Wang, J. Shen, G.J. Zhang, Y.P. Zhang, L.L. Guo, Y.H. Ge, L.H. Gao, and H.Z. Fu, Intermetallics 94, 83 (2018).

L. Wang, G.J. Zhang, J. Shen, Y.P. Zhang, H.X. Xu, Y.H. Ge, and H.Z. Fu, J. Alloys Compd. 732, 124 (2018).

L.Y. Sheng, J.T. Guo, Y.X. Tian, L.Z. Zhou, and H.Q. Ye, J. Alloys Compd. 475, 730 (2009).

Acknowledgements

The work is supported by the National Natural Science Foundation of China (51501147, 51601144, 51674196); Natural Science Basic Research Plan in Shaanxi Province of China (2016JQ5013); and the fund of the State Key Laboratory of Solidification Processing in NWPU (SKLSP201509).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wang, L., Xu, H., Shen, J. et al. Microstructures, Compressive Properties, and Microhardness of NiAl-Cr(Mo) Eutectic Alloys With Various Ni Contents. JOM 70, 2468–2474 (2018). https://doi.org/10.1007/s11837-018-3082-y

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11837-018-3082-y