Abstract

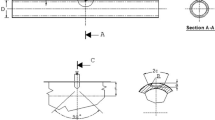

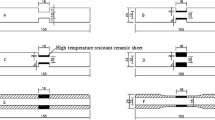

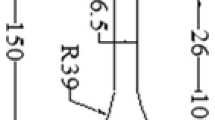

In a nuclear powerplant, the rotary equipment, such as a pump directly fitted with hanger in the piping system, experiences torsional and bending loads. Higher crack growth rate occurs because of this torsional load in addition to the bending load. Hence, it is necessary to study the fatigue behavior of piping components under the influence of combined torsional and bending load. In this study, experimental fatigue life evaluation was conducted on a notched stainless steel SA312 Type 304LN straight pipe having an outer diameter of 170 mm. The experimental crack depth was measured using alternating current potential drop technique. The fatigue life of the stainless steel straight pipe was predicted using experiments, Delale and Erdogan method, and area-averaged root mean square-stress intensity factor approach at the deepest and surface points of the notch. Afterward, the fatigue crack growth and crack pattern were discussed. As a result, fatigue crack growth predicted using analytical methods are in good agreement with experimental results.

Similar content being viewed by others

References

ASME. Boiler and Pressure Vessel Code, Rules for Inservice Inspection of Nuclear Power Plant Components. New York: The American Society of Mechanical Engineers, 1992

JSME. Codes for Nuclear Power Generation Facilities-rules on Fitness-for-service for Nuclear Power Plants. Japan Society of Mechanical Engineers, 2008

Li Y, Hasegawa K, Sakai M, Matsuura S, Miura N. Experimental investigation of failure estimation method for circumferentially cracked pipes subjected to combined bending and torsion moments. Journal of Pressure Vessel Technology, 2015, 137(2): 021202

Hasegawa K, Li Y, Bezensek B, Hoang P. Effect of torsion on collapse bending moment for 24-inch diameter schedule 80 pipes with wall thinning. In: ASME 2012 Pressure Vessels and Piping Conference. Toronto: American Society of Mechanical Engineers, 2012, 123–130

Pukazhendhi D, Vishnuvardhan S, Saravanan M, Gandhi P, Raghava G. Fatigue and fracture studies on 168 mm OD stainless steel straight pipes with circumferential outer surface crack on base metal. Sponsored Project SSP Report Nos 4 & 5. 2008

Paris P, Erdogan F. A critical analysis of crack propagation laws. Journal of Basic Engineering, 1963, 85(4): 528–533

Delale F, Erdogan F. The crack problem in a specially orthotropic shell with double curvature. Engineering Fracture Mechanics, 1983, 18(3): 529–544

Cruse T A, Besuner P. Residual life prediction for surface cracks in complex structural details. Journal of Aircraft, 1975, 12(4): 369–375

Arora P, Singh P K, Bhasin V, Vaze K K, Ghosh A K, Pukazhendhi D M, Gandhi P, Raghava G. Predictions for fatigue crack growth life of cracked pipes and pipe welds using RMS SIF approach and experimental validation. International Journal of Pressure Vessels and Piping, 2011, 88(10): 384–394

Rastogi R, Ghosh S, Ghosh A, Vaze K, Singh P. Fatigue crack growth prediction in nuclear piping using Markov chain Monte Carlo simulation. Fatigue & Fracture of Engineering Materials & Structures, 2017, 40(1): 145–156

Yang J, Lu G, Yu T, Reid S. Experimental study and numerical simulation of pipe-on-pipe impact. International Journal of Impact Engineering, 2009, 36(10–11): 1259–1268

Arora P, Singh P K, Bhasin V, Vaze K K, Pukazhendhi D M, Gandhi P, Raghava G. Fatigue crack growth behavior in pipes and elbows of carbon steel and stainless steel materials. Procedia Engineering, 2013, 55: 703–709

Hasegawa K, Li Y, Bezensek B, Hoang P H, Rathbun H J. Technical basis for application of collapse moments for locally thinned pipes subjected to torsion and bending proposed for ASME Section XI. Journal of Pressure Vessel Technology, 2016, 138(1): 011101

Nagapadmaja P, Kalyanaraman V, Satish Kumar S R, Chellapandi P. Experimental study on LBB behaviour of LMFBR pipe elbows. International Journal of Fatigue, 2008, 30(3): 574–584

Murthy D R, Pukazhendhi D, Navin D P, Chellapandi P, Chetal S. Investigations on shell-nozzle junction of steam generator for LBB justification. Fatigue & Fracture of Engineering Materials & Structures, 2007, 30(12): 1203–1213

Skorupa M, Skorupa A. Experimental results and predictions on fatigue crack growth in structural steel. International Journal of Fatigue, 2005, 27(8): 1016–1028

Wu S X. Shape change of surface crack during fatigue growth. Engineering Fracture Mechanics, 1985, 22(5): 897–913

Brennan F P, Ngiam S, Lee C. An experimental and analytical study of fatigue crack shape control by cold working. Engineering Fracture Mechanics, 2008, 75(3–4): 355–363

Li Y, Hasegawa K, Miura N, Hoshino K. Experimental investigation of failure estimation method for stainless steel pipes with a circumferential crack subjected to combined tensile and torsion loads. Journal of Pressure Vessel Technology, 2013, 135(4): 041405

Chu W Y, Hsiao C M, Jin L J, Liu T H. Fatigue crack initiation from a notch tip under a cyclic compressive load. Scripta Metallurgica, 1983, 17(8): 993–996

Kumar D V, Murthy D R, Seetharaman S, Gupta S, Bhasin K, Vaze H, Kushwaha S. Cyclic tearing and crack growth in circumferentially cracked straight pipes. Fatigue & Fracture of Engineering Materials & Structures, 2004, 27(11): 1061–1072

Jones N, Birch S, Birch R, Zhu L, Brown M. An experimental study on the lateral impact of fully clamped mild steel pipes. Proceedings of the Institution of Mechanical Engineers. Part E, Journal of Process Mechanical Engineering, 1992, 206(2): 111–127

Sahu V, Ray P, Verma B. Experimental fatigue crack growth analysis and modelling in part-through circumferentially precracked pipes under pure bending load. Fatigue & Fracture of Engineering Materials & Structures, 2017, 40(7): 1154–1163

Murakami Y, Keer L. Stress intensity factors handbook, Vol. 3. Journal of Applied Mechanics, 1993, 60(4): 1063

Pukazhendhi D M, Pazhani K C, Parivallal S. Experimental investigations of fatigue crack growth and behaviour on stainless steel elbows. Journal of Structural Engineering, 2017, 44(1): 95–104

Lin X. Fatigue crack growth simulation of surface cracks under arbitrary crack face loading. In: The 13th International Conference on Fracture. Beijing: Chinese Society of Theoretical and Applied Mechanics, 2013, 16–21

Acknowledgements

The authors thank the Director and Advisor (Management) for the constant support and encouragement extended in the R&D activities. The cooperation and support extended by the other scientists and technical staff of Fatigue & Fracture Laboratory, CSIR-SERC. S. Veerarajan appreciates Professor Shuenn-Yih Chang of the Department of Civil Engineering, National Taipei University of Technology (NTUT), Taiwan, China, for his financial support as well as NTUT for awarding him a Ph. D. scholarship.

Author information

Authors and Affiliations

Corresponding authors

Rights and permissions

About this article

Cite this article

Veerarajan, S., Pukazhendhi, D. & Gandhi, P. Fatigue crack growth behavior of a 170 mm diameter stainless steel straight pipe subjected to combined torsion and bending load. Front. Struct. Civ. Eng. 15, 905–913 (2021). https://doi.org/10.1007/s11709-021-0683-2

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11709-021-0683-2