Abstract

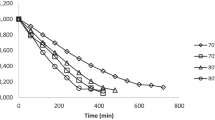

The aim of this research was to systematically evaluate the impact of varying ripeness stages (categorized into five distinct levels: I, II, III, IV, and V) on the drying behavior, moisture status, cellular injury, texture, rehydration properties, bioactive compounds, antioxidant activities, and sensory attributes of peaches. The ultimate goal was to identify the optimal ripeness stage of peaches for hot-air drying. Results demonstrated that significant disparities exist in drying characteristics among peaches of different ripeness levels. Peaches at ripeness stage III exhibited the most efficient drying kinetics, characterized by the shortest drying duration, highest drying rate, and maximum moisture diffusion coefficient. This was followed by peaches in stages II, I, IV, and V, the differences being attributed to variances in moisture mobility, content, and cellular injury. Additionally, stage III peaches displayed optimal levels of ascorbic acid, total phenolics, antioxidant capacity, and rehydration ratio. Conversely, peaches at stage V excelled in visual appearance, sugar-to-acid ratio, and flavor profile. Consequently, peaches at ripeness stage III are recommended for hot-air drying due to their superior drying efficiency and quality attributes. This study serves as a theoretical foundation for future work on quality categorization and drying methodologies for peaches.

Similar content being viewed by others

Data Availability

The data obtained during the study are available from the corresponding author upon suitable request.

References

S.K. Chang, C. Alasalvar, F. Shahidi, Review of dried fruits: phytochemicals, antioxidant efficacies, and health benefits. J. Funct. Foods 21, 113–132 (2016). https://doi.org/10.1016/j.jff.2015.11.034

L. Zhang, X.Y. Kou, X. Huang, G.H. Li, J.W. Liu, J.L. Ye, Peach-gum: a promising alternative for retarding the ripening and senescence in postharvest peach fruit. Postharvest Biol. Technol. 161, 111088 (2020). https://doi.org/10.1016/j.postharvbio.2019.111088

Y.B. Feng, B.G. Xu, A.E.A. Yagoub, H.L. Ma, Y.H. Sun, X. Xu, X.J. Yu, C.S. Zhou, Role of drying techniques on physical, rehydration, flavor, bioactive compounds and antioxidant characteristics of garlic. Food Chem. 343, 128404 (2021). https://doi.org/10.1016/j.foodchem.2020.128404

Y.Y. Jia, I. Khalifa, L.L. Hu, W. Zhu, J. Li, K.K. Li, C.M. Li, Influence of three different drying techniques on persimmon chips’ characteristics: a comparison study among hot-air, combined hot-air-microwave, and vacuum-freeze drying tchniques. Food Bioprod. Process. 118, 67–76 (2019). https://doi.org/10.1016/j.fbp.2019.08.018

E. Nakilcioglu-Tas, G. Cosan, S. Ötles, Optimization of process conditions to improve the quality properties of healthy watermelon snacks developed by hot-air drying. J. Food Meas. Charact. 15, 2146–2160 (2021). https://doi.org/10.1007/s11694-020-00808-3

K.H. Wang, Q.Y. Li, Y. Xue, Z.Q. Yang, P.Y. He, X.R. Jia, W.X. Ren, J. Wang, H.D. Xu, Ripening induced degradation of pectin and cellulose affects the medium- and short-wave infrared drying characteristics of mulberry. Food Chem. 434, 137490 (2024). https://doi.org/10.1016/j.foodchem.2023.137490

Y. Li, L. Li, X. Zhang, O. Mu, J. Tian, J. Yan, L. Guo, Y. Wang, L. Song, X. Yu, Differences in total phenolics, antioxidant activity and metabolic characteristics in peach fruits at different stages of ripening. LWT 178, 114586 (2023). https://doi.org/10.1016/j.lwt.2023.114586

P. Dabesor, D. Sanni, A. Kolawole, V. Enujiugha, O. Lawal, A. Edeh, Changes in physicochemical properties and enzymes associated with ripening of snake tomato (Trichosanthes cucumerina L.) fruit. Biocatal. Agric. Biotechnol. 40, 102313 (2023). https://doi.org/10.1016/j.bcab.2022.102313

P. Kumar, T. Shuprajhaa, P. Subramaniyan, A. Mohanasundaram, K. Shiva, M. Mayilvaganan, U. Subbaraya, Ripening dependent changes in skin color, physicochemical attributes, in-vitro glycemic response and volatile profiling of banana varieties. Food Biosci. 56, 1032274 (2023). https://doi.org/10.1016/j.fbio.2023.103274

A. Diop, J.M. Meot, M. Lechaudel, F. Chiroleu, N.D. Ndiaye, C. Mertz, M. Cisse, M. Chillet, Impact of preharvest and postharvest on color changes during convective drying of mangoes. Foods 10, 490 (2021). https://doi.org/10.3390/foods10030490

I. Karabulut, T. Bilenler, K. Sislioglu, I. Gokbulut, I.S. Ozdemir, F. Seyhan, K. Ozturk, Chemical composition of apricots affected by fruit size and drying methods. Dry. Technol. 36, 1937–1948 (2018). https://doi.org/10.1080/07373937.2018.1427762

H. Wang, X.Y. Li, J. Wang, S.K. Vidyarthi, H.O. Wang, X.G. Zhang, L. Gao, K.W. Yang, J.S. Zhang, H.W. Xiao, Effects of postharvest ripening on water status and distribution, drying characteristics, volatile profiles, phytochemical contents, antioxidant capacity and microstructure of kiwifruit (Actinidia deliciosa). Food Control 139, 109062 (2022). https://doi.org/10.1016/j.foodcont.2022.109062

L.Z. Deng, Z.L. Pan, Q. Zhang, Z.L. Liu, Y. Zhang, J.S. Meng, Z.J. Gao, H.W. Xiao, Effects of ripening stage on physicochemical properties, drying kinetics, pectin polysaccharides contents and nanostructure of apricots. Carbohydr. Polym. 222, 8 (2019). https://doi.org/10.1016/j.carbpol.2019.114980

Y.H. Zhou, Y.P. Pei, P.P. Sutar, D.H. Liu, L.Z. Deng, X. Duan, Z.L. Liu, H.W. Xiao, Pulsed vacuum drying of banana: effects of ripeness on drying kinetics and physicochemical properties and related mechanism. LWT 161, 113362 (2022). https://doi.org/10.1016/j.lwt.2022.113362

Y. Ando, K. Mizutani, N. Wakatsuki, Electrical impedance analysis of potato tissues during drying. J. Food Eng. 121, 24–31 (2014). https://doi.org/10.1016/j.jfoodeng.2013.08.008

Y. Ando, S. Hagiwara, H. Nabetani, I. Sotome, T. Okunishi, H. Okadome, T. Orikasa, A. Tagawa, Effects of prefreezing on the drying characteristics, structural formation and mechanical properties of microwave-vacuum dried apple. J. Food Eng. 244, 170–177 (2019). https://doi.org/10.1016/j.jfoodeng.2018.09.026

W.J.N. Fernando, H.C. Low, A.L. Ahmad, Dependence of the effective diffusion coefficient of moisture with thickness and temperature in convective drying of sliced materials. A study on slices of banana, cassava and pumpkin. J. Food Eng. 102, 310–316 (2011). https://doi.org/10.1016/j.jfoodeng.2010.09.004

T.X. Hu, J. Ye, P.W. Tao, H.X. Li, J.H. Zhang, Y.Y. Zhang, Z.B. Ye, The tomato HD-Zip I transcription factor SIHZ24 modulates ascorbate accumulation through positive regulation of the d-mannose/l-galactose pathway. Plant J. 85, 16–29 (2016). https://doi.org/10.1111/tpj.13085

L.Y. Zhou, X.N. Guo, J.F. Bi, J.Y. Yi, Q.Q. Chen, X.Y. Wu, M. Zhou, Drying of garlic slices (Allium sativum L.) and its effect on thiosulfinates, total phenolic compounds and antioxidant activity during infrared drying. J. Food Process. Preserv. 41, 12734 (2017). https://doi.org/10.1111/jfpp.12734

D.Q. Huang, Y.H. Zhao, M.H. Cao, L. Qiao, Z.L. Zheng, Integrated systems biology analysis of transcriptomes reveals candidate genes for acidity control in developing fruits of sweet orange (Citrus sinensis L. osbeck). Front. Plant Sci. 7, 486 (2016). https://doi.org/10.3389/fpls.2016.00486

D.T. Li, L.Z. Deng, T.T. Dai, M.S. Chen, R.H. Liang, W. Liu, C.M. Liu, J. Chen, J. Sun, Ripening induced degradation of pectin and cellulose affects the far infrared drying kinetics of mangoes. Carbohydr. Polym. 219, 119582 (2022). https://doi.org/10.1016/j.carbpol.2022.119582

L. Cui, Y.N. Chen, M. Li, T.Y. Liu, P. Yang, L.P. Guo, X. Wang, Detection of water variation in rosebuds during hot-air drying by LF-NMR and MRI. Dry. Technol. 38, 304–312 (2020). https://doi.org/10.1080/07373937.2019.1565577

J. Wang, W.S. Mu, X.M. Fang, A.S. Mujumdar, X.H. Yang, L.Y. Xue, L. Xie, H.W. Xiao, Z.J. Gao, Q. Zhang, Pulsed vacuum drying of thompson seedless grape: effects of berry ripeness on physicochemical properties and drying characteristic. Food Bioprod. Process. 106, 117–126 (2017). https://doi.org/10.1016/j.fbp.2017.09.003

J.R. Gonzalez-Araiza, M.C. Ortiz-Sanchez, F.M. Vargas-Luna, J.M. Cabrera-Sixto, Application of electrical bio-impedance for the evaluation of strawberry ripeness. Int. J. Food Prop. 20, 1044–1050 (2017). https://doi.org/10.1080/10942912.2016.1199033

Y.B. Feng, X.J. Yu, A.A. Yagoub, B.G. Xu, B.G. Wu, L. Zhang, C.S. Zhou, Vacuum pretreatment coupled to ultrasound assisted osmotic dehydration as a novel method for garlic slices dehydration. Ultrason. Sonochem. 50, 363–372 (2019). https://doi.org/10.1016/j.ultsonch.2018.09.038

F. Hidaka, T. Satoh, A. Fujioka, K. Takeda, H. Imanaka, N. Ishida, K. Imamura, Controlling the drying process in vacuum foam drying under low vacuum conditions by inducing foaming by needle stimulation of the solution. Dry. Technol. 37, 1520–1527 (2019). https://doi.org/10.1080/07373937.2018.1517363

B.G. Xu, M. Feng, B. Chitrakar, B.X. Wei, B. Wang, C.S. Zhou, H.L. Ma, B. Wang, L. Chang, G.Y. Ren, Selection of drying techniques for pingyin rose on the basis of physicochemical properties and volatile compounds retention. Food Chem. 385, 132539 (2022). https://doi.org/10.1016/j.foodchem.2022.132539

H.J. Zhou, Z.F. Yu, Z.W. Ye, Effect of bagging duration on peach fruit peel color and key protein changes based on iTRAQ quantitation. Sci. Hortic. 246, 217–226 (2019). https://doi.org/10.1016/j.scienta.2018.10.072

D.Z. Wang, X.C. Wang, Y.Y. Chen, Y. Wu, X.L. Zhang, Strawberry ripeness classification method in facility environment based on red color ratio of fruit rind. Comput. Electron. Agric. 214, 108313 (2023). https://doi.org/10.1016/j.compag.2023.108313

J. Kroehnke, J. Szadzińska, E.R. Kubzdela, R. Biegańska-Marecik, G. Musielak, D. Mierzwa, Osmotic dehydration and convective drying of kiwifruit (Actinidia deliciosa)—the influence of ultrasound on process kinetics and product quality. Ultrason. Sonochem. 71, 105377 (2021). https://doi.org/10.1016/j.ultsonch.2020.105377

Y.Y. Xu, Y.D. Xiao, C. Lagnika, D.J. Li, C.Q. Liu, N. Jiang, J.F. Song, M.A. Zhang, Comparative evaluation of nutritional properties, antioxidant capacity and physical characteristics of cabbage (Brassica oleracea var. capitate var L.) subjected to different drying methods. Food Chem. 309, 124935 (2020). https://doi.org/10.1016/j.foodchem.2019.06.002

I. Zahoor, M.A. Khan, Microwave assisted convective drying of bitter gourd: drying kinetics and effect on ascorbic acid, total phenolics and antioxidant activity. J. Food Meas. Charact. 13, 2481–2490 (2019). https://doi.org/10.1007/s11694-019-00168-7

T. Mahmood, F. Anwar, N. Afzal, R. Kausar, S. Ilyas, M. Shoaib, Influence of ripening stages and drying methods on polyphenolic content and antioxidant activities of mulberry fruits. J. Food Meas. Charact. 11, 2171–2179 (2017). https://doi.org/10.1007/s11694-017-9602-6

I. Doymaz, H. Demir, A. Yildirim, Drying of quince slices: effect of pretreatments on drying and rehydration characteristics. Chem. Eng. Commun. 202, 1271–1279 (2015). https://doi.org/10.1080/00986445.2014.921619

M.L. Rojas, P.E.D. Augusto, Microstructure elements affect the mass transfer in foods: the case of convective drying and rehydration of pumpkin. LWT 93, 102–108 (2018). https://doi.org/10.1016/j.lwt.2018.03.031

L. Qiao, M.H. Cao, J. Zheng, Y.H. Zhao, Z.L. Zheng, Gene coexpression network analysis of fruit transcriptomes uncovers a possible mechanistically distinct class of sugar/acid ratio-associated genes in sweet orange. BMC Plant Biol. 17, 186 (2017). https://doi.org/10.1186/s12870-017-1138-8

F.J. Xu, H.S. An, J.Y. Zhang, Z.H. Xu, F. Jiang, Effects of fruit load on sugar/acid quality and puffiness of delayed-harvest citrus. Horticulturae 7, 189 (2021). https://doi.org/10.3390/horticulturae7070189

M. Das-Purkayastha, A. Nath, B.C. Deka, C.L. Mahanta, Thin layer drying of tomato slices. J. Food Sci. Technol. MYS 50, 642–653 (2013). https://doi.org/10.1007/s13197-011-0397-x

R.G. Gong, W. Yang, Z.H. Wang, M.G. Liao, G.L. Liang, Study on the sugar-acid ratio and relevant metabolizing enzyme activities in navel orange fruits from different eco-regions. Rev. Bras. Frutic. 37, 835–844 (2015). https://doi.org/10.1590/0100-2945-210/14

K.H. Wang, J. Qi, Y. Jin, F. Li, J. Wang, H.D. Xu, Influence of fruit maturity and lactic fermentation on physicochemical properties, phenolics, volatiles, and sensory of mulberry juice. Food Biosci. 48, 101782 (2022). https://doi.org/10.1016/j.fbio.2022.101782

N.S. Janzantti, M. Monteiro, HS-GC-MS-O analysis and sensory acceptance of passion fruit during maturation. J. Food Sci. Technol. MYS 54, 2594–2601 (2017). https://doi.org/10.1007/s13197-017-2671-z

Funding

Zhejiang Provincial Natural Science Foundation of China (No. LTGN23C200015), Ningbo Public Welfare Technology Plan Project (No. 2022S142) and Ningbo Public Welfare Technology Plan Project (No. 2022S152).

Author information

Authors and Affiliations

Contributions

KS: investigation, methodology, writing—original draft. YF: conceptualization, project administration, supervision. YZ: investigation, methodology, writing—original draft. ZY: conceptualization, project administration, supervision. CZ: validation, formal analysis. AEGAY: writing—original draft. WC: methodology. JW: supervision.

Corresponding authors

Ethics declarations

Competing interests

The authors declare no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Suo, K., Feng, Y., Zhang, Y. et al. Selection of ripeness stages for hot-air drying of peaches based on drying characteristics and physicochemical properties. Food Measure 18, 1980–1990 (2024). https://doi.org/10.1007/s11694-023-02281-0

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-023-02281-0