Abstract

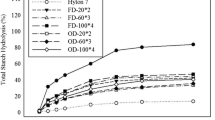

In the present investigation, rice starch isolated from broken rice of Ranjit variety of Assam was modified by osmotic pressure treatment (OPT) and heat moisture treatment (HMT). Response surface methodology (RSM) based on face-centered central composite design (FCCD) was used to optimize the process conditions of OPT and HMT with independent variables namely, temperature (X1:100–120 °C) and time (X2:15–45 min); and additionally moisture content (X3:20–30%) in HMT. The aim was to obtain higher final viscosity, setback viscosity and gel hardness; lower swelling power and solubility of rice starch on modification. All the independent factors were established as significant (p < 0.05) in deriving the OPT and HMT starches. Temperature of 117 °C and time of 35 min were the optimal conditions for OPT that gave final viscosity of 4718.42cP, setback viscosity of 2312.27cP, gel hardness of 73.12 g, swelling power of 16.21 g/g and solubility of 11.45%. The FCCD resulted in final viscosity of 5341.62cP, setback viscosity of 3337.05cP, gel hardness of 75.11 g, swelling power of 10.57 g/g and solubility of 5.39% at optimum conditions, namely, temperature of 111 °C, moisture content of 29% and time of 45 min for HMT. The response surface plots showed that OPT caused increase in the responses with increasing time and temperature except swelling power. Final viscosity, setback and gel hardness tended to increase but swelling power and solubility reduced in HMT with increase in time, temperature and moisture content. These research findings open up scope for further investigation on the OPT and HMT rice starches and their effective application in rice noodle processing.

Similar content being viewed by others

References

H. Dutta, C.L. Mahanta, Effect of hydrothermal treatment varying in time and pressure on the properties of parboiled rices with different amylose content. Food Res. Int. 49(2), 655–663 (2012)

S.P. Koh, K. Long, Comparison of physical, chemical and functional properties of broken rice and breadfruit starches against cassava starch. J. Trop. Agric. and Food Sci. 40(2), 211–219 (2012)

L.C. Okpala, P.N. Egwu, Utilisation of broken rice and cocoyam flour blends in the production of biscuits. Niger. Food J. 33(1), 8–11 (2015)

V.M. Limberger, F.B. Brum, L.D. Patias, A.P. Daniel, C.G. Comarela, T. Emanuelli, L.P. da Silva, Modified broken rice starch as fat substitute in sausages. Food Sci. Technol (Campinas) 31(3), 789–792 (2011)

S.C. Alcázar-Alay, M.A.A. Meireles, Physicochemical properties, modifications and applications of starches from different botanical sources. Food Sci. Technol. (Campinas) 35(2), 215–236 (2015)

D. Mudgil, S. Barak, B.S. Khatkar, Optimization of textural properties of noodles with soluble fiber, dough mixing time and different water levels. J. Cereal Sci. 69, 104–110 (2016)

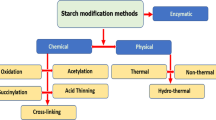

J.N. Bemiller, Starch modification: challenges and prospects. Starch 49, 127–131 (1997)

P. Halley, L. Avérous, Starch polymers: from genetic engineering to green applications, 1st edn. (Elsevier, Alpharetta, 2014), p. 485

E. da Rosa Zavareze, A.R.G. Dias, Impact of heat-moisture treatment and annealing in starches: a review. Carbohydr. Polym. 83(2), 317–328 (2011)

K.O. Adebowale, T.A. Afolabi, B.I. Olu-Owolabi, Hydrothermal treatments of finger millet (Eleusine coracana) starch. Food Hydrocoll. 19(6), 974–983 (2005)

E. da Rosa Zavareze, C.R. Storck, L.A.S. de Castro, M.A. Schirmer, A.R.G. Dias, Effect of heat-moisture treatment on rice starch of varying amylose content. Food Chem. 121(2), 358–365 (2010)

Z. Maache-Rezzoug, I. Zarguili, C. Loisel, D. Queveau, A. Buleon, Structural modifications and thermal transitions of standard maize starch after DIC hydrothermal treatment. Carbohydr. Polym. 74(4), 802–812 (2008)

S.K. Kim, M.S. Shin, Modification of physicochemical properties of rice starch by heat-moisture treatment. Hanguk Nonghwahak Hoechi 33(1), 1–7 (1990)

L.S. Collado, H. Corke, Heat-moisture treatment effects on sweet potato starches differing in amylose content. Food Chem. 65(3), 339–346 (1999)

H.J. Chung, Q. Liu, R. Hoover, The impact of annealing and heat-moisture treatments on rapidly digestible, slowly digestible and resistant starch levels in native and gelatinized corn, pea and lentil starches. Carbohydr. Polym. 75(3), 436–447 (2009)

A.K. Anderson, H.S. Guraya, C. James, L. Salvaggio, Digestibility and pasting properties of rice starch heat-moisture treated at the melting temperature (Tm). Starch-Stärke 54(9), 401–409 (2002)

C. Pukkahuta, S. Shobsngob, S. Varavinit, Effect of osmotic pressure on starch: New method of physical modification of starch. Starch-Stärke 59(2), 78–90 (2007)

C. Pukkahuta, B. Suwannawat, S. Shobsngob, S. Varavinit, Comparative study of pasting and thermal transition characteristics of osmotic pressure and heat–moisture treated corn starch. Carbohydr. Polym. 72(3), 527–536 (2008)

T.O. Fasuan, C.T. Akanbi, Application of osmotic pressure in modification of Amaranthus viridis starch. LWT-Food Sci. Technol. 96, 182–192 (2018)

J.L. Jane, Mechanism of starch gelatinization in neutral salt solutions. Starch-Stärke 45(5), 161–166 (1993)

C.L. Alsberg, Studies upon starch. Ind. Eng. Chem. 18(2), 190–193 (1926)

C.E. Mangels, C.H. Bailey, Relation of concentration to action of gelatinizing agents on starch1. J. Am. Chem. Soc. 55(5), 1981–1988 (1933)

M.A. Bezerra, R.E. Santelli, E.P. Oliveira, L.S. Villar, L.A. Escaleira, Response surface methodology (RSM) as a tool for optimization in analytical chemistry. Talanta 76(5), 965–977 (2008)

O.E. Dudu, A.B. Oyedeji, S.A. Oyeyinka, Y. Ma, Impact of steam-heat-moisture treatment on structural and functional properties of cassava flour and starch. Int. J. Biol. Macromol. 126, 1056–1064 (2019)

O.E. Dudu, L. Li, A.B. Oyedeji, S.A. Oyeyinka, Y. Ma, Structural and functional characteristics of optimised dry-heat-moisture treated cassava flour and starch. Int. J. Biol. Macromol. 133, 1219–1227 (2019)

S. Cham, P. Suwannaporn, Effect of hydrothermal treatment of rice flour on various rice noodles quality. J. Cereal Sci. 51(3), 284–291 (2010)

R. Karmakar, D.K. Ban, U. Ghosh, Comparative study of native and modified starches isolated from conventional and nonconventional sources. Int. Food Res. J. 21(2), 597–602 (2014)

A.O. Ashogbon, E.T. Akintayo, Recent trend in the physical and chemical modification of starches from different botanical sources: a review. Starch-Stärke 66(1–2), 41–57 (2014)

K. Neelam, S. Vijay, S. Lalit, Various techniques for the modification of starch and the applications of its derivatives. Int. Res. J. Pharm. 3(5), 25–31 (2012)

C. Pukkahuta, S. Varavinit, Structural transformation of sago starch by heat-moisture and osmotic-pressure treatment. Starch-Stärke 59(12), 624–631 (2007)

S. Yoenyongbuddhagal, A. Noomhorm, Effect of physicochemical properties of high-amylose Thai rice flours on vermicelli quality. Cereal Chem. 79(4), 481–485 (2002)

M. Bhattacharya, S.Y. Zee, H. Corke, Physicochemical properties related to quality of rice noodles. Cereal Chem. 76(6), 861–867 (1999)

R. Hormdok, A. Noomhorm, Hydrothermal treatments of rice starch for improvement of rice noodle quality. LWT Food Sci. Technol. 40, 1723–1731 (2007)

K. Lorlowhakarn, O. Naivikul, Modification of rice flour by heat moisture treatment (HMT) to produce rice noodles. Kasetsart J. 40(2), 135–143 (2006)

C. Chaichaw, O. Naivikul, M. Thongngam, Effect of heat-moisture treatment on qualities of gluten-free alkaline rice noodles from various rice flour varieties. Kasetsart J. (Nat. Sci.) 45(3), 490–499 (2011)

N.S. Sodhi, N. Singh, Morphological, thermal and rheological properties of starches separated from rice cultivars grown in India. Food Chem. 80(1), 99–108 (2003)

AOAC, Official methods of Analysis of the Association of Official Analytical Chemistry, 15th edn. (AOAC, Arlington, 1990)

W. Horwitz, G. Latimer, AOAC-Association of official analytical chemists, Official Methods of Analysis of AOAC International, 18th edn. (AOAC, Gaithersburg, 2005), pp. 75–76

O.S. Lawal, R. Lapasin, B. Bellich, T.O. Olayiwola, A. Cesàro, M. Yoshimura, K. Nishinari, Rheology and functional properties of starches isolated from five improved rice varieties from West Africa. Food Hydrocoll. 25(7), 1785–1792 (2011)

A.I. Khuri, J.A. Cornell, Response surfaces: designs and analyses, 2nd edn. (Routledge, Abingdon, 2018), pp. 165–169

L.S. Collado, H. Corke, Properties of starch noodles as affected by sweetpotato genotype. Cereal Chem. 74(2), 182–187 (1997)

G. Chen, K. Xiong, J. Peng, J. Chen, Optimization of combined mechanical activation-roasting parameters of titania slag using response surface methodology. Adv. Powder Technol. 21(3), 331–335 (2010)

G. Chen, J. Chen, C. Srinivasakannan, J. Peng, Application of response surface methodology for optimization of the synthesis of synthetic rutile from titania slag. Appl. Surf. Sci. 258(7), 3068–3073 (2012)

R. Hoover, T. Vasanthan, The effect of annealing on the physicochemical properties of wheat, oat, potato and lentil starches. J. Food Biochem. 17, 303–325 (1994)

J.N. BeMiller, R.L. Whistler, Carbohydrates, in Food chemistry, 3rd edn., ed. by O.R. Fennema (Marcel Dekker, New York, 1996), pp. 157–224

J.P. Mua, D.S. Jackson, Relationships between functional attributes and molecular structures of amylose and amylopectin fractions from corn starch. J. Agric. Food Chem. 45, 3848–3854 (1997)

K.S. Sandhu, N. Singh, Some properties of corn starches II: physicochemical, gelatinization, retrogradation, pasting and gel textural properties. Food Chem. 101, 1499–1507 (2007)

H. Liu, H. Corke, L. Ramsden, The effect of autoclaving on the acetylation of ae, wx and normal maize starches. Starch- Stärke 52, 353–360 (2000)

S. Puncha-arnon, D. Uttapap, Rice starch vs. rice flour: differences in their properties when modified by heat–moisture treatment. Carbohydr. Polym. 91, 85–91 (2013)

L.H. Xie, S.Q. Tang, J. Luo, X.J. Wei, G.N. Shao, G.A. Jiao, Z.H. Sheng, P.S. Hu, Physiochemical properties of rice starch for production of vermicelli with premium quality. J. Food Sci. Technol. 54(12), 3928–3935 (2017)

M. Kaur, N. Singh, K.S. Sandhu, H.S. Guraya, Physicochemical, morphological, thermal and rheological properties of starches separated from kernels of some Indian mango cultivars (Mangifera indica L.). Food Chem. 85(1), 131–140 (2004)

J. Bao, Rice: chemistry and technology, 4th edn. (Elsevier, Cambridge, 2018), pp. 557–558

V.P. Pinto, N.L. Vanier, B. Klein, E.R. Zavareze, M.C. Elias, L.C. Gutkoski, Physicochemical, crystallinity, pasting and thermal properties of heat–moisture-treated pinhao starch. Starch/Starke 64, 855–863 (2012)

V. Varatharajan, R. Hoover, Q. Liu, K. Seetharaman, The impact of heat-moisture treatment on the molecular structure and physicochemical properties of normal and waxy potato starches. Carbohydr. Polym. 81, 466–475 (2010)

V. Varatharajan, R. Hoover, J. Li, T. Vasanthan, K.K.M. Nantanga, K. Seetharaman, Q. Liu, E. Donner, S. Jaiswal, R.N. Chibbar, Impact of structural changes due to heat-moisture treatment at different temperatures on the susceptibility of normal and waxy potato starches towards hydrolysis by porcine pancreatic alpha amylase. Food Res. Int. 44(9), 2594–2606 (2011)

Z. Sui, T. Yao, Y. Zhao, X. Ye, X. Kong, L. Ai, Effects of heat–moisture treatment reaction conditions on the physicochemical and structural properties of maize starch: Moisture and length of heating. Food Chem. 173, 1125–1132 (2015)

Acknowledgements

The authors would like to thank the Department of Food Engineering and Technology, School of Engineering, Tezpur University, Assam, India for the facilities used in this study.

Funding

This research did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sectors.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Gayary, M.A., Mahanta, C.L. Optimization of process parameters of osmotic pressure treatment and heat moisture treatment for rice starch using response surface methodology. Food Measure 14, 2862–2877 (2020). https://doi.org/10.1007/s11694-020-00531-z

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-020-00531-z