Abstract

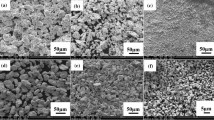

Functionally graded material (FGM) can tailor properties of components such as wear resistance, corrosion resistance, and functionality to enhance the overall performance. The selective laser melting (SLM) additive manufacturing highlights the capability in manufacturing FGMs with a high geometrical complexity and manufacture flexibility. In this work, the 316L/CuSn10/18Ni300/CoCr four-type materials FGMs were fabricated using SLM. The microstructure and properties of the FGMs were investigated to reveal the effects of SLM processing parameters on the defects. A large number of microcracks were found at the 316L/CuSn10 interface, which initiated from the fusion boundary of 316L region and extended along the building direction. The elastic modulus and nano-hardness in the 18Ni300/CoCr fusion zone decreased significantly, less than those in the 18Ni300 region or the CoCr region. The iron and copper elements were well diffused in the 316L/CuSn10 fusion zone, while elements in the CuSn10/18Ni300 and the 18Ni300/CoCr fusion zones showed significantly gradient transitions. Compared with other regions, the width of the CuSn10/18Ni300 interface and the CuSn10 region expand significantly. The mechanisms of materials fusion and crack generation at the 316L/CuSn10 interface were discussed. In addition, FGM structures without macro-crack were built by only altering the deposition subsequence of 316L and CuSn10, which provides a guide for the additive manufacturing of FGM structures.

摘要

功能梯度材料(FGM)可以在零件的不同区域定制其特性,例如耐磨性、耐腐蚀性和环境适应性。 激光选区熔化(SLM)在制造FGM 上具有出色表现,故本文采用SLM 技术制备了316L/CuSn10/18Ni300/ CoCr 四种材料的FGM,研究了FGM 的微观结构和性能,以揭示SLM 加工参数对缺陷的影响。在 316L/CuSn10 界面处发现了许多微裂纹,这些裂纹自316L 区域的熔合边界萌生并沿成型方向延伸。 18Ni300/CoCr 熔合区的弹性模量和纳米硬度显着下降,低于18Ni300 和CoCr 区域的弹性模量和纳米 硬度。铁元素和铜元素在316L/CuSn10 熔合区充分扩散,而CuSn10/18Ni300 和18Ni300/CoCr 熔合区 中的元素则表现出明显的梯度转变。与其他区域相比,CuSn10/18Ni300 界面和CuSn10 区域具界面结 合区域有明显的尺寸膨胀。最后,本文重点讨论了316L/CuSn10 界面处的材料熔合和裂纹形成的机理。 发现仅通过改变316L 和CuSn10 的沉积顺序就可以成型没有宏观裂纹的FGM,这为FGM 的增材制 造提供了指导。

Similar content being viewed by others

References

YIN Shuo, YAN Xing-chen, CHEN Chao-yue, JENKINS R, LIU Min, LUPOI R. Hybrid additive manufacturing of Al-Ti6Al4V functionally graded materials with selective laser melting and cold spraying [J]. Journal of Materials Processing Technology, 2018, 255: 650–655. DOI: https://doi.org/10.1016/j.jmatprotec.2018.01.015.

HINOJOS A, MIRELES J, REICHARDT A, FRIGOLA P, HOSEMANN P, MURR L E, WICKER R B. Joining of Inconel 718 and 316 stainless steel using electron beam melting additive manufacturing technology [J]. Materials & Design, 2016, 94: 17–27. DOI: https://doi.org/10.1016/j.matdes.2016.01.041.

ONUIKE B, HEER B, BANDYOPADHYAY A. Additive manufacturing of Inconel 718-copper alloy bimetallic structure using laser engineered net shaping (LENS™) [J]. Additive Manufacturing, 2018, 21: 133–140. DOI: https://doi.org/10.1016/j.addma.2018.02.007.

SHEN Chen, PAN Zeng-xi, CUIURI D, ROBERTS J, LI Hui-jun. Fabrication of Fe-FeAl Functionally graded material using the wire-arc additive manufacturing process [J]. Metallurgical and Materials Transactions B, 2015, 47(1): 763–772. DOI: https://doi.org/10.1007/s11663-015-0509-5.

GURIANOV D A, KALASHNIKOV K N, OSIPOVICH K S, CHUMAEVSKII A V. Obtaining the bimetallic composition by the electron beam freeform fabrication [C]// IOP Conference Series: Materials Science and Engineering. 2019: 597: 012043. DOI: https://doi.org/10.1088/1757-899x/597/1/012043.

ZHONG Yuan, RÄNNAR L E, WIKMAN S, KOPTYUG A, LIU Lei-feng, CUI Da-qing, SHEN Zhi-jian. Additive manufacturing of ITER first wall panel parts by two approaches: Selective laser melting and electron beam melting [J]. Fusion Engineering and Design, 2017, 116: 24–33. DOI: https://doi.org/10.1016/j.fusengdes.2017.01.032.

FRAZIER W E. Metal additive manufacturing: A review [J]. Journal of Materials Engineering and Performance, 2014, 23(6): 1917–1928. DOI: https://doi.org/10.1007/s11665-014-0958-z.

LEWANDOWSKI J J, SEIFI M. Metal additive manufacturing: A review of mechanical properties [J]. Annual Review of Materials Research, 2016, 46(1): 151–186. DOI: https://doi.org/10.1146/annurev-matsci-070115-032024.

RAFI H K, KARTHIK N V, GONG Hai-jun, STARR T L, STUCKER B E. Microstructures and mechanical properties of Ti6Al4V parts fabricated by selective laser melting and electron beam melting[J] Journal of Materials Engineering and Performance, 2013, 22(12): 3872–3883. DOI: https://doi.org/10.1007/s11665-013-0658-0.

BANDYOPADHYAY A, HEER B. Additive manufacturing of multi-material structures [J]. Materials Science and Engineering R: Reports, 2018, 129: 1–16. DOI: https://doi.org/10.1016/j.mser.2018.04.001.

WEI Chao, SUN Zhe, HUANG Yi-he, LI Lin. Embedding anti-counterfeiting features in metallic components via multiple material additive manufacturing [J]. Additive Manufacturing, 2018, 24: 1–12. DOI: https://doi.org/10.1016/j.addma.2018.09.003.

ZHANG Xiao-ji, CHUEH Yuan-hui, WEI Chao, SUN Zhe, YAN Ji-wang, LI Lin. Additive manufacturing of three-dimensional metal-glass functionally gradient material components by laser powder bed fusion with in situ powder mixing [J]. Additive Manufacturing, 2020, 33: 101113. DOI: https://doi.org/10.1016/j.addma.2020.101113.

WEI Chao, SUN Zhe, CHEN Qian, LIU Zhu, LI Lin. Additive manufacturing of horizontal and 3D functionally graded 316L/Cu10Sn components via multiple material selective laser melting [J]. Journal of Manufacturing Science and Engineering, 2019, 141(8): 1–14. DOI: https://doi.org/10.1115/1.4043983.

ZHANG Xiao-ji, WEI Chao, CHUEH Yuan-hui, LI Lin. An integrated dual ultrasonic selective powder dispensing platform for three-dimensional printing of multiple material metal/glass objects in selective laser melting[J]. Journal of Manufacturing Science and Engineering, 2019, 141(1): 11003. DOI: https://doi.org/10.1115/1.4041427.

MEI Xin-liang, WANG Xiang-yu, PENG Yin-bo, GU Hong-yan, ZHONG Gao-yan, YANG Shou-feng. Interfacial characterisation and mechanical properties of 316L stainless steel/Inconel 718 manufactured by selective laser melting [J]. Materials Science and Engineering A, 2019, 758: 185–191. DOI: https://doi.org/10.1016/j.msea.2019.05.011.

LIU Z H, ZHANG D Q, SING S L, CHUA C K, LOH L E. Interfacial characterisation of SLM parts in multi-material processing: Metallurgical diffusion between 316L stainless steel and C18400 copper alloy [J]. Materials Characterization, 2014, 94: 116–125. DOI: https://doi.org/10.1016/j.matchar.2014.05.001.

CHEN Cai-yan, GU Dong-dong, DAI Dong-hua, DU Lei, WANG Rui, MA Cheng-long, XIA Mu-jian. Laser additive manufacturing of layered TiB2/Ti6Al4V multi-material parts: Understanding thermal behavior evolution [J]. Optics & Laser Technology, 2019, 119. DOI: https://doi.org/10.1016/j.optlastec.2019.105666.

DAI Dong-hua, GU Dong-dong, POPRAWE R, XIA Mu-jian. Influence of additive multi-layer feature on thermodynamics, stress and microstructure development during laser 3D printing of aluminum-based material [J]. Science Bulletin, 2017, 62(11): 779–787. DOI: https://doi.org/10.1016/j.scib.2017.05.007.

BOBBIO L D, OTIS R A, BORGONIA J P, DILLON R P, SHAPIRO A A, LIU Zi-kui, BEESE A M. Additive manufacturing of a functionally graded material from Ti-6Al-4V to Invar: Experimental characterisation and thermodynamic calculations [J]. Acta Materialia, 2017, 127: 133–142. DOI: https://doi.org/10.1016/j.actamat.2016.12.070.

TOMASHCHUK I, SALLAMAND P, CICALA E, PEYRE P, GREVEY D. Direct keyhole laser welding of aluminum alloy AA5754 to titanium alloy Ti6Al4V [J]. Journal of Materials Processing Technology, 2015, 217: 96–104. DOI: https://doi.org/10.1016/jjmatprotec.2014.10.025.

DEMIR A G, PREVITALI B. Multi-material selective laser melting of Fe/Al-12Si components [J]. Manufacturing Letters, 2017, 11: 8–11. DOI: https://doi.org/10.1016/j.mfglet.2017.01.002.

SING S L, LAM L P, ZHANG D Q, LIU Z H, CHUA C K. Interfacial characterisation of SLM parts in multi-material processing: Intermetallic phase formation between AlSi10Mg and C18400 copper alloy [J]. Materials Characterization, 2015, 107: 220–227. DOI: https://doi.org/10.1016/j.matchar.2015.07.007.

ONUIKE B, BANDYOPADHYAY A. Additive manufacturing of Inconel 718-Ti6Al4V bimetallic structures [J]. Additive Manufacturing, 2018, 22: 844–851. DOI: https://doi.org/10.1016/j.addma.2018.06.025.

KOOPMANN J, VOIGT J, NIENDORF T. Additive manufacturing of a steel-ceramic multi-material by selective laser melting [J]. Metallurgical and Materials Transactions B, 2019, 50(2): 1042–1051. DOI: https://doi.org/10.1007/s11663-019-01523-1.

WEI Chao, LI Lin, ZHANG Xiao-ji, CHUEH Yuan-hui. 3D printing of multiple metallic materials via modified selective laser melting [J]. CIRP Annals, 2018, 67(1): 245–248. DOI: https://doi.org/10.1016/j.cirp.2018.04.096.

TAN Chao-lin, ZHANG Xin-yue, DONG Dong-dong, ATTARD B, WANG Di, KUANG Min, MA Wen-you, ZHOU Ke-song. In-situ synthesised interlayer enhances bonding strength in additively manufactured multi-material hybrid tooling [J]. International Journal of Machine Tools and Manufacture, 2020, 155: 103592. DOI: https://doi.org/10.1016/j.ijmachtools.2020.103592.

ZHANG Ming-kang, YANG Yong-qiang, WANG Di, SONG Chang-hui, CHEN Jie. Microstructure and mechanical properties of CuSn/18Ni300 bimetallic porous structures manufactured by selective laser melting [J]. Materials & Design, 2019, 165: 107583. DOI: https://doi.org/10.1016/j.matdes.2019.107583.

CHEN Jie, YANG Yong-qiang, SONG Chang-hui, ZHANG Ming-kang, WU Shi-biao, WANG Di. Interfacial microstructure and mechanical properties of 316L /CuSn10 multi-material bimetallic structure fabricated by selective laser melting [J]. Materials Science and Engineering A, 2019, 752: 75–85. DOI: https://doi.org/10.1016/j.msea.2019.02.097.

CARTER L N, MARTIN C, WITHERS P J, ATTALLAH M M. The influence of the laser scan strategy on grain structure and cracking behaviour in SLM powder-bed fabricated nickel superalloy [J]. Journal of Alloys and Compounds, 2014, 615: 338–347. DOI: https://doi.org/10.1016/j.jallcom.2014.06.172.

TAN Chao-lin, WANG Di, MA Wen-you, CHEN Yao-rong, CHEN Shi-jie, YANG Yong-qiang, ZHOU Ke-song. Design and additive manufacturing of novel conformal cooling molds [J]. Materials & Design, 2020, 196: 109147. DOI: https://doi.org/10.1016/j.matdes.2020.109147.

WANG Rui, GU Dong-dong, XI Li-xia, LIN Kai-jie, GUO Meng, ZHANG Hong-mei. Selective laser melted TiB2/Ti6Al4V graded materials and first-principle calculations [J]. Materials Letters, 2019, 254: 33–36. DOI: https://doi.org/10.1016/j.matlet.2019.07.015.

YAN Lei, CHEN Yi-tao, LIOU F. Additive manufacturing of functionally graded metallic materials using laser metal deposition [J]. Additive Manufacturing, 2020, 31: 100901. DOI: https://doi.org/10.1016/j.addma.2019.100901.

TAN Chao-lin, ZHOU Ke-song, KUANG Tong-chun. Selective laser melting of tungsten-copper functionally graded material [J]. Materials Letters, 2019, 237: 328–331. DOI: https://doi.org/10.1016/j.matlet.2018.11.127.

TAN Chao-lin, ZHOU Ke-song, MA Wen-you, MIN Liu. Interfacial characteristic and mechanical performance of maraging steel-copper functional bimetal produced by selective laser melting based hybrid manufacture [J]. Materials & Design, 2018, 155: 77–85. DOI: https://doi.org/10.1016/j.matdes.2018.05.064.

MAGNABOSCO I, FERRO P, BONOLLO F, ARNBERG L. An investigation of fusion zone microstructures in electron beam welding of copper-stainless steel [J]. Materials Science and Engineering A, 2006, 424(1, 2): 163–173. DOI: https://doi.org/10.1016/j.msea.2006.03.096.

TEY C F, TAN Xi-peng, SING S L, YEONG W Y. Additive manufacturing of multiple materials by selective laser melting: Ti-alloy to stainless steel via a Cu-alloy interlayer [J]. Additive Manufacturing, 2020, 31: 100970. DOI: https://doi.org/10.1016/j.addma.2019.100970.

TALIC B, HENDRIKSEN P V, WIIK K, LEIN H L. Thermal expansion and electrical conductivity of Fe and Cu doped MnCo2O4 spinel [J]. Solid State Ionics, 2018, 326: 90–99. DOI: https://doi.org/10.1016/j.ssi.2018.09.018.

Author information

Authors and Affiliations

Contributions

The overarching research goals were developed by WANG Di, WU Wei-hui and YANG Yong-qiang. WANG Di and WANG Hao-liang conducted experiments and provided relevant data. DENG Guo-wei and CHEN Jie analyzed the results of experiments. TAN Chao-lin and DENG Guo-wei drafted the manuscript and revised the final version.

Corresponding author

Additional information

Conflict of interest

WANG Di, DENG Guo-wei, YANG Yong-qiang, CHEN Jie, WU Wei-hui, WANG Hao-liang, TAN Chao-lin declare that they have no conflict of interest.

Foundation item: Project(2020B090922002) supported by Guangdong Provincial Key Field Research and Development Program, China; Projects(51875215, 52005189) supported by the National Natural Science Foundation of China; Project(2019B1515120094) supported by Guangdong Provincial Basic and Applied Basic Research Fund, China

Rights and permissions

About this article

Cite this article

Wang, D., Deng, Gw., Yang, Yq. et al. Interface microstructure and mechanical properties of selective laser melted multilayer functionally graded materials. J. Cent. South Univ. 28, 1155–1169 (2021). https://doi.org/10.1007/s11771-021-4687-9

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-021-4687-9

Key words

- selective laser melting

- multilayer functionally graded material

- interfacial characterization

- crack defects

- mechanical properties