Abstract

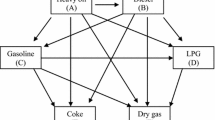

Dual-loop circulating fluidized bed (CFB) reactors have been widely applied in industry because of their good heat and mass transfer characteristics and continuous handling ability. However, the design of such reactors is notoriously difficult owing to the poor understanding of the underlying mechanisms, meaning it has been heavily based on empiricism and stepwise experiments. Modeling the gas-solid CFB system requires a quantitative description of the multiscale heterogeneity in the sub-reactors and the strong coupling between them. This article proposed a general method for modeling multiloop CFB systems by utilizing the energy minimization multiscale (EMMS) principle. A full-loop modeling scheme was implemented by using the EMMS model and/or its extension models to compute the hydrodynamic parameters of the sub-reactors, to achieve the mass conservation and pressure balance in each circulation loop. Based on the modularization strategy, corresponding interactive simulation software was further developed to facilitate the flexible creation and fast modeling of a customized multi-loop CFB reactor. This research can be expected to provide quantitative references for the design and scale-up of gas-solid CFB reactors and lay a solid foundation for the realization of virtual process engineering.

Similar content being viewed by others

Abbreviations

- a :

-

acceleration, m · s−2

- C d :

-

constant

- D :

-

diameter, m

- d b :

-

bubble diameter, m

- f :

-

volume fraction of the clusters

- f b :

-

volume fraction of the bubble phase

- G s :

-

solids circulation rate or solids flux, kg · m−2 · s

- g :

-

gravity acceleration, m · s−2

- H :

-

height, m

- I m :

-

solid inventory, kg

- M s :

-

mass flow rate, kg · s−1

- N gs :

-

Nst mass-specific energy dissipation rate for suspending and transporting particles, J · kg−1 · s

- N gs0 :

-

Nst0 normalized Ngs or Nst

- N T :

-

total energy dissipation rate with respect to unit mass of particles, J · kg−1 · s

- r, R :

-

radius, m

- U s :

-

superficial velocity, m · s−1

- W gs, W st :

-

volume-specific energy dissipation rate for suspending and transporting particles, J · m−3 · s

- Δp :

-

pressure drop, kPa

- \({\overline \varepsilon _{\rm{r}}}\) :

-

average voidage between zero and r

- ε :

-

voidage

- ϕ :

-

degree of valve opening

- μ :

-

shear viscosity, Pa · s

- ρ :

-

density, kg ·m−3

- τ :

-

interfacial shear stress, N·m−2

- ζ :

-

empirical coefficient

- b:

-

bubble phase

- c:

-

dense phase

- e:

-

emulsion phase

- f:

-

dilute phase

- g:

-

gas

- i:

-

interphase

- max:

-

maximum

- mf:

-

minimum fluidization

- p:

-

particle

- r:

-

radial location

- w:

-

wall

- z:

-

axial coordinate

References

Grace J, Avidan A, Knowlton T. Circulating Fluidized Beds. London: Chapman & Hall Press, 1997, 1–18

Wang X. Gas-solid flow patterns of a dual-loop FCC riser with varying diameter. Dissertation for the Doctoral Degree. Beijing: Institute of Process Engineering, Chinese Academy of Sciences, 2006, 33–64

Joshi J, Nandakumar K. Computational modeling of multiphase reactors. Annual Review of Chemical and Biomolecular Engineering, 2015, 6: 347–378

Zhang N, Lu B, Wang W, Li J. 3D CFD simulation of hydrodynamics of a 150 MWe circulating fluidized bed boiler. Chemical Engineering Journal, 2010, 162(2): 821–828

Hu S, Liu X. A general EMMS drag model applicable for gas-solid turbulent beds and cocurrent downers. Chemical Engineering Science, 2019, 205: 14–24

Hu S, Liu X. A CFD-PBM-EMMS integrated model applicable for heterogeneous gas-solid flow. Chemical Engineering Journal, 2020, 383: 123122

Lu B, Zhang N, Wang W, Li J, Chiu J, Kang S. 3-D full-loop simulation of an industrial-scale circulating fluidized-bed boiler. AIChE Journal. American Institute of Chemical Engineers, 2013, 59(4): 1108–1117

Nikolopoulos A, Nikolopoulos N, Charitos A, Grammelis P, Kakaras E, Bidwe A, Varela G. High-resolution 3-D full-loop simulation of a CFB carbonator cold model. Chemical Engineering Science, 2013, 90: 137–150

Syamlal M, Guenther C, Cugini A, Ge W, Wang W, Yang N, Li J. Computational science: Enabling technology development. Chemical Engineering Progress, 2011, 107(1): 23–39

Ge W, Guo L, Liu X, Meng F, Xu J, Huang W, Li J. Mesoscience-based virtual process engineering. Computers & Chemical Engineering, 2019, 126: 68–82

Li J, Kwauk M. Exploring complex systems in chemical engineering: the multi-scale methodology. Chemical Engineering Science, 2003, 58: 521–535

Liu X, Guo L, Xia Z, Lu B, Zhao M, Meng F, Liu Z, Li J. Harnessing the power of virtual reality. Chemical Engineering Progress, 2012, 108(7): 28–33

Hu S, Liu X, Zhang N, Li J, Ge W, Wang W. Quantifying cluster dynamics to improve EMMS drag law and radial heterogeneity description in coupling with gas-solid two-fluid method. Chemical Engineering Journal, 2017, 307: 326–338

Pallares D, Johnsson F. Macroscopic modelling of fluid dynamics in large-scale circulating fluidized beds. Progress in Energy and Combustion Science, 2006, 32(5): 539–569

Werther J, Hartge E, Ratschow L, Wischnewski R. Simulation-supported measurements in large circulating fluidized bed combustors. Particuology, 2009, 7(4): 324–331

Haus J, Hartge E, Heinrich S, Werther J. Dynamic flowsheet simulation of gas and solids flows in a system of coupled fluidized bed reactors for chemical looping combustion. Powder Technology, 2016, 316: 628–640

Liu X, Hu S, Jiang Y, Li J. Extension and application of energy-minimization multi-scale (EMMS) theory for full-loop hydrodynamic modeling of complex gas-solid reactors. Chemical Engineering Journal, 2015, 278: 492–503

Li J, Kwauk M. Particle-fluid two-phase flow: the energy-minimization multi-scale method. Beijing: Metallurgical Industry Press, 1994, 23–40

Liu X, Jiang Y, Liu C, Wang W, Li J. Hydrodynamic modeling of gas-solid bubbling fluidization based on energy-minimization multiscale (EMMS) theory. Industrial & Engineering Chemistry Research, 2014, 53(7): 2800–2810

Zhang Z, Hu S, Liu X, Zhao H. Modeling the hydrodynamics of cocurrent gas-solid downers according to energy-minimization multi-scale theory. Particuology, 2016, 29: 110–119

Liu J, Liu X, Zhang Z, Zhao H, Ge W. Modeling the axial hydrodynamics of gas-solid counter-current downers. Particuology, 2020, 50: 135–143

Hu S, Liu X, Li J. Steady-state modeling of axial heterogeneity in CFB risers based on one-dimensional EMMS model. Chemical Engineering Science, 2013, 96: 165–173

Li J, Tung Y, Kwauk M. Axial voidage profiles of fast fluidized beds in different operating regions. In: Basu P, Large J F, eds. The 2nd International Conference on Circulating Fluidized Beds. Oxford: Pergamon Press, 1988, 193–203

Rhodes M, Geldart D. A model for the circulating fluidized bed. Powder Technology, 1987, 53(3): 155–162

Kwauk M, Li H. Handbook of Fluidization. Beijing: Chemical Industry Press, 2008, 584–609

Bi X, Liu X. High density and high solids flux CFB risers for steam gasification of solids fuels. Fuel Processing Technology, 2010, 91(8): 915–920

Jones D, Davidson J. The flow of particles from a fluidised bed through an orifice. Rheologica Acta, 1965, 4(3): 180–192

Herbert P, Reh L. ETH-CFB Measurement Database: General Description and Operations Manual, 1999, 1–29

Acknowledgements

We would like to thank the Strategic Priority Research Program of the Chinese Academy of Sciences (No. XDA07080400) and the National Natural Science Foundation of China (Grant No. U1710251) for their financial support. Many thanks to the anonymous reviewers for their constructive suggestions, which were extremely helpful in improving this article.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Hu, S., Liu, X. Development of a hydrodynamic model and the corresponding virtual software for dual-loop circulating fluidized beds. Front. Chem. Sci. Eng. 15, 579–590 (2021). https://doi.org/10.1007/s11705-020-1953-6

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11705-020-1953-6