Abstract

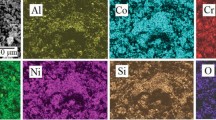

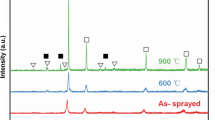

A novel surface cladding technique was developed to prepare the FeCrNiMn alloy and high carbon steel cladding layers, and the microhardness, bonding strength, abrasion wear and corrosion resistance were investigated. The microstructures of the cladding layers were analyzed by using X-ray diffraction (XRD), scanning electron microscopy (SEM), and energy dispersive spectrometry (EDS). The results show that the bonding strength between the substrate and the two cladding layers were (432.6±21) and (438.3±12) MPa,respectively. Vickers hardness values of the two cladding layers were HV 418.5 and HV 329.6, respectively. The corrosion current densities of the two coatings were 2.926×10–6 and 6.858×10–6 A/cm2 after electrochemical corrosion test in 3.5% NaCl solution, and the wear rate were 1.78×10–7 and 1.46×10–6 mm3/mN after sliding wear test, respectively. This indicates that a well metallurgical bonding between the coating and the substrate was achieved, the abrasion wear and corrosion resistance of both coatings had been greatly improved compared with the substrate. The novel cladding technology is promising for preparing wear-and-corrosion resistant coatings.

摘要

本文提出了一种新颖的表面熔覆涂层技术, 并通过此技术制备了FeCrMn 合金与高碳钢涂层, 并对比研究了涂层的显微硬度、结合强度、耐磨损和耐腐蚀性能。采用X 射线衍射(XRD)、扫描电 子显微镜(SEM)和能谱(EDS)对涂层的微观组织、结构及元素分布进行了分析。两种涂层与基体 的结合强度分别达到了(432.6±21)和 (438.3±12) MPa,维氏硬度分别达到了HV 418.5 和HV 329.6,两 种涂层在3.5% NaCl 溶液中的电化学腐蚀电流密度分别为2.926×10-6 和6.858×10-6 A/cm2,磨损速率分 别为1.78×10–7 和1.46×10–6 mm3/mN。研究结果表明:本技术制备的涂层能够与基体达到良好的冶金 结合同时具有优异的耐腐蚀耐磨损性能,可望发展成为一种制备耐蚀耐磨涂层的新方法。

Similar content being viewed by others

References

MANNA I, MAJUMDAR J D, CHANDRA B R, NAYAK S, DAHOTRE N B. Laser surface cladding of Fe-B-C, Fe-B-Si and Fe-BC-Si-Al-C on plain carbon steel[J]. Surface & Coatings Technology, 2006, 201(1, 2): 434–440.

ZHOU Sheng, HUANG Yong, ZENG Xiao, HU Qian. Microstructure characteristics of Ni-based WC composite coatings by laser induction hybrid rapid cladding [J]. Materials Science and Engineering A, 2008, 480(1, 2): 564–572.

WANG Shan, CHENG Jing, YI Cheng, KE Li. Corrosion resistance of Fe-based amorphous metallic matrix coating fabricated by HVOF thermal spraying [J]. Transactions of Nonferrous Metals Society of China, 2014, 24(1): 146–151.

LIU Yong, LIU Su, WANG Shun. Microstructure and abrasion wear behavior of Ni-based laser cladding alloy layer at high temperature [J]. Journal of Central South University of Technology, 2005, 12(4): 403–405.

ABE N, MORIMOTO J, TOMIE M, DOI C. Formation of WC-Co layers by an electron beam cladding method and evaluation of the layer properties [J]. Vacuum, 2000, 59(1): 373–380.

KULU P, ZIMAKOV S. Wear resistance of thermal sprayed coatings on the base of recycled hardmetal [J]. Surface & Coatings Technology, 2000, 130(1): 46–51.

ISHIZAKI T, HIEDA J, SAITO N, TAKAI O. Corrosion resistance and chemical stability of super-hydrophobic film deposited on magnesium alloy AZ31 by microwave plasma-enhanced chemical vapor deposition [J]. Electrochimica Acta, 2010, 55(23): 7094–7101.

EZHILSELVI V, NITHIN J, BALARAJU J N, SUBRAMANIAN S. The influence of current density on the morphology and corrosion properties of MAO coatings on AZ31B magnesium alloy [J]. Surface & Coatings Technology, 2016, 288: 221–229.

GUO Huo, WANG Qian, WANG Wen, GUO Jun, LIU Qi, ZHU Min. Investigation on wear and damage performance of laser cladding Co-based alloy on single wheel or rail material [J]. Wear, 2015, 328: 329–337.

NIE P, OJO O A, LI Z. Modeling analysis of laser cladding of a nickel-based superalloy [J]. Surface & Coatings Technology, 2014, 258: 1048–1059.

PAUL C P, KHAJEPOUR A. Automated laser fabrication of cemented carbide components [J]. Optics & Laser Technology, 2008, 40(5): 735–741.

YU You, ZHOU Jian, REN Shu, WANG Ling, XIN Ben, CAO Si. Tribological properties of laser cladding NiAl intermetallic compound coatings at elevated temperatures [J]. Tribology International, 2016, 104: 321–327.

LIU Kun, LI Ya, WANG Juan. In-situ reactive fabrication and effect of phosphorus on microstructure evolution of Ni/Ni–Al intermetallic composite coating by laser cladding [J]. Materials & Design, 2016, 105: 171–178.

CHENG Jiang, LIU Dan, LIANG Xiu, CHEN Yong. Evolution of microstructure and mechanical properties of in situ synthesized TiC–TiB2/CoCrCuFeNi high entropy alloy coatings [J]. Surface & Coatings Technology, 2015, 281(7): 109–116.

YAN Hua, ZHANG Jie, ZHANG Pei, YU Zhi, LI Chong, XU Pei, LU Yun. Laser cladding of Co-based alloy/TiC/CaF2, self-lubricating composite coatings on copper for continuous casting mold [J]. Surface & Coatings Technology, 2013, 232(1): 362–369.

SHEPELEVA L, MEDRES B, KAPLAN W D, BAMBERGER M, WEISHEIT A. Laser cladding of turbine blades [J]. Surface & Coatings Technology, 2000, 125(1–3): 45–48.

WENG Fei, CHEN Chuan, YU Hui. Research status of laser cladding on titanium and its alloys: A review [J]. Materials & Design, 2014, 58(6): 412–425.

QUAZI M M, FAZAL M A, HASEEB A S M A, YUSOF FMASJUKI H H, ARSLAN A. Effect of rare earth elements and their oxides on tribo-mechanical performance of laser claddings: A review [J]. Journal of Rare Earths, 2016, 34(6): 549–564.

SHAKHOVA I, MIRONOV E, AZARMI F, ASFONOV A. Thermo-electrical properties of the alumina coatings deposited by different thermal spraying technologies [J]. Ceramics International, 2017, 43(17): 15392–15401.

AKIN S R K, TURAN S, GENCOGLU P D, MANDAL H. Effect of SiC addition on the thermal diffusivity of SiAlON ceramics [J]. Ceramics International, 2017, 43(16): 13469–13474.

DAS P, PAUL S, BANDYOPADHYAY P P. Preparation of diamond reinforced metal powders as thermal spray feedstock using ball milling [J]. Surface & Coatings Technology, 2016, 286: 165–171.

KIRBIYIK F, GOK M G, GOLLER G, FIRBIYIK F, GOK M G, GOLLER G. Microstructural, mechanical and thermal properties of Al2O3/CYSZ functionally graded thermal barrier coatings [J]. Surface & Coatings Technology, 2017, 329.

LAI Quan, ABRAHAMS R, YAN Wen, SOODI M. Investigation of a novel functionally graded material for the repair of premium hypereutectoid rails using laser cladding technology [J]. Composites Part B Engineering, 2017, 130: 174–191.

ERFANMANESH M, ABDOLLAHPOUR H, MOHAMMADIANSEMNANI H, SHOJARAZAVI R. An empirical-statistical model for laser cladding of WC-12Co powder on AISI 321 stainless steel [J]. Optics & Laser Technology, 2017, 97: 180–186.

HSU W L, YANG Y C, CHEN C Y, YEH J W. Thermal sprayed high-entropy NiCo0.6Fe0.2Cr1.5SiAlTi0.2 coating with improved mechanical properties and oxidation resistance [J]. Intermetallics, 2017, 89: 105–110.

TENG Jie, LI Hua, CHEN Gang. Wear mechanism for spray deposited Al-Si/SiCp composites under dry sliding condition [J]. Journal of Central South University, 2015, 22(8): 2875–2882.

ZHAO Guo, WEN Guang, SHENG Guang, JING Yan. Effects of rapid solidification process and 0.1%Pr/Nd addition on characteristics of Sn-9Zn solder alloy and interfacial properties of Cu/solder/Cu joints [J]. Journal of Central South University, 2016, 23(8): 1831–1838.

BADISCH E, KATSICH C, WINKELMANN H, FRANEK F, ROY M. Wear behaviour of hardfaced Fe-Cr-C alloy and austenitic steel under 2-body and 3-body conditions at elevated temperature [J]. Tribology International, 2010, 43(7): 1234–1244.

MANAF A, LEONOWICZ M, DAVIES H A, BUCKLEY R A. Effect of grain size and microstructure on magnetic properties of rapidly solidified Fe82.4Nd13.1B4.5 alloy [J]. Journal of Applied Physics, 1991, 70(10): 6366–6368.

LUO Xi, YAO Zheng, ZHANG Ping, CHEN Yu, YANG Hong, WU Xiao, ZHANG Ze, LIN Yu, XU Shang. Tribological behaviors of Fe−Al−Cr−Nb alloyed layer deposited on 45 steel via double glow plasma surface metallurgy technique [J]. Transactions of Nonferrous Metals Society of China, 2015, 25: 3694–3699.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(2016JJ2025) supported by the Natural Science Foundation of Hunan Province, China; Project(U1560105) supported by the National Natural Science Foundation of China

Rights and permissions

About this article

Cite this article

Chen, G., Shen, Sc., Ni, S. et al. Spray deposition of FeCrNiMn and high carbon steel coatings by thermite reaction. J. Cent. South Univ. 25, 2962–2970 (2018). https://doi.org/10.1007/s11771-018-3966-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-018-3966-6