Abstract

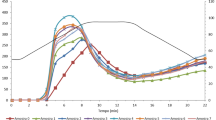

Wikau maombo flour has a great potential as an economical food products in Southeast Sulawesi. The aims of this study were to apply the traditional methods of cassava flour manufacturing process roomates including peeling, washing, the immersion of sea water, fermentation, drying, milling and analyze the characteristic of wikau Matombo flour. The cassava was immersed for 24 h in sea water prior to fermentation in 1–4 days. Fermented flour in 3 days is the choosen product due to its good organoleptic and mass-produced analysis. The cyanide content of the flour was 2.7 mg/kg, whereas the content of carbohydrate, protein, fat, ash, moisture and crude fiber were 87.69 ± 0.1, 2.4 ± 0.1, 0.34 ± 0.02, 1.04 ± 0.59, 6.23 ± 0.48 and 2.30 ± 0.72 %, respectively. FTIR analysis showed that the intensity of peaks in 1016, 1150, 1650, 2990 and 3390 cm−1 were found to decrease with a longer fermentation. Based on the XRD analysis, the crystallinity of Wikau maombo flour decreased as the fermentation time increase. With a long fermentation, the morphology of the flour was observed as irregular granules with starch granule size. The physicochemical properties of wikau Matombo flour including swelling power, crystallinity, solubility, cyanide content, viscosity, pasting temperature, pH and granule size were 8.39 ± 0.06 g/g, 24.41 %, 66 ± 0.27 %, 2.7 ± 0.03 mg/kg, 4061cP, 74.1 °C, 6.5 ± 0.05 and 5–15 μm, respectively.

Similar content being viewed by others

References

S.K. Kobawila, D. Louembe, S. Keleke, J. Hounhouigan, C. Gamba, Reduction of the cyanide content during fermentation of cassava roots and leaves to produce bikedi and ntoba mbodi, two food products from Congo. Afr. J. Biotechnol. 4(7), 689–696 (2005)

N.A. Adamafio, M. Sakyiamah, T. Josephyne, Fermentation in cassava (Manihot esculenta Crantz) pulp juice improves nutritive value of cassava peel. Afr. J. Biochem. Res. 4(3), 51–56 (2010)

L.M. Nwokocha, N.A. Aviara, C. Senan, P.A. Williams, A comparative study of some properties of cassava (Manihot esculenta, Crantz) and cocoyam (Colocasia esculenta, Linn) starches. Carbohyd. Polym. 76, 362–367 (2009)

E.A. Uyoh, V.O. Ntui, N.N. Udoma, Effect of local cassava fermentation methods on some physiochemical and sensory properties of fufu. Pak. J. Nutr. 8(8), 1123–1125 (2009)

G. Oboh, A.A. Akindahunsi, Biochemical changes in cassava products (flour & gari) subjected to Saccharomyces cerevisae solid media fermentation. Food Chem. 82, 599–602 (2003)

W.D.R. Putri, C. Marseno, M.N. Cahyanto, Effect of biodegradation by Lactic Acid Bacteria on physical properties of cassava starch. Int. Food Res. J. 18(3), 1149–1154 (2011)

W.D.R. Putri, Y. Nakagawa, H. Kawasaki, M. Mika, Haryadi, M.N. Cahyanto, D.W. Marseno, Identification Studies of Lactic Acid Bacteria Isolated during Cassava Fermentation, using a combined methods based on their Phenotypic and Genotypic Characteristics. Report of Sandwich-Like Program on Doctoral Research Grant. (Gadjah Mada University, Indonesia, 2010)

M.O. Adegunwa, L.O. Sanni, B. Maziya-Dixon, Effects of fermentation length and varieties on the pasting properties of sour cassava starch. Afr. J. Biotechnol. Afr. J. Biotechnol. 10(42), 8428–8433 (2011)

Association of Official Agricultural Chemists (AOAC), Official methods of analysis, 15th ed. (Association of Official Analytical Chemists, Washington, DC, 1990)

S. Abera, S.K. Rakshit, Comparison of physicochemical and functional properties of cassava starch extracted from fresh root and dry chip. Starch-Starke 55, 287–296 (2003)

J.H. Bradbury, Development of a sensitive picrate method to determine total cyanide and acetone cyanohydrin contents of gari from cassava. Food Chem. 113, 1329–1333 (2009)

F.B. Apea-Bah, I. Oduro, W.O. Ellis, O. Safo-Kantanka, Factor analysis and age at harvest effecton the quality of flour from four Cassava varieties. World J. Dairy Food Sci. 6, 43–54 (2011)

J.D. Schofield, Wheat proteins: structure and functionality in milling and breadmaking. In Wheat production, properties and quality, ed. W. Bushuk & V. F. Rasper (Chapman & Hall, London, 1994), pp. 72–106

J.O. Akingbala, K.O. Falade, M.A. Ogunjobi, The effect of root maturity, preprocess holding and flour storage on the quality of cassava biscuit. Food Bioprocess. Technol. 4, 451–457 (2011)

Y.C. Muzanila, J.G. Brennan, R.D. King, Residual cyanogens, chemical composition and afatoxins in cassava flour from Tanzanian villages. Food Chem. 70, 45–49 (2000)

F.N.A. Aryee, I. Oduro, W. Ellis, J.J. Oafuakwa, The physicochemical properties of Xour samples from the roots of 31 varieties of cassava. Food Contr. 17, 916–922 (2006)

G. Bi, X. Feng, Kai, Producing and making method of whole cassava flour. CN 104172018 A (Patent) (2014)

A. Ekanayake, P.R. Bunke, Process for Producing Cassava Flour. US 20120003356 A1 (Patent) (2012)

W. Tongdeesoontorn, L.J. Mauer, S. Wongruong, Mechanical and physical properties of cassava starch-gelatin composite films. Int. J. Polym. Mater. 61, 778–792 (2012)

C.M.L. Franco, R.A.F. Cabral, D.Q. Tavares, Structural andphysicochemical characteristics of lintnerized native and sour cassava starches. Starch-Starke 54, 469–475 (2002)

N. Charoenkul, D. Uttapap, W. Pathipanawat, Y. Takeda, Physicochemical characteristics of starches and flours from cassava varieties having different cooked root textures. LWT-Food Sci. Technol. 44, 1774–1781 (2011)

A.C. Eliasson, M. Gudmunsson, Starch: physicochemical and functional properties aspects, in Eliasson A.C. (edited). Carbohydrate in Food (Marcel Dekker, Inc, New York, 1996), pp. 431–504

H. Liu, L. Ramsden, H. Corke, Physical properties and enzimatic digestbility of phosphorilated and normal maize starch preparated at different pH levels. J Cereal. Chem. 76(6), 938–943 (1999)

A.M. Hermansson, K. Svegmark, Developments in the understanding of starch functionality: a review. Trends Food Sci. Tech. 7, 345–353 (1996)

F. Xie, H. Liu, P. Chen, T. Xue, L. Chen, L. Yu, P. Corrigan, Physical properties and enzimatic digestbility of phosphorilated and normal maize starch preparated at different pH levels. Int. J. Food Eng. 2(5), (2006)

N. Singh, J. Singh, L. Kaur, N.S. Sodhi, B.S. Gill, Morphological, thermal and rheological properties of starches from different botanical sources: a review. Food Chem 81(21), 9–231 (2003)

Z. Chen, Physicochemical properties of sweetpotato starches and their application in noodle products. Ph.D, Thesis Wageningen University (2003)

H-J. Chung, Q. Liu, R. Hoover, Effect of single and dual hydrothermal treatments on the crystalline structure, thermal properties, and nutritional fractions of pea, lentil, and navy bean starches. Food Res. Inter. 43, 501–508 (2010)

J. Vetter, Plant cyanogenic glycosides. Toxicon 38, 11–36 (2000)

O.B. Oyewole, S.L. Odunfa, Effect of length of fermentation on the functional characteristics of fermented cassava ‘fufu’. J. Food Technol. Afr. 6, 38–40 (2001)

H.A. Adeniran, O.M. Ajifolokun, Microbiological studies and sensory evaluation of breadfruit and cassava co-fermented into gari analogue. Nig. Food J. 33, 39–47 (2015)

B.O. Omafuvbe, S.H. Abiose, O.O. Shonukan, Fermentation of soybean (Glycine max) for soy-daddawa production by starter cultures of Bacillus. Food Microbiol. 19, 561–566 (2003)

Acknowledgments

The authors would like to acknowledge the Directorate General of Strengthening Research and Development, Ministry of Research, Technology and Higher Education, Indonesia for financial support under “MP3EI” grant research.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Wahyuni, S., Ansharullah, Saefuddin et al. Physico-chemical properties of Wikau maombo flour from cassava (Manihot esculenta Crantz). Food Measure 11, 329–336 (2017). https://doi.org/10.1007/s11694-016-9401-5

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11694-016-9401-5