Abstract

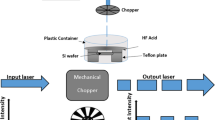

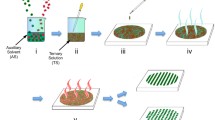

In this work, we present plasma etching alone as a directed assembly method to both create the nanodot pattern on an etched polymeric (PMMA) film and transfer it to a silicon substrate for the fabrication of silicon nanopillars or cone-like nanostructuring. By using a shield to control sputtering from inside the plasma reactor, the size and shape of the resulting nanodots can be better controlled by varying plasma parameters as the bias power. The effect of the shield on inhibitor deposition on the etched surfaces was investigated by time-of-flight secondary ion mass spectroscopy (ToF-SIMS) measurements. The fabrication of quasi-ordered PMMA nanodots of a diameter of 25 nm and period of 54 nm is demonstrated. Pattern transfer to the silicon substrate using the same plasma reactor was performed in two ways: (a) a mixed fluorine-fluorocarbon-oxygen nanoscale etch plasma process was employed to fabricate silicon nanopillars with a diameter of 25 nm and an aspect ratio of 5.6, which show the same periodicity as the nanodot pattern, and (b) high etch rate cryogenic plasma process was used for pattern transfer. The result is the nanostructuring of Si by high aspect ratio nanotip or nanocone-like features that show excellent antireflective properties.

Similar content being viewed by others

References

Gogolides E, Vassilios C, George K, Dimitrios K, Katerina T, George B, Marilena V, Angeliki T. Controlling roughness: From etching to nanotexturing and plasma-directed organization on organic and inorganic materials. Journal of Physics. D, Applied Physics, 2011, 44(17): 174021

Franssila S. Optical Lithography. Introduction to Microfabrication. Hoboken: John Wiley & Sons, Ltd., 2010, 103–113

Stulen R H, Sweeney D W. Extreme ultraviolet lithography. IEEE Journal of Quantum Electronics, 1999, 35(5): 694–699

Pfeiffer H C. Direct write electron beam lithography: A historical overview. In: Proceedings of SPIE Photomask Technology. Monterey: SPIE, 2010, 782316

Chou S Y, Krauss P R, Renstrom P J. Nanoimprint lithography. Journal of Vacuum Science & Technology. B, 1996, 14(6): 4129–4133

Schift H. Nanoimprint lithography: An old story in modern times? A review. Journal of Vacuum Science & Technology. B, 2008, 26(2): 458

Colson P, Henrist C, Cloots R. Nanosphere lithography: A powerful method for the controlled manufacturing of nanomaterials. Journal of Nanomaterials, 2013, 2013: 1–19

Zhang G, Wang D. Colloidal lithography—the art of nanochemical patterning. Chemistry, an Asian Journal, 2009, 4(2): 236–245

Haynes C, Van Duyne P. Nanosphere lithography: A versatile nanofabrication tool for studies of size-dependent nanoparticle optics. Journal of Physical Chemistry B, 2001, 105: 5599–5611

Hamley I W. Nanostructure fabrication using block copoly-mers—Review. Nanotechnology, 2003, 14: 16

Tallegas S, Baron T, Gay G, Aggrafeil C, Salhi B, Chevolleau T, Cunge G, Bsiesy A, Tiron R, Chevalier X, et al. Block copolymer technology applied to nanoelectronics. Physica Status Solidi. C, Current Topics in Solid State Physics, 2013, 10(9): 1195–1206

Seeger K, Palmer R E. Fabrication of silicon cones and pillars using rough metal films as plasma etching masks. Applied Physics Letters, 1999, 74(11): 1627–1629

Ostrikov K. Plasma nanoscience: From nature’s mastery to deterministic plasma-aided nanofabrication. IEEE Transactions on Plasma Science, 2007, 35(2): 127–136

Levchenko I, Ostrikov K, Diwan K, Winkler K, Mariotti D. Plasma-driven self-organization of Ni nanodot arrays on Si(100). Applied Physics Letters, 2008, 93(18): 183102

Hsu C H, Lo H C, Chen C F, Wu C T, Hwang J S, Das D, Tsai J, Chen L C, Chen K H. Generally applicable self-masked dry etching technique for nanotip array fabrication. Nano Letters, 2004, 4(3): 471–475

Gharghi M, Sivoththaman S. Formation of nanoscale columnar structures in silicon by a maskless reactive ion etching process. Journal of Vacuum Science & Technology. A, Vacuum, Surfaces, and Films, 2006, 24(3): 723

Muñoz-García J, Vázquez L, Castro M, Gago R, Redondo-Cubero A, Moreno-Barrado A, Cuerno R. Self-organized nanopatterning of silicon surfaces by ion beam sputtering. Materials Science and Engineering R Reports, 2014, 86: 1–44

Gago R, Vázquez L, Plantevin O, Metzger T H, Muñoz-García J, Cuerno R, Castro M. Order enhancement and coarsening of self-organized silicon nanodot patterns induced by ion-beam sputtering. Applied Physics Letters, 2006, 89(23): 233101

Frost F, Ziberi B, Schindler A, Rauschenbach B. Surface engineering with ion beams: From self-organized nanostructures to ultra-smooth surfaces. Applied Physics. A, Materials Science & Processing, 2008, 91(4): 551–559

Vourdas N, Kontziampasis D, Kokkoris G, Constantoudis V, Goodyear A, Tserepi A, Cooke M, Gogolides E. Plasma directed assembly and organization: Bottom-up nanopatterning using top-down technology. Nanotechnology, 2010, 21(8): 85302

Gogolides E, Tserepi A, Constandoudis V, Vourdas N, Boulousis G, Vlachopoulou M E, Tsougeni K, Kontziampasis D. Method for the fabrication of periodic structures on polymers using plasma processes. European Patent, EP2300214, 2009-12-17

Kontziampasis D, Constantoudis V, Gogolides E. Plasma directed organization of nanodots on polymers: Effects of polymer type and etching time on morphology and order. Plasma Processes and Polymers, 2012, 9(9): 866–872

Kokkoris G, Gogolides E. The potential of ion-driven etching with simultaneous deposition of impurities for inducing periodic dots on surfaces. Journal of Physics. D, Applied Physics, 2012, 45(16): 165204

Kokkoris G. Towards control of plasma-induced surface roughness: Simultaneous to plasma etching deposition. European Physical Journal Applied Physics, 2011, 56(2): 24012

Gogolides E, Zeniou A. Variable Faraday shield for a substrate holder, a clamping ring, or an electrode, or their combination in a plasma reactor. European Patent, EP3261111, 2017-04-26

Vijaya-Kumar M K, Constantoudis V, Gogolides E, Pret A V, Gronheid R. Contact edge roughness metrology in nanostructures: Frequency analysis and variations. Microelectronic Engineering, 2012, 90: 126–130

Kokkoris G, Vourdas N, Gogolides E. Plasma etching and roughening of thin polymeric films: A fast, accurate, in situ method of surface roughness measurement. Plasma Processes and Polymers, 2008, 5(9): 825–833

Dussart R, Tillocher T, Lefaucheux P, Boufnichel M. Plasma cryogenic etching of silicon: From the early days to today’s advanced technologies. Journal of Physics. D, Applied Physics, 2014, 47(12): 123001

Smyrnakis A, Almpanis E, Constantoudis V, Papanikolaou N, Gogolides E. Optical properties of high aspect ratio plasma etched silicon nanowires: Fabrication-induced variability dramatically reduces reflectance. Nanotechnology, 2015, 26(8): 085301

Ellinas K, Smyrnakis A, Malainou A, Tserepi A, Gogolides E. “Mesh-assisted” colloidal lithography and plasma etching: A route to large-area, uniform, ordered nano-pillar and nanopost fabrication on versatile substrates. Microelectronic Engineering, 2011, 88(8): 2547–2551

Jansen H V. The black silicon method II. Microelectronic Engineering, 1995, 27: 475–480

Jansen H V. Black silicon method. VIII. A study of the performance of etching silicon using SF6-O2-based chemistry with cryogenical wafer cooling and a high density ICP source. Microelectronics Journal, 2001, 32: 769–777

Acknowledgements

The authors would like to thank Dr. Dimitrios Kontziampasis for his contribution in the AFM measurements and his important work on the development of the plasma directed assembly process. This work was supported by (a) the Research Excellence Project ‘Plasma Directed Assembly and Organization—PlasmaNanoFactory’ which is implemented under the ‘Aristeia I’ Action of the ‘Operational Programme Education and Lifelong Learning’ (Project ID 695) and is co-funded by the European Social Fund (ESF) and National Resources, (b) the Ph.D. fellowship programme of NCSR Demokritos which supported Dr. A. Smyrnakis, and (c) the M. Smoluchowski Krakow Research Consortium (in the framework of the KNOW project).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Smyrnakis, A., Zeniou, A., Awsiuk, K. et al. A non-lithographic plasma nanoassembly technology for polymeric nanodot and silicon nanopillar fabrication. Front. Chem. Sci. Eng. 13, 475–484 (2019). https://doi.org/10.1007/s11705-019-1809-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11705-019-1809-0