Abstract

Exploring the correlation between the density and the thermo-physical properties of the Al2O3-CaO-MgO-SiO2 quaternary slag system is a subject of great interest in the domain of high alumina slag systems. This work attempts to establish correlations between (a) molar volume/density with enthalpy of mixing and (b) molar volume/density with slag viscosity, for the quaternary slag systems. The former is targeted based on existing models to determine the slag density and enthalpy of mixing first and then to develop machine-learning models which can suitably extrapolate the enthalpy of mixing as a function of slag composition, temperature and density. The volume shrinkage and the exothermic enthalpy of mixing between the slag constituent components are correlated in the current work. The later part would involve the conjunction of two hybrid machine-learning models, one for predicting slag viscosity as a function of slag compositions and temperature, and the other which predicts slag viscosity with the incorporation of slag density. The work will facilitate the establishment of two novel quantitative relationships that could provide better insights into the blast furnace quaternary slag systems.

Similar content being viewed by others

Explore related subjects

Discover the latest articles, news and stories from top researchers in related subjects.Avoid common mistakes on your manuscript.

1 Introduction

Slag density in the blast furnace ironmaking process is dependent on a complex set of parameters which govern the thermodynamics and kinetics of the slag formation and transport, respectively.[1] The slag-metal separation rate is directly influenced by the slag density which affects the productivity of the process.[2] The network structure of the Al2O3-MgO-CaO-SiO2 quaternary slag system incorporating minor constituents[3,4,5,6] can be a prime factor responsible for the high density of the slag. However, no quantified correlation of the structure of the slag with density can be directly established. The more fundamental quantities like the enthalpy of mixing[7,8,9,10] can be correlated to the slag density to make an understanding. This would enable cross-correlating the slag density with the structure, which is related to the enthalpy of mixing.[11] Exothermic enthalpy of mixing would mean a denser slag system being energetically favoured and vice-versa. Another crucial thermophysical quantity is the viscosity of the slag which has been a subject of study for a long period of time in the quaternary systems.[12,13,14,15,16,17] Slag viscosity is not an independent governing quantity, but rather a dependent property which is a function of many fundamental parameters. The key importance of viscosity is to govern the slag transport and removal rate,[18,19,20] which strongly impacts productivity. The understanding of the inter-property correlations as mentioned above, is crucial to modern blast furnace ironmaking which is undergoing a transition where the utilization of low-grade iron ores is posing significant challenges to the slag practice.[21,22,23,24,25] High alumina slag[26] where Al2O3 content is more than 15 wt.% is responsible for the formation of highly dense and viscous slags which affect productivity.[26,27,28,29,30] The complex alumino-silicate structure of the slag[31] is responsible for increasing the slag viscosity which needs to be counteracted. Here, the correlation between the density of the slag and slag viscosity is essential as both quantities are influenced by the underlying slag structure. The industrial-level engineering of the slag chemistry via dilution or minor constituent addition[31,32,33,34,35] can then be targeted for a specific property without independently measuring both. For instance, the slag density can be determined using suitable experimental techniques or models and its relationship with slag viscosity can be established henceforth, without using tedious steps to measure the viscosity simultaneously.

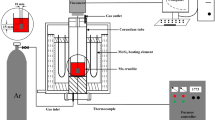

The measurement of slag density for different quaternary slag compositions and temperatures has been experimentally performed by various scholarly groups.[1,2,36,37] The relationship of slag density (molar volume) with the slag composition and temperature was established using the CALPHAD approach by Moharana et al. and the group,[1] which is also the core input to this work. The mathematical model developed in the work showed density trends for different slag systems with composition variation and as well as temperature variation. Density measurements using the Archimedes principle have been performed by Muhmood and Seetharaman which provided insights into variation for the low silica quaternary slag systems.[38]

The correlation between viscosity and slag composition has been theoretically studied by Hazra et al. which demonstrates that high alumina content primarily increases the viscosity of the slag thereby affecting productivity.[16] In another study, Pal et al. used machine learning models to derive insights into the role of MgO, CaO/SiO2 (C/S) ratio and Al2O3 content on the slag viscosity.[17] Slag viscosity has also been determined using molecular dynamics to get atomic-level insights into the structure-property correlation.

Despite the availability of adequate literature on the individual properties of the slag system, there is a significant gap in the study of the inter-property correlation of the quaternary slag. To the best of our knowledge, no study has been done experimentally or computationally which correlates the slag density and viscosity to establish a relationship.

The objective of this study is to establish correlations between the slag density and mixing enthalpy as well as slag density and slag viscosity. It involves the quantification of slag density as a function of known quantities like composition of constituents, temperature, and enthalpy of mixing while taking slag density as an independent variable when correlating with viscosity. The correlations would enable a better understanding of the role of these quantities in governing the slag transport dynamics. Additionally, a more physical relationship can be derived using the following relationship of molar volume and density to extend the correlations made with density:

The study makes use of machine learning (ML) models to correlate these quantities. Due to its capacity to manage the complicated interaction of many factors inherent in the slag domain, machine learning (ML) is highly favoured for creating inter-property correlations in the slag domain. The slag system has various compositional, temperature, and structural factors that interact in complex ways, making typical analytical techniques difficult and time-consuming. ML excels in capturing nonlinear connections and identifying patterns in large datasets, which is critical for dealing with complicated slag compositions and their associated characteristics. For these reasons, ML is chosen over the standard CALPHAD approach to make the correlations.

In the subsequent sections, the model development, deployment and predictions are discussed to derive insights into the slag systems.

2 Model Development

The machine learning models were developed to predict the slag density, enthalpy of mixing and viscosity as a function of slag composition and temperature. A total of 4 models were developed and deployed, with the final model incorporating density as an input feature along with composition and temperature, to predict the viscosity. The training data for the models was obtained in three steps: (a) The density data were obtained using the model developed by Moharana et al.[1] (b) The mixing enthalpy and viscosity data were obtained by calculating the raw composition vs temperature data in FactSage to make the hybrid dataset (c) The viscosity data were also obtained by utilizing the model developed by Pal et al.[17] to populate the fitting data. All the models were tuned using hyperparameter optimization to obtain the best-fit model. Python's scikit-learn package[39] was used to import all the necessary models. The distribution of data and correlation matrix for the first model is shown in Fig. 1 and the correlation matrices for the other 3 models are shown as a part of Fig. 2.

The negative correlation of enthalpy of mixing with the slag constituents is depicted in Fig. 1(b). The heatmap also shows a negative correlation of enthalpy with temperature indicating the enthalpy of mixing increases in positive magnitude, which is expected for endothermic reactions at high temperatures.

The correlation matrix as shown in Fig. 2(a) depicts a negative correlation between density and temperature suggesting that as the temperature increases, the density tends to decrease. For the slag components, the correlation with density is positive for Al2O3 and CaO but negative for MgO and SiO2. On the other hand, Figure 2(b) shows a negative correlation of the slag components except for SiO2 which is due to the network-breaking and network-forming tendencies of the constituents respectively for the existing quaternary-composition space. This verifies the non-linear relationship of density and viscosity which is investigated in the further sections.

The hyperparameter optimization was done by iterating over the following models- Linear regression, Ridge regression, K nearest neighbours, Decision tree, Support vector machine, Random Forest, Adaboost and ExtraTrees regression. The training procedure was carried out by splitting the data into 80:20 train:test split. For choosing the best-fit model, two metrics, namely R2 score and mean square error (MSE) were chosen. The R2 score of any model validation represents the proportion of variation in the dependent variable and ranges from 0 to 1. A high R2 value indicates a more dependable and accurate model. The following equation is used to get the R2 score.

Similarly, the mean square error value is described as:

where n is the number of data points used in the model construction.

The result of the hyperparameter optimization implied that ExtraTrees regression is the best fit model for all the four models. However, the model parameters were different for all four cases in order to maximize the R2 score and minimizing the M.S.E. The performance metrics for the aforementioned models is shown in Table 1.

The ExtraTrees regressor is an ensemble algorithm for learning that makes predictions by combining numerous decision trees.[40] ExtraTrees, unlike regular decision trees or random forests, use a high degree of randomness throughout the training process. ExtraTrees successfully decreases variance and overfitting by employing random subsets of the data and randomly picking features for node splitting. This improves the generalization performance. With the provided hyperparameters, the ExtraTrees regressor model is the overall best choice for prediction. The model's ensemble nature, along with randomization and hyperparameter optimization, allows it to properly manage the dataset's complexities and details. The ExtraTrees regressor demonstrates improved accuracy and generalization capabilities by utilizing the power of multiple decision trees and feature randomization, making it a great choice for slag property prediction in this case. However, it is important to highlight that model selection may be dependent on the unique characteristics of the dataset, and subsequent assessments on varied datasets should be undertaken to confirm its robustness.

The four ML models utilizing this algorithm were now provided with multiple test datasets to make suitable predictions in the regime of interest. The detailed description and analysis of these predictions is given in the subsequent section.

3 Results and Discussion

3.1 Enthalpy of Mixing of Quaternary Slag System

The Al2O3-MgO-CaO-SiO2 quaternary slag system has a negative enthalpy of mixing indicating exothermicity at a given temperature as predicted by FactSage. To establish this relationship, the absolute enthalpy of mixing (ΔHmix) is selected as the basis for training the model. This is done to follow the practice that is often used in the literature.

To understand the dependence of ΔHmix on the slag composition, three different test sets were chosen. In the first case, the variation of Al2O3 was correlated with ΔHmix for a fixed MgO content of 10 wt.% and fixed CaO/SiO2 or C/S ratio of 1. The curve showing this relationship at three different temperatures, T=1773K, 1823K and 1873K, is presented in Fig. 3(a).

In the quaternary slag system, there is a significant increase in the ΔHmix (in the negative direction) as the Al2O3 content increases. The relationship is depicted in Fig. 3(a), which shows that ΔHmix increases almost linearly with increasing Al2O3 content. This is to be expected, as the content of Al2O3 increases the complexity of the slag growth (alumina network), resulting in an increase in enthalpy due to stronger atomic interactions. This is an indication of higher exothermicity.

Notably, the lines show ΔHmix overlap at 1773K and 1823K, indicating a constant enthalpy shift at these temperatures across various Al2O3 contents. The dominance of particular interactions that remain relatively consistent within this temperature range can be attributed to this phenomenon. However, at a higher temperature, i.e., 1873K, the curve shifts upward showing significant deviation from the previous two temperatures. This is indicative of a change in the slag structure, possibly the breakage of the alumino-silicate network at a higher temperature resulting in smaller chains and clusters.

A similar but reverse trend is observed for the slag system where the C/S ratio is varied from 0.9 to 1.2 in steps of 0.05 to study the variation of ΔHmix. For studying the effect of the C/S ratio, slag composition is chosen with 18 wt.% fixed Al2O3, 10 wt.% fixed MgO and three different temperatures as in the previous case. As shown in Fig. 3(b), the ΔHmix values decrease (in the negative direction) as the C/S ratio is increased with the observation for temperatures seeming consistent with the previous case. The drop in ΔHmix observed as the C/S ratio increases can be due to the preferred generation of energetically favourable phases of CaO dissolving the SiO2 and Al2O3 to form calcium silicates/aluminates, resulting in decreased enthalpy and higher stability in the quaternary slag system. Again, the higher temperature would mean a more depolymerised structure, which would have a relatively higher enthalpy of mixing than the lower-temperature counterparts.

A rather more complex relationship is shown between the MgO content and ΔHmix as shown in Fig. 3(c). The observed behaviour of ΔHmix with increasing MgO wt.% reveals a two-stage behaviour. The almost steady ΔHmix trend is shown with slight deviations upto 14 wt.% MgO, followed by a sharp increase in the negative direction. There is an indication of compound formation at temperatures below the liquidus temperature, corresponding to an increase in the exothermicity.

The enthalpy of mixing relationship with slag composition and temperature would be further used to make correlations with slag density in the subsequent subsections.

3.2 Density Variation with Composition and Temperature

The density predictor model is run on the same input datasets to make predictions on slag density as Al2O3, MgO, C/S and temperature are varied. Density being a physical property shows a more direct relationship without complexity with the slag composition and temperature, as compared to the enthalpy of mixing. The density of the slag system is shown to increase with increasing Al2O3 content in Fig. 4(a). The increase in density is indicative of a more polymerised structure which is resulting with the addition of Al2O3. This trend may be divided into three separate regions: a quick increase at low Al2O3 contents, a steady increase at higher contents, and a rapid increase at even higher contents. As the temperature rises from 1773 K to 1873 K, the curve moves downward. This behaviour indicates that densities are lower at higher temperatures.

Thermal energy disrupts the atomic configurations and lowers the overall packing density of the slag particles at high temperatures. As a result, when the temperature rises, the density of the slag system drops.

A direct and linear relationship between the C/S ratio and slag density can be observed in Fig. 4(b). The slag density increases linearly as the C/S ratio increases from 0.9 to 1.2. The variations in the slag system caused by altering the C/S ratio can explain this behaviour. Lower C/S ratios (about 0.9) result in a silica-rich slag system, whereas higher C/S ratios result in an increased amount of CaO. Denser calcium silicate phases form inside the slag matrix when the C/S ratio rises, leading to an apparent increase in slag density. Furthermore, the tendency of greater slag density at lower temperatures is consistent with the preceding case. Similarly, the increase in MgO content, also increase the slag density as shown in Fig. 4(c), which can be attributed to the same phenomenon of basic oxide phases forming in the slag resulting in higher density of the slag.

3.3 Correlation of Density of Slag with Enthalpy of Mixing

The density and mixing enthalpy prediction models using the same inputs, enable the establishment of a correlation between the slag density and enthalpy of mixing.

As shown in Fig. 5, the exothermicity and density are parabolically correlated upto 15 wt.% Al2O3 after which they start to deviate. The deviation is more pronounced at higher temperatures due to the complexity of the slag structure which the model captures to some extent. Higher exothermicity implies greater density which falls under the argument that stronger bonds lead to denser phases. The correlation is also affected by the nature of the Al2O3 bonding as there can be changes in the network forming ability at higher contents that might affect the relationship of density with the exothermicity.

3.4 Viscosity Variation with Composition and Temperature

It has been noted that viscosity responds differently to different compositional parameters. In particular, because of Al2O3 network-forming qualities, which improve covalent bonding and structural rigidity, an increase in Al2O3 content is linked to an increase in viscosity as shown in Fig 6(a). When the C/S ratio (CaO/SiO2) rises to a certain threshold, the fluxing effect of CaO causes the network to break, which is why the viscosity drops. Beyond this point, though, the extra CaO could lead to the creation of additional phases and a subsequent increase in viscosity which is demonstrated in Fig 6(b). Furthermore, Figure 6(c) shows that the addition of MgO tends to reduce viscosity, serving as a flux and network moderator to improve the transport and fluidity.

3.5 Viscosity and Density Correlation for the Slag

Figure 7 shows the relationship between the density and viscosity of the slags as the Al2O3 content is increased from 5 to 20 wt.% and MgO, C/S ratio are kept fixed at 10 wt.% and 1 respectively. The viscosity increases slowly with the increase in density at 1773K whereas the rise is more rapid at higher temperatures. The relationship established between the viscosity and density by the machine learning model is a direct one. The direct correlation between the viscosity and density has been pre-established using the absolute reaction-rate theory proposed by Glasstone et al.[41] This is given by the equation:

where h= Planck’s constant, N= Avogadro’s number, Vm= Molar volume, G* = Gibbs energy of activation per mole.

Our model validates the above empirical relationship although it is data driven. This can be counted as the first ever attempt to the best of our knowledge. The relationship between viscosity and density could be extrapolated to an even complex set of conditions by re-training the model with more features. This falls under the scope of a future work with an advantage of high-throughput correlations that can be used for complex environments like the blast furnace.

4 Conclusion

The density of the blast furnace slag systems was found to be intrinsically correlated to the enthalpy of mixing and viscosity. The complex interplay of slag structure in the high alumina regime and the governing parameters like temperature and constituent compositions were modelled using machine learning and correlated to obtain direct correlations between density and enthalpy of mixing. It was verified that higher exothermicity or more negative enthalpy of mixing, resulted in a higher density with a deviation in the trend at 15 wt.% Al2O3. The viscosity of the slag increased with higher densities of slag as Al2O3 was varied from 5 to 20 wt.%. This established a direct correlation between the viscosity and the density of slag using machine learning that was validated against the absolute reaction-rate theory proposed by Glasstone et al.[41] The relationship was more linear at higher temperatures and parabolic at low temperatures. The work has a scope to be used for more complex systems with minor additions to better understand the impact of slag density on blast furnace productivity.

Change history

17 June 2024

A Correction to this paper has been published: https://doi.org/10.1007/s11669-024-01129-4

References

N. Moharana, S. Seetharaman, N.N. Viswanathan, and K.C. Hari Kumar, Modelling the Density of Al2O3-CaO-MgO-SiO2 System using the CALPHAD Approach, Calphad, 2020, 71, 101781.

Y. Liu, X. Lv, C. Bai, and X. Zhang, Density of the Blast Furnace Slag Bearing TiO2 at 1673 K, ISIJ Int., 2014, 54(9), p 2017–2024.

Q. Shu, A Viscosity Estimation Model for Molten Slags in Al2O3-CaO-MgO-SiO2 System, Steel Res. Int., 2009, 80(2), p 107–113.

X. Shen, M. Chen, and N. Wang, A Structurally-based Viscosity Model of the Fully Liquid Slags in the CaO-MgO-Al2O3-FeO-SiO2 System, ISIJ Int., 2019, 59(11), p 1940–1946.

J. Fang, Z. Pang, X. Xing, and R. Xu, Thermodynamic Properties, Viscosity and Structure of CaO-SiO2-MgO-Al2O3-TiO2-Based Slag, Materials, 2020, 2021(14), p 124.

Q.F. Shu, X. Zhang, and K.C. Chou, Structural Viscosity Model for Aluminosilicate Slags, Ironmak. Steelmak., 2015, 42(9), p 641–647.

J. Zhang, K. Jiao, J. Zhang, H. Ma, Y. Zong, Z. Guo, and Z. Wang, Thermal Stability of Molten Slag in Blast Furnace Hearth, ISIJ Int., 2021, 61(8), p 2227–2236.

S.A. Decterov, V. Swamy, and I.H. Jung, Thermodynamic Modeling of the B2O3-SiO2 and B2O3-Al2O3 Systems, Int. J. Mater. Res., 2007, 98(10), p 987–994.

J. Zhang, C. Wang, K. Jiao, J. Zhang, Z. Liu, H. Ma, X. Fan, and Z. Guo, Effect of BaO and MnO on High-Temperature Properties and Structure of Blast Furnace Slag, J. Non-Cryst. Solids, 2021, 571, 121066.

Z.Y. Chang, K.X. Jiao, J.L. Zhang, and X.J. Ning, Experimental Investigation of Relationship Between Enthalpy Change and Viscosity in Blast Furnace Type Slags, ISIJ Int., 2019, 59(1), p 39–45.

P. Azadi, J. Winz, E. Leo, R. Klock, and S. Engell, A Hybrid Dynamic Model for the Prediction of Molten Iron and Slag Quality Indices of a Large-Scale Blast Furnace, Comput. Chem. Eng., 2022, 156, 107573.

C. Han, M. Chen, W. Zhang, Z. Zhao, T. Evans, A.V. Nguyen, and B. Zhao, Viscosity Model for Iron Blast Furnace Slags in SiO2-Al2O3-CaO-MgO System, Steel Res. Int., 2015, 86(6), p 678–685.

N. Saito, N. Hori, K. Nakashima, and K. Mori, Viscosity of Blast Furnace Type Slags, Metall. and Mater. Trans. B., 2003, 34(5), p 509–516.

R. Xu, J. Zhang, X. Fan, W. Zheng, and Y. Zhao, Effect of MnO on High-Alumina Slag Viscosity and Corrosion behavior of Refractory in Slags, ISIJ Int., 2017, 57(11), p 1887–1894.

C.Y. Sun, X.H. Liu, J. Li, X.T. Yin, S. Song, and Q. Wang, Influence of Al2O3 and MgO on the Viscosity and Stability of CaO-MgO-SiO2-Al2O3 Slags with CaO/SiO2= 10, ISIJ Int., 2017, 57(6), p 978–982.

S. Hazra, S. Pal, D.D. Biswajeet, M. Sahoo, G.S. Tarachand, D. Bhattacharyya, S. Nag, and S. Seetharaman, Optimization of High Alumina Slag Practice in Blast Furnace Ironmaking: An Industrial Approach (PART 1: Fundamental Aspects), Ironmak. Steelmak., 2023, 50(8), p 1124–1137.

S. Pal, M. Sahoo, D.D. Biswajeet, S. Hazra, G.S. Tarachand, D. Bhattacharyya, S. Nag, and S. Seetharaman, Optimization of High Alumina Slag Practice in Blast Furnace Ironmaking: an Industrial Approach. Part 2: Data-Driven Aspects, Ironmak. Steelmak., 2023, 50(8), p 1138–1145.

H. Liu, Y. Qin, Y. Yang, Q. Zhang, and N. Deng, Influence of Al2O3 Content on the Melting and Fluidity of Blast Furnace Type Slag with low TiO2 Content, J. Chem., 2018, 2018, p 1–6.

L. Xu, G. Qing, X. Cheng, M. Xu, B. Zhao, and J. Liao, Experimental Study on Desulfurization and Removal of Alkali Behavior of BF Slag System in Low-Slag Ironmaking, Metals, 2023, 13(2), p 414.

M. Oge, D. Ozkan, M.B. Celik, M.S. Gok, and A.C. Karaoglanli, An Overview of Utilization of Blast Furnace and Steelmaking Slag in Various Applications, Mater. Today Proceed., 2019, 11, p 516–525.

Maulik, S.C. and Bhattacharyya, K.K. A Beneficiation Scheme for Reduction of Alumina in Iron Ores from Barsua (2004)

S. Roy, A. Das, and M.K. Mohanty, Feasibility of Producing Pellet Grade Concentrate by Beneficiation of Iron Ore Slime in India, Sep. Sci. Technol., 2007, 42(14), p 3271–3287.

R.K. Upadhyay, A.S. Venkatesh, and S. Roy, Mineralogical Characteristics of Iron Ores in Joda and Khondbond Areas in Eastern India with Implications on Beneficiation, Resour. Geol., 2010, 60(2), p 203–211.

J.N. Tiwary, S. Sarkar, B. Mishra, and U.K. Mohanty, Structural Aspects of Blast Furnace Slag, Emerg. Mater. Res., 2013, 2(3), p 152–162.

Yadav, U.S., Das, B.K. and Baijal, A.D. Sinter Quality at Tata Steel: Past, Present and Future. In Proceedings of the Seminar on Raw Material Preparation for Metallurgical Industries: Problems and Solutions, April 8-9 2002 (p. 187). Allied Publishers. (2002)

L. Yao, S. Ren, X. Wang, Q. Liu, L. Dong, J. Yang, and J. Liu, Effect of Al2O3, MgO, and CaO/SiO2 on Viscosity of High Alumina Blast Furnace Slag, Steel Res. Int., 2016, 87(2), p 241–249.

Q. Chenglin, Z. Jianliang, S. Jiugang, L. Weijia, Z. Zhixing, and Z. Xuesong, Study of Boronizing Mechanism of High-Alumina Slag, Steel Res. Int., 2011, 82(11), p 1319–1324.

B.C. Jha, A. Sharma, G. Verma, and J. Sahoo, A Study on High-Grade Iron ore Beneficiation to Reduce Alumina for Enhanced Blast Furnace Productivity, Trans. Indian Nat. Acad. Eng., 2020, 5(3), p 573–579.

B. Nandy, S. Chandra, D. Bhattacharjee, and D. Ghosh, Assessment of Blast Furnace Behaviour Through Softening-Melting Test, Ironmak. Steelmak., 2006, 33(2), p 111–119.

K. Das, A. Agrawal, A.S. Reddy, and R.V. Ramna, Factsage Studies to Identify the Optimum Slag Regime for Blast Furnace Operation, Trans. Indian Inst. Met., 2021, 74, p 419–428.

R.Z. Xu, J.L. Zhang, R.Y. Ma, K.X. Jiao, and Y.A. Zhao, Influence of TiO2 on the Viscosity of a High Alumina Slag and on Carbon Brick Corrosion, Steel Res. Int., 2018, 89(3), p 1700353.

L. Deng, X. Zhang, M. Zhang, and X. Jia, Effect of CaF2 on Viscosity, Structure and Properties of CaO-Al2O3-MgO-SiO2 Slag Glass Ceramics, J. Non-Cryst. Solids, 2018, 500, p 310–316.

R.Z. Xu, J.L. Zhang, Z.Y. Wang, and K.X. Jiao, Influence of Cr2O3 and B2O3 on Viscosity and Structure of High Alumina Slag, Steel Res. Int., 2017, 88(4), p 1600241.

Y. Gao, L. Bian, and Z. Liang, Influence of B2O3 and TiO2 on Viscosity of Titanium-Bearing Blast Furnace Slag, Steel Res. Int., 2015, 86(4), p 386–390.

Xu, R.Z., Zhang, J.L., Han, W.X., Chang, Z.Y. and Jiao, K.X., 2018. Effect of BaO and Na2O on the viscosity and structure of blast furnace slag. Ironmaking & Steelmaking.

M. Persson, T. Matsushita, J. Zhang, and S. Seetharaman, Estimation of molar volumes of some binary slags from enthalpies of mixing, Steel Res. Int., 2007, 78(2), p 102–108.

M. Persson, J. Zhang, and S. Seetharaman, A thermodynamic approach to a density model for oxide melts, Steel Res. Int., 2007, 78(4), p 290–298.

L. Muhmood, and S. Seetharaman, Density measurements of low silica CaO-SiO2-Al2O3 slags, Metall. Mater. Trans. B, 2010, 41(4), p 833–840.

F. Pedregosa, G. Varoquaux, A. Gramfort, V. Michel, B. Thirion, O. Grisel, M. Blondel, P. Prettenhofer, R. Weiss, V. Dubourg, and V.J. Scikit-learn, Machine Learning in Python, J. Mach. Learn. Res., 2011, 12, p 2825–2830.

Mastelini, S.M., Nakano, F.K., Vens, C. and de Leon Ferreira, A.C.P. Online Extra Trees Regressor. IEEE Trans. Neural Netw. Learn. Syst. (2022)

S. Glasstone, K.J. Laidler, and H. Eyring, The Theory of Rate Process. McGraw-Hill, New York, NY, 1941.

Funding

Open access funding provided by Royal Institute of Technology.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This invited article is part of a special tribute issue of the Journal of Phase Equilibria and Diffusion dedicated to the memory of Thaddeus B. “Ted” Massalski. The issue was organized by David E. Laughlin, Carnegie Mellon University; John H. Perepezko, University of Wisconsin–Madison; Wei Xiong, University of Pittsburgh; and JPED Editor-in-Chief Ursula Kattner, National Institute of Standards and Technology (NIST).

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

Open Access This article is licensed under a Creative Commons Attribution 4.0 International License, which permits use, sharing, adaptation, distribution and reproduction in any medium or format, as long as you give appropriate credit to the original author(s) and the source, provide a link to the Creative Commons licence, and indicate if changes were made. The images or other third party material in this article are included in the article's Creative Commons licence, unless indicated otherwise in a credit line to the material. If material is not included in the article's Creative Commons licence and your intended use is not permitted by statutory regulation or exceeds the permitted use, you will need to obtain permission directly from the copyright holder. To view a copy of this licence, visit http://creativecommons.org/licenses/by/4.0/.

About this article

Cite this article

Hazra, S., Biswajeet, D.D., Pal, S. et al. Inter-property Correlation of Al2O3-CaO-MgO-SiO2 Quaternary Slag System in Blast Furnace Ironmaking. J. Phase Equilib. Diffus. 45, 703–712 (2024). https://doi.org/10.1007/s11669-024-01123-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11669-024-01123-w