Abstract

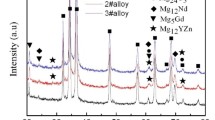

The tensile creep resistance of Mg-5.5%Zn-(0.7%, 1.5%, 3.5%, 7.5%)Y (mass fraction, %) gravity-casting alloys was investigated systematically. The corresponding physical models were established for analyzing the microstructure evolution and creep mechanism. The results show that four second phases are found in Mg-5.5%Zn-(0.7%, 1.5%, 3.5%, 7.5%)Y alloys, including Mg3ZnY, Mg3Zn6Y, Mg3Zn3Y2 and Mg7Zn3, where the rare earth rich phase (Mg3ZnY, Mg3Zn6Y, Mg3Zn3Y2) with high melting point can more effectively improve the creep resistance properties of alloys than Mg7Zn3. With the increasing of Y content, the creep resistance of alloys is improved correspondingly. The alloys with (1.5%, 3.5%)Y addition exhibit high creep resistance at temperatures from 175 °C to 200 °C and load from 55 MPa to 70 MPa. The 7.5%Y added alloy presents excellent creep resistance even at 275 °C and 55 MPa. The second phase which shows discontinuous distribution at the grain boundary of (0.7%, 1.5%, 3.5%)Y added alloys has preferred orientation and clogs in triple junctions of grain boundary. Simultaneously, the arrangement of second phase particles along tensile direction and the formation of denuded zones are observed during the creep process. Moreover, the crack initiates in these areas and propagates along grain boundary. Compared with discontinuous second phase, the continuous skeleton-like second phase of 7.5%Y added alloy at grain boundary has a better effect on improving the creep resistance properties of alloys.

Similar content being viewed by others

References

MORDIKE B L, EBERT T. Magnesium properties-applications-potential [J]. Material Science and Engineering, 2001, 302(1): 37–45.

CHEN Zhen-hua, CHEN Ding. Heat-resistant magnesium alloys [M]. Beijing: Chemistry Industry Press, 2007: 29–48. (in Chinese)

PADEZHNOVA E M, MELNIK E V, MILIYEVSKIY R A. Investigation of the Mg-Y-Zn system [J]. Russian Metallurgy, 1982, 4: 185–188.

LUO Zi-peng, ZHANG Si-qin. Comment on the so-called Z-phase in magnesium alloys containing zinc and rare-earth elements [J]. Journal of Material Science Letter, 1993, 12: 1490–1493.

ZHAO Zu-de, CHEN Qiang, YANG Lin, SHU Da-yu, ZHAO Zhi-xiang. Microstructure and mechanical properties of Mg-Zn-Y-Zr alloy prepared by solid state recycling [J]. Transactions of Nonferrous Metals Society of China, 2011, 21(2): 265–271.

PIERCE F S, POON S J, GUO Q. Electron localization in metallic quasicrystals [J]. Science, 1993, 261: 737–739.

HAGIHARA K, YOKOTANI N, UMAKOSHI Y. Plastic deformation behavior of Mg12YZn with 18R long-period stacking ordered structure [J]. Intermetallics, 2010, 18: 267–276.

JANOT C. Quasicrystals [M]. Oxford: Clarendon Press, 1994: 157.

XIE Guang-ming, MA Zhong-yi, GENG Lin, CHEN Rong-shi. Microstructural evolution and mechanical properties of friction stir welded Mg-Zn-Y-Zr alloy [J]. Material Science and Engineering A, 2007, 471: 63–68.

SRINIVASAN A, AJITHKUMAR K K, SWAMINATHAN J, PILLAI U T S, PAI B C. Creep behavior of AZ91 magnesium alloy [J]. Procedia Engineering, 2013, 55: 109–113.

GARCESA G, ONORBEA E, DOBESB F, PEREZ P, ANTORANZ J M, ADEVA P. Effect of microstructure on creep behaviour of cast Mg97Y2Zn1 (at.%) alloy [J]. Material Science and Engineering A, 2012, 539: 48–55.

MORDIKE B L. Development of highly creep resistant magnesium alloys [J]. Journal of Materials Processing Technology, 2001, 117: 391–394.

MORDIKE B L. Creep-resistant magnesium alloys [J]. Material Science and Engineering, 2002, 324: 103–112.

GIFKINS R G. Grain boundary sliding and its accommodation during creep and superplasticity [J]. Materials Transactions, 1976, 7: 1225–1232.

GITTUS J H. Theory of superplastic flow in two-phase materials: Roles of interphase-boundary dislocation, ledges, and diffusion [J]. Journal of Engineering Materials and Technology, 1977, 99: 244–251.

LANGDON T G. A method of distinguishing between diffusion creep and Harper-Dorn creep at low stress levels [J]. Scripta Materialia, 1996, 35: 733–737.

CICCO M D, KONISHI H, CAO G, CHOI H S, TURNG L S P EREPEZKO H, KOU S, LAKES R, LI Xiao-chun. Strong, ductile magnesium-zinc nanocomposites [J]. Metallurgical and Materials Transactions A, 2009, 40: 3038–3045.

WANG Bai-shu, LIU Yong-bing, AN Jian, LI Rong-guang, SU Zhen-guo, CAO Zhan-yi. Morphological evolutions of cast and melt-spun Mg97Zn1Y2 alloys during deformation and heat-treating [J]. Transactions of Nonferrous Metals Society of China, 2008, 18: 69–75.

CHINO Y, MABUCHI M, HAGIWARA S, IWASAKI H, YAMAMOTO A, TSUBAKINO H. Novel equilibrium two phase Mg alloy with the long-period ordered structure [J]. Scripta Materialia, 2004, 51: 711–714.

ONORBE E, GARCES G, PEREZ P, CABEZAS S, KLAUS M, CENZEL C, FRUTOS E, ADEVA P. The evolution of internal strain in Mg–Y–Zn alloys with a long period stacking ordered structure [J]. Scripta Materialia, 2011, 65: 719–722.

AMBERGER D, EISENLOHR P, GÖKEN M. On the importance of a connected hard-phase skeleton for the creep resistance of Mg alloys [J]. Acta Materialia, 2012, 60: 2277–2289

LANGDON T G. Identifying creep mechanisms at low stresses [J]. Material Science and Engineering, 2000, 283: 266–273.

LANGDON T G. A method of distinguishing between diffusion creep and Harper-Dorn creep at low stress levels [J]. Scripta Materialia, 1996, 35: 733–737.

KASSNER M E, PEREZ-PRADO M T. Five-power-law creep in single phase metals and alloys [J]. Progress in Materials Science, 2000, 45: 1–102.

RUANO O A, SHERBY O D, WADSWORTH J, WOLFENSTINE J. Rebuttal to “In defense of diffusional creep” [J]. Progress in Materials Science, 1996, 211: 66–71.

JANIKI V, HNILICAI F, ZUNA P, OCENASEK V, STULIKOVA I. Cavitation and grain boundary sliding during creep of Mg-Y-Nd-Zn-Mn alloy [J]. Transactions of Nonferrous Metals Society of China, 2008, 18: 64–68.

PEKGULERYUZ M O, KAYA A A. Creep resistant magnesium alloys for powertrain applications [J]. Advanced Engineering Materials, 2003, 5: 866–878.

HERRING C. Diffusional viscosity of a polycrystalline solid [J]. Applied Physics A, 1950, 21: 43445.

COBLE R L. Model for boundary diffusion controlled creep in polycrystalline materials [J]. Applied Physics A, 1963, 34: 1679–1682.

CHOKSHI A H, MUKHERJEE A K, LANGDON T G. Superplasticity in advanced materials [J]. Materials Science and Engineering Reports, 1993, 10: 237–274.

LANGDON T G. An evaluation of the strain contributed by grain boundary sliding in superplasticity [J]. Material Science and Engineering, 1994, 174: 225–230.

Author information

Authors and Affiliations

Corresponding author

Additional information

Foundation item: Project(14JJ1013) supported by Natural Science Foundation of Hunan Province, China

Rights and permissions

About this article

Cite this article

Chen, G., Zhang, Yb., Xia, Wj. et al. Microstructure and tensile creep resistance of Mg-5.5%Zn-(0.7%, 1.5%, 3.5%, 7.5%)Y alloys. J. Cent. South Univ. 22, 4112–4122 (2015). https://doi.org/10.1007/s11771-015-2957-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11771-015-2957-0