Abstract

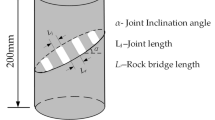

for a deeper understanding of the deformation failure behavior of jointed rock, numerical compression simulations are carried out on a rock specimen containing non-persistent joints under confining pressure with the bonded-particle model. The microscopic parameters which can reflect the macroscopic mechanical properties and failure behavior of artificial jointed specimens are firstly calibrated. Then, the influence of joint inclination and confining pressure on stress — strain curves, crack patterns, and contact force distributions of jointed rock are investigated. The simulation results show that both the compressive strength and elastic modulus of the specimens increase with increasing confining pressure, and these two mechanical parameters decrease first and then increase with the increase of joints inclination. The sensitivity of strength and elastic modulus to confining pressure is not the same in different joints inclinations, which has the least impact on specimens with α =90°. Under low confining pressure, the failure modes are controlled by the joint inclination. As the confining pressure increased, the initiation and propagation of tensile crack are gradually inhibited, and the failure mode is transferred from tensile failure to shear-compression failure. Finally, the reinforcement effect of prestressed bolt support on engineering fractured rock mass is discussed.

摘要

节理岩体的力学特性对于工程岩体的安全至关重要. 为了更好的掌握节理岩体的变形破坏规律, 采用离散元程序对不同围压作用下的断续节理岩体进行了模拟实验研究. 首先, 以室内试验数据为基础, 标定了能够反映节理试件宏观力学行为和变形破坏特征的数值模型细观参数. 然后, 研究了节理倾角和围压对节理试样应力应变曲线、破裂模式和接触力分布的影响规律. 结果表明; 试件的抗压强度和弹性模量随围压的增加而增加, 随节理组倾角的增加呈现出先减小后增大的变化趋势; 不同节理组倾角下试件的强度和弹性模量对围压的敏感性不同, 其中节理组倾角为90& deg; 时影响最小; 在低围压下, 试样的破坏模式由节理组倾角控制; 随着围压的增大, 拉裂缝的萌生和扩展逐渐受到抑制, 破坏模式由拉破坏向剪切-压缩破坏转变. 最后, 进一步探讨了预应力锚固支护对工程裂隙岩体的加固作用.

Similar content being viewed by others

References

BOBET A. The initiation of secondary cracks in compression [J]. Engineering Fracture Mechanics, 2000, 66(2): 187–219. DOI: https://doi.org/10.1016/S0013-7944(00)00009-6.

HUANG R Q, HUANG D. Evolution of rock cracks under unloading condition [J]. Rock Mechanics and Rock Engineering, 2014, 47(2): 453–466. DOI: https://doi.org/10.1007/s00603-013-0429-0.

ZHONG Zhu, DA Huang, ZHANG Yong-fa, et al. Experimental study on the effects of unloading normal stress on shear mechanical behaviour of sandstone containing a parallel fissure pair [J]. Rock Mechanics and Rock Engineering, 2020, 53(4): 1647–1663. DOI: https://doi.org/10.1007/s00603-019-01997-0.

LAJTAI E Z, CARTER B J, DUNCAN E J S. En echelon crack-arrays in potash salt rock [J]. Rock Mechanics and Rock Engineering, 1994, 27(2): 89–111. DOI: https://doi.org/10.1007/BF01020207.

DA Huang, CEN Duo-feng, MA Guo-wei, et al. Step-path failure of rock slopes with intermittent joints [J]. Landslides, 2015, 12(5): 911–926. DOI: https://doi.org/10.1007/s10346-014-0517-6.

PARK C H, BOBET A. Crack initiation, propagation and coalescence from frictional flaws in uniaxial compression [J]. Engineering Fracture Mechanics, 2010, 77(14): 2727–2748. DOI: https://doi.org/10.1016/j.engfracmech.2010.06.027.

BOBET A, EINSTEIN H H. Fracture coalescence in rocktype materials under uniaxial and biaxial compression [J]. International Journal of Rock Mechanics and Mining Sciences, 1998, 35(7): 863–888. DOI: https://doi.org/10.1016/S0148-9062(98)00005-9.

LAJTAI E Z. Brittle fracture in compression [J]. International Journal of Fracture, 1974, 10(4): 525–536. DOI: https://doi.org/10.1007/BF00155255.

YANG Sheng-qi, JING Hong-wen. Strength failure and crack coalescence behavior of brittle sandstone samples containing a single fissure under uniaxial compression [J]. International Journal of Fracture, 2011, 168(2): 227–250. DOI: https://doi.org/10.1007/s10704-010-9576-4.

WONG L N Y, EINSTEIN H H. Crack coalescence in molded gypsum and carrara marble: Part 1. macroscopic observations and interpretation [J]. Rock Mechanics and Rock Engineering, 2009, 42(3): 475–511. DOI: https://doi.org/10.1007/s00603-008-0002-4.

CHEN Miao, YANG Sheng-qi, PATHEGAMA G R, et al. Fracture processes of rock-like specimens containing nonpersistent fissures under uniaxial compression [J]. Energies, 2018, 12(1): 79. DOI: https://doi.org/10.3390/en12010079.

ZHOU Xiao-ping, ZHANG Jian-zhi, WONG L N Y. Experimental study on the growth, coalescence and wrapping behaviors of 3D cross-embedded flaws under uniaxial compression [J]. Rock Mechanics and Rock Engineering, 2018, 51(5): 1379–1400. DOI: https://doi.org/10.1007/s00603-018-1406-4.

ZHOU Xiao-ping, ZHANG Jian-zhi, QIAN Qi-hu, et al. Experimental investigation of progressive cracking processes in granite under uniaxial loading using digital imaging and AE techniques [J]. Journal of Structural Geology, 2019, 126: 129–145. DOI: https://doi.org/10.1016/j.jsg.2019.06.003.

ZHOU Xiao-ping, WANG Yun-teng, ZHANG Jian-zhi, et al. Fracturing behavior study of three-flawed specimens by uniaxial compression and 3D digital image correlation: Sensitivity to brittleness [J]. Rock Mechanics and Rock Engineering, 2019, 52(3): 691–718. DOI: https://doi.org/10.1007/s00603-018-1600-4.

WONG L N Y, EINSTEIN H H. Crack coalescence in molded gypsum and Carrara marble: Part 2—Microscopic observations and interpretation [J]. Rock Mechanics and Rock Engineering, 2009, 42(3): 513–545. DOI: https://doi.org/10.1007/s00603-008-0003-3.

LEE H, JEON S. An experimental and numerical study of fracture coalescence in pre-cracked specimens under uniaxial compression [J]. International Journal of Solids and Structures, 2011, 48(6): 979–999. DOI: https://doi.org/10.1016/j.ijsolstr.2010.12.001.

ZHANG Jian-zhi, ZHOU Xiao-ping. AE event rate characteristics of flawed granite: From damage stress to ultimate failure [J]. Geophysical Journal International, 2020, 222(2): 795–814. DOI: https://doi.org/10.1093/gji/ggaa207.

CHEN Xin, LIAO Zhi-hong, PENG Xi. Deformability characteristics of jointed rock masses under uniaxial compression [J]. International Journal of Mining Science and Technology, 2012, 22(2): 213–221. DOI: https://doi.org/10.1016/j.ijmst.2011.08.012.

LIN Qi-bin, CAO Ping, MENG Jing-jing, et al. Strength and failure characteristics of jointed rock mass with double circular holes under uniaxial compression: Insights from discrete element method modelling [J]. Theoretical and Applied Fracture Mechanics, 2020, 109: 102692. DOI: https://doi.org/10.1016/j.tafmec.2020.102692.

LIN Qi-bin, CAO Ping, LIU Yin-zhu, et al. Mechanical behaviour of a jointed rock mass with a circular hole under compression-shear loading: Experimental and numerical studies [J]. Theoretical and Applied Fracture Mechanics, 2021, 114: 102998. DOI: https://doi.org/10.1016/j.tafmec.2021.102998.

ZHOU X P, YANG H Q. Multiscale numerical modeling of propagation and coalescence of multiple cracks in rock masses [J]. International Journal of Rock Mechanics and Mining Sciences, 2012, 55: 15–27. DOI: https://doi.org/10.1016/j.ijrmms.2012.06.001.

BI J, ZHOU X P, QIAN Q H. The 3D numerical simulation for the propagation process of multiple pre-existing flaws in rock-like materials subjected to biaxial compressive loads [J]. Rock Mechanics and Rock Engineering, 2016, 49(5): 1611–1627. DOI: https://doi.org/10.1007/s00603-015-0867-y.

WANG Yun-teng, ZHOU Xiao-ping, SHOU Yun-dong. The modeling of crack propagation and coalescence in rocks under uniaxial compression using the novel conjugated bond-based peridynamics [J]. International Journal of Mechanical Sciences, 2017, 128–129: 614–643. DOI: https://doi.org/10.1016/j.ijmecsci.2017.05.019.

CAMONES L A M, VARGAS E D A, DE FIGUEIREDO R P, et al. Application of the discrete element method for modeling of rock crack propagation and coalescence in the step-path failure mechanism [J]. Engineering Geology, 2013, 153: 80–94. DOI: https://doi.org/10.1016/j.enggeo.2012.11.013.

HUANG Yan-hua, YANG Sheng-qi, RANJITH P G, et al. Strength failure behavior and crack evolution mechanism of granite containing pre-existing non-coplanar holes: Experimental study and particle flow modeling [J]. Computers and Geotechnics, 2017, 88: 182–198. DOI: https://doi.org/10.1016/j.compgeo.2017.03.015.

BAHAADDINI M, SHARROCK G, HEBBLEWHITE B K. Numerical investigation of the effect of joint geometrical parameters on the mechanical properties of a non-persistent jointed rock mass under uniaxial compression [J]. Computers and Geotechnics, 2013, 49: 206–225. DOI: https://doi.org/10.1016/j.compgeo.2012.10.012.

CHEN Miao, YANG Sheng-qi, RANJITH P G, et al. Cracking behavior of rock containing non-persistent joints with various joints inclinations [J]. Theoretical and Applied Fracture Mechanics, 2020, 109: 102701. DOI: https://doi.org/10.1016/j.tafmec.2020.102701.

CAO Ri-hong, CAO Ping, LIN Hang, et al. Mechanical behavior of brittle rock-like specimens with pre-existing fissures under uniaxial loading: Experimental studies and particle mechanics approach [J]. Rock Mechanics and Rock Engineering, 2016, 49(3): 763–783. DOI: https://doi.org/10.1007/s00603-015-0779-x.

FAN Xiang, KULATILAKE P H S W, CHEN Xin. Mechanical behavior of rock-like jointed blocks with multi-non-persistent joints under uniaxial loading: A particle mechanics approach [J]. Engineering Geology, 2015, 190: 17–32. DOI: https://doi.org/10.1016/j.enggeo.2015.02.008.

SAGONG M, BOBET A. Coalescence of multiple flaws in a rock-model material in uniaxial compression [J]. International Journal of Rock Mechanics and Mining Sciences, 2002, 39(2): 229–241. DOI: https://doi.org/10.1016/S1365-1609(02)00027-8.

ZHOU X P, CHENG H, FENG Y F. An experimental study of crack coalescence behaviour in rock-like materials containing multiple flaws under uniaxial compression [J]. Rock Mechanics and Rock Engineering, 2014, 47(6): 1961–1986. DOI: https://doi.org/10.1007/s00603-013-0511-7.

LIU Jun-feng, YANG Hai-qing, XIAO Yang, et al. Macro-mesoscopic fracture and strength character of pre-cracked granite under stress relaxation condition [J]. Rock Mechanics and Rock Engineering, 2018, 51(5): 1401–1412. DOI: https://doi.org/10.1007/s00603-018-1399-z.

YANG S Q, JIANG Y Z, XU W Y, et al. Experimental investigation on strength and failure behavior of pre-cracked marble under conventional triaxial compression [J]. International Journal of Solids and Structures, 2008, 45(17): 4796–4819. DOI: https://doi.org/10.1016/j.ijsolstr.2008.04.023.

DA Huang, GU Dong-ming, YANG Chao, et al. Investigation on mechanical behaviors of sandstone with two preexisting flaws under triaxial compression [J]. Rock Mechanics and Rock Engineering, 2016, 49(2): 375–399. DOI: https://doi.org/10.1007/s00603-015-0757-3.

YANG Xu-xu, KULATILAKE P H S W, JING Hong-wen, et al. Numerical simulation of a jointed rock block mechanical behavior adjacent to an underground excavation and comparison with physical model test results [J]. Tunnelling and Underground Space Technology, 2015, 50: 129–142. DOI: https://doi.org/10.1016/j.tust.2015.07.006.

ZHOU Xiao-ping, PENG Sen-lin, ZHANG Jian-zhi, et al. Failure characteristics of coarse and fine sandstone containing two parallel fissures subjected to true triaxial stresses [J]. Theoretical and Applied Fracture Mechanics, 2021, 112: 102932. DOI: https://doi.org/10.1016/j.tafmec.2021.102932.

YANG Sheng-qi, CHEN Miao, JING Hong-wen, et al. A case study on large deformation failure mechanism of deep soft rock roadway in Xin’An coal mine, China [J]. Engineering Geology, 2017, 217: 89–101. DOI: https://doi.org/10.1016/j.enggeo.2016.12.012.

ZANG Chuan-wei, CHEN Yang, CHEN Miao, et al. Research on deformation characteristics and control technology of soft rock roadway under dynamic disturbance [J]. Shock and Vibration, 2021: 6625233. DOI: https://doi.org/10.1155/2021/6625233.

WU Kui, SHAO Zhu-shan, QIN Su. An analytical design method for ductile support structures in squeezing tunnels [J]. Archives of Civil and Mechanical Engineering, 2020, 20(3): 1–13. DOI: https://doi.org/10.1007/s43452-020-00096-0.

QIN Su, WU Kui, SHAO Zhu-shan. Analytical assessment of coupled influences of surrounding rock reinforcement and deformation release on tunnel response [J]. Geomechanics and Engineering, 2021, 26(6): 541–550. DOI: https://doi.org/10.12989/GAE.2021.26.6.541.

ZHANG Guang-chao, ZANG Chuan-wei, CHEN Miao, et al. Ground response of entries driven adjacent to a retreating longwall panel [J]. International Journal of Rock Mechanics and Mining Sciences, 2021, 138: 104630. DOI: https://doi.org/10.1016/j.ijrmms.2021.104630.

YANG Sheng-qi, CHEN Miao, HUANG Yan-hua, et al. An experimental study on fracture evolution mechanism of a non-persistent jointed rock mass with various anchorage effects by DSCM, AE and X-ray CT observations [J]. International Journal of Rock Mechanics and Mining Sciences, 2020, 134: 104469. DOI: https://doi.org/10.1016/j.ijrmms.2020.104469.

YANG Sheng-qi, CHEN Miao, TAO Yan. Experimental study on anchorage mechanical behavior and surface cracking characteristics of a non-persistent jointed rock mass [J]. Rock Mechanics and Rock Engineering, 2021, 54(3): 1193–1221. DOI: https://doi.org/10.1007/s00603-020-02325-7.

Author information

Authors and Affiliations

Corresponding authors

Additional information

Foundation item

Projects(52004145, 51904164) supported by the National Natural Science Foundation of China; Project(ZR2020QE119) supported by the Natural Science Foundation of Shandong Province, China; Project(SICGM202107) supported by the Open Fund of the Key Laboratory of Mining Disaster Prevention and Control, China

Contributors

The overarching research goals were developed by CHEN Miao and ZANG Chuan-wei. CHEN Miao, DING Zi-wei and ZHOU Guang-lei analyzed the calculated results. The initial draft of the manuscript was written by CHEN Miao. JIANG Bang-you and ZHANG Guang-chao revised the initial draft. CHEN Miao and ZHANG Cheng-peng replied to reviewers’ comments and revised the final version.

Conflict of interest

All the authors declare that they have no conflict of interest.

Rights and permissions

About this article

Cite this article

Chen, M., Zang, Cw., Ding, Zw. et al. Effects of confining pressure on deformation failure behavior of jointed rock. J. Cent. South Univ. 29, 1305–1319 (2022). https://doi.org/10.1007/s11771-022-4991-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-022-4991-z

Key words

- stability of surrounding rock

- non-persistent joints

- confining pressure

- cracking process

- discrete element method (DEM)