Abstract

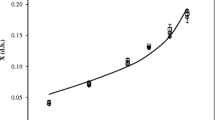

Jackfruit flour was significantly (p < .05) different from other flours due to its highest water absorption capacity (WAC) (1.57 g/g), particle size (PS) (384.984 µm) and lowest loss factor (tanδ), foaming stability (FS) (32.6%). The different blends consisting of jackfruit flour at 0.5%, 1%, 5%, 10%, 20%, 30% levels with equal proportions of rice and pigeonpea flour were prepared. The higher the substitution of jackfruit flour in blends, PS and WAC were increased whereas peak viscosity, trough viscosity, relative crystallinity, oil absorption capacity, foaming properties were decreased. A mixture of spherical, polyhedral and irregular shaped starch granules with less smooth granule surfaces can be observed using scanning electron microscopy. Micrographs of blends showed swollen and slightly elongated starch granules with distorted structure. Pattern recognition methods such as principal component analysis and linear discriminate analysis were performed to classify jackfruit flesh flour, rice flour and pigeonpea flour based blends on the basis of rheological, functional, microstructural and pasting properties. The variables like setback viscosity, FS, tanδ, final viscosity and WAC exhibited higher discrimination power.

Similar content being viewed by others

References

D. Gupta, S. Mann, A. Sood, R.K. Gupta, Phytochemical, nutritional and antioxidant activity evaluation of seeds of jackfruit (Artocarpus heterophyllus Lam.). Int. J. Pharm. Biosci. 2(4), 336–345 (2011)

R. Feili, W. Zzaman, A. Wan, N. Wan, A. Yang, Tajul, Physical and sensory analysis of high fiber bread incorporated with jackfruit rind flour. J Food Sci. Technol. 1(2), 30–36 (2013)

R. Feili, Utilization of jackfruit (Artocarpus Heterophyllus Lam.) rind powder as value added ingredient in bread. Master Thesis submitted to Universiti Sains Malaysia (2014)

M.A. Soobrattee, V.S. Neergheen, A. Luximon-Ramma, O.I. Aruma, T. Bahorun, Phenolics as potential antioxidant therapeutic agents: mechanism and action. J. Mutat. R. 579, 200–213 (2005)

P. Kaushal, H.K. Sharma, Osmo-convective dehydration kinetics of jackfruit (Artocarpus heterophyllus). J. Saudi Soc. Agric. Sci. 15, 118–126 (2016)

M. Corredig, W. Kerr, L. Wicker, Particle size distribution of orange juice cloud after addition of sensitized pectin. J. Agric. Food Chem. 48, 4918–4923 (2001)

L.E. Morales-Martínez, L.A. Bello-Pérez, M.M. Sánchez-Rivera, E. Ventura-Zapata, A.R. Jiménez-Aparicio, Morphometric, physicochemical, thermal, and rheological properties of rice (Oryza sativa L.) Cultivars Indica × Japonica. Food Nutr. Sci. 5, 271–279 (2014)

P. Bhattacharyya, U. Ghosh, H. Gangopadhyay, U. Raychaudhuri, Physico-chemical characteristics of extruded snacks prepared from rice (Oryza sativa L.), corn (Zea mays L.) and taro [Colocasia esculenta (L.) Schott] by twin screw extrusion. J. Sci. Ind. Res. 65, 165–168 (2006)

F.W. Sosulski, The centrifuge method for determining flour absorption in hard red spring wheats. Cereal Chem. 39, 344–350 (1962)

M.J.Y. Lin, E.S. Humbert, F.W. Sosulski, Certain functional properties of sunflower meal products. J Food Sci 39, 368–370 (1974)

V.I. Morris, Starch gelation and retrogradation. Trends Food Sci. Technol. 7, 2–6 (1990)

C.Y. Lii, M.L. Tsai, K.H. Tseng, Effect of amylose content on the rheological property of rice starch. Cereal Chem. 73, 415–420 (1996)

X.M. Liang, J.M. King, Pasting and crystalline property differences of commercial and isolated rice starch and added amino acids. J. Food Sci. 68, 832–838 (2003)

B. Yadav, S. Ritika, B. Yadav, M. Kumar, Suitability of pigeon pea and rice starches and their blends for noodle making. LWT Food Sci. Technol. 44, 1415–1421 (2011)

K. Ghiasi, K. Varriano-Marston, R.C. Hoseney, Gelatinization of wheat starch. II. Starch-surfactant interaction. Cereal Chem. 59, 86 (1982)

V.F. Abioye, B.I.O. Ade-Omowaye, G. Babarinde, M.K. Adesigbin, Chemical, physico-chemical and sensory properties of soy plantain flour. Afr. J. Food Sci. 5(4), 176–180 (2011)

E. Oti, E.N.T. Akobundu, Physical, functional and amylograph pasting properties of cocoyam-soybean-crayfish flour blends. Niger. Food. J. 25(1), 161–170 (2008)

T.O. Akanbi, S. Nazamid, A.A. Adebowale, Functional and pasting properties of a tropical breadfruit (Artocarpus altilis) starch from Ile-Ife, Osun State, Nigeria. Int. Food Res. J. 16, 151–157 (2009)

F.N.A. Aryee, I. Oduro, W.O. Ellis, J.J. Afuakwa, The physicochemical properties of flour samples from the roots of 31 varieties of cassava. Food Control. 17, 916–922 (2006)

M. Kaur, K.S. Sandhu, N. Singh, Comparative study of the functional, thermal and pasting properties of flours from different field pea (Pisum sativum L.) and pigeon pea (Cajanus cajan L.) cultivars. Food Chem. 104, 259–267 (2007)

K.O. Adebowale, O.S. Lawal, Microstructure, physicochemical properties and retrogradation behavior of Macuna bean (Macuna pruriens) starch on heat moisture treatments. Food Hydrocoll. 17, 265–272 (2003)

J. Loh, The effect of shear rate and strain on the pasting behavior of food starches. J. Food Eng. 16, 75–89 (1992)

I. Oduro, W. Ellis, N. Dziedzoave, K. Nimako-Yeboah, Quality of gari from selected processing zones in Ghana. Food Control. 11, 297–303 (2000)

M.O. Iwe, N. Michael, N.E. Madu, N.E. Obasi, G.I. Onwuka, T.U. Nwabueze, J.O. Onuh, Physicochemical and pasting properties of high quality cassava flour (HQCF) and wheat flour blends. Agrotechnology 6, 3–10 (2017)

D.A. Murugkar, P. Gulati, N. Kotwaliwale, C. Gupta, Evaluation of nutritional, textural and particle size characteristics of dough and biscuits made from composite flours containing sprouted and malted ingredients. J. Food Sci. Technol. 52(8), 5129–5137 (2015)

J. Cain, An alternative technique for determining ANSI/CEMA standard 550 flowability ratings for granular materials. Powder Hand. Proc. 14(3), 218–220 (2002)

Y. Wang, L. Zhang, X. Li, G. Wenyuan, Physicochemical properties of starches from two different Yam (Dioscorea Opposita Thunb.) residues. Braz. Arch. Boil. Technol. 54(2), 243–251 (2011)

W. Tongdeesoontorn, L.J. Mauer, S. Wongruong, Mechanical and physical properties of cassava starch-gelatin composite films. J. Polym. Mater. 61, 778–792 (2012)

S. Hizukuri, T. Kaneko, T. Takeda, Measurement of the chain length of amylopectin and its relevance to the origin of crystalline polymorphism. Biochim. Biophys. Acta 760, 188–191 (1983)

J.D. Ferry, Viscoelastic Properties of Polymers (Wiley, New York, 1980)

I.A. Lambert, J.L. Kokini, Effect of l-cysteine on the rheological properties of wheat flour. Cereal Chem. 78, 226–230 (2001)

N. Singh, J. Singh, L. Kaur, N.S. Sodhi, B.S. Gill, Morphological, thermal and rheological properties of starches from different botanical sources—a review. Food Chem. 81, 219–231 (2003)

U. Singh, Functional properties of grain legume flours. J. Food Sci. Technol. 38, 191–199 (2001)

N.Y.N. Aboubakar, J. Scher, C.M.F. Mbofung, Physicochemical, thermal properties and micro structure of six varieties of taro (Colocasia esculenta L. Schott) flours and starches. J. Food Eng. 86, 294–305 (2008)

P. Houson, G.S. Ayenor, Appropriate processing and food functional properties of maize flour. Afr. J. Sci. Technol. 3, 121–126 (2002)

J.I. Okoye, J.F. Igwe, Effect of sprouting and fermentation on the chemical composition and functional properties of African Yam bean. J. Sci. Technol. 19, 42–47 (2013)

O. Osundahusi, T. Fagbemi, E. Kesselman, E. Shimoni, Comparison of the physicochemical properties and pasting characteristics of flour and starch from red and white sweet potato cultivars. Agric. J. Food Chem. 51, 2232–2236 (2003)

M.J. Chen, C.W. Lin, Factors affecting the water holding capacity of fibrinogen/plasma protein gels optimized by response surface methodology. J. Food Sci. 67, 2579–2582 (2002)

O.S. Eke, E.N.T. Akobundu, Functional properties of African yam bean (Sphenostylis stenocarpa) seed flour as affected by processing. Food Chem. 48, 337–340 (1993)

D.K. Dev, E. Quensil, Preparation and functional properties of linseed protein products containing differing levels of vegetable protein products. J. Food Sci. 40, 805 (1988)

J.E. Kinsella, Functional properties of proteins in foods. A survey. Crit. Rev. Food Sci. Nutr. 7, 219–280 (1976)

T.N. Fagbemi, Effect of blanching and ripening on functional properties of plantain (Musa aab) flour. Plant Foods Hum. Nutr. 54, 261–269 (1999)

D.E. Graham, M.C. Philips, The Conformation of Proteins at the Air-Water Interface and Their Role in Stabilizing Foam, ed. by R.J. Akers. Foams (Academic Press, New York, 1976), pp. 237–255

I.Y. Mizubuti, O.B. Júnior, L.W. de Oliveira Souza, R.S. dos Santos Ferreira da Silva, E.I. Ida, Response surface methodology for extraction optimization of pigeon pea protein. Food Chem. 70, 259–265 (2000)

P. Kaushal, V. Kumar, H.K. Sharma, Comparative study of physicochemical, functional, anti-nutritional and pasting properties of taro (Colocasia esculenta), rice (Oryza sativa), pigeon pea (Cajanus cajan) flour and their blends. LWT-Food Sci. Technol. 48, 56–59 (2012)

E. Nwokolo, Nutritional quality of the seeds of the African breadfruit (Treculia Africana Decne). Trop. Sci. 27, 39–47 (1985)

M. Noorfarahzilah, J.S. Lee, M.S. Sharifudin, A.B. Mohd Fadzelly, M. Hasmadi, Applications of composite flour in development of food products. Int. Food. Res. J. 21(6), 2061–2074 (2014)

J.P. Cherry, K.H. McWatters, Whippability and Aeration in “Protein Functionality in Foods”, ed. by J.P. Cherry. ACS Symposium Series, 147 (American Chemical Society, Washington, DC, 1981), pp. 149

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Sharma, H.K., Kaushal, P. & Singh, A.P. Rheological measurements of composite flour containing Jackfruit (Artocarpus heterophyllus Lam.) flesh flour and its identification by pattern recognition methods. Food Measure 13, 404–420 (2019). https://doi.org/10.1007/s11694-018-9955-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-018-9955-5