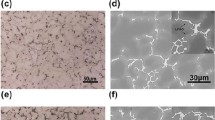

The effect of varying Zn contents (0, 0.4, and 0.8 wt.%) on the microstructure and mechanical properties of an Mg–6Y–2Nd–1Gd–0.5Zr alloy was systematically evaluated to improve the above characteristics. An as-cast alloy is shown to mainly consist of α-Mg, Mg24Y5, Mg12Nd, and Mg5Gd phases. An addition of Zn to the alloy results in the Mg12YZn phase formation and grain refinement. An increase in a Zn volume from 0.4 to 0.8 wt.% brings about a narrower solidification temperature range. After solution treatment, Mg12Nd and Mg24Y5 mainly disappear, but a Mg12YZn content grows. The tensile strength, yield strength, and elongation of a solution-treated Mg–6Y–2Nd–1Gd–0.5Zr–0.4Zn alloy are 284 MPa, 218 MPa, and 6.5%, respectively.

Similar content being viewed by others

References

P. Sevvel and V. Jaiganesh, “Influence of the arrangement of materials and microstructural analysis during FSW of AZ80A & AZ91C Mg alloys,” Arch. Metall. Mater., 62, No. 3, 1795–1801 (2017).

J. Zhao, J. Zhang, and W. C. Liu, “Effect of Y content on microstructure and mechanical properties of as-cast Mg–8Li–3Al–2Zn alloy with duplex structure,” Mater. Sci. Eng. A, 650, 240–247 (2016).

Q. Chen, J. Lin, and D. Y. Shu, “Microstructure development, mechanical properties and formability of Mg-Zn-Y-Zr magnesium alloy,” Mater. Sci. Eng. A, 554, 129–141 (2012).

Q. Chen, D. Y. Shu, and Z. D. Zhao, “Microstructure development and tensile mechanical properties of Mg–Zn–RE–Zr magnesium alloy,” Mater. Design, 40, 488–496 (2012).

S. Kleiner, O. Beffort, and P. J. Uggowitzer, “Microstructure evolution during reheating of an extruded Mg–Al–Zn alloy into the semisolid state,” Scr. Mater., 51, 405–410 (2004).

F. Shi, C. Q. Wang, and Z. M. Zhang, “Microstructures, corrosion and mechanical properties of as-cast Mg–Zn–Y–(Gd) alloys,” Trans. Nonferr. Metal. Soc., 25, No. 7, 2172–2180 (2015).

D. K. Xu, W. N. Tang, and L. Liu, “Effect of Y concentration on the microstructure and mechanical properties of as-cast Mg–Zn–Y–Zr alloys,” J. Alloy. Compd., 423, No. 1, 129–134 (2006).

J. Wang, J. W. Fu, and X. G. Dong, “Microstructure and mechanical properties of as-cast Mg–Al–Sn–Y–Nd alloy,” Mater. Design, 36, 432–437(2012).

T. Morishige, M. Tsujikawa, and S. Oki, “Friction stir processing of cast Mg-Y-Zn alloy,” Adv. Mater. Res., 59, No. 15, 369–374 (2007).

J. L. Li, R. S. Chen, and W. Ke, “Microstructure and mechanical properties of Mg–Gd–Y–Zr alloy cast by metal mould and lost foam casting,” Trans. Nonferr. Metal. Soc., 21, No. 4, 761–766 (2011).

T. Kekule, H. Kudrnová, and M. Vlach, “Development of microstructure and properties of Mg–Y–(Nd)–Zn alloys during heat and mechanical treatment,” Defect Diffus. Forum, 369, 157–162 (2016).

R. P. Lu, J. F. Wang, and Y. L. Chen, “Effect of heat treatment on the morphology of long-period stacking ordered phase the corresponding damping capacities and mechanical properties of Mg–Zn–Y alloys,” J. Alloy. Compd., 639, 541–546 (2015).

B. Chen, D. L. Lin, X. Q. Zeng, and C. Lu, “Effects of yttrium and zinc addition on the microstructure and mechanical properties of Mg–Y–Zn alloys,” J. Mater. Sci., 45, No. 9, 2510–2517 (2010).

T. Morishige, M. Tsujikawa, and S. Oki, “Grain refinement of Mg–Y–Zn alloy by friction stir processing,” Adv. Mater. Res., 91, No. 26, 465–468 (2007).

M. Yamasaki, M. Sasaki, and M. Nishijima, “Formation of 14H long period stacking ordered structure and profuse stacking faults in Mg–Zn–Gd alloys during isothermal aging at high temperature,” Acta Mater., 55, No. 20, 6798–6805 (2007).

M. Yamasaki, K. Hashimoto, and K. Hagihara, “Effect of multimodal microstructure evolution on mechanical properties of Mg-Zn-Y extruded alloy,” Acta Mater., 59, 3646–3658 (2011).

J. Wang, X. G. Fang, and S. S. Wu, “Effects of heat treatment on microstructure evolution and mechanical properties of Mg-6Zn-1.4Y-0.6Zr alloy, China Foundry, 14, No. 3, 199–204 (2017).

W. Rong, Y. Zhang, Y. J. Wu, et al., “Effects of Zr and Mn additions on formation of LPSO structure and dynamic recrystallization behavior of Mg-15Gd-1Zn alloy,” J. Alloy. Compd., 692, 805–816(2017).

Author information

Authors and Affiliations

Corresponding author

Additional information

Translated from Problemy Prochnosti, No. 4, pp. 124 – 131, July – August, 2019.

Rights and permissions

About this article

Cite this article

Tao, J.Q., Huang, S.H., Zhao, G.Z. et al. Effect of Zn on the Mechanical Properties and Microstructure of as-Cast and Solution-Treated Mg–6Y–2Nd–1Gd–0.5Zr Alloys. Strength Mater 51, 609–615 (2019). https://doi.org/10.1007/s11223-019-00107-3

Received:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11223-019-00107-3