Abstract

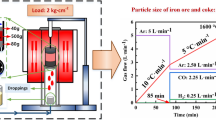

The optimized use of MgO flux in the agglomeration of high-chromium vanadium-titanium magnetite was investigated systematically through sinter and pellet experiments. MgO was added in the form of magnesite. When the content of MgO in the sinter was increased from 1.95wt% to 2.63wt%, the low-temperature reduction degradation index increased from 80.57% to 82.71%. When the content of MgO in the pellet was increased from 1.14wt% to 2.40wt%, the reduction swelling index decreased from 15.2% to 8.6%; however, the compressive strength of the oxidized pellet decreased dramatically and it was 1985 N with an MgO content of 1.14wt%. This compressive strength does not satisfy the requirements for blast-furnace production. When all of the aforementioned results were taken into account, the sinter with a high MgO content (2.63wt%) matching the pellet with a low MgO content (less than 1.14wt%) was the rational burden structure for smelting high-chromium vanadium-titanium magnetite in blast furnaces.

Similar content being viewed by others

References

M.Y. Zhu, Modern Metallurgy (Metallurgy of Iron and Steel), Metallurgical Industry Press, Beijing, 2008.

X.L. Wang, Iron and Steel Metallurgy, Metallurgical Industry Press, Beijing, 2002.

S.L. Wu, H.L. Han, W.Z. Jiang, J.M. Zhu, G.S. Feng, and Z.C. Zhang, MgO interaction mechanism in sinter, J. Univ. Sci. Technol. Beijing, 31(2009), No. 4, p. 428.

U.S. Yadav, B.D. Pandey, B.K. Das, and D.N. Jena, Influence of magnesia on sintering characteristics of iron ore, Ironmaking Steelmaking, 29(2002), No. 2, p. 91.

Q. Gan, Q. He, and Y.C. Wen, Study on Influence of MgO on mineral composition and metallurgical properties of V-bearing titaniferous magnetite sinter, Iron Steel, 43(2008), No. 8, p. 7.

S. Dwarapudi, T.K. Ghosh, A. Shankar, V. Tathavadkar, D. Bhattacharjiee, and R. Venugopal, Effect of pyroxenite flux on the quality and microstructure of hematite pellets, Int. J. Miner. Process., 96(2010), No. 1–4, p. 45.

Q.J. Gao, F.M. Shen, G. Wei, X. Jiang, and H.Y. Zheng, Effects of MgO containing additive on low-temperature metallurgical properties of oxidized pellet, J. Iron Steel Res. Int., 20(2013), No. 7, p. 25.

Q. Gan, Q. He, and Y.C. Wen, Influence of MgO content on productivity and quality of V-bearing titaniferous magnetite sinter, Iron Steel Vanadium Titanium, 29(2008), No. 1, p. 54.

X.H. Fan, Q.W. Li, M. Gan, X.L. Chen, L.S. Yuan, and Z.Y. Ji, Influence and mechanism of MgO on strength of high basicity sinter, J. Cent. South Univ. Sci. Technol., 43(2012), p. 3325.

K. Higuchi, M. Naito, M. Nakano, and Y. Takamoto, Optimization of chemical composition and microstructure of iron ore sinter for low-temperature drip of molten iron with high permeability, ISIJ Int., 44(2004), No. 12, p. 2057.

M. Nakano, M. Naito, K. Higuchi, and K. Morimoto, Nonspherical carbon composite agglomerates: lab-scale manufacture and quality assessment, ISIJ Int., 44(2004), No. 12, p. 2079.

H. Kimura, T. Ogawa, M. Kakiki, A. Matsumoto, and F. Tsukihashi, Effect of Al2O3 and MgO additions on liquidus for the CaO-SiO2-FeOx system at 1573 K, ISIJ Int., 45(2005), No. 4, p. 506.

J. Tang, Y. Zhang, M.S. Chu, and X.X. Xue, Preparation of oxidized pellets with high chromium vanadium-titanium magnetite, J. Northeast. Univ. Nat. Sci., 34(2013), No. 4, p. 545.

J. Tang, Y. Zhang, M.S. Chu, and X.X. Xue, Effect of the increasing percent of high chromium vanadium-titanium magnetite on quality of oxidized pellets, J. Northeast Univ. Nat. Sci., 34(2013), No. 7, p. 956.

Ironmaking plant of Pangang Group Panzhih Steel & Vanadium, Pangang Group Vanadium Titanium, Technological Paper Assembly of Strengthening Smelting Vanadium-titanium Magnetite in Large-scale Blast Furnace for Panzhihua Iron & Steel, 2000–2010, p. 626 and 632.

Y.M. Chen and R. Chen, Microstructure of Sinter and Pellet, Central South University Press, Changsha, 2002.

M. Matsumura, M. Hoshi, and T. Kawaguchi, Improvement of sinter softening property and reducibility by controlling chemical compositions, ISIJ Int., 45(2005), No. 4, p. 594.

G.F. Zhou and F. Yang, Effects of adding MgO on pelletizing ability and strength of pellet, Res. Iron Steel, 37(2009), No. 2, p. 10.

S. Dwarapudi and M. Ranjan, Influence of oxide and silicate melt phases on the RDI of iron ore pellets suitable for shaft furnace of direct reduction process, ISIJ Int., 50(2010), No. 11, p.1581.

X.H. Fan, M. Gan, T. Jiang, X. Chen, and L. Yuan, Influences of MgO on roasting properties of oxidized iron ore pellets, [in] The 2010 TMS Annual Meeting & Exhibition, Warrendale, 2010, p. 559.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Tang, J., Chu, Ms. & Xue, Xx. Optimized use of MgO flux in the agglomeration of high-chromium vanadium-titanium magnetite. Int J Miner Metall Mater 22, 371–380 (2015). https://doi.org/10.1007/s12613-015-1082-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s12613-015-1082-2