Abstract

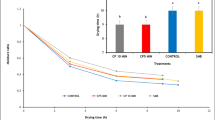

The presence of carbon and nitrogenous compounds in mango processing by-products makes them excellent substrates for the biosynthesis of many microbial metabolites using the fermentation process. Pre-treatment of the substrate with retention of crucial microbial growth supporting compounds is vital for designing and optimizing fermentation media for enhanced production of desired metabolites. Keeping this in mind, we analyzed the effect of convective hot air drying (50, 60, 70, and 80 °C) conditions on the bioactive compounds (especially carbohydrates and nitrogen), physico-chemical attributes, mineral elements, fermentable sugar, and microbial safety of mango peels (Cv-chausa) powder. Results indicated that different drying temperatures insignificantly (P > 0.05) affected the carbohydrates and reducing sugar (except at 80 °C) along with nitrogen and protein contents. The pH, ascorbic acid, total phenolic, and antioxidant activity decreased with an increase in drying temperatures. Inductively coupled plasma-optical emission spectrometry analysis revealed increased concentrations of majority nutrients with incremental temperature, possibly due to excessive desiccation and substantial dry matter increase. After 30 days at room temperature storage, the microbial load was within safe limits, as samples were devoid of food pathogens. Briefly, the study suggests the effectiveness of convective hot air drying (at 70–80 °C) for efficient drying and prolonged storage of stable powdered form mango peels (MP). The obtained MP powder can be used as a feedstock (with safe storability, preserved bioactive, primarily carbon and nitrogen compounds) for the year-round use in the microbial fermentation process and potential development of functional food.

Similar content being viewed by others

References

N. Karic, A.S. Maia, A. Teodorovic, N. Atanasova et al., Bio-waste valorisation: Agricultural wastes as biosorbents for removal of (in) organic pollutants in wastewater treatment. Chem. Eng. J. Adv. 9, 100239 (2022). https://doi.org/10.1016/j.ceja.2021.100239

J.X. Lai, X. Chen, J. Bu, B.B. Hu, M.J. Zhu, Direct production of astaxanthin from food waste by Phaffia rhodozyma. Process. Biochem. 113, 224–233 (2022). https://doi.org/10.1016/j.procbio.2022.01.003

R. Yukesh Kannah, J. Merrylin, T. Poornima Devi et al., Food waste valorization: biofuels and value added product recovery. Bioresour. Technol. Rep. 11, 100524 (2020). https://doi.org/10.1016/j.biteb.2020.100524

M. Nadeem, M. Imran, A. Khalique, Promising features of mango (Mangifera indica L.) kernel oil: a review. J. Food Sci. Technol. 53(5), 2185–2195 (2016). https://doi.org/10.1007/s13197-015-2166-8

Directorate of Marketing and Inspection. Post harvest profile of mango. Department of Agriculture & Cooperation, Ministry Of Agriculture, Government of India, pp. 16 (2013).

C.P. Lamilla, S.R. Vaudagna, S.M. Alzamora, M. Mozgovoj, A. Rodriguez, Effect of the high-pressure assisted-infusion processing on nutritional and antioxidant properties of mango cubes. Innov. Food Sci. Emerg. Technol. 71, 102725 (2021). https://doi.org/10.1016/j.ifset.2021.102725

J. Gomez-Caturla, J. Ivorra-Martinez, D. Lascano, R. Balart et al., Development and evaluation of novel nanofibers based on mango kernel starch obtained by electrospinning. Polym. Test. 106, 107462 (2022). https://doi.org/10.1016/j.polymertesting.2021.107462

L. Serna-Cock, E. Garcia-Gonzales, C. Torres-Leon, Agro-industrial potential of the mango peel based on its nutritional and functional properties. Food Rev. Int. 32(4), 364–376 (2015). https://doi.org/10.1080/87559129.2015.1094815

N.A.A. Aziz, L.M. Wong, R. Bhat, L.H. Cheng, Evaluation of processed green and ripe mango peel and pulp flours (Mangifera indica var. Chokanan) in term of chemical composition, antioxidant compounds and functional properties. J. Sci. Food Agric. 92(3), 557–563 (2012). https://doi.org/10.1002/jsfa.4606

D.S. Sogi, M. Siddiq, I. Greiby, K.D. Dolan, Total phenolics, antioxidant activity, and functional properties of ‘Tommy Atkins’ mango peel and kernel as affected by drying methods. Food Chem. 141(3), 2649–2655 (2013)

A. Nagel, S. Neidhart, T. Anders, P. Elstner, S. Korhummel, T. Sulzer, R. Carle, Improved processes for the conversion of mango peel into storable starting material for the recovery of functional co-products. Ind. Crops Prod. 61, 92–105 (2014). https://doi.org/10.1016/j.indcrop.2014.06.034

O.A. Raimbault, O.O. Tewe, Protein enrichment of sweet potato by solid substrate fermentation using four monoculture fungi. Niger. J. Biotechnol. 9(1), 1–4 (2001)

K.B. Munishamanna, K.B. Suresha, R. Veena, S. Subramany, Solid state fermentation of mango peel and mango seed waste by different yeasts and bacteria for nutritional improvement. Intl. J. Food. Ferment. Technol. 7(1), 111–118 (2017)

A.H. Jawad, A.F. Alkarkhi, O.C. Jason, A.M. Easa, N.N. Norulaini, Production of the lactic acid from mango peel waste—factorial experiment. J. King Saud Univ. Sci. 25, 39–45 (2013). https://doi.org/10.1016/j.jksus.2012.04.001

C.M. Ajila, K.A. Naidu, S.G. Bhat, U.J.S.P. Rao, Bioactive compounds and antioxidant potential of mango peel extract. Food Chem. 105, 982–988 (2007). https://doi.org/10.1016/j.foodchem.2007.04.052

A.L. Vásquez-Caicedo, S. Schilling, R. Carle, S. Neidhart, Effects of thermal processing and fruit matrix on-carotene stability and enzyme inactivation during transformation of mangoes into purée and nectar. Food Chem. 102, 1172–1186 (2007). https://doi.org/10.1016/j.foodchem.2006.07.005

I. Pott, S. Neidhart, W. Mühlbauer, R. Carle, Quality improvement of nonsulphited mango slices by drying at high temperatures. Innov. Food Sci. Emerg. Technol. 6, 412–419 (2005). https://doi.org/10.1016/j.ifset.2005.05.004

J. Patrón-Vázquez, L. Baas-Dzul, N. Medina-Torres, T. Ayora-Talavera, A. Sánchez-Contreras, U. García-Cruz, N. Pacheco, The effect of drying temperature on the phenolic content and functional behavior of flours obtained from lemon wastes. Agronomy 9, 1–16 (2019). https://doi.org/10.3390/agronomy9090474

R. Oliver-Simancas, M. Díaz-Maroto, M. Perez-Coello, M. Alanon, Viability of pre-treatment drying methods on mango peel by-products to preserve flavouring active compounds for its revalorisation. J. Food Eng. 279, 109953 (2020). https://doi.org/10.1016/j.jfoodeng.2020.109953

E. Dorta, M.G. Lobo, M. González, Using drying treatments to stabilise mango peel and seed: effect on antioxidant activity. LWT Food Sci. Technol. 45, 261–268 (2012). https://doi.org/10.1016/j.lwt.2011.08.016

Q. Ma, J. Bi, J. Yi, X. Wu, X. Li, Y. Zhao, Stability of phenolic compounds and drying characteristics of apple peel as affected by three drying treatments affected by three drying treatments. Food Sci. Hum. Wellness 10(2), 174–182 (2021). https://doi.org/10.1016/j.fshw.2021.02.006

B. De Ancos, C. Sánchez-Moreno, L. Zacarías, M.J. Rodrigo, S. Sáyago Ayerdí, F.J. Blancas Benítez, J.A. Domínguez Avila, G.A. González-Aguilar, Effects of two different drying methods (freeze-drying and hot air-drying) on the phenolic and carotenoid profile of ‘Ataulfo’ mango by-products. J. Food Meas. Charact. 12, 2145–2157 (2018)

A.D.P. Sanchez-Camargo, L.F. Gutierrez, S.M. Vargas, H.A. Martinez-Correa, F. Parada-Alfonso, C.E. Narvaez-Cuenca, Valorisation of mango peel: proximate composition, supercritical fluid extraction of carotenoids, and application as an antioxidant additive for edible oil. J Supercrit. Fluids 152, 104574 (2019)

AOAC, Official Method of Analysis, 18th edn. (Association of Officiating Analytical Chemists, Washington DC, 2005)

J.E. Hedge, B.T. Hofreiter, Carbohydrate Chemistry, 17th edn. (Academic Press, New York, 1962)

S. Sadasivam, A. Manickam, Biochemical Methods for Agricultural Sciences (Wiley Eastern Limited, New Delhi, 1992), pp. 6–7

G.L. Miller, Use of dinitrosalicylic acid reagent for determination of reducing sugar. Anal. Chem. 31, 426–428 (1959)

AOAC, Official Methods of Analysis, 17th edn. (The Association of Official Analytical Chemists, Gaithersburg, 2000)

S. Zinabu Hailu, M. Tassew Alemayehu, Physicochemical properties and nutritional values of Carissa Spinarum L./A “GAM” fruit. Int. J. Fruit Sci. 21(1), 826–834 (2021). https://doi.org/10.1080/15538362.2021.1936348

P.D. Pathak, S.A. Mandavgane, B.D. Kulkarni, Characterizing fruit and vegetable peels as bioadsorbents. Curr. Sci. 110(11), 2114–2123 (2016). https://doi.org/10.18520/cs/v110/i11/2114-2123

P. Nath, A. Dukare, S. Kumar, S. Kale, P. Kannaujia, Black carrot (Daucus carota subsp sativus.) anthocyanin-infused potato chips: Effect on bioactive composition, color attributes, cooking quality, and microbial stability. J. Food Process. Preserv. 46, e16180 (2022). https://doi.org/10.1111/jfpp.16180

Y.F. Cheng, R. Bhat, Functional, physicochemical and sensory properties of novel cookies produced by utilizing underutilized jering (Pithecellobium jiringa Jack.) legume flour. Food Biosci. 14, 54–61 (2016). https://doi.org/10.1016/j.fbio.2016.03.002

V.L. Singleton, R. Orthofer, R.M. Lamuela-Raventos, Analysis of total phenols and other oxidation substrates and antioxidants by means of Folin-Ciocalteu reagent. Methods Enzymol. 299, 152–179 (1999). https://doi.org/10.1016/S0076-6879(99)99017-1

R. Scherer, H.T. Godoy, Antioxidant activity index (AAI) by the 2, 2-diphenyl-1-picrylhydrazyl method. Food Chem. 112(3), 654–658 (2009). https://doi.org/10.1016/j.foodchem.2008.06.026

A. Dukare, P. Kannaujia, S. Kale, N. Indore, R.K. Singh, S. Ram, Plastic film and organic mulching increases rhizosphere microbial population, plant growth, and mineral uptake in low input grown tomato in the northwestern region of India. J. Plant Nutr. 44(6), 814–828 (2020). https://doi.org/10.1080/01904167.2020.1860219

G.R. Askari, Z. Emam-Djomeh, S.M. Mousavi, Investigation of microwave treatment on the optical properties of apple slices during drying. Drying Technol. 26, 1362–1368 (2008). https://doi.org/10.1080/07373930802333502

M. Vargas, M. Chafer, A. Albors, A. Chiralt, M. Gonzalez-Martinez, Physicochemical and sensory characteristics of yoghurt produced from mixtures of cows’ and goats’ milk. Int. J. Dairy Technol. 18, 1146–1152 (2008). https://doi.org/10.1016/j.idairyj.2008.06.007

R.R. Mphahlele, P.B. Pathare, U.L. Opara, Drying kinetics of pomegranate fruit peel (cv. Wonderful). Sci. Afr. 5, e00145 (2019). https://doi.org/10.1016/j.sciaf.2019.e00145

M. Vega-Galvez, L.P. Miranda, L.K. Diaz, L. Lopez, K. Rodriguez, K. Di Scala, Effective moisture diffusivity determination and mathematical modeling of the drying curves of the olive-waste cake. Bioresour. Technol. 101, 7265–7270 (2010). https://doi.org/10.1016/j.biortech.2010.04.040

S.A. Motri, T.F. Zagrouba, Convective drying kinetics of prickly pear seeds. IOSR. J. Environ. Sci. Toxicol. Food Technol. 6, 35–42 (2013). https://doi.org/10.9790/2402-0633542

H. Umbreen, M.U. Arshad, F. Saeed, N. Bhatty, A.I. Hussain, Probing the functional potential of agro-industrial wastes in dietary interventions. J. Food Process. Preserv. 39(6), 1665–1671 (2015). https://doi.org/10.1111/jfpp.12396

C.M. Ajila, K. Leelavathi, U.J.S. Prasada Rao, Improvement of dietary fiber content and antioxidant properties in soft dough biscuits with the incorporation of mango peel powder. J. Cereal Sci. 48, 319–326 (2008). https://doi.org/10.1016/j.jcs.2007.10.001

O. Patino-Rodriguez, L.A. Bello-Perez, E. Agama-Acevedo, G. Pacheco-Vargas, Pulp and peel of unripe stenospermocarpic mango (Mangifera indica L. cv Ataulfo) as an alternative source of starch, polyphenols and dietary fibre. Food Res. Int. 138, 109719 (2020). https://doi.org/10.1016/j.foodres.2020.109719

P. Correia, A. Leitão, M.L. Beirão-da-Costa, The effect of drying temperatures on morphological and chemical properties of dried chestnuts flours. J. Food Eng. 90, 325–332 (2009). https://doi.org/10.1016/j.jfoodeng.2008.06.040

A.K. Obeng, D. Premjet, S. Premjet, Fermentable sugar production from the peels of two durian (Duriozi bethinus Murr.) cultivars by phosphoric acid pretreatment. Resources 7, 60 (2018)

M. Lewandowska, K. Szymanska, N.D. Kordala, A. Abrowska, W. Bednarski, A. Juszczuk, Evaluation of Mucor indicus and Saccharomyces cerevisiae capability to ferment hydrolysates of rape straw and Miscanthus giganteus as affected by the pretreatment method. Bioresour. Technol. 212, 262–270 (2016). https://doi.org/10.1016/j.biortech.2016.04.063

B. McAdam, M. Brennan Fournet, P. McDonald, M. Mojicevic, Production of polyhydroxy butyrate (PHB) and factors impacting its chemical and mechanical characteristics. Polymers (Basel) 12(12), 2908 (2020). https://doi.org/10.3390/polym12122908

S. Marçal, M. Pintado, Mango peels as food ingredient/additive: nutritional value, processing, safety and applications. Trends Food Sci. Technol. 114, 472–489 (2021). https://doi.org/10.1016/j.tifs.2021.06.012

M. Wongkaew, S. Kittiwachana, N. Phuangsaijai, B. Tinpovong et al., Fruit characteristics, peel nutritional compositions, and their relationships with mango peel pectin quality. Plants 10, 1148 (2021). https://doi.org/10.3390/plants10061148

B. Kaur, P.P. Srivastav, Effect of cryogenic grinding on chemical and morphological characteristics of mango (Mangifera indica L.) peel powder. J. Food Process. Preserv. 42(4), 13583 (2018). https://doi.org/10.1111/jfpp.13583

J. Baddi, D. Vijayalakshmi, N.A. Durgannavar, R. Chandru, Mango peel: a potential source of natural bioactive phyto-nutrients in functional food. Asian J. Dairy Food Res. 34, 75 (2015). https://doi.org/10.5958/0976-0563.2015.00016.0

W. Somsub, R. Kongkachuichai, P. Sungpuag, R. Charoensiri, Effects of three conventional cooking methods on vitamin c, tannin, myo-inositol phosphates contents in selected Thai vegetables. J. Food Compos. Anal. 21(2), 187–197 (2008). https://doi.org/10.1016/j.jfca.2007.08.002

C.I. Owuarnanarn, C.I. Iwuoha, N.C. Onuegbu, C.C. Ogueke, J.N. Nwosu, Quality characteristics of processed flours from trifoliate yarn (Dioscorea dumetorum) as influenced by steeping and boiling in varying concentration of Trona solution over time. Am. J. Food Technol. 8(3), 162–172 (2013). https://doi.org/10.3923/ajft.2013.162.172

C.S. Shivamathi, S. Gunaseelan, M.R. Soosai, N.S. Vignesh, I.M.G. Moorthy, Process optimization and characterization of pectin derived from underexploited pineapple peel biowaste as a value added product. Food Hydrocoll. 123, 107141 (2021). https://doi.org/10.1016/j.foodhyd.2021.107141

S.S. Hosseini, F. Khodaiyan, M. Kazemi, Z. Najari, Optimization and characterization of pectin extracted from sour orange peel by ultrasound assisted method. Int. J. Biol. Macromol. 125, 621–629 (2019). https://doi.org/10.1016/j.ijbiomac.2018.12.096

R.F. Dibanda, E.P. Akdowa, Q.M. Tongwa et al., Effect of microwave blanching on antioxidant activity, phenolic compounds and browning behaviour of some fruit peelings. Food Chem. 302, 125308 (2020). https://doi.org/10.1016/j.foodchem.2019.125308

V.R. Lebaka, Y.J. Wee, W. Ye, M. Korivi, Nutritional composition and bioactive compounds in three different parts of mango fruit. Int. J. Environ. Res. Public Health 18, 741 (2021). https://doi.org/10.3390/ijerph18020741

S. Yatnatti, D. Vijayalakshmi, R. Chandru, Processing and nutritive value of mango seed kernel flour. Curr. Res. Nutr. Food Sci. 2(3), 170–175 (2014). https://doi.org/10.12944/CRNFSJ.2.3.10

S. Mohammed, M. Edna, K. Siraj, The effect of traditional and improved solar drying methods on the sensory quality and nutritional composition of fruits: a case of mangoes and pineapples. Heliyon 6, e04163 (2020). https://doi.org/10.1016/j.heliyon.2020.e04163

S. Rafiq, B. Singh, Y. Gat, Effect of different drying techniques on chemical composition, color and antioxidant properties of kinnow (Citrus reticulata) peel. J. Food Sci. Technol. 56(5), 2458–2466 (2019). https://doi.org/10.1007/s13197-019-03722-9

S. Suna, C. Tamer, B. Inceday, G. Sinir, O. Copur, Impact of drying methods on physicochemical and sensory properties of apricot pestil. Indian J. Tradit. Knowl. 13, 47–55 (2014)

B. Dereje, A. Girima, Effect of pretreatments and drying methods on the rehydration ratio of dried mango (Mangifera Indica L.) slices and evaluation of some properties of its peel flours. Food Sci. Qual. Manage. (2020). https://doi.org/10.7176/FSQM/96-01

L. Reddy, V.S. Obulam, Y.J. Wee, Production of ethanol from mango (Mangifera indica L.) peel by Saccharomyces cerevisiae CFTRI101. Afr. J. Biotechnol. 10, 4183–4189 (2011). https://doi.org/10.5897/AJB10.2286

F. Fernandes, A. Farias, L. Carneiro, R. Santos, R. Torres, J. Silva, J. Souza, E. Souza, Dilute acid hydrolysis of wastes of fruits from amazon for ethanol production. AIMS Bioeng. 8(3), 221–234 (2021). https://doi.org/10.3934/bioeng.2021019

Z. Yang, H. Kang, Y. Guo, G. Zhuang, Z. Bai et al., Dilute-acid conversion of cotton straw to sugars and levulinic acid via 2-stage hydrolysis. Ind. Crops Prod. 46, 205–209 (2013). https://doi.org/10.1016/j.indcrop.2013.01.031

J. Cheng, Q. Liu, Y. Zhang, Z. Wang, M. Gao, S. Li, Preparation and properties of antibacterial and antioxidant mango peel extract/polyvinyl alcohol composite films. J. Food Process. Preserv. 46, e16206 (2022). https://doi.org/10.1111/jfpp.16206

A.S. Dukare, R.K. Singh, R.K. Jangra, B. Bhushan, Non-fungicides-based promising technologies for managing post-production penicillium induced spoilage in horticultural commodities: a comprehensive review. Food Rev. Int. 38(3), 227–267 (2022). https://doi.org/10.1080/87559129.2020.1727497

D. Alp, Ö. Bulantekin, The microbiological quality of various foods dried by applying different drying methods: a review. Eur. Food Res. Technol. 247, 1333–1343 (2021). https://doi.org/10.1007/s00217-021-03731-z

Acknowledgements

This study was funded by Indian Council of Agricultural Research (ICAR), Department of Agricultural Research and Education (DARE), Government of India. The authors of this manuscript acknowledge the Director, ICAR-CIPHET, Ludhiana, for the financial assistance and technical facilities required for carrying out the experimental work under the institute project on “Microbial production of PolyHydroxyButyrate (bioplastic) using mango by-products.” Further, we are very grateful to the citrus estate laboratory, State Horticulture Department, Abohar, Punjab (India), for providing ICP-OES facilities for mineral analysis.

Author information

Authors and Affiliations

Contributions

AD: Conceptualization, methodology, investigation, validation, formal analysis, writing—original draft preparation; MKS, methodology, investigation, validation, data analysis, contribution in writing; BB: methodology, investigation, validation, formal analysis and contribution in writing in relevant section; SD: data analysis, writing—review and editing, final draft supervision and monitoring. All authors read and approved the final manuscript.

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no confict of interest.

Ethical approval

This article does not contain any studies with human participants or animals performed by any of the authors.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Dukare, A., Samota, M.K., Bibwe, B. et al. Using convective hot air drying to stabilize mango peel (Cv-Chausa): evaluating effect on bioactive compounds, physicochemical attributes, mineral profile, recovery of fermentable sugar, and microbial safety. Food Measure 16, 3897–3909 (2022). https://doi.org/10.1007/s11694-022-01496-x

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-022-01496-x