Abstract

A systematic investigation of Ni and Zn spinel ferrites preparation via oxalate route, involving a detailed characterization of synthesized precursors, in situ study of thermally induced decomposition reactions and analyses of the prepared ferrites is presented. Although the oxalate route in general is rather well known, the detailed investigations of the decomposition reactions of the well-characterized bimetal oxalate precursors have been mostly omitted by the authors. The formation of the solid solution, i.e., the incorporation of both metals into the single oxalate crystal structure, is essential for the subsequent decomposition reaction and synthesis of pure spinel ferrites. The optimally prepared precursor decomposes in a single reaction step at relatively low temperatures, evading the undesirable sintering, and allowing the preparation of microporous/mesoporous ferrites with relatively high BET areas.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Nickel ferrite and zinc ferrite belong to transition metal oxides with a spinel structure. These spinel ferrites are described by the chemical formula \({\mathrm{M}}^{2+}{\mathrm{Fe}}_{2}^{3+}{\mathrm{O}}_{4}^{2-}\), where \({\mathrm{M}}^{2+}\) represents a divalent metal cation, most often Ni, Zn, Co, Mn, Mg, Cu, etc. (Narang and Pubby 2021). Spinel ferrites are characterized by good thermal (Mostafa et al. 2023), mechanical (Nikam et al. 2023) and chemical stability (Liandi et al. 2023), together with their non-toxicity (Zhang et al. 2020). They are also known for their excellent magnetic (Ergin et al. 2023), electrical (Rana et al. 2021) and optical properties (Kumari et al. 2020), which can be controlled by changing their physical structure (Basavanagoudra et al. 2021). This is also true for nanostructured ferrites, which can exhibit additional exceptional properties e.g., an extremely small crystallite size, large surface areas, porosity or different particle morphology (Amiri et al. 2019; Iqbal et al. 2021; Wu et al. 2019; Misra et al. 2004). All these interesting properties of Ni and Zn nanoferrites bring many possibilities in a wide range of applications, which include e.g., sensors (Šutka and Gross 2016; Jia and Misra 2011; You et al. 2017; Manikandan et al. 2020, 2018; Sankaranarayanan et al. 2022), photocatalysis (Šutka et al. 2015; Arimi et al. 2018; Hou et al. 2017), battery cells (Zhong et al. 2016; Zayani et al. 2021) and solar cells (Shanmugam et al. 2021), biomedical applications (Lasheras et al. 2016; Ishaq et al. 2017; Ruthradevi et al. 2017), microwave absorption (Isha et al. 2014; Pubby et al. 2020) etc.

In bulk, NiFe2O4 possesses an inverse spinel structure, where all the divalent Ni ions occupy octahedral sites and Fe3+ cations are distributed equally between tetrahedral and octahedral sites of the structure. On the other hand, ZnFe2O4 has typically normal spinel structure with all the Zn2+ cations located in tetrahedral sites and all the Fe3+ cations in octahedral sites (Amiri et al. 2019; Kaur and Bhargava 2020). A modification in the distribution of divalent cations among tetrahedral and octahedral sites often occurs during the transition to the nanometric scale, nano-ferrites mostly form a mixed spinel structure described by the formula \(\left({\mathrm{M}}_{1-j}^{2+}{\mathrm{Fe}}_{j}^{3+}\right)\left[{\mathrm{M}}_{j}^{2+}{\mathrm{Fe}}_{2-j}^{3+}\right]{\mathrm{O}}_{4}^{2-}\). Index j represents the degree of inversion and occurs in the interval 0 < j < 1, where j = 0 means normal spinel and j = 1 inverse spinel (Birgani et al. 2015; Kaur and Bhargava 2020).

The variation of ion sublattice occupancy also depends on a preparation method (Chaudhari et al. 2022). Many approaches for the synthesis of spinel ferrites from solid state to wet-chemistry methods, such as sol–gel method (Pubby et al. 2020; Kim et al. 2014), solvothermal and hydrothermal synthesis (Ruthradevi et al. 2017), microemulsion (Misra et al. 2004), coprecipitation (Šutka et al. 2015; Vigneswari and Raji 2017), mechanochemical synthesis (Narasimharao et al. 2023; İçin et al. 2021) and thermal decomposition (Iqbal et al. 2021), have already been reported in the literature. The chemical synthesis, in contrast to conventional ceramic methods, allows greater control over the originating particles, in terms of their size, homogeneity, morphology, phase purity, crystallinity or the aforementioned distribution of cations between both sublattices. Changes in the catalytic, electrical and magnetic properties of the given particles are also related to the changes in their structure and the preparation approach (Chaudhari et al. 2022; Patil et al. 2022; Shang et al. 2023).

Of the mentioned synthesis routes, the coprecipitation method of the oxalate precursor and its following thermal decomposition is often preferred due to its simplicity, high yield and low decomposition temperature. The coprecipitation reaction produces a solid solution consisting of two different metals, which enables the subsequent calcination to obtain homogeneous oxides in a single reaction step with control of particle size, crystallinity and purity (Chaudhari et al. 2022; Diodati et al. 2014). Using this synthesis process, Chaudhari et al. (2022) prepared a series of nickel–zinc ferrites by calcinating the oxalate solution at a temperature of 350 °C for 3 h followed by sintering at 1000 °C for 4 h. ZnFe2O4 nanorods with a mesoporous-structured surface were successfully prepared by Zhong et al. (2016) by annealing the oxalate precipitate in air at a temperature of 500 °C for 3 h. Both NiFe2O4 and ZnFe2O4 were synthesized by Diodati et al. (2014) also by coprecipitation of oxalates and subsequent thermal decomposition in air at a temperature of 900 °C for 5 h. However, the detailed investigations of bimetal oxalate precursors have been mostly omitted by the authors. In our previous work (Lisníková et al. 2022) we showed that the formation of the solid solution, i.e. the incorporation of both metals into the single oxalate crystal structure, is essential for the subsequent decomposition reaction and synthesis of pure spinel cobalt ferrites.

In this paper, we describe the preparation of nickel ferrite and zinc ferrite via oxalate route, including the precursor verification step, in order to show the possibility of modifying the properties of the prepared spinel particles by changing the decomposition temperature. The development of mean coherent length (MCL), morphology, phase composition and BET surface area of the prepared samples was monitored using X-ray diffraction, scanning electron microscopy with EDX detector, Mössbauer spectroscopy and N2 adsorption measurements, respectively. The differences in the evolution of these parameters with temperature depending on the type of metal (Ni or Zn) are shown as well.

Experimental

Chemicals

Iron(II) chloride tetrahydrate (99%) and nickel(II) chloride hexahydrate (98%) were purchased from Penta Ltd. Zinc(II) chloride anhydrous (98%) and oxalic acid dihydrate (99.8%) were bought from Lach-Ner Ltd. All reagents were used without further purification.

Synthesis

The bimetal NiFe and ZnFe oxalates were prepared by co-precipitation following the procedure described in (Lisníková et al. 2022). Briefly, stoichiometric amounts of Fe2+, Ni2+ or Zn2+ precursors were dissolved in 50 ml of deionised water. Using the syringe and the linear motor, the cation solution was dropwise added (with constant rate 0.55 ml/min) into an aqueous solution of oxalic acid with constant stirring. In both cases, 5.22 mmol of Ni2+ (Zn2+) precursor, 10.45 mmol of Fe2+ precursor and 23.5 mmol of oxalic acid were used to obtain oxalates with a metal concentration ratio of Ni (Zn) and Fe of 1:2. For the detailed characterization of bimetal oxalates, iron, nickel and zinc oxalates labelled as Fe_ox, Ni_ox and Zn_ox were synthesized, with an analogous process to bimetal samples.

Next, each of the bimetal oxalates (NiFe_ox, ZnFe_ox) was calcined in a laboratory furnace (LAC LE/05 with Ht40P controller) for 2 h at the selected temperature (heating rate 2 °C/min) to prepare spinel ferrites, i.e. nickel ferrite and zinc ferrite. Decomposition temperatures were selected based on the in situ XRD data of the respective oxalate. Each sample was labelled according to the calcination temperature e.g., NiFe_ox_330.

Characterization techniques

A Bruker D8 ADVANCE diffractometer with Bragg–Brentano parafocusing geometry, equipped with a position-sensitive LYNXEYE detector and an X-ray tube using Co Kα radiation was used to measure X-ray diffraction patterns of the prepared samples. A 0.6 mm divergence slit and 2.5° axial Soller slits were inserted into the primary beam path, whereas Fe Kβ filter and 2.5° axial Soller slits were implemented into the secondary beam path. All diffraction patterns were measured in the 2θ range of 10–100° with a scan step of 0.02°. The obtained patterns were analysed with MAUD program (Lutterotti 2010).

Observation of the thermally induced decomposition of bimetal oxalates was performed by in situ XRD using an XRK 900 in situ XRD chamber (Anton Paar) with a constant flow of synthetic air. Both samples of bimetal oxalates were heated from 30 to 750 °C and the individual diffraction patterns were collected after every 10 °C step. Each diffraction pattern was measured for 15–20 min at the corresponding temperature.

Transmission 57Fe Mössbauer spectra of iron containing samples were obtained at room temperature using OLTWINS dual spectrometer developed at Palacký University Olomouc, Czech Republic, using a custom velocity unit (Novák et al. 2022) with motion control using an autotuning procedure (Procházka et al. 2020). A radioactive source 57Co embedded in rhodium matrix was used and the collected spectra were evaluated using MossWinn 4.0 software (Klencsár et al. 1996). The velocity axis was calibrated by measuring the α-iron sample at room temperature.

The morphology of coprecipitated and calcinated powdered samples was monitored using a scanning electron microscope VEGA3 LMU equipped with Everhart–Thornley type secondary electron detector (Tescan). The accelerating voltage was set to 20 kV. SEM observations were done after depositing a 20 nm Cr layer on the samples using a sputtering device Q 150T ES (Quorum Technologies) to increase the conductivity. Energy dispersive X-ray microanalysis (EDX) using an additional Si(Li) XFlash 410 EDX detector (Bruker) was used to map the distribution of elements in the prepared bimetal samples. The metal ratios were determined using standardless PB-ZAF method integrated in QUANTAX software (Bruker).

N2 adsorption–desorption isotherms of calcinated samples were obtained using an adsorption analyser Autosorb iQ from Quantachrome Instruments Anton Paar. Prior to the measurements the samples were outgassed for 2 h at 100 °C and then at room temperature for 12 h. The BET areas of the calcinated samples were computed according to the Brunauer–Emmett–Teller model. Rouquerol’s rule was used to determine the BET range of adsorption points.

Results and discussion

NiFe and ZnFe oxalate precursors

Two oxalate precursors were investigated, nickel–iron oxalate denoted as NiFe_ox and zinc-iron oxalate denoted as ZnFe_ox. In both cases, they were solid solutions (Fe/Ni = 2, respectively Fe/Zn = 2), which were prepared by the coprecipitation method. Details of oxalate synthesis are given in the Experimental Section.

Bimetal nature of oxalate precursors can be verified using several experimental techniques including XRD, Mössbauer spectroscopy and EDX microanalysis, as described in our previous work on cobalt ferrites (Lisníková et al. 2022).

Firstly, the formation of a solid solution of bimetal oxalates can be revealed by comparing XRD data (Gnanamani et al. 2016; Lisníková et al. 2022). The X-ray diffraction patterns of the prepared samples in 2θ range 19–28° are shown in Fig. 1 and Fig. 2 (for full diffraction patterns see Supplementary data, Figs. S1–S5). All the prepared oxalate samples were found to crystallize as β-polymorph. When comparing the diffraction pattern of NiFe_ox to those of Fe_ox and Ni_ox samples, a slight shift in the positions of the diffraction maxima belonging to reflections (202) and (004) can be observed. In the case of bimetal NiFe_ox sample, individual diffraction maxima are found between the respective diffraction maxima of both simple oxalates, clearly indicating the formation of a solid solution.

Similarly, the diffraction line of ZnFe_ox sample corresponding to (202) plane of metal oxalate dihydrate lies between the respective diffraction maxima of the single simple oxalates Zn_ox and Fe_ox, evenly as in the case of the combination of Ni and Fe. Contrary to the NiFe_ox a small peak was observed at the foot of the (202) reflection, which might signal that the sample contains a small amount of Fe_ox as well. However, the Fe_ox in the sample was not observed with other techniques (e.g. Mössbauer spectroscopy). The observed shifts of the diffraction peaks in both NiFe_ox and ZnFe_ox thus indicate the incorporation of both metals into the single oxalate crystal structure within the majority of the sample.

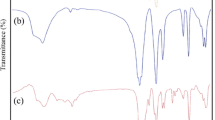

Secondly, the Fe-containing samples were dehydrated by heating at 200 °C in nitrogen stream and then studied by transmission Mössbauer spectroscopy. It has previously been observed that slight differences in quadrupole splitting occur in ferrous oxalate depending on metal substitution (Devillers et al. 1987; Lisníková et al. 2022). Figure 3 shows a detail of the Mössbauer spectra of anhydrous Fe_ox, NiFe_ox and ZnFe_ox samples. The hyperfine parameters of the measured oxalate samples are shown in Table 1. All three spectra were fitted with a doublet, which is typical for iron-containing oxalates. In Fig. 3, a slight decrease in the value of quadrupole splitting could be observed for ZnFe_ox bimetal sample with respect to iron oxalate sample i.e., from ΔEQ = 1.62 mm/s for Fe_ox to ΔEQ = 1.55 mm/s. This change in the quadrupole splitting points to the successful formation of a solid solution of the bimetal oxalate in ZnFe_ox sample. No difference in quadrupole splitting between the NiFe_ox and Fe_ox samples (within the experimental error) was detected. However, according to Devillers et al. (1987) the change in quadrupole splitting depends not only on the degree of substitution but also on the type of substituting metal i.e. ΔEQ follows Fe > Ni > Mg/Co > Mn > Zn. Mössbauer spectroscopy thus could not provide a conclusive result on the formation of the solid solution in the case of NiFe_ox.

Thirdly, the prepared bimetal samples were also studied using EDX microanalysis and the mapping of metal elements in both samples was carried out. The images in Fig. 4 show the presence of iron and nickel in the NiFe_ox sample (Fig. 4a–c) and the presence of iron and zinc in the ZnFe_ox sample (Fig. 4d–f). The distribution maps of NiFe_ox (Fig. 4a) and ZnFe_ox (Fig. 4d) suggested a homogeneous occurrence of both elements. Moreover, the iron distribution map corresponds to the distribution map of the secondary respective metal. If the prepared samples were not solid solutions of bimetal oxalates, the distribution maps of iron would not match the distribution maps of nickel and zinc (Lisníková et al. 2022). Metal ratios of the mapped regions were found to be nearly 2:1 as expected. However, a slight excess of either metal could not be excluded due to a relatively high error, which is caused by the high amount of C and O (i.e. the organic part of the oxalates) in the samples. Estimated atomic concentrations are given in Supplementary data, Table S1 and Table S2.

Besides EDX microanalysis, the morphology of the bimetal samples was studied. SEM images of NiFe_ox and ZnFe_ox samples are shown in Fig. 5. Figure 5a shows aggregates of particles with a deformed cubic morphology belonging to the NiFe_ox sample, with particle sizes ranging in units of micrometres. The ZnFe_ox sample (Fig. 5b) contains elongated spike-shaped particles oriented radially from centres of individual aggregates and with length ranged from units to tens of micrometres. Both NiFe_ox and ZnFe_ox combined the morphological features observed for individual Ni, Zn and Fe oxalates (see Fig. S6). It could be seen that large aggregates of smaller microcrystals in NiFe_ox were similar to those observed for Ni oxalate (Fig. S6a), while ZnFe_ox particles retained the original larger size of the Zn oxalate microcrystals (Fig. S6b). Cuboid shape of Fe oxalate particles (Fig. S6c) was then found in both NiFe_ox and ZnFe_ox. Although, the morphology of the oxalate particles can be controlled, in general, through the modification of synthesis parameters (e.g. addition of surfactant (Zhou et al. 2008)), in this case the variability in the morphology was the result of different chemical composition as all other synthesis parameters were kept the same for all samples.

The thermal decomposition to spinel ferrites

An ultimate confirmation of the bimetal nature of oxalate sample is also provided by in situ XRD, although this method is destructive towards the sample. The existence of a solid solution of bimetal oxalate manifests itself as a single-step formation of the spinel phase.

The thermally induced decomposition of NiFe_ox and ZnFe_ox bimetal samples was investigated by in situ XRD. Figures 6 and 7 show in situ XRD maps and selected diffraction patterns of NiFe_ox, resp. ZnFe_ox samples. Rietveld analysis of selected XRD diffraction patterns was performed to determine the phase composition of the samples at corresponding temperatures.

The first transformation step for the bimetal samples was the transition to the dehydrated form of oxalate, which occurred at temperature of ≈ 170 °C for the NiFe_ox sample and already at temperature of ≈ 150 °C in the case of the ZnFe_ox sample. The XRD patterns of the dehydrated phases are shown in Figs. 6b and 7b.

Further heating of the bimetal samples resulted in a conversion to an amorphous phase. Looking at the in situ XRD map of NiFe_ox (Fig. 6), it is possible to observe this transition around the temperature ≈ 250 °C, while the ZnFe_ox sample was in the dehydrated phase for a longer temperature range and the transition to the amorphous phase occurred at the temperature of ≈ 280 °C. For comparison, in the case of ferrous oxalate, this transformation occurs at much lower temperature, i.e. around ≈ 180 °C (Koga and Sato 2011). In both cases, this off-set single step transformation further verified the bimetal nature of the prepared NiFe_ox and ZnFe_ox samples.

In the case of the NiFe_ox sample, the crystalline material started to form again when the temperature reached ≈ 450 °C. By evaluating the relevant XRD pattern, it was found that all observed diffractions belong to nickel spinel ferrite. Subsequent heating of the sample up to 750 °C brought the narrowing of the diffraction peaks, especially visible at the (311) reflection, indicating the increasing crystallinity and crystallite size. Additionally no shift in the peak position, which would indicate the change in the lattice dimensions, was observed. Rietveld refinement also revealed the presence of a small amount of hematite (approximately 2% in the diffraction pattern obtained at 750 °C). This small amount of hematite might have been the result of a local inhomogeneous distribution of metals in favour of Fe. We presume that hematite was present from the onset of the crystallization, however due to its small amount its diffraction lines became visible only after certain level of crystallinity was reached.

The formation of a new crystalline material from the amorphous phase of the ZnFe_ox sample can be observed in the in situ XRD map (Fig. 7) already around 400 °C. MAUD analysis of the XRD pattern revealed the presence of a pure spinel phase of zinc ferrite. Evaluation of the diffraction pattern measured at 750 °C determined a small amount of zincite (approximately 5%) in the resulting sample. Zincite formation might have been preferred locally due to the slight excess of zinc. Similarly to hematite, zincite diffraction lines became apparent only after certain point in the map due to its small amount. Additionally the growth of the crystallites (the decreasing of peak width) appeared to be faster than in the case of nickel ferrite, which might explain the relatively lower crystallization temperature onset of zinc ferrite (400 °C) compared to nickel ferrite (450 °C). Generally, the crystallization of amorphous phase, depend not only on thermodynamic properties but spatial distribution as well. (Baumgartner et al. 2020). Moreover, Chhabra et al. showed the correlation between the size of ferrous oxalate particles and the crystallinity of ferric oxide particles calcined at the same temperature (Chhabra et al. 1995). We presume that in this case the difference between the ferrite crystallization temperatures could also be inherently connected with different particle morphology of both samples.

Nickel and zinc spinel ferrites

Finally, ex situ calcination of NiFe_ox and ZnFe_ox samples was performed in a laboratory furnace at different temperatures. This series of samples shows how individual properties of nickel and zinc spinel ferrites evolve. Using adsorption analyser, XRD and Mössbauer spectroscopy, changes in BET surface areas of the prepared samples with respect to the increasing sizes of their MCL and also the variation of ion sublattice occupancy were investigated.

Figures 8 and 9 display the Mössbauer spectra of NiFe_ox and ZnFe_ox samples calcinated at 330 °C, 400 °C, 450 °C, 600 °C and 750 °C. Mössbauer measurements were performed at room temperature for all the samples. The hyperfine parameters of the measured samples are shown in Table 2.

The spectrum of the NiFe_ox_330 sample in Fig. 8a consists of one doublet, whose hyperfine parameters δ = 0.32 mm/s and ΔEQ = 0.60 mm/s are typical for iron atoms in Fe3+ charge state. The doublet in nickel ferrite spectra is usually associated with paramagnetic or superparamagnetic behaviour. (Malik et al. 2010) The absence of the sextet component indicated the missing magnetic ordering in the sample, which was probably the result of the poor crystallinity. This was evidenced by small MCL sizes in Rietveld refinement results of the corresponding XRD pattern, see below.

In Fig. 8b, one doublet is observed at the centre of spectrum along with significant depression in the base line, which indicates the beginning of the magnetic ordering that was formed within the NiFe_ox_400 sample.

Figure 8c already shows a certain degree of magnetic ordering formed in the sample NiFe_ox_450. However, the ordering was not sufficient to distinguish between the tetrahedral (T) and octahedral positions (O). Therefore, the distribution of hyperfine magnetic fields was applied for this sextet component in the Mössbauer spectrum. Additionally, a small amount of doublet component was still observed in the spectrum.

The spectra in Fig. 8d, e reveal an evident magnetic ordering in the samples NiFe_ox_600 and NiFe_ox_750. Each of the spectra was fitted with two sextet components representing T and O sites of the nickel ferrite structure. As the calcination temperature increased, a development in the areas of the two sub-spectra could be observed, which indicates the possibility of controlling the distribution of iron atoms between the tetrahedral and octahedral positions of the spinel structure to certain degree by simply altering the calcination temperature.

In the case of the calcinated ZnFe_ox samples, it is not possible to observe a transition to a magnetically ordered structure with the rising calcination temperature. Contrary to nickel ferrite, the bulk form of the zinc ferrite displays the paramagnetic ordering of the spins of Fe atoms (Singh et al. 2013).

Figure 9 shows the spectra of samples ZnFe_ox_330 (Fig. 9a) and ZnFe_ox_750 (Fig. 9b), the spectra of other samples of the ZnFe series i.e., ZnFe_ox_400, ZnFe_ox_450 and ZnFe_ox_600 can be found in Supplementary data, Figs. S7–S9. All the spectra of the calcinated ZnFe_ox samples consist of one doublet. Isomer shift of this component remained nearly constant for all the calcinated samples around the value 0.35 mm/s implying Fe3+ charge state of iron atoms. On the other hand, quadrupole splitting exhibited a perspicuous decrease from ΔEQ = 0.54 mm/s (sample ZnFe_ox_330) to ΔEQ = 0.39 mm/s (sample ZnFe_ox_750) similarly as described by Singh et al. (2008). The Mössbauer spectra together with the relevant XRD patterns indicate the formation of well crystalline particles of zinc ferrite from the amorphous phase with increasing calcination temperature.

Figure 10 shows the evolution of MCL of NiFe_ox and ZnFe_ox samples calcinated at different temperatures (330 °C, 400 °C, 450 °C, 600 °C and 750 °C). The MCL values were obtained by Rietveld refinement of the respective XRD patterns of the calcined samples (see Supplementary data, Table S3. and Figs. S10–S19 for the fitted XRD patterns). The obtained data indicate a faster increase in MCL for the zinc ferrite samples, from 8 (sample ZnFe_ox_330) to 90 nm (sample ZnFe_ox_750). On the other hand, the increase in MCL for nickel ferrite samples shows a milder course with values from 5 (sample NiFe_ox_330) to 46 nm (sample NiFe_ox_750).

The results obtained from N2 adsorption measurements correlate well with the results of MCL measurements. Adsorption isotherms of calcinated samples can be found in the Supplementary data, Figs. S20–S29. Figure 11 displays the evolution of the BET surface area of the calcinated NiFe_ox and ZnFe_ox samples. In both cases, it can be observed a decrease in the size of the BET surface area of the samples related to the increasing size of their MCL as well as to the increasing calcination temperature. The calcinated NiFe_ox samples show an obvious decrease in the BET surface area from 186 m2/g (sample NiFe_ox_330) to 19 m2/g (sample NiFe_ox_750). The calcinated zinc-ferrite samples possessed a larger MCL compared to nickel-ferrite samples, which is related to the lower values of the BET surface areas decreasing from 153 m2/g (sample ZnFe_ox_330) to 11 m2/g (sample ZnFe_ox_750).

Conclusions

An oxalate route was used for a preparation of two series of Ni and Zn ferrites. Based on our experience with CoFe oxalate system (Lisníková et al. 2022), the precursors were first analyzed to verify the formation of solid solution of oxalates. Both XRD and EDX mapping results indicated the incorporation of metals into single structure for both bimetal oxalate system. However, Mössbauer spectroscopy was not able to give conclusive results in the case of the NiFe_ox sample. Nonetheless, other methods confirmed the bimetal nature.

In situ XRD revealed a) the single-step decomposition of the oxalate precursors at temperatures shifted relative to the decomposition temperature of ferrous oxalate, which also indicated the formation of solid solution for both NiFe_ox and ZnFe_ox; and b) the temperature of major structural transformations. It also confirmed that using bimetal oxalates leads to a formation of pure ferrites (≥ 95%). Results obtained by preparing and characterizing ferrites at these selected temperatures indicate the possibility to control the various properties of the prepared ferrites e.g., ion sublattice occupancy, MCL sizes and BET areas, simply by selecting different calcination temperature, thus to tune the ferrite parameters for an application of choice. Moreover, the results show that these properties evolve with temperature differently for both investigated systems.

References

Amiri M, Salavati-Niasari M, Akbari A (2019) Magnetic nanocarriers: evolution of spinel ferrites for medical applications. Adv Coll Interface Sci 265:29–44. https://doi.org/10.1016/j.cis.2019.01.003

Arimi A, Megatif L, Granone LI, Dillert R, Bahnemann DW (2018) Visible-light photocatalytic activity of zinc ferrites. J Photochem Photobiol, A 366:118–126. https://doi.org/10.1016/j.jphotochem.2018.03.014

Basavanagoudra H, Tanakanti R, Patil MK, Inamdar SR, Goudar KM (2021) Synthesis, characterization, and properties of spinel zinc ferrite nanoparticles by chemical coprecipitation technique. Macromol Symp 400(1):3–7. https://doi.org/10.1002/masy.202100138

Baumgartner J, Ramamoorthy RK, Freitas AP, Neouze MA, Bennet M, Faivre D, Carriere D (2020) Self-confined nucleation of iron oxide nanoparticles in a nanostructured amorphous precursor. Nano Lett 20(7):5001–5007. https://doi.org/10.1021/acs.nanolett.0c01125

Birgani AN, Niyaifar M, Hasanpour A (2015) Study of cation distribution of spinel zinc nano-ferrite by X-ray. J Magn Magn Mater 374:179–181. https://doi.org/10.1016/j.jmmm.2014.07.066

Chaudhari ND, Nadargi DY, Kabbur SM, Kambale RC, Das A, Suryavanshi SS (2022) Investigation of structural, morphological and elastic properties of Ni–Zn ferrite grown with an oxalate precursor. J Electron Mater 51(6):2732–2740. https://doi.org/10.1007/s11664-022-09582-y

Chhabra V, Lal M, Maitra AN, Ayyub P (1995) Preparation of ultrafine high density gamma ferric oxide using aerosol OT microemulsions and its characterization. Colloid Polym Sci 273(10):939–946. https://doi.org/10.1007/BF00660371

Devillers M, Ladrière J, Apers D (1987) Mössbauer study of 57Fe-doped simple and mixed dihydrated oxalates of bivalent metals (M = Mg, Mn, Fe Co, Ni, Zn). Inorg Chim Acta 126(1):71–77. https://doi.org/10.1016/S0020-1693(00)81242-6

Diodati S, Nodari L, Natile MM, Caneschi A, De Julián Fernández C, Hoffmann C, Kaskel S et al (2014) Coprecipitation of oxalates: an easy and reproducible wet-chemistry synthesis route for transition-metal ferrites. Eur J Inorg Chem 5:875–887. https://doi.org/10.1002/ejic.201301250

Ergin İ, İçin K, Güngüneş H, Özçelik B (2023) Detailed studies on structural, morphological, optical, magnetic and mossbauer properties of Cu-substituted cobalt ferrite nanoparticles. Phys Scr. https://doi.org/10.1088/1402-4896/acb691

Gnanamani MK, Jacobs G, Hamdeh HH, Shafer WD, Liu F, Hopps SD, Thomas GA, Davis BH (2016) Hydrogenation of carbon dioxide over Co–Fe bimetallic catalysts. ACS Catal 6(2):913–927. https://doi.org/10.1021/acscatal.5b01346

Hou G, Li Y, An W, Gao S, Zhang W, Cui W (2017) Fabrication and photocatalytic activity of magnetic core@shell ZnFe2O4@Ag3PO4 heterojunction. Mater Sci Semicond Process 63(March):261–268. https://doi.org/10.1016/j.mssp.2017.02.033

İçin K, Öztürk S, Çakil DD, Sünbül SE (2021) Mechanochemical synthesis of SrFe12O19 from recycled mill scale: effect of synthesis time on phase formation and magnetic properties. J Alloys Compd 873:23. https://doi.org/10.1016/j.jallcom.2021.159787

Iqbal B, Laybourn A, Ul-Hamid A, Zaheer M (2021) Size-controlled synthesis of spinel nickel ferrite nanorods by thermal decomposition of a bimetallic Fe/Ni–MOF. Ceram Int 47(9):12433–12441. https://doi.org/10.1016/j.ceramint.2021.01.100

Isha S, Najim M, Smitha P, Singh D, Varma GD (2014) Microwave absorption properties of nanostructured nickel ferrite. In: 2014 International conference on electronics and communication system, pp 220–24. https://doi.org/10.1109/ECS.2014.6892701

Ishaq K, Saka AA, Kamardeen AO, Ahmed A, Alhassan haq MI, Abdullahi H (2017) Characterization and antibacterial activity of nickel ferrite doped α-alumina nanoparticle. Eng Sci Technol Int J 20(2):563–69. https://doi.org/10.1016/j.jestch.2016.12.008

Jia Z, Misra RDK (2011) Magnetic sensors for data storage: perspective and future outlook. Mater Technol 26(4):191–199. https://doi.org/10.1179/175355511X13109965351077

Kaur A, Bhargava GK (2020) Review paper on nickel–zinc nano ferrite. Mater Today Proc. 37(Part 2):3082–86. https://doi.org/10.1016/j.matpr.2020.09.016

Kim KJ, Kim MH, Kim CS (2014) Structural phase transition, electronic structure, and magnetic properties of sol–gel-prepared inverse-spinel nickel-ferrites thin films. J Magn 19(2):111–115. https://doi.org/10.4283/JMAG.2014.19.2.111

Klencsár Z, Kuzmann E, Vértes A (1996) User-friendly software for Mössbauer spectrum analysis. J Radioanal Nucl Chem 210(1):105–118. https://doi.org/10.1007/BF02055410

Koga N, Sato Y (2011) Formation and transformation kinetics of amorphous iron(III) oxide during the thermally induced transformation of ferrous oxalate dihydrate in air. J Phys Chem A 115(2):141–151. https://doi.org/10.1021/jp110407n

Kumari C, Dubey HK, Naaz F, Lahiri P (2020) Structural and optical properties of nanosized Co substituted Ni ferrites by coprecipitation method. Phase Transit 93(2):207–216. https://doi.org/10.1080/01411594.2019.1709120

Lasheras X, Insausti M, Gil De Muro I, Garaio E, Plazaola F, Moros M, Matteis L, De MD, La Fuente J, Lezama L (2016) Chemical synthesis and magnetic properties of monodisperse nickel ferrite nanoparticles for biomedical applications. J Phys Chem C 120(6):3492–3500. https://doi.org/10.1021/acs.jpcc.5b10216

Liandi AR, Cahyana AH, Kusumah AJF, Lupitasari A, Alfariza DN, Nuraini R, Sari RW, Kusumasari FC (2023) Recent trends of spinel ferrites (MFe2O4: Mn Co, Ni, Cu, Zn) applications as an environmentally friendly catalyst in multicomponent reactions: a review. Case Stud Chem Environ Eng 7(December 2022):100303. https://doi.org/10.1016/j.cscee.2023.100303

Lisníková S, Kopp J, Vrba V, Novák P (2022) Single-phase precursors for the preparation of spinel ferrites via oxalate route: the study of cobalt ferrite synthesis. Chem A Eur J. https://doi.org/10.1002/chem.202104331

Lutterotti L (2010) Total pattern fitting for the combined size–strain–stress–texture determination in thin film diffraction. Nucl Inst Methods Phys Res B 268(3–4):334–340. https://doi.org/10.1016/j.nimb.2009.09.053

MAUD: materials analysis using diffraction (2021). http://maud.radiographema.eu/.

Malik R, Annapoorni S, Lamba S, Raghavendra Reddy V, Gupta A, Sharma P, Inoue A (2010) Mössbauer and magnetic studies in nickel ferrite nanoparticles: effect of size distribution. J Magn Magn Mater 322(23):3742–3747. https://doi.org/10.1016/j.jmmm.2010.07.019

Manikandan V, Sikarwar S, Yadav BC, Mane RS (2018) Fabrication of tin substituted nickel ferrite (Sn–NiFe2O4) thin film and its application as opto-electronic humidity sensor. Sens Actuators A 272:267–273. https://doi.org/10.1016/j.sna.2018.01.059

Manikandan V, Petrila I, Kavita S, Mane RS, Denardin JC, Lundgaard S, Juodkazis S, Vigneselvan S, Chandrasekaran J (2020) Effect of Vd-doping on dielectric, magnetic and gas sensing properties of nickel ferrite nanoparticles. J Mater Sci Mater Electron 31(19):16728–16736. https://doi.org/10.1007/s10854-020-04228-3

Misra RDK, Gubbala S, Kale A, Egelhoff WF (2004) A comparison of the magnetic characteristics of nanocrystalline nickel, zinc, and manganese ferrites synthesized by reverse micelle technique. Mater Sci Eng B Solid-State Mater Adv Technol 111(2–3):164–174. https://doi.org/10.1016/j.mseb.2004.04.014

Mostafa M, Khalaf A, El-Maghraby EM, Dagher RA, Hemeda OM (2023) The impact of la substitution on the structural, molecular, morphological, and thermal properties of Mn0.6Zn0.4Fe2O4. J Supercond Novel Magn 36(4):1277–1290. https://doi.org/10.1007/s10948-023-06564-x

Narang SB, Pubby K (2021) Nickel spinel ferrites: a review. J Magn Magn Mater 519:1–58. https://doi.org/10.1016/j.jmmm.2020.167163

Narasimharao K, Mostafa MMM, Al-Amshany ZM, Bajafar W (2023) Mechanochemical synthesized CaO/ZnCo2O4 nanocomposites for biodiesel production. Catalysts 13(2):23. https://doi.org/10.3390/catal13020398

Nikam CU, Birajdar AP, Kadam SS, Choudhari SS, Shinde VS, Shelke SB, Kadam RH, Kale GH (2023) Effect of cation distribution on structural and mechanical properties of Y3+substituted Co–Zn spinel ferrites nanoparticles. J Phys Conf Ser 2426(1):23. https://doi.org/10.1088/1742-6596/2426/1/012030

Novák P, Procházka V, Stejskal A (2022) Universal drive unit for detector velocity modulation in mössbauer spectroscopy. Nucl Instrum Methods Phys Res Sect A Accel Spectrom Detect Assoc Equip 1031(2021):166573. https://doi.org/10.1016/j.nima.2022.166573

Patil K, Saleem M, Phadke S, Mishra A (2022) Structural, electrical and magnetic properties of (Cu/Co)Fe2O4 spinel ferrite materials. Appl Phys A Mater Sci Process 128(11):1–11. https://doi.org/10.1007/s00339-022-06149-w

Procházka V, Novák P, Vrba V, Stejskal A, Dudka M (2020) Autotuning procedure for energy modulation in Mössbauer spectroscopy. Nucl Instrum Methods Phys Res Sect B 483(November):55–62. https://doi.org/10.1016/j.nimb.2020.08.015

Pubby K, Vijay Babu K, Bindra Narang S (2020) Magnetic, elastic, dielectric, microwave absorption and optical characterization of cobalt-substituted nickel spinel ferrites. Mater Sci Eng B Solid-State Mater Adv Technol 255(March):114513. https://doi.org/10.1016/j.mseb.2020.114513

Rana G, Dhiman P, Kumar A, Vo DVN, Sharma G, Sharma S, Naushad M (2021) Recent advances on nickel nano-ferrite: a review on processing techniques, properties and diverse applications. Chem Eng Res Des 175:182–208. https://doi.org/10.1016/j.cherd.2021.08.040

Ruthradevi T, Akbar J, Suresh Kumar G, Thamizhavel A, Kumar GA, Vatsa RK, Dannangoda GC, Martirosyan KS, Girija EK (2017) Investigations on nickel ferrite embedded calcium phosphate nanoparticles for biomedical applications. J Alloy Compd 695:3211–3219. https://doi.org/10.1016/j.jallcom.2016.11.300

Sankaranarayanan R, Shailajha S, Dineshkumar C, Felchiya Jasmine A (2022) Investigation on structural and H2 gas sensing response of AlCdZnNiFe2O4 sensor material. Ceram Int 48(1):720–731. https://doi.org/10.1016/j.ceramint.2021.09.152

Shang Y, Luo F, Duan Z (2023) Influence of MnZn ferrite homogeneous fibers on the microstructure, magnetic, and mechanical properties of MnZn ferrite materials. Materials. https://doi.org/10.3390/ma16010209

Shanmugam AK, Rathanasamy R, Kaliyannan GV, Nagarajan N, Palanisamy M (2021) Spinel zinc ferrite nanostructured thin-films for enhanced light-harvesting in polycrystalline solar cells. Mater Sci Pol 39(1):24–32. https://doi.org/10.2478/msp-2021-0002

Singh JP, Srivastava RC, Agrawal HM, Kushwaha RPS (2008) 57Fe Mössbauer spectroscopic study of nanostructured zinc ferrite. Hyperfine Interact 183(1–3):221–228. https://doi.org/10.1007/s10751-008-9756-z

Singh LH, Govindaraj R, Amarendra G, Sundar CS (2013) Partial inversion in nano zinc ferrite as studied using Mossbauer spectroscopy. AIP Conf Proc 1512:322–323. https://doi.org/10.1063/1.4791041

Šutka A, Gross KA (2016) Spinel ferrite oxide semiconductor gas sensors. Sens Actuators B Chem 222:95–105. https://doi.org/10.1016/j.snb.2015.08.027

Šutka A, Millers M, Vanags M, Joost U, Maiorov M, Kisand V, Pärna R, Juhnevica I (2015) Comparison of photocatalytic activity for different Co-precipitated spinel ferrites. Res Chem Intermed 41(12):9439–9449. https://doi.org/10.1007/s11164-015-1969-6

Vigneswari T, Raji P (2017) Structural and magnetic properties of calcium doped nickel ferrite nanoparticles by Co-precipitation method. J Mol Struct 1127:515–521. https://doi.org/10.1016/j.molstruc.2016.07.116

Wei QM, Li JB, Chen YJ, Han YS (2001) X-ray study of cation distribution in NiMn1−XFe2−XO4 ferrites. Mater Charact 47(3–4):247–252. https://doi.org/10.1016/S1044-5803(01)00177-2

Wu K, Li J, Zhang C (2019) Zinc ferrite based gas sensors: a review. Ceram Int 45(9):11143–11157. https://doi.org/10.1016/j.ceramint.2019.03.086

You J, Chen X, Zheng B, Geng X, Zhang C (2017) Suspension plasma-sprayed ZnFe2O4 nanostructured coatings for Ppm-level acetone detection. J Therm Spray Technol 26(4):728–734. https://doi.org/10.1007/s11666-017-0536-7

Zayani W, Azizi S, El-Nasser KS, Othman Ali I, Molière M, Fenineche N, Mathlouthi H, Lamloumi J (2021) Electrochemical behavior of a spinel zinc ferrite alloy obtained by a simple sol–gel route for Ni–MH battery applications. Int J Energy Res 45(4):5235–5247. https://doi.org/10.1002/er.6140

Zhang H, Wang J, Zeng Y, Wang G, Han S, Yang Z, Li B, Wang X, Gao J, Zheng L, Liu X, Huo Z, Yu R (2020) Leucine-coated cobalt ferrite nanoparticles: synthesis, characterization and potential biomedical applications for drug delivery. Phys Lett Sect A General At Solid State Phys 384(24):126600. https://doi.org/10.1016/j.physleta.2020.126600

Zhong XB, Yang ZZ, Wang HY, Lu L, Jin B, Zha M, Jiang QC (2016) A novel approach to facilely synthesize mesoporous ZnFe2O4 nanorods for lithium ion batteries. J Power Sources 306:718–723. https://doi.org/10.1016/j.jpowsour.2015.12.102

Zhou W, Tang K, Zeng S, Qi Y (2008) Room temperature synthesis of rod-like FeC2O4· 2H2O and its transition to maghemite, magnetite and hematite nanorods through controlled thermal decomposition. Nanotechnology 19(6):065602. https://doi.org/10.1088/0957-4484/19/6/065602

Acknowledgements

Authors thank to internal IGA grant of Palacký University (IGA_PrF_2023_003). Authors would like to thank Vlastimil Vrba for his help with XRD analysis.

Funding

Open access publishing supported by the National Technical Library in Prague.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

On behalf of all authors, the corresponding author states that there is no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This work was presented at the European Symposium on Analytical Spectrometry ESAS 2022 & 17th Czech-Slovak Spectroscopic Conference held in Brno, Czech Republic on September 4-9, 2022.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Lisníková, S., Novák, P. & Kopp, J. Nickel–iron and zinc–iron bimetal oxalates: preparation, characterization and thermal decomposition to spinel ferrites. Chem. Pap. 78, 1–12 (2024). https://doi.org/10.1007/s11696-023-03047-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11696-023-03047-0