Abstract

Intrinsically conducting polymers and their copolymers and composites with redox-active organic molecules prepared by chemical as well as electrochemical polymerization may yield active masses without additional binder and conducting agents for secondary battery electrodes possibly utilizing the advantageous properties of both constituents are discussed. Beyond these possibilities these polymers have found many applications and functions for various further purposes in secondary batteries, as binders, as protective coatings limiting active material corrosion, unwanted dissolution of active mass ingredients or migration of electrode reaction participants. Selected highlights from this rapidly developing and very diverse field are presented. Possible developments and future directions are outlined.

Similar content being viewed by others

Avoid common mistakes on your manuscript.

Introduction

Electronic and electric devices and with growing importance the use of renewable energies need systems for energy storage and conversion. Electrochemical systems are in a prominent position. Most likely they (and specifically lithium ion batteries (Pirnat et al. 2012)) will not provide economically viable large-scale and long-term storage different from frequent advertisements with rather unrealistic claims (e.g., Armand and Tarascon 2008). But they will certainly have an important role in short-term storage, power quality management and storage at off-grid locations. Their use in mobile and portable applications will definitely grow further. In particular, because of cost considerations and availability of raw materials there are absolutely good reasons to look for organic replacements for the currently used metal-based and inorganic electrode materials. Less environmental problems, in particular, when devices are not properly discarded or recycled and basically unlimited supplies are just a few further arguments.

Very soon after the discovery of their redox behavior (see, e.g., Otero and Cantero 1999; Kita et al. 1986; Matsunaga et al. 1990; Nishio and Furukawa 2011; Mammone 1987) intrinsically conducting polymers ICPs have been proposed as active materials for secondary batteries. Early reviews on their use as active mass or as an additional ingredient improving stability and other performance data are available (Novak et al. 1997; Holze and Wu 2014). Radical polymers (aliphatic and non-aromatic radical-bearing polymers) have been suggested for many applications in energy conversion and storage (Oyaizu and Nishide 2009; Suga et al. 2011), charge transport by self-exchange processes is sufficient even in the absence of charge transport along conjugated segments of a polymer chain to support electrode reactions. Some considerations on tuning the redox potential of molecular storage materials possible of general applicability have been reported by Jouhara et al. (2018). The particular challenge of finding materials with suitably positive potential for use as a positive electrode is highlighted. For an early example of the latter material see (Nakahara et al. 2002), the influence of electrode thickness has been examined (Kim et al. 2007) with a thinner electrode yielding higher mass utilization (about 100% at 17 μm thickness). This presumably rather general finding has been reconfirmed in a more recent report on mass utilization of supercapacitor electrodes (Ge et al. 2021).

The recent rise of interest in organic materials (monomers, oligomers, polymers, copolymers, composites and hybrids) as active masses in electrodes of secondary batteries (Armand and Tarascon 2008; Armand et al. 2009; Chen et al. (2008), Chen et al. 2009; Chen 2019; Walker et al. 2010) has moved beyond the developments briefly outlined above. In particular, studies of molecules or repeat units in larger entities showing a defined redox activity which can be employed for charge storage and when combined into a cell for energy storage have focused on molecules related to quinone and on ferrocene-related species (Fig. 1).

The interest in the latter is also due to the possibility to use natural sources containing significant amounts of quinone-like units like lignin (Admassie et al. 2016); the use of biobased electrode materials has also been addressed elsewhere (Liedel et al. 2018).

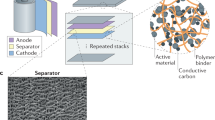

The redox and thus charge storage capabilities of organic molecules can be employed in different ways. The material of interest can simply be mixed with a binder and, if needed, a conductive material like acetylene black. The molecules can also be made part of a polymer or a copolymer involving in the latter case, for example an intrinsically conducting polymer and said redox-active entity. Two fundamentally different approaches with implications for the molecular structure, the starting materials and the preparation process are conceivable: The redox-active moieties are attached to the molecular backbone of the conducting polymer (Fig. 2) or can be made part of the copolymer chain (Fig. 3).

Both products are true copolymers. For details of nomenclature and experimental approaches toward a distinction as well as differentiation from polymer blends or alloys or simple mixtures of homopolymers see (Holze 2011). With respect to optimized electronic conductance of the ICP component, a structure as suggested in Fig. 2 seems to be advantageous because the conjugation along the chain necessary for charge movement (i.e., conduction) along the molecular chain is not disturbed, possibly interrupted, by different molecules like quinone units in a polyaniline chain.

Charge storage in battery and in supercapacitor electrode materials can proceed in two initially different ways: By charge separation typical of a capacitor and by electrochemical redox transformation mostly associated with chemical changes, too.

In the former case electrons are moved into/out of the electronically conducting material (commonly called the electrode), to maintain electroneutrality ions compensating for this charge movement are accumulated or dispersed in the adjacent ionically conducting phase. The interaction between the ions and the electrode may be strong enough to suggest chemisorption, weaker interaction may be called physisorption. In both cases electrosorption is operative. Sorptive behavior may affect the capacitive performance of the electrochemical interface. Because other factors like ion size, diffusivity, pore size, etc., also affect the performance adsorption is frequently invoked, but hardly examined more closely in the reported literature.

Redox transformations observed with battery electrode materials show widely varying forms. They all share the reversibility of the reaction. A very simple case is the negative lead electrode in the lead acid battery:

An organometallic analogue of this reaction is the ferrocene/ferrocinium electrode according to.

with the Fe(II)/(III) acting as electron source/sink. For charge compensation counterions will move in/out of the respective polymer. Such reaction is not feasible with all metal-free organic electrode materials suggested both for use in the negative and the positive electrode. Instead for metal-ion batteries at the negative electrode a material acting as metal host releasing the metal as cation upon discharge will be required; at the positive electrode the corresponding processes will happen (see Fig. 4).

Redox transformation of a poly(1,4-anthraquinone) during charge/discharge as electrode material in a lithium-ion battery (Song et al. 2015)

Charge transfer and storage are associated with changes in bonding from, e.g., double to single bonds, bond rearrangements and redistribution of electrons participating in such bond systems. This is very much different from storage processes in materials like graphene or metal oxides like LiCoO2. Certainly in these cases stoichiometries can be established enabling theoretical charge density calculations. But a fundamental difference—the dominance of covalent bonds in organic materials vs. electrostatic bonding in metal oxides—remains. Graphite at first glance also seems to belong to the class of organic materials because of the covalent bonds between the carbon atoms, but the host’s interaction with the lithium or any other metal is more of the non-directional electrostatic or metallic type. Structural aspects like layered architecture in graphite or many other electrode materials (TiS2, etc.) or availability of tunnels and other voids are presumably more relevant in more crystalline inorganic materials than in polymeric materials.

Beyond the use of ICPs as active masses their inclusion as binder in electrodes for lithium-ion batteries has been suggested. In the following overview these various uses are addressed and illustrated with examples. Since our earlier review (Holze and Wu 2014) the number of reports on the use of ICPs, their copolymers and their combination with other ingredients beyond redox-active molecules as well as their use as auxiliary materials in various functions have yielded a substantial number of reports. Selective reviews on, e.g., use of PANI (Chen 2019; Gilhotra et al. 2019; Li and Gong , 2020; Luo et al. 2019), polycarbazole (Nayana and Kandasubramanian 2020), PEDOT (Chen and Li , 2020), polypyrrole (Bocchetta et al. 2020) and polyindole (Zhou and Xu 2017) are available. But even more impressive than plain numbers is the width of applications. This makes strict selection of reports included here difficult. Thus, we have decided to focus on representative examples instead of attempting (most likely in vain) to include every report applying most likely arbitrary rules. This will possibly be more helpful in demonstrating the versatility of ICPs and redox-active organic materials for electrodes in secondary batteries thus inspiring and encouraging further research.

Assignment of a report and a described material to any of the classes introduced below were sometimes difficult, possibly arbitrary. Whether an ICP serves as a coating of an active material (a metal oxide, for example) in its various shapes or as an embedding or host material can sometimes be concluded only from the experimental description, unfortunately the authors not always clearly defined function of the various constituents of their electrode materials.

Modeling of ICPs (e.g., PEDOT) in contact with an ionic liquid has been introduced providing a glimpse at charge distributions and interactions between charged PEDOT and the mobile species (Craig et al. 2020).

Because of possible confusion some terms repeatedly used in the following text are defined following, for some of them a brief definition has been mentioned in passing above.

Intrinsically conducting polymers are macromolecular, polymeric substances with extended conjugated π-electron systems showing electronic conductivity without added conducting filler materials. Typical examples are conjugated polymers like polyaniline and polyacetylene. Electronic (not ionic) conduction proceeds by electron movement along more or less extended conjugated parts of the polymer chains. Between chains electron hopping becomes operative.

The electrical conductivity of these polymers depends strongly on the degree of oxidation or, as usually stated the degree of doping, which implies the creation of positively (p-doping) or reduction creating negatively charged delocalized states (n-doping) which are compensated by corresponding insertion of counterions. The doping/dedoping processes in the conducting polymers are related to the mixed electronic and ionic transport in the bulk of the material. The electronic conductivity is due to the motion of delocalized electrons or holes along the polymer chains with conjugated bonds, which is accompanied by corresponding motion of charge-compensating ions. These doping processes alter the electrical and optical properties of the intrinsically conducting polymers, and thus, potential control is a prerequisite for obtaining desired properties of polymers.

Some of the numerous ICPs have established themselves as important compounds and components in much different applications, e.g., as antistatic coating, as material in electrolytic capacitors, in printed circuit manufacturing, in organic electronics.

Extrinsically conducting polymers (the term is less common, a frequently used definition does not appear to be established yet) are polymers which become conductive after addition of an electronically conducting agent, and most frequently these materials are just called conducting polymers.

Conducting polymers are macromolecular, polymeric substances showing electronic conductivity only when conducting materials like graphite, acetylene black or metal powders have been mixed into the polymers. Typical examples are conducting rubber or metal-filled polymers. These materials are widely used as flexible contact materials in electronics and in applications where electrostatic charging needs to be handled.

Redox-active polymers (also: redox polymers) are polymers with redox functionalities incorporated either in the polymer chain or as pendant group at the polymer chain (Inzelt 2008). As the main difference from ICPs is charge transport proceeds by exchange reactions between the localized redox groups. Redox polymers are applied in sensors, medicine and energy technology (Casado and Mecerreyes 2020).

Successful application of an ICP in whatever function critically depends on the stability of the ICP itself, but even more on the stability of the device. Thus, particular attention is paid to stability aspects in the following overview. When stated in the original reports we have included information about number of recorded charge/discharge cycles, capacity retention after a number of cycles and further details helpful in assessing stability of a material or a device. This property is frequently not considered adequately for a practical use: A battery stable for 50 cycles or less can hardly be called a promising option despite highly optimistic claims of an author. Unfortunately, reports are sometimes a bit diffuse regarding the distinction between stability of an electrode and of a complete cell. When cell data are definitely reported this is explicitly stated below.

The energy storage performance of an electrochemical device critically depends on the amounts of charge stored in both electrodes and the cell voltage observed between these electrodes. Energy storage with respect to a single electrode does not make sense, it is impossible. Why and how it is frequently reported nevertheless has been discussed elsewhere (Ge et al. 2020, 2021; Holze and Wu 2021). Storage capabilities in terms of theoretical and/or theoretical gravimetric or volumetric charge densities (sometimes slightly imprecisely called capacities (see Dubal et al. 2015, 2016a, b), in units of A·s·g−1) can be calculated. In case of a battery electrode (material) with a well-established electrode reaction equation calculation of a theoretical value of a gravimetric charge density assuming complete conversion of the reactants and exact knowledge of the electrode reaction (Beck and Euler 1984) is no problem. Reporting of volumetric data will be more difficult because reliable and exact knowledge or even more determination of the volume of a more or less porous electrode is a non-trivial task. Practical values are more complicated because they depend on experimental parameters. The electrode potential limits where charge/discharge have been started and stopped are obviously of major importance, because of the influence of charge/discharge current on electrode potential (overpotentials (Vetter 1967)), values, will be smaller when reported at higher currents. Accordingly, comparisons between different reports and materials may be rather imprecise. Matters are even more complicated with supercapacitor electrode materials. For double-layer storage materials there are no electrode reaction equations, accordingly this point of reference is missing. Because the amount of charge stored with these materials depends on the change of electrode potential a value of charge specified with respect to this change and the mass (in units of A s V−1 g−1 or F g−1) can be provided based on experimental data. Theoretical storage capabilities (sometimes also called capacitances, see (Dubal et al. 2015, 2016a, b)) are difficult to establish (Ge et al. 2021). For supercapacitor electrode materials utilizing redox reactions this problems becomes even more intricate. The availability of a redox reaction equation (even when incorrectly displayed as frequently observed) suggests a calculation as simple as done for a battery electrode material sometimes conveniently neglecting the rather different electrochemical response of the material (pseudocapacitive). This matter appears to be beyond the scope of the present report, but the noticeable merger of supercapacitor and battery electrode materials with some materials discussed below showing up also in supercapacitor electrodes (Holze 2020) suggests a short mentioning. In any case in the present report storage data are not provided. Although the dominant aim of many reported studies seems to be a value as high as possible incomplete reporting of experimental parameters and frequently lack of comparability as discussed elsewhere (Ge et al. 2020) leave such numbers with rather limited practical value.

Active masses

Following ICPs, further polymers, copolymers and further combinations are briefly presented starting with materials employing in addition to an ICP a redox-active moiety.

Quinones in secondary batteries

2-Aminoanthraquinone as redox-active storage material was kept in place by a combination of polyacrylic acid and PANI (Tong et al. 2020). The latter provided electronic conductivity, the former condensed with the amino-compound keeping the otherwise soluble molecule in place. Two thousand cycles could be achieved.

The lithium salt of poly(2,5-dihydroxy-p-benzoquinonyl sulfide) (60%wt) mixed with acetylene black (30%wt.) and PTFE (10 wt.) as binder was used as the positive electrode in a lithium-ion battery by Song et al. (2014). At an average polymerization degree of 7 solubility of the organic material in the electrolyte solution was irrelevant, further advantages of the electrode mixture resulted in a capacity retention of 90% after 1500 cycles at a Coulomb efficiency of around 100%. Poly(2,5-dihydroxy-1,4-benzoquinone-3,6-methylene) as a positive electrode material for lithium-ion batteries has been proposed (Le Gall et al. 2003), it kept 90% of its initial storage capability after 100 cycles.

A quinone-formaldehyde polymer was synthesized by Pirnat et al. and studied as an electrode mass for lithium-ion batteries (Pirnat et al. 2016). Poly(5-amino-1,4-dihydroxy anthraquinone) (see Fig. 5) has been proposed as positive electrode material for lithium-ion batteries by Zhao et al. (2013).

Reaction scheme of the polymerization of 5-amino-1,4-dihydroxy anthraquinone into poly(5-amino-1,4-dihydroxy anthraquinone) (Zhao et al. 2013)

The PANI-related molecular structure was invoked as supporting electronic conductivity of the material, nevertheless the electrode material contained 40%wt. acetylene black and 19%wt. binder (PTFE).

Rapid performance deterioration of polyquinone as a positive electrode material in a lithium-ion battery by electrochemical lithiation has been reported by Ignatova et al. (2017). In a theoretical study of poly(2,5-diaza-1,4-benzoquinone) Shestakov estimated promising storage capability (Shestakov et al. 2018). Polyanthraquinone has been prepared by a simple polycondensation reaction with poly(1,5-anthraquinone) being particularly stable as positive electrode in a lithium-ion battery (Song et al. 2015).

Poly(2,5-dihydroxyl-1,4-benzoquinonyl sulfide) (see Fig. 6) in a composite with CNTs has been used as positive electrode in a flexible pouch lithium-ion battery with a negative lithium electrode employing PANI-coated CNTs as lithium metal hosts (Zhang et al. 2019a).

After 90 cycles about 71% of the initial cell capacitance were retained.

Sterby et al. (2017) prepared a PEDOT from EDOT monomer units functionalized with p-benzoquinone using various linker groups. The material was tested in aqueous secondary batteries. Fast redox conversion of the quinone unit was found in an electrode potential region where the PEDOT was electronically conducting. This aspect is of particular importance when considering preparation of an active mass without added conducting carbon.

Inclusion of the catechol moiety increased the storage capability threefold. PEDOT with pyridine and quinone groups in the sidechains (see Fig. 7) with the pyridine moiety acting as proton trap keeping the protons released during oxidation of the hydroxyl group at the hydroquinone substituent thus making this electrode material versatile in nonaqueous electrolyte solutions (Ǻkerlund et al. 2019).

Substituted PEDOT with pyridine and quinone groups in the sidechains (Ǻkerlund et al. 2019)

A quinone-substituted PEDOT (Fig. 8) has been suggested as positive electrode material for lithium-ion batteries (Oka et al. 2019). The redox transition of the pendant quinone happens in the electrode potential range wherein PEDOT is in its highly conducting state, this supports utilization of its storage capability. High rate capability of the material with a water-in-salt electrolyte has been observed.

Substituted PEDOT with quinone groups in the sidechain (Oka et al. 2019)

A polymer with a polythiophene backbone and diethyl terephthalate pendant groups has been proposed as negative electrode material for lithium-ion batteries (Yang 2016). The high rate capability is attributed to the open (porous) morphology and the fast electron transport along the PTh backbone. Designation of the material as redox polymer instead of intrinsically conducting polymer (Inzelt 2008) is slightly confusing.

Electrode kinetics of poly(pyrrol-3-ylhydroquinone) suggested as electrode mass for secondary batteries have been examined (Karlsson et al. 2014). With very thin films kinetics were limited by the quinone redox process.

Cross-conjugated oligomeric quinones combined with CNTs have been suggested as cathode material for lithium-ion batteries with a two-step lithiation process as charge storage reaction depicted in Fig. 9 Jing et al. (2017).

Ninety-six percent of the initial storage capability were still present after 250 cycles, this suggests effective suppression of active mass dissolution being a common problem of organic electrode materials in lithium-ion batteries with organic solvents in the electrolyte solution.

The lithium salt of tetrahydroxybenzoquinone has been proposed as a positive electrode material for a lithium-ion battery (Chen et al. 2009). Tetrahydro-hexaquinone has been examined as an electrode material by Zou et al. (2014). A quinone derivative of calyx[4]arene combined with carbon black used as the positive electrode in a lithium-ion battery showed improved stability and kinetics when comparing materials obtained by chemical and electrochemical grafting of the active moieties ion a carbon support (Pirnat et al. 2012). Success of electrochemical grafting depended more on surface properties of the used carbon substrate. Dibenzo[b,i]thianthrene-5,7,12,14-tetraone has been suggested as a particularly stable positive electrode material providing large storage capability (Ma et al. 2016).

Sulfonated substituted anthraquinone has been examined as positive electrode material in a potassium-ion battery by Zhao et al. (2018). After 100 cycles no capacity loss was noticed.

An option for utilization of the redox capability of quinones has already been discussed previously: Their use in the counteranion incorporated in an ICP upon its (reversible) oxidation for charge balancing (Holze 2020). The redox storage capability of PEDOT has thus been enhanced by adding anthraquinone-2-sulfonate (Sheng et al. 2020). Both rate capability and stability of the electrode could be increased. After 10,000 cycles 173.5% of the initial capacity were found when 0.03 M of the anthraquinone-2-sulfonate had been added to the electrolyte. A gel electrolyte presumably helped in limiting self-discharge.

PEDOT with a bifunctional dopant composed of 4-vinylcatechol and styrenesulfonic acid moieties (Fig. 10) has been proposed as positive electrode (Chhin et al. 2019).

Low electronic conductivity and gradual dissolution of molecular quinones have been noticed as a major drawback for their use in batteries with nonaqueous electrolyte solutions resulting in incomplete material utilization and insufficient cycling stability (Takada et al. 2001). To overcome both limitations poly(3,4-dihydroxystyrene) PDHS (see Fig. 11) has been prepared and combined with PEDOT into a composite for use as a positive electrode material in a lithium-ion battery (Lukyanov et al. 2019).

PHS alone shows moderate performance. When combined with PEDOT the rate performance was improved considerably suggesting a catalytic effect of PEDOT, after 50 cycles about 65% of the initial capacitance were left.

The glass fiber separator in a lithium-ion sulfur battery was modified with potassium-modified graphene, PANI and poly-1,5-diaminoanthraquinone for enhanced suppression of polysulfide movement (Kiai and Kizil 2019). The noticed suppression was assigned to a “strong binding energy for the adsorption of polysulfides.”

Trapping of quinones inside a zeolite-templated carbon (ZTC) has been suggested as another option to suppress their dissolution and associated electrode capacitance loss (Nueangnoraj et al. 2016). When two different quinones, e.g., anthraquinone and tetrachlorohydroquinone, with different redox potentials were used, an organic proton battery could be assembled with 29% capacitance loss after 500 cycles.

Somewhat beyond the scope of this update is the use of 3,4,9,10-perylene–tetracarboxylicacid–dianhydride (PTCDA) as positive electrode material for a sodium-ion battery with a capacity retention of 66.1% after 200 cycles (Chen et al. 2015).

Ferrocenes in secondary batteries

Su et al. (2015) reported on a ferrocene-substituted aniline (6-(2-amino-phenol-9H-yl)-hexyl ferrocenecarboxylate) (Fig. 12) that has been synthesized and polymerized by chemical oxidation. For comparison a copolymer with aniline and PANI were prepared. The copolymer kept 76.3% of its initial capacitance after 30 cycles as a positive electrode.

Park et al. (2007) have prepared a copolymer of pyrrol and [(ferrocene) amidopropyl]pyrrole (Fig. 13) yielding a redox-active copolymer with a charge storage capability bigger than the one already provided by the plain PPy.

The observed storage capability was deemed to be unattractive, further research went toward LiFePO4 (LFP) embedded in PPy yielding more than double storage capability. PPy doped with poly(styrenesulfonate-co-vinylferrocene) (see Fig. 14) was proposed as positive electrode in a neutral electrolyte solution zinc battery (Lee et al. 1995). Within 500 cycles no loss of Coulombic efficiency was found.

A homopolymer of 4-(1H-pyrrol-1-yl) phenyl ferrocenecarboxylate (see Fig. 15) has been compared with its copolymer with pyrrol and with PPy for use as positive electrode material in a lithium-ion battery (Su et al. 2013). When compared to plain PPy the copolymer showed a major increase of storage capacity attributed to the ferrocene moiety.

Ferrocene-containing coordination polymers have been suggested as electrode materials for lithium-ion batteries by Strekalova et al. (2019) and Khrizanforov et al. (2019). GO covalently modified with alkyne-terminated ferrocene by a click reaction subsequently mixed with Mn3O4 and PANI was made into an electrode using additional carbon black and PVDF as a binder on a carbon paper support (Payami et al. 2020) The author did not suggest use of the electrode as positive or negative one. Stability data are a further missing detail.

Miscellaneous copolymers in active masses

Poly(aniline-co-N-methylthionine) (see Fig. 16) has been proposed as active mass for a zinc-ion battery (Chen et al. 2016). The observed gain in storage capability was attributed to the redox-active N-methylthionine. 99.4% of the initial capacity were found after 150 cycles.

An ester-functionalized poly(aniline-co-fluorene) (see Fig. 17) was suggested as positive electrode for lithium-ion batteries (Li et al. 2017) showing a capacity retention of 95.2% after 50 cycles.

A copolymer of N-phenyl-p-phenylenediamine and pyrene (see Fig. 18) has been suggested for the positive electrode of a lithium-ion battery (Yao et al. 2019a).

An output voltage of 3.2 V and 75.2% capacity retention after 180 cycles were noticed.

The use of PANI as active mass has been hampered by the pH-dependency of the electrochemical activity of this ICP. A copolymer poly(aniline-co-o-aminophenol) provided only minor improvements when compared with plain PANI, stability, in particular, was not noteworthy (Mu 2004). The use of self-doping PANI (sulfonated aniline was used as a comonomer) as positive electrode in an aqueous zinc-PANI battery may solve this problem (Shi et al. 2018). A copolymer of aniline and metanilic acid (3-aminobenzo sulfonic acid) at a 1:1 molar ratio was employed. Similar results were observed with m-aminobenzoic acid as comonomer (Rahmanifar et al. 2002). A copolymer of aniline and azure C was examined as positive electrode material in a quasi-solid zinc battery (Li et al. 2019c). More than 1000 cycles were recorded. PEDOT:PSS was used as proton source for pH-management in PANI as positive electrode in a flexible zinc-ion battery keeping about 80% of its initial capacitance after 1500 cycles (Liu et al. 2019a). A flexible, all-in-one solid-state zinc-ion battery with a composite of PANI and reduced graphene oxide with a solid electrolyte has been described (Zhang et al. 2019b). 94.6% of the initial capacity were still present after 500 cycles. An assembly of PPy-coated nanowires of MnO2 and carbon nanotubes has been examined as positive electrode for a flexible aqueous zinc-ion battery (Zhang et al. 2020c). 87.4% of the initial storage capability were still present after 1000 cycles. A similar approach with nanorods of α-MnO2 coated with PPy by a “self-polymerization” (using MnO2 as the oxidant) process has been described (Guo et al. 2020). Significant improvement ascribed to suppressed leaching of Mn2+-ions and improved electrode kinetics were stated.

Carbon cloth with deposited PANI on it has been soaked in an aqueous solution of [Fe(CN)6]4− yielding a positive electrode material for a zinc-ion battery (Yao et al. 2020). Addition of the hexacyanoferrate improved capacity retention after 1000 cycles from 17 to 71%. Nevertheless reports with plain PANI as active mass for zinc-ion batteries have appeared with rather incomplete details and no data on stability, see, e.g., (Li et al. 2020a).

A copolymer of PANI and a sulfur-containing substituted aniline has been examined as positive electrode in search for a stable lithium–sulfur battery (Dai et al. 2019). After 500 cycles 70.5% capacity retention were recorded. A similar approach with a highly cross-linked, electronically conducting sulfur-rich copolymer with PANI has been reported (Key et al. 2020). After 450 cycles about 73% of the initial capacitance were still present.

Copolymers of thiophene and EDOT have been examined as positive electrode material with the 1:1 copolymer being the most stable material (Chang et al. 2005). Copolymers of thiophene and pyrrole at various comonomer ratios have been examined as positive electrode masses for lithium-ion batteries, for comparison PPy prepared at various humidity levels were included (Sanchez De Pinto et al. 1997). The electrodeposition potential had a significant effect on the storage capability of the copolymer, the material prepared at 3. 9 V versus Li/Li+ achieved the highest value.

A copolymer of aniline and o-nitroaniline used as positive electrode in a sodium-ion battery showed only minor capacity losses during 50 cycles and a remarkable rate capability (Zhao et al. 2012).

Copolymerization of pyrrole and N-(3-hydroxypropyl)pyrrole yielded a positive electrode mass for a lithium-ion battery with higher current and charge storage capability (Chen-Yang et al. 2004). Copolymerization with dopamine resulted in a rather moderate increase in storage capability (Liedel et al. 2018). Agglomeration of PPy negatively affecting its performance as positive electrode in lithium-ion batteries can be suppressed by copolymerization of pyrrole and 4-(1H-pyrrol-1-yl)phenol (see Fig. 19) yielding a material with more suitable morphology and tripled storage capability (Su et al. 2012).

PPy, polyazulene and their copolymers have been compared as positive electrode masses for a nonaqueous lithium-ion battery (Naoi et al. 1990). Polyazulene showed the highest specific capacitance and rate capability. The latter was attributed to higher diffusivity in polyazulene.

Radicals in active masses

A copolymer prepared by chemical oxidation of aniline and (4-(6-(2-amino-phenol-9H-yl)hexanoyloxy)-2,2,6,6-tetramethylpiperidin-1-yloxy) (Fig. 20) has been examined in the positive electrode of a lithium-ion battery (Xu et al. 2016). Even the polymer obtained with an optimized comonomer ratio had only 82.7% of the initial capacitance left after 20 cycles at 31.3% Coulombic efficiency.

A copolymer of pyrrole and Py-C-TEMPO (see Fig. 21) was used as positive electrode active mass (Xu et al. 2017).

The charge/discharge curves do not show plateaus typical of battery electrode materials but instead are more similar to those obtained with pseudocapacitive materials (Holze 2017) suggesting strong electronic interactions between the redox centers. Significant capacity losses were observed already after 20 cycles.

ICPs and composites in secondary batteries

Although the rather limited success of early applications of PANI and PPy in secondary batteries seemed to slow down a bit further development suggestions of ICPs as active masses sometimes with particular attention to specific morphologies and architectures have resulted in a renaissance. Improvement in the perceived structural instability of plain PANI as an electrode material has been achieved by polymerizing aniline in the presence of aramid nanofibers and single-walled carbon nanotubes (Flouda et al. 2020). Nanopillars of PANI deposited on cracked carbon fibers have been suggested for a flexible aqueous zinc-ion battery (Li et al. 2019d). After 1500 cycles the electrode retained 93.2% of its initial capacity. PANI on carbon paper has been proposed as a negative electrode for a lead acid battery (He et al. 2019). 84.2% of the initial cell capacity were present after 3000 cycles.

PPy and lithium (tri-(4-carboxyphenyl)amine) have been suggested as positive electrode for a lithium-ion battery (Su et al. 2020). At optimum composition about 10% capacity loss of the electrode were observed after 100 cycles.

A composite of PANI and 2,5-dimercapto-1,3,4-thiadiazole has been suggested for use in a lithium-ion battery with a gel electrolyte (Sotomoura et al. 1992). Stability data were not reported, the redox reaction used for charge storage was attributed to the organic disulfide, whereas PANI was designated a promoter. Another copolymer of aniline and 1,4-dihydrobenzo[d][1,2]dithiin-5-ylamin has been suggested later as potential electrode material (Cho et al. 2001). Practical utilization of the many attractive advantages of sulfur itself as an electrode material in lithium-ion batteries has so far been hampered by several challenges, the solubility of polysulfide intermediates and the associated redox shuttle mechanism is presumably the most prominent. Many attempts to eliminate this problem have been reported. Nano-microspherical and nanotubular PANI-sulfur composites have been suggested with the latter showing higher storage capability and better cycling stability at only 40% loss after 70 cycles (Wang and Zhang , 2020). The use of PANI as described above will add “dead weight” to the electrode because PANI does not contribute to charge storage. Thus, optimization of PANI coating thickness is welcome as reported by Yao et al. (2019b). At 2 wt% PANI after 500 cycles 55% capacity retention were reported. Another option is the use of PPy-coated nanotubes of MnO2 (Du et al. 2019). The modified nanotubes accommodated volume changes of the sulfur particles and suppressed polysulfide diffusion; during 700 cycles 0.088% capacity decay per cycle were observed. Nanosheets of zirconium phosphate coated with PPy served as host for sulfur in a lithium–sulfur battery with the PPy acting as a physical barrier and an electronic conductivity enhancer (Liu et al. 2019b). A mesoporous composite of TiO2 and sulfur with an encapsulation of PPy successfully prevented escape of soluble polysulfides, in addition PPy increased electronic conductivity of the electrode material for a lithium–sulfur battery (Song et al. 2020). 0.103% capacitance per cycle loss were measured during 300 cycles. Less pronounced effects were reported for composites of TiO2 in PEDOT (Liu et al. 2020d). Microspheres of Co3O4 embedded in PPy nanotubes served as hosts for sulfur in a lithium–sulfur battery (Wu et al. 2020b). 0.034% capacitance loss per cycle were observed during 1900 cycles. Channels established by PPy in a sulfur-rich triazine framework contributed to 86.8% capacity retention after 500 cycles of this positive electrode material (Kim et al. 2020). Further concepts employing ICPs as encapsulating or restraining material to keep sulfur in place and restrict polysulfide movement have been reported (Ahn et al. 2020; Chelladurai et al. 2020; Díez et al. 2020; Gao et al. 2020b, c; Ghosh et al. 2019; Hu et al. 2020; Huang et al. 2020; Kaiser et al. 2019; Lu et al. 2019; Lan et al. 2020; Liu et al. 2019c; Rajkumar et al. 2019; Raulo et al. 2019; Ren et al. 2020b; Song et al. 2019; Tang et al. 2019; Wang et al. 2019a, 2020d, e; Wei et al. 2019b, c, 2020a, b, c; Wu et al. 2019, 2020c; Yang et al. 2020a, b). An overview of the various uses of ICPs in lithium–sulfur batteries is available (Hong et al. 2020).

Growing interest in using selenium instead of sulfur and combining this positive electrode material with other negative ones has resulted in similar considerations for, e.g., a sodium–selenium battery see (Zhang et al. 2019c).

Enhanced storage capability of hyper-protonated PANI nanorods has been observed for an aluminum-ion battery employing \({\text{AlCl}}_{{2}}^{ + }\) as active species (Wang et al. 2020a) Noticeably stability, in particular only 0.003% capacitance loss per cycle during 8000 cycles was stated ported. Theoretical considerations regarding the interactions between chloroaluminate ions and PANI have been reported (Wang et al. 2020b).

Layered titanate with PANI inserted for increased interlayer spacing and enhanced structural stability as well as higher electronic conductivity has been suggested as negative electrode mass for sodium and potassium-ion batteries (Liao et al. 2020). With sodium ions 99.6% of the initial capacitance were found after 2500 cycles, and with K+ no obvious fading was seen after 2500 cycles. In V2O5 suggested as positive electrode material for a zinc-ion battery sluggish electrode kinetics (slow zinc-ion intercalation/deintercalation) could be accelerated by intercalating PANI resulting in increased interlayer spacing (Liu et al. 2020e). A very similar approach has been reported by Chen et al. (2020c); for V2O5 as positive electrode material in an aqueous zinc-ion battery the same approach and rationale has been reported (Liu et al. 2020f). Nanowires of V2O5 coated with PPy showed 95% capacity retention after 1000 cycles in an aqueous zinc-ion battery (Qin et al. 2020). For increased mass loading with VO2 in the positive electrode a 3D current collector and binder based on carbon fabric and PEDOT has been tested (Ma et al. 2020b). After 2000 cycles 23% capacity loss for a full cell were recorded. As another option ultrathin nanobelts of VO2 and PEDOT, the exact architecture remains unclear have been suggested with 84.5% capacity retention of the full battery after 1000 cycles (Liu et al. 2020a, b, c, yd, e, f).

As discussed above the problem of needing an acidic electrolyte (solution) for PANI to work properly and a neutral solution to avoid excessive corrosion of zinc in a secondary battery a polymer of aniline-2,5-disulfonic acid has been suggested (Wang et al. 2020f). With a quasi-solid electrolyte a flexible battery with 80% capacity retention after 1000 cycles was prepared. Instead of the Ph-dependency of the electrochemical activity of PANI its agglomeration has been invoked as a major cause of poor mass utilization in an aqueous zinc-ion battery (Wang et al. 2019g). Consequently, combination with graphene was proposed resulting in a material with 95.05% capacity retention after 100 cycles. PPy grown on an aerogel of polyvinyl alcohol served as a flexible positive electrode in an aqueous zinc-ion battery with 76.7% of the initial storage capability left after 1000 cycles (Li et al. 2019j).

A composite of sulfur and PPy with PSS (the copolymer claimed to be formed in this report is hardly conceivable given the experimental procedure, any experimental evidence is absent) has been suggested as positive electrode for a lithium–sulfur battery (Han et al. 2019). 64% of the initial capacitance were found after 200 cycles. A copolymer of sulfur and 3-butylthiophene encapsulated with PEDOT:PSS has been examined in a lithium–sulfur battery (Zeng et al. 2017). High stability of the material (99.947% capacitance retention per cycle during 500 cycles) was attributed to the high conductivity of the material, physical and chemical confinement of polysulfide electrode reaction intermediates.

In particular, for metal-ion batteries beyond lithium-ion the suitability of ICPs has been examined again, e.g., for an aluminum-ion battery using an ionic liquid as electrolyte (Schoetz et al. 2020). A polymer of o-phenylenediamine has been examined as positive electrode for an aqueous zinc-ion battery; it had 66.2% of its initial capacitance left after 3000 cycles (Zhang et al. 2020a).

Composites of ICPs with metal chalcogenides for use as supercapacitor electrode material have been reviewed elsewhere (Fu et al. 2019); given the ongoing merger of the fields of secondary batteries and supercapacitors the reader may inspect this report for further suggestions.

Auxiliary components and functions

ICPs have been examined as auxiliary materials in secondary batteries in various functions. Strictly speaking ICPs do not act as active masses in these applications, they serve mostly in other functions. Any charge storage is of minor importance if it proceeds at all. Nevertheless these materials act as vital components in battery electrodes meriting their mentioning here. Most frequently, they can be used as coating or as embedding material, obviously these functions may be difficult to distinguish sometimes. Associated functions and advantages of the use of ICPs will be discussed below with selected examples.

A polypyrrole-coated LiV3O8-nanocomposite has been prepared by Liu et al. (2013) for use as a negative electrode material in a lithium-ion battery with an aqueous electrolyte solution. The basically promising performance of the vanadate was initially compromised by insufficient stability caused by rapid release of vanadium ions into the electrolyte solution. The coating kept these ions in the coated particle (see Fig. 22) and thus enhanced performance stability (see Fig. 23).

Cycling stability of coated and uncoated LiV3O8 in 0.5 M Li2SO4 aqueous electrolyte solution [based on data in Liu et al. (2013)]

A coating with PPy of V2O5 suggested as positive electrode material in nonaqueous lithium-ion batteries served the same purpose, up to 5000 cycles were recorded (Liang et al. 2020). Core–shell nanobelts of V2O5 coated with PEDOT have shown remarkable lithium storage capability and even at high rate (10 C) no capacity loss after 500 cycles (Ren et al. 2020a).

Dissolution of MnO2 from an aerogel composite of MnO2 and reduced graphene oxide could be suppressed by coating with PANI (82.7% capacity retention after 600 cycles) (Mao et al. 2020). Reduced electric resistance of the material and enhanced electrode kinetics were also noticed.

Coating of particles with an ICP (or any other material, also) is frequently associated with the terminology core–shell. The shell—in the present context an ICP—serves again various purposes. As shown above it can keep reactants inside the particle. The function can include mitigation of volume changes otherwise possibly resulting in active mass pulverization. By mechanical and implicitly electronic contact with other coated particles it can also enhance electron transport across the electrode. A typical example is the use of a PEDOT:PSS shell around a SnO2 core (Li et al. 2019e). Overall performance improvements, in particular a major stability improvement, were reported. PPy has been used as a coating instead yielding an electrode with 85% capacity retention after 300 cycles (Wang et al. 2019b). LixSn has been examined as negative electrode material with a coating of PPy (Li et al. 2019a). Stable capacity with 86.1% retention after 300 cycles was reported. Another conversion material considered for use as positive electrode in a sodium-ion battery is CoS2. Like in the previous example volume changes and subsequent electrode pulverization limit the usability of the pristine material. Coating particles of an aerogel of CoS2 and rGO with pyrrole yielding PPy by a vapor-phase process yielded a material with 65.8% capacity retention after 700 cycles. (Liu et al. 2020c).

Conventionally, carbon coatings are used as a shell to increase the conductivity of electrode materials. A comparison of a carbon coating and polymer coating of LiV3O8 has shown that the polymer coating provides a greater capacity of the material, but is inferior to carbon in stability (Cao et al. 2015).

Particles of lithium iron silicate, a material with an attractive theoretical charge density, have been encapsulated with PEDOT (Rasool et al. 2020). Some of the numerous drawbacks limiting its application initially could be mitigated. In a similar way the use of δ-MnO2 as a conversion electrode material for the negative electrode of a lithium-ion battery has been hampered by the inherently low electronic conductivity of δ-MnO2 and insufficient cycling stability. Coating with PPy has been suggested as an option to remedy both shortfalls (Sui et al. 2020). With films about 50 nm thick 95% of the initial capacitance were observed after 120 cycles. The thickness of such coating with PPy by vapor-phase polymerization on particles of FeS2 has been examined when the composite was used in the positive electrode of a lithium-ion battery (Wang et al. 2019c). An optimum thickness of 5 nm was identified. The advantage of a conformal coating of constant thickness using this methodology has also been reported for coating of PPy on CuO (Zhou et al. 2019). The coating significantly enhanced the available storage capability and cycling stability. Similar results have been reported for this system elsewhere (Feng et al. 2020). Using a wet process a slightly thinner coating of PPy (about 3 nm) was identified as an optimum thickness for a LiNi0.5Co0.2Mn0.3O2 (NCM523) electrode in a lithium-ion battery (Li et al. 2019f). Coating of this material (also abbreviated as NMC532) with PANI by a vapor-phase process has been investigated thoroughly (Shao et al. 2021). With the best material 84% of the electrode’s initial capacity were still present after 100 cycles. A mixed uniform coating layer of PPy and lithium polyacrylate on particles of Li1.2Ni0.2Mn0.6O2 showing both ionic and electronic conductivity protects the active material against corrosion and other superficial side reactions resulting in 88.5% capacity retention after 100 cycles (Mu et al. 2019). A combination of PPy and LiNi1/3Co1/3Mn1/3O2 (it remains open whether the ICP served as host or as coating material) resulted in overall performance improvement in a lithium-ion battery (Zhu et al. 2020). Coating of a binary composite of ZnS and reduced graphene oxide yielded a very stable (157% capacity retention after 200 cycles) with remarkable storage capability (Xu et al. 2019). The advantageous properties of the mixed-valence compound Sb2WO6 are marred by structural collapse during cycling as a battery electrode material. Coating of microspheres of this material with PPy yielded an electrode material showing stable capacity retention during 200 cycles after significant losses in the initial cycles (Yang et al. 2020a). Wrapping of MOF-derived microsheets of ZnMnO3 with PPy yielded a more stable material with improved rate capability (Sun et al. 2020). A coating of PANI (initially called chemisorbed PANI in the report) resulted in increased surface area and optimum porosity of Co3O4 enabling a storage capability greater by 50% as compared to the uncoated oxide for use as positive electrode in a supercapacitor/battery hybrid (Izwan Misnon et al. 2020). Manganese hexacyanoferrate as a positive electrode material for sodium-ion batteries shows high theoretical storage capability and working electrode potential, its prospects are dimmed by insufficient cycling stability and poor current capability because of low electronic conductivity. Both flaws can be alleviated with PEDOT. The “reinforcement” reported by Wang et al. (2020c) is apparently a coating of the particles which results in 78.2% capacity retention after 1000 cycles and further improvements.

Boosting of the sodium storage in Prussian blue nanocubes and its analogues has been observed (Kim et al. 2019a). During 100 cycles no capacity loss was observed. Further considerations of the function of coatings have been discussed elsewhere (Kim et al. 2019b). MoS2 as an attractive material for lithium (Gao et al. 2020a) and sodium-ion storage in the negative electrode suffers from poor electronic conductivity and volume changes during charge/discharge. Using hollow nitrogen-doped carbon spheres as host for MoS2 and a coating with PPy a material with a fairly stable sodium storage capability after serious losses in the initial cycles was prepared (Wang et al. 2019d). MoO3 particles employed as hosts for Al3+-ions in an aluminum-ion battery have been coated with PPy (Wang et al. 2019e). 83.2% capacity retention after 100 cycles were reported.

Lithium-rich manganese compounds attractive as positive electrodes for lithium-ion batteries are hampered by poor rate performance, lacking stability and voltage decay. In case of Li1.2Mn0.54Ni0.13Co0.13O2 a mixed coating of PANI and Li1.4Al0.4Ti1.6(PO4)3 suppressed active mass dissolution and improved rate performance showing 79% capacity retention after 200 cycles (Lai et al. 2019). A similar approach has been studied for nickel-rich LiNi0.8Co0.1Mn0.1O2 with a coating of PPy and LiAlO2 (Ma et al. 2020a). After 100 cycles (presumably the meaning of “loop”) 92.8% of the initial electrode capacitance was left.

Another coating on a much larger scale is the encapsulation of the lithium metal electrode used as negative electrode securing dendrite-free metal deposition upon charging. A mesoporous PPy-graphene oxide heterostructure has been proposed enabling 1000 stable charge/discharge cycles with more than 90% capacitance retention after 450 cycles (Shi et al. 2020).

The low electronic conductivity of MnOx has hampered its use as a positive electrode material in zinc-ion batteries. A nanocomposite with PPy prepared in a simple one-pot reaction has shown good rate performance and stability (Li et al. 2020b).

Most simply a composite electrode material can be obtained by simply pressing LiMn2O4 and PPy powder without using any binder (Kuwabata et al. 1999). It was shown that PPy works well as a conducting matrix, improving electrochemical performance of the composite cathode material LiMn2O4/PPy.

ICPs can be used as the (only) binder, completely replacing traditional polymer like PVDF.

With increased amounts of ICPs electrodes without added carbon can be prepared, for example for LiFePO4 with 17–20 wt% of PEDOT (Cíntora-Juárez et al. 2014). Various preparation methods were tried, clear distinctions between coating of active material particles, mixing with ICP powder (blending) or electropolymerization of the ICP in the presence of active material particles are hard to identify. This difficulty will possibly cause uncertainties regarding assignment of a particular material in the following overview.

By emulsion polymerization a copolymer of conductive polypyrrole and poly(acrylonitrile/butyl acrylate) was prepared for use as a binder in the positive electrode in a lithium-ion battery with Li4Ti5O12 as active mass (Qi et al. 2020). Improved rate capability was attributed to the conducting PPy-segments whereas the enhanced stability was assumed to be due to the adhesive properties of the second polymer, in particular, when the ratio of the comonomers was at the optimum.

PEDOT has been used as a conductivity-enhancing coating on LiFePO4 by Lepage et al. (2011) for use as positive electrode active mass in lithium-ion batteries. The coating with a thickness of a few nanometers was applied with a soft chemistry procedure. The oxidative capability of Li(1−x)FePO4 was utilized to polymerize chemically EDOT yielding PEDOT-coated particles as schematically illustrated in Fig. 24.

No additional carbon was needed to achieve the electronic conductivity of the active mass, as a binder PVDF was used.

Similar results were reported using PEDOT:PSS (see Fig. 25) coated from its solution (Dinh et al. 2013). Coating with PEDOT:PSS from an aqueous dispersion has been suggested as another option (Raj and Sil 2019) (while conveniently ignoring the report by Lepage et al. (2011)). Various modes of blending/mixing LiFePO4 with PEDOT have been evaluated, stability data were not provided (Ozerova et al. 2020). Uniform coating of LiFePO4 with PPy (as already mentioned above) of about 5 nm thickness yielded a positive lithium-ion battery material with promising low-temperature performance and rate capability, both presumably due to the added PPy coating, and a capacity stable for at least 50 cycles (Gao et al. 2019).

At this point it is worth noting that of all examined ICPs PEDOT:PSS has probably the brightest perspective for application in battery materials. In many reports it is simply blended as its dispersion (which is stable and commercially available) into a standard-composition electrode containing added carbon and one of the conventional binders. Beyond the positive effects of the ICP there is almost no change in the process of preparation of the electrode; in addition good mechanical stability provided by conventional binders.

Cíntora-Juárez et al. (2015) examined two compositions of LiFePO4 electrodes containing PEDOT:PSS in different ratios: LFP/C/PVDF/PEDOT:PSS 79/7/7/7 and 84/8/7/1. Since PEDOT:PSS is not very conductive (about 1 S cm−1) added ethylene glycol and dimethyl sulfoxide, which increase the conductivity of the polymer, were tried. In both cases a significant improvement in electrochemical performance was observed compared to electrodes prepared with PVDF only.

Using PEDOT:PSS as a binder can reduce the content of inactive battery components as proposed by Das et al. (2015) to use compositions without added carbon with increased mass of LFP 92 and 94 wt%. This type of dispersion can be easily modified for use in printing technologies. PEDOT:PSS and LFP ink was used to print lithium-ion battery cathodes showing improved performance compared to electrodes printed with carbon additives and PVDF (Syrový et al. 2016).

Potentially, replacing conventional binder with PEDOT:PSS allows an increase of the mass fraction of the active component up to 99.5%, thus reaching extremely high capacity values (Kim et al. 2014). However, the decrease in the mass fraction of the binder inevitably worsens the mechanical properties of electrode materials, which is exacerbated by the relatively moderate adhesion of PEDOT:PSS, as well as by by-products of phase separation of dispersion when drying out.

An alternative approach using a redox copolymer poly(4-((10-(12-dodecyl phenoxazine) vinylpyridinium)-co-4-vinylpyridine) (Fig. 26) as binder has been suggested (Wang et al. 2009). Charge is shuttled between the current collector and particles of LiFePO4 via the phenoxazine units.

A copolymer of polyaniline and poly(ethylene glycol) has been suggested as a coating for LiFePO4 (Dong et al. 2014). The electrodes prepared with added acetylene black and PVDF as a binder kept 95.7% of their initial capacitance after 100 cycles. This copolymer has also been coated on LiNi0.6Co0.1Mn0.3O2 for the positive electrode in a lithium-ion battery (Yoo et al. 2017). Enhanced electrode kinetics and improved stability (3% capacitance loss during 50 cycles) were attributed to the coating. The use of ICPs as an effective means to remedy poor electronic conductivity and volume changes of electrode materials has been extended to, e.g., ZnFe2O4 (Hou et al. 2019). Nanowires encapsulated with PPy showed a capacity almost stable over more than 200 cycles after some initial fluctuation assigned to some activation process. Spherical particles of ZnFe2O4 coated with PPy for use as positive electrode material (Jiang et al. 2019); the capacity remained practically unchanged after 500 cycles. Coating of nanosheets of ZnFe2O4 with PPy yielded a positive electrode material with 94.9% capacity retention after 200 cycles (Jin et al. 2020).

PEDOT:PSS has been suggested as a binder improving rate performance and stability, in particular, of lithium titanate as negative electrode material in lithium-ion batteries by Zeng et al. (2018), Wang et al. (2014) and Liu et al. (2016). Both ionic and electronic conductivity of the ICP were utilized. A further improvement in performance by reduction of the added amount of conducting carbon was achieved by Eliseeva et al. (2019) with a combination of PEDOT:PSS and carboxymethyl cellulose CMC as binders. This combination provided sufficient conductivity enabling a significant reduction of the required addition of carbon, it further avoided the chemical incompatibility problems encountered with PVDF as a binder and lithium titanate and yielded superior performance and stability (see Fig. 27). Similar improvements were observed with MoS2 as active positive electrode material and this binder combination (Volkov et al. 2020). Further materials combination of PEDOT:PSS with electrode materials for lithium-ion batteries have been reviewed by Eliseeva et al. (2019), (2020), and Kamenskii et al. (2019).

The effect of conductive binder on the interfacial resistance and Li+-ion transport is somewhat similar to the influence of carbon coating of active grains, when carbonization provides the greatly enhanced surface electronic conductivity of particles. The wrapping of active grains by conducting polymer PEDOT:PSS provides more reliable electrical contact between neighboring particles. In combination with ionic conductivity of both ICP components of binder this would greatly enhance the interfacial coupled electron and ion transfer and Li+ ion transport in pores around active grains. This is illustrated in Fig. 28, the difference between non-conductive and conductive binders, the possible mechanism of electron and ion pathways in conductive binder is indicated.

Electronic and ionic transport in electrode materials (based on Eliseeva et al. 2017)

The conductive polymer coating of active particles increases the electronic conductivity on the surface of an individual particle and reduces the transfer resistance of ionic and electronic charge. In case of non-conducting PVDF binder, charge transfer occurs only in the region of point contact of active grains with carbon black particles.

Using only PEDOT:PSS as conducting additive resulted in inferior high-rate performance when compared with CNTs in a positive electrode of LiNi0.5Co0.2Mn0.3O2 (Medvedev et al. 2020). The optimized binder and conducting additive combinations addressed above were not included in this comparison.

Chitosan-grafted PANI has been suggested as another binder system for negative silicon electrode for lithium-ion batteries (Rajeev et al. 2020). At 1:1 ratio of both constituents conductivities (both ionic and electronic) and mechanical properties including adhesion were best. 42% of the initial capacitance were found in the 200th cycle. PEDOT cross-linked with glycerol with PSS as counter anion has been suggested for a negative silicon electrode (Liu et al. 2020a). After 200 cycles the electrode had 68.3% of its initial capacitance left. A polymeric binder poly(1-pyrenemethyl methacrylate-co-methacrylic acid) (Fig. 29) has been examined for a nanosilicon negative electrode in a lithium-ion battery (Zhao et al. 2015). A stable capacity is found after 50 cycles, evidence of the conductivity of the binder (neither ionic nor electronic) is not shown.

The influence of PANI structure (linear, cross-linked, star-like) on performance of a silicon electrode has been examined; star-like PANI turned out to be best performing (Han et al. 2020). A 3-D binder system composed of PANI, polyacrylic acid and phytic acid was used for preparing a negative silicon electrode for a lithium-ion battery (Wang et al. 2019f). 83.6% capacitance retention were found after 100 deep cycles. PEDOT:PSS has been used together with rGO to prepare nanosilicon particles into a negative electrode showing moderately stable capacity along 500 cycles (Qi et al. 2019). When using SiOx as the starting material for a negative silicon electrode in a lithium-ion battery microparticles of this material coated with bilayers of carbon and PEDOT have turned out to be beneficial yielding an electrode with a capacity stable along 1000 cycles (Wu et al. 2020a). Because of environmental concerns water-soluble binders for active masses in secondary batteries are gaining growing attention. A copolymer of polyvinylpyrrolidone and PANI has been reported for use in a silicon electrode for lithium-ion batteries (Zheng et al. 2019). Evidence of hydrogen bonding between the comonomers was somewhat unusually taken as proof of true copolymerization (for a critical examination see also Holze 2011). At optimum composition after 100 cycles 47.3% of the initial storage capacity of the electrode were left.

Copper foil used as negative electrode support and current collector in lithium-ion batteries has been coated with PANI (Zhang et al. 2020e). Storage capability and stability were increased, and the cell impedance decreased. Corrosion protection could also be achieved with a coating of electrodeposited PPy (Jiang et al. 2020a, b). A reported charge transfer resistance—presumably the corrosion resistance—was increased sevenfold even after 500 h of contact between coated metal foil and electrolyte solution. No cell performance data were provided. At the positive electrode in lithium-ion batteries an aluminum foil is used as current collector and mechanical support. Its coating with PEDOT by chemical vapor deposition has been suggested (Lepage et al. 2019). A 30% increase in discharge capacity was attributed to this coating.

PPy has been examined as corrosion protection for a zinc electrode in aqueous ZnSO4 electrolyte solution providing 67% inhibition efficiency (Nuanwat and Pattananuwat 2019).

Reduced self-discharge and enhanced corrosion protection (75.8% corrosion inhibition) in an aqueous zinc-ion battery was achieved by coating the zinc electrode with PANI (Nam et al. 2019); after 24 h storage 96.9% of the initial capacitance were still available. A coating with PPy has been suggested for improved control of both plating and stripping of the negative zinc electrode (Zhang et al. 2020f). After 12,000 cycles 96% of the electrode capacity were still available. An enhanced corrosion protection of PANI coated on the zinc electrode in a zinc–air battery by adding zinc phtaholcyanine has been noticed (Deyab and Mele 2019). Corrosion inhibition grew from 74.8% without the addition to 97.7% resulting in increased capacity retention.

Lightweight grids for lead-acid batteries have been prepared from polymers coated with lead (Martha et al. 2006). Corrosion protection of these coatings at both electrodes is particularly important, it was afforded by coating with PANI resulting in batteries with improved gravimetric energy density and high rate capability.

Miscellaneous uses of ICPs

Solid electrolytes with composites containing various combinations of PPy or PANI have been suggested (Dalas et al. 1995). Gel electrolytes for lithium-ion batteries based on combinations of PANI and polyacrylonitrile have been studied (Amaral et al. 2007). Advantageous electrochemical performance and stability were reported. Enhanced conductivity of PANI by incorporation of polyethyleneoxide has been reported (Yang et al. 2017), this may possibly be useful for enhancing current-carrying properties of electrode materials. Coating of a polypropylene separator with PANI increased wetting with a nonaqueous electrolyte solution resulting in increased ionic conductance (Hao et al. 2019). Coating of a polyethylene separator with particles of AlF3 and a copolymer of EDOT and ethylene glycol yielded decreased thermal shrinkage and improved electrolyte solution uptake resulting in improved cycling performance (Shin et al. 2015). Molecular sieves coated with PEDOT:PSS have been proposed as water scavenger for lithium-ion batteries with NMC as positive electrode (Xue et al. 2020). Coating of the separator for a lithium-ion sulfur battery with a blend of PEDOT:PSS and carbon black resulted in overall performance improvements (Yi et al. 2019). A similar effect was achieved with a coating of porous PPy spheres (Li et al. 2019g). To prevent polysulfide diffusion an additional interlayer of carbon fibers coated with PPy has been proposed (Li et al. 2019h). Beyond physical adsorption of polysulfide the interlayer also reduced electrode polarization of the sulfur electrode. Vapor-phase deposition of PPy on a commercial Celgard separator yielded a separator with several advantages (Li et al. 2019i).

An interlayer of PPy on carbon cloth assisted in loading Li4Ti5O12 nanosheets for use as negative electrode in a sodium-ion battery (Jiang et al. 2020a). After 1100 cycles 96.6% of the initial capacitance were retained.

A composite of CNTs and PEDOT has been suggested as mechanical support and current collector instead of metal foils, when incorporated with further active mass, e.g., positive electrodes have been prepared (Rousselot et al. 2020).

A skeleton of PEDOT:PSS keeps an ionic liquid providing ion channels in an aqueous zinc-polysulfide battery in place (Zhao et al. 2020).

ICPs have been examined as coatings in the positive electrodes of metal air batteries (Cao et al. 2020).

Modification of the frequently used lignosulfonate as an expander in the negative electrode of a lead acid battery (Pavlov 2006) with PANI has been proposed (Chen et al. 2020b). Significant overall performance improvements were noted.

Precursors and templates

Several ICPs can be prepared chemically as well as electrochemically in a variety of shapes and morphologies, for example see Dubal et al. (2016b), Stejskal et al. (2010) and Stejskal and Trchova (2018). These morphologies may be suitable as electrode material themselves, but they may also be used as precursor in subsequent carbonization or pyrolysis steps yielding carbon structures related to the advantageous structural details of the precursor. A particular advantage of the use of ICPs as precursor materials in such transformation is the easy introduction of heteroatoms (nitrogen, sulfur) into the resulting carbon material. These additions (sometimes slightly misleadingly called dopants) frequently result in enhanced electronic conduction (for example, see (Zhang et al. 2020b, 2020d)).

Dubal et al. (2019) have carbonized PPy-nanopipes yielding a host material for the negative electrode of a lithium-ion capacitor, together with the pristine nanopipes as positive electrode they assembled a capacitor keeping 93% of its initial capacitance after 2000 cycles. Whereas the positive electrode shows pseudocapacitive behavior (see Holze 2017), the negative electrode is a battery-type electrode.

In a simplified approach an ICP can be used as a heteroatom source for preparation of, e.g., nitrogen-containing carbon materials (Li et al. 2019b). Mesoporous spheres of TiO2 embedded in PPy yielded after carbonization a negative electrode material for a lithium-ion battery (Chen et al. 2020a) 53% of the initial electrode capacity were left after 500 cycles.

The particular morphology, e.g., nanotubes, can be used as template (Wei et al. 2019a) for active material deposition first, followed by pyrolysis or carbonization.

Conclusions

Intrinsically conducting polymers, their copolymers with redox-active molecules, and their composites with such molecules have attracted growing attention in secondary battery research and development. Their application ranges from being the sole active material to use as a binder, protective coating of active material, precursor for active masses, and separator. However, despite the significant progress on all aspects, stability of the obtained electrodes and cell constituents varies widely and too much for practical use; further research should be focused on this aspect which is definitely of major practical importance. When combined with more attention to a rational electrode design in terms of architecture and possible mass utilization keeping an eye on possible and actually utilized capabilities of the polymer component(s) in an actual electrode obtained materials carefully and comparably examined for performance and stability will provide attractive options in electrochemical energy technology.

References

Admassie S, Ajjan FN, Elfwing A, Inganäs O (2016) Biopolymer hybrid electrodes for scalable electricity storage. Mater Horiz 3:174–185. https://doi.org/10.1039/c5mh00261c

Ahn S, Noguchi T, Momma T, Nara H, Yokoshima T, Togasaki N, Osaka T (2020) Facile fabrication of sulfur/Ketjenblack-PEDOT:PSS composite as a cathode with improved cycling performance for lithium sulfur batteries. Chem Phys Lett 749:137426. https://doi.org/10.1016/j.cplett.2020.137426

Ǻkerlund L, Emanuelsson R, Hernández G, Ruipérez F, Casado N, Brandell D, Strømme M, Mecerreyes D, Sjödin M (2019) In situ investigations of a proton trap material: a PEDOT-based copolymer with hydroquinone and pyridine side groups having robust cyclability in organic electrolytes and ionic liquids. ACS Appl Energy Mater 2:4486–4495. https://doi.org/10.1021/acsaem.9b00735

Amaral FA, Dalmolin C, Canobre SC, Bocchi N, Rocha-Filho RC, Biaggio SR (2007) Electrochemical and physical properties of poly(acrylonitrile)/poly(vinyl acetate)-based gel electrolytes for lithium ion batteries. J Power Sources 164:379–385. https://doi.org/10.1016/j.jpowsour.2006.10.049

Armand M, Tarascon JM (2008) Building better batteries. Nature 451:652–657. https://doi.org/10.1038/451652a

Armand M, Grugeon S, Vezin H, Laruelle S, Ribiere P, Poizot P, Tarascon JM (2009) Conjugated dicarboxylate anodes for Li-ion batteries. Nat Mater 8:120–125. https://doi.org/10.1038/NMAT2372

Beck F, Euler KJ (1984) Elektrochemische Energiespeicher. VDE-Verlag GmbH, Berlin

Bocchetta P, Frattini D, Tagliente M, Selleri F (2020) Electrochemical deposition of polypyrrole nanostructures for energy applications: a review. Curr Nanosci 16:462–477. https://doi.org/10.2174/1573413715666190717113600

Cao X, Zhang J, Zhu L (2015) Preparation of LiV3O8 /polypyrrole and their derived LiV3O8 carbon composites as cathode materials for lithium rechargeable batteries. J Nanosci Nanotechnol 15:7081–7086. https://doi.org/10.1166/jnn.2015.10546

Cao D, Shen X, Wang Y, Liu J, Shi H, Gao X, Liu X, Fu L, Wu Y, Chen Y (2020) Conductive polymer coated cathodes in Li–O2 batteries. ACS Appl Energy Mater 3:951–956. https://doi.org/10.1021/acsaem.9b02024

Casado N, Mecerreyes D (2020) Introduction to redox polymers: classification, characterization methods and main applications. In: Casado N, Mecerreyes D (eds) Redox polymers for energy and nanomedicine. RSC, Cambridge, pp 1–26

Chang CC, Her LJ, Hong JL (2005) Copolymer from electropolymerization of thiophene and 3,4-ethylenedioxythiophene and its use as cathode for lithium ion battery. Electrochim Acta 50:4461–4468. https://doi.org/10.1016/j.electacta.2005.02.008

Chelladurai K, Venkatachalam P, Rengapillai S, Liu WR, Huang CH, Marimuthu S (2020) Effect of polyaniline on sulfur/sepiolite composite cathode for lithium–sulfur batteries. Polymers 12:755. https://doi.org/10.3390/POLYM12040755

Chen Y (2019) A review of polyaniline based materials as anodes for lithium ion batteries. IOP Conf Ser Mater Sci Eng 677:022115. https://doi.org/10.1088/1757-899X/677/2/022115

Chen HW, Li C (2020) PEDOT: fundamentals and its nanocomposites for energy storage. Chin J Polym Sci 38:435–448. https://doi.org/10.1007/s10118-020-2373-2

Chen H, Armand M, Demailly G, Dolhem F, Poizot P, Tarascon JM (2008) From biomass to a renewable LixC6O6 organic electrode for sustainable Li-ion batteries. Chemsuschem 1:348–355. https://doi.org/10.1002/cssc.200700161

Chen HY, Armand M, Courty M, Jiang M, Grey CP, Dolhem F, Tarascon JM, Poizot P (2009) Lithium salt of tetrahydroxybenzoquinone: toward the development of a sustainable Li-ion battery. J Am Chem Soc 131:8984–8988. https://doi.org/10.1021/ja9024897

Chen Y, Luo W, Carter M, Zhou K, Dai J, Fu K, Lacey S, Li T, Wan J, Han X, Bao Y, Hu L (2015) Organic electrode for non-aqueous potassium-ion batteries. Nano Energy 18:205–211. https://doi.org/10.1016/j.nanoen.2015.10.015

Chen C, Hong X, Chen A, Xu T, Lu L, Lin S, Gao Y (2016) Electrochemical properties of poly(aniline-co-N-methylthionine) for zinc-conducting polymer rechargeable batteries. Electrochim Acta 190:240–247. https://doi.org/10.1016/j.electacta.2015.12.125

Chen Q, Yuan F, Yin SM, Zhu M, Cai GS (2020a) Pomegranate-like C@TiO2mesoporous honeycomb spheres for high performance lithium ion batteries. Nanotechnology 31:435410. https://doi.org/10.1088/1361-6528/aba302

Chen C, Liu Y, Chen Y, Li X, Cheng J, Chen S, Lin J, Zhang X, Zhang Y (2020b) Effect of polyaniline-modified lignosulfonate added to the negative active material on the performance of lead-acid battery. Electrochim Acta 338:135859. https://doi.org/10.1016/j.electacta.2020.135859

Chen S, Li K, Hui KS, Zhang J (2020c) Regulation of lamellar structure of vanadium oxide via polyaniline intercalation for high-performance aqueous zinc-ion battery. Adv Funct Mater 30:202003890. https://doi.org/10.1002/adfm.202003890

Chen-Yang YW, Li JL, Wu TL, Wang WS, Hon TF (2004) Electropolymerization and electrochemical properties of (N-hydroxyalkyl)pyrrole/pyrrole copolymers. Electrochim Acta 49:2031–2040. https://doi.org/10.1016/j.electacta.2003.12.033

Chhin D, Padilla-Sampson L, Malenfant J, Rigaut V, Nazemi A, Schougaard SB (2019) Conducting polymers doped with bifunctional copolymers for improved organic batteries. ACS Appl Energy Mater 2:7781–7790. https://doi.org/10.1021/acsaem.9b01104

Cho JS, Sato S, Takeoka S, Tsuchida E (2001) Synthesis of disulfide-containing aniline and copolymerization with aniline. Macromolecules 34:2751–2756. https://doi.org/10.1021/ma001802h

Cíntora-Juárez D, Pérez-Vicente C, Ahmad S, Tirado JL (2014) Improving the cycling performance of LiFePO4 cathode material by poly(3,4-ethylenedioxythiopene) coating. RSC Adv 4:26108. https://doi.org/10.1039/c4ra05286b

Cíntora-Juárez D, Pérez-Vicente C, Kazim S, Ahmad S, Tirado JL (2015) Judicious design of lithium iron phosphate electrodes using poly(3,4-ethylenedioxythiophene) for high performance batteries. J Mater Chem A 3:14254–14262. https://doi.org/10.1039/C5TA03542B

Craig B, Skylaris CK, Schoetz T, de León CP (2020) A computational chemistry approach to modelling conducting polymers in ionic liquids for next generation batteries. Energy Rep 6:198–208. https://doi.org/10.1016/j.egyr.2020.03.025

Dai S, Feng Y, Wang P, Wang H, Liang H, Wang R, Linkov V, Ji S (2019) Highly conductive copolymer/sulfur composites with covalently grafted polyaniline for stable and durable lithium-sulfur batteries. Electrochim Acta 321:134678. https://doi.org/10.1016/j.electacta.2019.134678

Dalas E, Tsamouras D, Bouropoulos N (1995) Primary solid state batteries. Ionics 1:235–241. https://doi.org/10.1007/BF02426023

Das PR, Komsiyska L, Osters O, Wittstock G (2015) PEDOT: PSS as a functional binder for cathodes in lithium ion batteries. J Electrochem Soc 162:A674–A678. https://doi.org/10.1149/2.0581504jes

Deyab MA, Mele G (2019) Polyaniline/Zn-phthalocyanines nanocomposite for protecting zinc electrode in Zn-air battery. J Power Sources 443:227264. https://doi.org/10.1016/j.jpowsour.2019.227264

Díez N, Sevilla M, Fuertes AB (2020) N/S-Co-doped porous carbon nanoparticles serving the dual function of sulfur host and separator coating in lithium–sulfur batteries. ACS Appl Energy Mater 3:3397–3407. https://doi.org/10.1021/acsaem.9b02221

Dinh HC, Lim H, Park KD, Yeo IH, Kang Y, Mho SI (2013) Long-term cycle stability at a high current for nanocrystalline LiFePO4 coated with a conductive polymer. Adv Nat Sci Nanosci Nanotechnol 4:015011. https://doi.org/10.1088/2043-6262/4/1/015011

Du P, Wei W, Dong Y, Liu D, Wang Q, Peng Y, Chen S, Liu P (2019) Sulfur impregnation in polypyrrole-modified MnO2 nanotubes: efficient polysulfide adsorption for improved lithium-sulfur battery performance. Nanoscale 11:10097–10105. https://doi.org/10.1039/c8nr10353d

Dubal DP, Wu Y, Holze R (2015) Supercapacitors as fast storage systems for electric energy. Bunsen-Magazin 17:216–227

Dubal DP, Wu YP, Holze R (2016a) Supercapacitors: from the Leyden jar to electric busses. Chemtexts 2:13. https://doi.org/10.1007/s40828-016-0032-6

Dubal DP, Chodankar NR, Caban-Huertas Z, Wolfart F, Vidotti M, Holze R, Lokhande CD, Gomez-Romero P (2016b) Synthetic approach from polypyrrole nanotubes to nitrogen doped pyrolyzed carbon nanotubes for asymmetric supercapacitors. J Power Sources 308:158–165. https://doi.org/10.1016/j.jpowsour.2016.01.074