Abstract

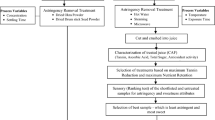

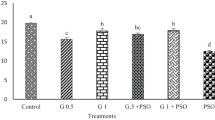

The application of enzymatic peeling technology aided with vacuum infusion has been studied extensively in this study to ease the peeling process of key lime (Citrus aurantifolia) fruit. Through response surface methodology, the optimum parameters such as vacuum pressure (450–600 mmHg), pectinase concentration (0.5–1.0%, v/v), duration of soaking time (15–45 min) and their effects on physicochemical properties of key lime fruit have been determined. The optimal conditions determined in this study were 600 mmHg of vacuum pressure, 0.93% v/v of pectinase concentration and 45 min of soaking time. The physicochemical properties analysed such as colour, pH, titratable acidity, total soluble solids, moisture content, and ascorbic acid content show no significant (p > 0.05) effect of enzymatic-peeling on quality parameters of key lime fruit products. The intensity of puree colour was significantly (p ≤ 0.05) improved by the vacuum-aided enzymatic treatment. Overall, vacuum-aided enzymatic treatment is an improved peeling method compared to the conventional method as it simplifies the process, reduces processing time and retains quality parameters of the key lime fruit products.

Similar content being viewed by others

References

M.S. Ladaniya, Citrus Fruit: Biology, Technology, and Evaluation, 1st edn. (Elsevier Inc., Atlanta, 2008), pp. 1–10

USDA, Brazil drives global orange production decline. https://public.govdelivery.com/accounts/USDAFAS/subscriber/new. Accessed 26 Jan 2018

A. Perez, K. Plattner, Fruits and tree nuts outlook (FTS-357) USDA. Accessed 26 Sept 2014

MOA, Third National Agricultural Policy (1998-2010). Ministry of Agriculture and Agro-based Industry Malaysia (2016)

SABA, 38 benefits of lime (Kaccha nimbu) for skin, hair, and health. http://www.stylecraze.com/articles/benefits-of-lime-for-skin-hair-and-health. Accessed 31 Aug 2018

Z. Zou, W. Xi, Y. Hu, C. Nie, Z. Zhou, Food Chem. 196, 885 (2016)

S.K. Fagodia, H.P. Singh, D.R. Batish, R.K. Kohli, Ind. Crop Prod. 108, 708 (2017)

A. Hazniza, A. Osman, H.M. Ghazali, R.A. Rahman, H. Adnan, A. Osman, R.A. Rahman, J. Trop. Agric. Sci. 37(1), 67 (2009)

I. Toker, A. Bayιndιrlι, Lebenson Wiss Technol. 36(2), 215 (2003)

M. Noguchi, Y. Ozaki, J. Azuma, Jpn. Agric. Res. Q. 49(4), 313 (2015)

M.T. Pretel, P. Sanchez-Bel, I. Egea, F. Romojaro, Tree For. Sci. Biotechnol. 2(Special Issue 1), 52 (2008)

M.T. Pretel, A. Amoros, M.A. Botella, M. Serrano, F. Romojaro, J. Sci. Food Agric. 84, 86 (2005)

A. Hassan, Z. Othman, J. Siriphanich, Postharvest Biology and Technology of Tropical and Subtropical Fruits, 1st edn. (Woodhead Publishing, Cambridge, 2011), pp. 194–217

M.T. Pretel, P. Lozano, F. Riquelme, F. Romojaro, Process Biochem. 32(1), 43 (1997)

M.J. Rodrigo, B. Alquezar, E. Alos, J. Lado, L. Zacarias, Sci. Hortic. 163, 46 (2013)

F. Liu, A. Osman, S. Yusof, H.M. Ghazali, J. Food Process. Preserv. 28(5), 336 (2004)

P.B. Pathare, U.L. Opara, F.A.J. Al-Said, Food Bioprocess Technol. 6(1), 36 (2013)

R. Assawarachan, A. Noomhorm, Int. J. Agric. Biol. Eng. 3(1), 74 (2010)

R. Shamsudin, I.O. Mohamed, N.K.M. Yaman, J. Food Eng. 66, 395 (2005)

S. Ranganna, Handbook of Analysis and Quality Control for Fruit and Vegetable Products, 2nd edn. (Tata McGraw Hill Publishing Company Limited, New Delhi, 1997), pp. 11–12

AOAC, Official Methods of Analysis, 18th edn. (Association of Official Analytical Chemists, Virginia, 2005)

AOAC, Official Methods of Analysis, 17th edn. (Association of Official Analytical Chemists, Virginia, 2000)

J. Bruemmer, A. Griffin, Florida State Hortic. Soc. 91, 112 (1978)

Y. Liu, E. Heying, S.A. Tanumihardjo, Compr. Rev. Food Sci. Food Saf. 11(6), 530 (2012)

S.J. Kays, Postharvest Biol. Technol. 15(3), 233 (1999)

C. Sanchez, A.B. Baranda, I. Martínez de Maranon, Food Chem. 163, 37 (2014)

L. Wang, Q. Mu, W. Li, S. Wang, S. Zhang, J. Food Sci. 34(20), 312 (2013)

Z.W. Cui, S.Y. Xu, D.W. Sun, Drying Technol. 22(3), 563 (2004)

P. Sanchez-Bel, I. Egea, M. Serrano, A. Romojaro, M.T. Pretel, Food Sci. Technol. Int. 18(1), 63–72 (2012)

K.L. Penniston, S.Y. Nakada, R.P. Holmes, D.G. Assimos, J. Endourol. 22(3), 567 (2008)

Y. Yamaki, J. Jpn. Soc. Hortic. Sci. 57, 568 (1989)

R.L. Shrestha, D. Datta, D.M. Dhakal, K.P. Gautum, S. Paudyal, Am. J. Plant Sci. 3, 1688 (2012)

S.S. Manjunatha, P.S. Raju, A.S. Bawa, Czech J. Food Sci. 5, 456 (2012)

F. Vesali, M. Gharibkhani, M.H. Komarizadeh, Aust. J. Crop Sci. 5(2), 111 (2011)

S.S. Manjunatha, P.S. Raju, A.S. Bawa, J. Food Sci. Technol. 51(11), 3038 (2014)

A.M. Pisoschi, A.F. Danet, S. Kalinowski, J. Autom. Methods Manag. Chem. 2008, 1 (2008)

A. Bisconsin-junior, J. Fernando, R. Alvarenga, A. Rosenthal, M. Monteiro, J. Food Process. Technol. 6(2), 1 (2015)

M.K. Bull, K. Zerdin, E. Howe, D. Goicoechea, P. Paramanandhan, R. Stockman, C.M. Stewart, Innov. Food Sci. Emerg. Technol. 5(2), 135 (2004)

Acknowledgements

The authors acknowledge the financial support provided by the Universiti Putra Malaysia and mentoring from teaching staff and laboratory staff of the Faculty of Food Science and Technology. Authors extend thanks to colleagues for editing the manuscript before submission.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Hussain, N., Ishak, I., Kamal, M.A.A. et al. Peeling of key lime (Citrus aurantifolia) fruit aided with vacuum infusion, different levels of pectinase concentration and soaking time. Food Measure 13, 2095–2105 (2019). https://doi.org/10.1007/s11694-019-00130-7

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-019-00130-7