Abstract

Grape pomace is a high potential by-product due to its content of valuable compounds, such as pectin. It is highly perishable and requires pretreatment for its conservation. Therefore, this work aims to evaluate the effect of four drying methods: convective drying, freeze-drying, infrared-radiation drying, and solar drying, on the properties of pectin fractions obtained from pisco grape pomace. Freeze-drying and convection drying reported the highest extraction yields. The drying of grape pomace by all the methods evaluated decreased the degree of esterification on the pectins. The highest reducing sugar content (19.8%) and antioxidant capacity (7238 µmol TE/100 g d.m.) were obtained from freeze-drying pretreatment. The highest galacturonic acid content (28.4%) and molecular weight (63.3 kDa) were found in the pectin obtained from the convective drying pretreatment. Thus, each drying method evaluated affects the pectin’s physicochemical properties differently. Also, pectin fractions with a high degree of methoxylation and a high antioxidant capacity were obtained from pisco grape pomace. This study provides information about the effect of drying as a pretreatment of pisco grape pomace on the properties of the pectin obtained from it.

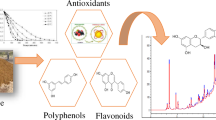

Graphical abstract

Similar content being viewed by others

References

FAO. (2019). The State of Food and Agriculture. In Moving forward on food loss and waste reduction. Licence: CC BY-NC-SA 3.0 IGO

K.L. Ong, G. Kaur, N. Pensupa et al., Trends in food waste valorization for the production of chemicals, materials and fuels: Case study South and Southeast Asia. Bioresour Technol 248, 100–112 (2018). https://doi.org/10.1016/j.biortech.2017.06.076

S. Djilas, J. Čanadanović-Brunet, G. Ćetković, By-products of fruits processing as a source of phytochemicals. Chem Ind Chem Eng Q 15, 191–202 (2009). https://doi.org/10.2298/CICEQ0904191D

C. Beres, G.N.S. Costa, I. Cabezudo et al., Towards integral utilization of grape pomace from winemaking process: A review. Waste Manag 68, 581–594 (2017). https://doi.org/10.1016/j.wasman.2017.07.017

R.A. Muhlack, R. Potumarthi, D.W. Jeffery, Sustainable wineries through waste valorisation: A review of grape marc utilisation for value-added products. Waste Manag 72, 99–118 (2018). https://doi.org/10.1016/j.wasman.2017.11.011

G. Spigno, L. Marinoni, G.D. Garrido, 1—State of the Art in Grape Processing By-Products, in Handbook of Grape Processing By-Products. ed. by C.M. Galanakis (Academic Press, Cambridge, 2017), pp. 1–27

R.G. Maroun, H.N. Rajha, E. Vorobiev, N. Louka, 7—Emerging Technologies for the Recovery of Valuable Compounds From Grape Processing By-Products, in Handbook of Grape Processing By-Products. ed. by C.M. Galanakis (Academic Press, Cambridge, 2017), pp. 155–181

L. Flutto, PECTIN | Food Use, in Encyclopedia of Food Sciences and Nutrition, 2nd edn., ed. by B. Caballero (Academic Press, Oxford, 2003), pp. 4449–4456

K.J. Nunan, I.M. Sims, A. Bacic et al., Changes in cell wall composition during ripening of grape berries. Plant Physiol 118, 783–792 (1998). https://doi.org/10.1104/pp.118.3.783

K.R. Corbin, Y.S.Y. Hsieh, N.S. Betts et al., Grape marc as a source of carbohydrates for bioethanol: Chemical composition, pre-treatment and saccharification. Bioresour Technol 193, 76–83 (2015). https://doi.org/10.1016/j.biortech.2015.06.030

R. Apolinar-Valiente, I. Romero-Cascales, E. Gómez-Plaza et al., Cell wall compounds of red grapes skins and their grape marcs from three different winemaking techniques. Food Chem 187, 89–97 (2015). https://doi.org/10.1016/j.foodchem.2015.04.042

R. Minjares-Fuentes, A. Femenia, M.C. Garau, J.A. Meza-Velázquez, Ultrasound-assisted extraction of pectins from grape pomace using citric acid: A response surface methodology approach. Carbohydr Polym 106, 179–189 (2014). https://doi.org/10.1016/j.carbpol.2014.02.013

C. Colodel, L.C. Vriesmann, R.F. Teófilo, C.L. de Oliveira Petkowicz, Optimization of acid-extraction of pectic fraction from grape (Vitis vinifera cv. Chardonnay) pomace, a Winery Waste. Int J Biol Macromol 161, 204–213 (2020). https://doi.org/10.1016/j.ijbiomac.2020.05.272

M.R. González-Centeno, C. Rosselló, S. Simal et al., Physico-chemical properties of cell wall materials obtained from ten grape varieties and their byproducts: grape pomaces and stems. LWT—Food Sci Technol 43, 1580–1586 (2010). https://doi.org/10.1016/j.lwt.2010.06.024

A.M. Goula, K. Thymiatis, K. Kaderides, Food and Bioproducts Processing Valorization of grape pomace : Drying behavior and ultrasound extraction of phenolics. Food Bioprod Process 100, 132–144 (2016). https://doi.org/10.1016/j.fbp.2016.06.016

C. Drosou, K. Kyriakopoulou, A. Bimpilas, M. Krokida, A comparative study on different extraction techniques to recover red grape pomace polyphenols from vinification prets. Ind Crop Prod 75, 141–149 (2015). https://doi.org/10.1016/j.indcrop.2015.05.063

M.A. Monsoor, Effect of drying methods on the functional properties of soy hull pectin. Carbohydr Polym 61, 362–367 (2005). https://doi.org/10.1016/j.carbpol.2005.06.009

OIV (2019) Statistical Report on World Vitiviniculture (pp. 1–23). International Organisation of Vine and Wine. https://www.oiv.int/en/oiv-life/oiv-2019-report-on-the-world-vitivinicultural-situation

SAG (2020) Catastro Vitícola Nacional 2018. Servicio Agricola Ganadero, División de Protección Agrícola y Forestal, Subdepartamento de Viñas y Vinos, Chile. http://www.sag.cl/ambitos-de-accion/catastro-viticola-nacional/1490/publicaciones

A. Vega-Gálvez, M. Miranda, C. Bilbao-Sáinz et al., Empirical modeling of drying process for apple (cv. Granny Smith) slices at different air temperatures. J Food Process Preserv 32, 972–986 (2008). https://doi.org/10.1111/j.1745-4549.2008.00227.x

A. Vega-Gálvez, J. Poblete, I. Quispe-Fuentes et al., Chemical and bioactive characterization of papaya (Vasconcellea pubescens) under different drying technologies: evaluation of antioxidant and antidiabetic potential. J Food Meas Charact 13, 1980–1990 (2019). https://doi.org/10.1007/s11694-019-00117-4

C.H. Geerkens, A. Nagel, K.M. Just et al., Mango pectin quality as influenced by cultivar, ripeness, peel particle size, blanching, drying, and irradiation. Food Hydrocoll 51, 241–251 (2015). https://doi.org/10.1016/j.foodhyd.2015.05.022

A. Ninčević Grassino, M. Brnčić, D. Vikić-Topić et al., Ultrasound assisted extraction and characterization of pectin from tomato waste. Food Chem 198, 93–100 (2016). https://doi.org/10.1016/j.foodchem.2015.11.095

A.M. Bochek, N.M. Zabivalova, G.A. Petropavlovskii, Determination of the esterification degree of polygalacturonic Acid. Russ J Appl Chem 74, 796–799 (2001). https://doi.org/10.1023/A:1012701219447

M.M. Bradford, A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal Biochem 72, 248–254 (1976). https://doi.org/10.1016/0003-2697(76)90527-3

N. Blumenkrantz, G. Asboe-Hansen, New method for quantitative determination of uronic acids. Anal Biochem 54, 484–489 (1973). https://doi.org/10.1016/0003-2697(73)90377-1

P. Li, J. Xia, Z. Nie, Y. Shan, Pectic oligosaccharides hydrolyzed from orange peel by fungal multi- enzyme complexes and their prebiotic and antibacterial potentials. LWT—Food Sci Technol 69, 203–210 (2016). https://doi.org/10.1016/j.lwt.2016.01.042

D. Sun, X. Chen, C. Zhu, Physicochemical properties and antioxidant activity of pectin from hawthorn wine pomace: A comparison of different extraction methods. Int J Biol Macromol 158, 1239–1247 (2020). https://doi.org/10.1016/j.ijbiomac.2020.05.052

L. Zhang, J. Li, S. Hogan et al., Inhibitory effect of raspberries on starch digestive enzyme and their antioxidant properties and phenolic composition. Food Chem 119, 592–599 (2010). https://doi.org/10.1016/j.foodchem.2009.06.063

J.A. Moses, T. Norton, K. Alagusundaram, B.K. Tiwari, Novel drying techniques for the food industry. Food Eng Rev 6(3), 43–55 (2014). https://doi.org/10.1007/S12393-014-9078-7

F. Dranca, M. Oroian, Extraction, purification and characterization of pectin from alternative sources with potential technological applications. Food Res Int 113, 327–350 (2018). https://doi.org/10.1016/j.foodres.2018.06.065

M. Güzel, Ö. Akpınar, Food and Bioproducts Processing Valorisation of fruit by-products : Production characterization of pectins from fruit peels. Food Bioprod Process 115, 126–133 (2019). https://doi.org/10.1016/j.fbp.2019.03.009

B. Muhoza, S. Xia, J. Cai et al., Food Hydrocolloids Gelatin and pectin complex coacervates as carriers for cinnamaldehyde: Effect of pectin esteri fi cation degree on coacervate formation, and enhanced thermal stability. Food Hydrocolloids 87, 712–722 (2019). https://doi.org/10.1016/j.foodhyd.2018.08.051

J.P. Van Buren, CHAPTER 1 - Function of Pectin in Plant Tissue Structure and Firmness, in The Chemistry and Technology of Pectin. ed. by R.H. Walter (Academic Press, San Diego, 1991), pp. 1–22

Z. Qin, H.-M. Liu, X.-C. Cheng, X.-D. Wang, Effect of drying pretreatment methods on structure and properties of pectins extracted from Chinese quince fruit. Int J Biol Macromol 137, 801–808 (2019). https://doi.org/10.1016/j.ijbiomac.2019.06.209

E. Tsami, G.K. Vagenas, D. Marinos-Kouris, Moisture sorption isotherms of pectins. J Food Process Preserv 16, 151–161 (1992). https://doi.org/10.1111/j.1745-4549.1992.tb00197.x

D. Dehnad, S.M. Jafari, M. Afrasiabi, Influence of drying on functional properties of food biopolymers: From traditional to novel dehydration techniques. Trends Food Sci Technol 57, 116–131 (2016). https://doi.org/10.1016/j.tifs.2016.09.002

J. Mierczyńska, J. Cybulska, A. Zdunek, Rheological and chemical properties of pectin enriched fractions from different sources extracted with citric acid. Carbohydr Polym 156, 443–451 (2017). https://doi.org/10.1016/j.carbpol.2016.09.042

V.V. Smirnov, V.V. Golovchenko, F.V. Vityazev et al., The antioxidant properties of pectin fractions isolated from vegetables using a simulated gastric fluid. J Chem (2017). https://doi.org/10.1155/2017/5898594

A.A. Sundar-Raj, S. Rubila, R. Jayabalan, thottiam Vasudevan R, A review on pectin: Chemistry due to general properties of pectin and its pharmaceutical uses. Sci Rep 1, 550–553 (2012)

R. Apak, S. Gorinstein, V. Böhm et al., Methods of measurement and evaluation of natural antioxidant capacity/activity (IUPAC Technical Report). Pure Appl Chem 85, 957–998 (2013). https://doi.org/10.1351/PAC-REP-12-07-15

X. Wang, Q. Chen, X. Lü, Pectin extracted from apple pomace and citrus peel by subcritical water. Food Hydrocoll 38, 129–137 (2014). https://doi.org/10.1016/j.foodhyd.2013.12.003

K. Nara, A. Yamaguchi, N. Maeda, H. Koga, Antioxidative activity of water soluble polysaccharide in pumpkin fruits (Cucurbita maxima Duchesne). Biosci Biotechnol Biochem 73, 1416–1418 (2009). https://doi.org/10.1271/bbb.80529

Acknowledgements

The authors wish to acknowledge ANID doctoral scholarship N° 21181191 and ANID Fondecyt Regular research Grant No. 1190260.

Funding

Agencia Nacional de Investigación y Desarrollo de Chile (ANID),doctoral scholarship no 21181191, Pamela Vásquez, Fondecyt research Grant No. 1190260, Claudia Bernal.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no relevant financial or non-financial interest to disclose.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

Vásquez, P., Vega-Gálvez, A. & Bernal, C. Production of antioxidant pectin fractions, drying pretreatment methods and physicochemical properties: towards pisco grape pomace revalue. Food Measure 16, 3722–3734 (2022). https://doi.org/10.1007/s11694-022-01482-3

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-022-01482-3