Abstract

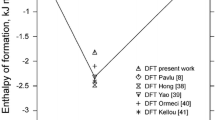

The Cr–Ti system was investigated by several experimental methods and first-principles calculations. The thermodynamic activity of the body-centered cubic solid solution was measured by Knudsen effusion mass spectrometry. The stability of all three polymorphic structures of the Laves phase (C14, C15, and C36) was determined by differential thermal analysis, and the equilibrium tie-lines with the solid solution were obtained by combining results from diffusion couples and equilibrated alloys. The enthalpy of formation of the Laves phases with the corresponding end-members were calculated using density functional theory and the obtained values were integrated in the models. The experimental and computed data available in the literature was reviewed and the binary system was assessed by the Calphad method. The present evaluation results in an improved thermodynamic description, which can describe the experimentally observed activity in a large temperature range. The temperatures of the invariant reactions between the C15 and the C36 phase with the Cr-rich and the Ti-rich bcc solid solution were significantly modified. The difference of the temperature of transformation between the C15 and the C36 polytypes on both sides of the Laves phase is much smaller than reported previously.

Similar content being viewed by others

Change history

29 March 2024

A Correction to this paper has been published: https://doi.org/10.1007/s11669-024-01106-x

References

H. Brearley, Cutlery, US1197256A, 1916.

B. Sun, X. Zuo, X. Cheng, and X. Li, The Role of Chromium Content in the Long-Term Atmospheric Corrosion Process, Npj Mater. Degrad., 2020, 4(1), p 1-9. https://doi.org/10.1038/s41529-020-00142-5

M.F. Ashby, Material and process selection charts, in: Mater. Sel. Mech. Des., 2nd ed, Butterworth-Heinemann, Boston, MA, 1999, p 413-466.

V.N. Svechnikov, M.Y. Teslyuk, Y.A. Kocherzhinsky, V.V. Petkov, and E.V. Dabizha, Three Modifications of TiCr2, Dopov. Akad. Nauk Ukr. RSR, 1970, 32(9), p 837-837. in Ukranian

J.D. Livingston, Laves-phase superalloys?, Phys. Status Solidi Appl. Mater. Sci, 1992, 131(2), p 415-423. https://doi.org/10.1002/pssa.2211310215

M. Bououdina, D. Grant, and G. Walker, Review on Hydrogen Absorbing Materials-Structure, Microstructure, and Thermodynamic Properties, Int. J. Hydrog. Energy, 2006, 31(2), p 177-182. https://doi.org/10.1016/j.ijhydene.2005.04.049

E. Akiba and H. Iba, Hydrogen Absorption by Laves Phase Related BCC Solid Solution, Intermetallics, 1998, 6(6), p 461-470. https://doi.org/10.1016/S0966-9795(97)00088-5

F. Stein and A. Leineweber, Laves Phases: A Review of Their Functional and Structural Applications and an Improved Fundamental Understanding of Stability and Properties, J. Mater. Sci., 2021, 56(9), p 5321-5427. https://doi.org/10.1007/s10853-020-05509-2

J.N. Mundy, C.W. Tse, and W.D. McFall, Isotope Effect in Chromium Self-Diffusion, Phys. Rev. B, 1976, 13(6), p 2349-2357. https://doi.org/10.1103/PhysRevB.13.2349

J.N. Mundy, H.A. Hoff, J. Pelleg, S.J. Rothman, L.J. Nowicki, and F.A. Schmidt, Self-Diffusion in Chromium, Phys. Rev. B, 1981, 24(2), p 658-665. https://doi.org/10.1103/PhysRevB.24.658

U. Köhler and C. Herzig, On the Anomalous Self-Diffusion in B.C.C., Titanium, Phys. Status Solidi B, 1987, 144(1), p 243-251. https://doi.org/10.1002/pssb.2221440122

N.E. Walsöe de Reca and C.M. Libanati, Autodifusion de Titanio Beta y Hafnio Beta, Acta Metall., 1968, 16(10), p 1297-1305. https://doi.org/10.1016/0001-6160(68)90010-2

T.B. Massalski, H. Okamoto, P.R. Subramanian, L. Kacprzak, Eds., Binary Alloy Phase Diagrams ASM International, Metals Park, 1990

F.C. Frank and J.S. Kasper, Complex Alloy Structures regarded As Sphere Packings. II. Analysis and Classification of Representative Structures, Acta Crystallogr., 1959, 12(7), p 483-499. https://doi.org/10.1107/S0365110X59001499

W. Baumann and A. Leineweber, Solid Solubility by Anti-Site Atoms in the C36-TiCr2 Laves Phase Revealed by Single-Crystal x-ray Diffractometry, J. Alloys Compd., 2010, 505(2), p 492-496. https://doi.org/10.1016/j.jallcom.2010.06.117

K. Ioroi, Y. Aono, X. Xu, T. Omori, and R. Kainuma, Melting Point of Pure Cr and Phase Equilibria in the Cr-Si Binary System, J. Phase Equilib. Diffus., 2022, 43(2), p 229-242. https://doi.org/10.1007/s11669-022-00954-9

W. Zhuang, J. Shen, Y. Liu, L. Ling, S. Shang, Y. Du, and J.C. Schuster, Thermodynamic Optimization of the Cr-Ti System, Z. Metallkd., 2000, 91(2), p 121-127.

R. Vogel and B. Wenderott, Das Zustandsschaubild Eisen-Eisentitanid-Chromtitanid-Chrom, Arch. für Eisenhüttenwes, 1940, 14(6), p 279-282. https://doi.org/10.1002/srin.194000912. in German

M.K. McQuillan, A Provisional Constitutional Diagram of the Chromium-Titanium System, J. Inst. Met., 1951, 79(11), p 379-390.

P. Duwez and J. Taylor, A Partial Titanium-Chromium Phase Diagram and the Crystal Structure of TiCr2, Trans. Am. Soc. Met., 1952, 44, p 495-517.

R. van Thyne, H. Kessler and M. Hansen, The Systems Titanium-Chromium and Titanium-Iron, Trans. Am. Soc. Met., 1952, 44, p 974-989.

F. Cuff, N. Grant, and C. Floe, Titanium-Chromium Phase Diagram, Trans. Am. Inst. Min. Metall. Eng., 1952, 194(8), p 848-853.

B. Levinger, High Temperature Modification of TiCr2, Trans. Am. Inst. Min. Metall. Eng., 1953, 197(2), p 196-196.

M.K. McQuillan, A Redetermination and Interpretation of the Titanium-Rich Region of the Titanium Chromium System, J. Inst. Met., 1954, 82(9), p 433-439.

I.I. Kornilov, V.S. Mikheev, and T.S. Chernova, Constitution Diagram of Ti-Cr, Trudy Inst. Metall. Akad. Nauk SSSR, 1957, 2, p 126-134. in Russian

Y.A. Bagariatskii, G.I. Nosova, and T.V. Tagunova, Study of the Phase Diagrams of the Alloys Titanium-Chromium, Titanium-Tungsten, and Titanium-Chromium-Tungsten, Prepared by the Method of Powder Metallurgy, Zh. Neorg. Khim., 1958, 3(3), p 777-785. in Russian

A.W. Goldenstein, A.G. Metcalfe, and W. Rostoker, The Effect of Stress on the Eutectoid Decomposition of Titanium Chromium Alloys, Trans. Am. Soc. Met., 1959, 51, p 1036-1053.

K. Gross and I. Lamborn, Allotropic Modifications of TiCr2, J. Inst. Met., 1960, 88(9), p 416-416.

I. Ageev, O. Karpinski, and L. Petrova, Stability of Beta-Solid Solution of Titanium-Chromium Alloys, Zh. Neorg. Khim., 1961, 6(8), p 1976-1978.

F. Ermanis, P. Farrar, and H. Margolin, A Reinvestigation of the Systems Ti-Cr and Ti-V, Trans. Metall. Soc. Aime., 1961, 221(5), p 904-908.

V.S. Mikheev and V.S. Aleksashin, Electrical Volume Resistivity of Alloys of the Titanium-Chromium System up to Temperatures of 1100 °C, Fiz. Met. Metalloved., 1962, 14(2), p 231-237.

V.S. Mikheyev and T.S. Chernova, Solubility of Chromium in α-Titanium and Mechanical Properties of the Binary System Titanium-Chromium, Titan Ego Splavy SSSR Inst Met., 1962, 7, p 35-73.

V.N. Svechnikov, Y.A. Kocherzhinskii, and V.I. Latysheva, Consitution Diagram of Chromium Titanium, Vopr. Fiz. Met. Metalloved., 1962, 16, p 132-135. in Ukranian

P. Farrar and H. Margolin, A Reinvestigation of Chromium-Rich Region of Titanium-Chromium System, Trans. Metall. Soc. Aime., 1963, 227(6), p 1342-1345.

N.V. Ageev and M.S. Model, Decay of Solid Solutions of Niobium and and Titanium in Chromium, Dokl. Akad. Nauk SSSR, 1963, 148(1), p 84-85. in Russian

M. Pool, R. Speiser, and G. Pierre, Activities of Chromium and Titanium in Binary Chromium-Titanium Alloys, Trans. Metall. Soc. Aime., 1967, 239(8), p 1180-1186.

E. Rudy, Ternary Phase Equilibria in Transition Metal-Boron–Carbon–Silicon Systems. Part 5. Compendium of Phase Diagram Data, AFML-TR-65-2, Air Force Materials Laboratory, Air Force Systems Command, Wright-Patterson Air Force Base, OH, 1969.

S.A. Minayeva and P.B. Budberg, Phase Structure of Ti-Cr Alloys, Russ. Metall., 1971, 4, p 144-147.

F. Faudot, J. Bigot, Study of Chromium solubility in α pure-Titanium, Titanium Science and Technology, Proceedings of the Fifth International Conference on Titanium, Munich, Deutsche Gesellschaft für Metalkunde e. V., 1984, 3, p 1445-1449.

H. Kudielka, Zum Aufbau des Dreistoff-Systems Titan-Niob-Chrom, DFG Final Report, 1990.

M. Sluiter and P.E.A. Turchi, Phase Stability in Ti-V and Ti-Cr Alloys: A Theoretical Investigation, Phys. Rev. B, 1991, 43(15), p 12251-12266. https://doi.org/10.1103/PhysRevB.43.12251

K.C. Chen, S.M. Allen, and J.D. Livingston, Stoichiometry and Alloying Effects on the Phase Stability and Mechanical Properties of TiCr2-Base LAVES Phase Alloys, MRS Online Proc. Libr., 1994, 364, p 1401-1406. https://doi.org/10.1557/PROC-364-1401

K.C. Chen, S.M. Allen, and J.D. Livingston, Microstructures of two-Phase Ti–Cr Alloys Containing the TiCr2 Laves Phase Intermetallic, J. Mater. Res., 1997, 12(6), p 1472-1480. https://doi.org/10.1557/JMR.1997.0203

K.C. Chen, S.M. Allen, and J.D. Livingston, Factors Affecting the Room-Temperature Mechanical Properties of TiCr2-Base Laves Phase Alloys, Mater. Sci. Eng. A, 1998, 242(1), p 162-173. https://doi.org/10.1016/S0921-5093(97)00526-1

J.C. Zhao, M.R. Jackson, and L.A. Peluso, Mapping of the Nb-Cr-Ti Phase Diagram Using Difusion Multiples, Z. Metallkd., 2004, 95(3), p 142-146. https://doi.org/10.3139/146.017927

W. Baumann, A. Leineweber, and E.J. Mittemeijer, The Kinetics of a Polytypic Laves Phase Transformation in TiCr2, Intermetallics, 2011, 19(4), p 526-535. https://doi.org/10.1016/j.intermet.2010.11.027

M. Chandran, P.R. Subramanian, and M.F. Gigliotti, First Principles Calculation of mIxing Enthalpy of β-Ti with Transition Elements, J. Alloys Compd., 2013, 550, p 501-508. https://doi.org/10.1016/j.jallcom.2012.10.141

R. Sahara, S. Emura, and K. Tsuchiya, Theoretical Investigation of Effect of Alloying Elements on Phase Stability in Body-Centered Cubic Ti-X alloys (X=V, Cr, Fe Co, Nb, and Mo), J. Alloys Compd., 2015, 634, p 193-199. https://doi.org/10.1016/j.jallcom.2015.02.005

L. Zhu, Q. Zhang, Z. Chen, C. Wei, G.-M. Cai, L. Jiang, Z. Jin, and J.-C. Zhao, Measurement of Interdiffusion and Impurity Diffusion Coefficients in the bcc Phase of the Ti–X (X = Cr, Hf, Mo, Nb, V, Zr) Binary Systems Using Diffusion Multiples, J. Mater. Sci., 2017, 52(6), p 3255-3268. https://doi.org/10.1007/s10853-016-0614-0

S. Xu, H. Zhang, G. Yang, Y. Liang, X. Xu, J. He, and J. Lin, Phase Equilibria in the Ti–Al–Cr System at 1000 °C, J. Alloys Compd., 2020, 826, 154236. https://doi.org/10.1016/j.jallcom.2020.154236

K. Ohsaka, E.H. Trinh, J.C. Holzer, and W.L. Johnson, Gibbs Free Energy Difference Between the Undercooled Liquid and the β PHase of a Ti-Cr Alloy, Appl. Phys. Lett., 1992, 60(9), p 1079-1081. https://doi.org/10.1063/1.106450

J.-C. Crivello, Private communication, SQS calculations of the BCC-Ti, 2022.

J. Pavlů, J. Vřešt’ál, and M. Šob, Thermodynamic Modeling of Laves Phases in the Cr–Hf and Cr–Ti Systems: Reassessment Using First-Principles Results, Calphad, 2010, 34(2), p 215-221. https://doi.org/10.1016/j.calphad.2010.03.003

M.H.F. Sluiter, Lattice Stability Prediction of Elemental Tetrahedrally Close-packed Structures, Acta Mater., 2007, 55(11), p 3707-3718. https://doi.org/10.1016/j.actamat.2007.02.016

X.-Q. Chen, W. Wolf, R. Podloucky, and P. Rogl, Ab Initio Study of Ground-State Properties of the Laves Phase Compounds TiCr2, ZrCr2, and HfCr2, Phys. Rev. B, 2005, 71, 174101. https://doi.org/10.1103/PhysRevB.71.174101

L. Kaufman and H. Nesor, Coupled Phase Diagrams and Thermochemical data for Transition Metal Binary Systems - I, Calphad, 1978, 2(1), p 55-80. https://doi.org/10.1016/0364-5916(78)90005-6

I. Ansara, A.T. Dinsdale, and M.H. Rand, COST 507: Thermochemical Database for Light Metal Alloys, Office for Official Publications of the European, Communities, 1998, 2, p 1-420.

J.Y. Lee, J.H. Kim, S.I. Park, and H.M. Lee, Phase Equilibrium of the Ti–Cr–V Ternary System in the Non-Burning β-Ti alloy Region, J. Alloys Compd., 1999, 291(1), p 229-238. https://doi.org/10.1016/S0925-8388(99)00144-9

G. Ghosh, Thermodynamic and Kinetic Modeling of the Cr-Ti-V System, J. Phase Equilibria., 2002, 23(4), p 310-328. https://doi.org/10.1361/105497102770331569

D.M. Cupid, M.J. Kriegel, O. Fabrichnaya, F. Ebrahimi, and H.J. Seifert, Thermodynamic Assessment of the Cr–Ti and first Assessment of the Al–Cr–Ti Systems, Intermetallics, 2011, 19(8), p 1222-1235. https://doi.org/10.1016/j.intermet.2011.03.031

H. Sun, Y. Zhang, Q. Pan, Y. Liu, W. Zheng, and X.-G. Lu, Thermodynamic Modeling of the Ni-Ti-Cr System and the B2/B19′ Martensitic Transformation, Calphad, 2022, 79, 102505. https://doi.org/10.1016/j.calphad.2022.102505

H.M. Rietveld, A Profile Refinement Method for Nuclear and Magnetic Structures, J. Appl. Crystallogr., 1969, 2(2), p 65-71. https://doi.org/10.1107/S0021889869006558

A. Berche, C. Rado, O. Rapaud, C. Guéneau, and J. Rogez, Thermodynamic Study of the U-Si System, J. Nucl. Mater., 2009, 389(1), p 101-107. https://doi.org/10.1016/j.jnucmat.2009.01.014

P. Gardie, G. Bordier, J.J. Poupeau, and J. Le Ny, Thermodynamic Activity Measurements of U-Fe and U-Ga alloys by Mass Spectrometry, J. Nucl. Mater., 1992, 189(1), p 85-96. https://doi.org/10.1016/0022-3115(92)90422-H

M. Baıchi, C. Chatillon, C. Guèneau, and S. Chatain, Mass Spectrometric Study of UO2–ZrO2 Pseudo-Binary System, J. Nucl. Mater., 2001, 294(1), p 84-87. https://doi.org/10.1016/S0022-3115(01)00477-9

S. Chatain, T. Alpettaz, S. Gossé, and C. Guéneau, Thermodynamic Activity Measurements in Nickel-Base Industrial Alloys and Steels by Knudsen cell – Mass Spectrometry, J. Chem. Thermodyn., 2017, 114, p 144-150. https://doi.org/10.1016/j.jct.2017.01.015

J. Safarian and T.A. Engh, Vacuum Evaporation of Pure Metals, Metall. Mater. Trans. A, 2013, 44(2), p 747-753. https://doi.org/10.1007/s11661-012-1464-2

Z.-K. Liu, Computational Thermodynamics and its Applications, Acta Mater., 2020, 200, p 745-792. https://doi.org/10.1016/j.actamat.2020.08.008

G. Kresse and J. Furthmüller, Efficiency of Ab-Initio Total Energy Calculations for Metals and Semiconductors using a Plane-Wave Basis Set, Comput. Mater. Sci., 1996, 6(1), p 15-50. https://doi.org/10.1016/0927-0256(96)00008-0

G. Kresse and D. Joubert, From Ultrasoft Pseudopotentials to the Projector Augmented-Wave Method, Phys. Rev. B, 1999, 59(3), p 1758-1775. https://doi.org/10.1103/PhysRevB.59.1758

P.E. Blöchl, Projector Augmented-Wave Method, Phys. Rev. B, 1994, 50(24), p 17953-17979. https://doi.org/10.1103/PhysRevB.50.17953

J.P. Perdew, K. Burke, and M. Ernzerhof, Generalized Gradient Approximation Made Simple, Phys. Rev. Lett., 1996, 77(18), p 3865-3868. https://doi.org/10.1103/PhysRevLett.77.3865

J.-C. Crivello, R. Souques, A. Breidi, N. Bourgeois, and J.-M. Joubert, ZenGen, a tool to Generate Ordered Configurations for Systematic First-Principles Calculations: The Cr–Mo–Ni–Re System as a Case Study, Calphad, 2015, 51, p 233-240. https://doi.org/10.1016/j.calphad.2015.09.005

H.J. Monkhorst and J.D. Pack, Special Points for Brillouin-Zone Integrations, Phys. Rev. B, 1976, 13(12), p 5188-5192. https://doi.org/10.1103/PhysRevB.13.5188

A.T. Dinsdale, SGTE data for pure elements, Calphad, 1991, 15(4), p 317-425. https://doi.org/10.1016/0364-5916(91)90030-N. Version 5.0 (2009) https://www.sgte.net/en/free-pure-substance-database

Z.H. Yan, T. Klassen, C. Michaelsen, M. Oehring, and R. Bormann, Inverse Melting in the Ti-Cr System, Phys. Rev. B, 1993, 47(14), p 8520-8527. https://doi.org/10.1103/PhysRevB.47.8520

W. Baumann, Private Communication, DTA Experiments on the Cr-Ti System, 2012.

J.P. Gros, I. Ansara, M. Allibert, Prediction of alpha/beta equilibria in Titanium-based alloys containing Al, Mo, Zr, Cr (Part I), in: Societé Française de Métallurgie, Cannes, 1988, p 1553.

A. van de Walle, Q. Hong, S. Kadkhodaei, and R. Sun, The Free Energy of Mechanically Unstable Phases, Nat. Commun., 2015, 6(1), p 7559. https://doi.org/10.1038/ncomms8559

S. Kadkhodaei, Q.-J. Hong, and A. van de Walle, Free Energy Calculation of Mechanically Unstable but Dynamically Stabilized bcc Titanium, Phys. Rev. B, 2017, 95(6), 064101. https://doi.org/10.1103/PhysRevB.95.064101

A. Flores, To be published, Experimental investigation of the Cr-Mo-Ti system, 2023.

Acknowledgment

The authors thank Shigehiro Ishikawa for his contribution to the EPMA, DTA, and XRD experiments and Thierry Alpettaz for KEMS activity measurements.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This invited article is part of a special tribute issue of the Journal of Phase Equilibria and Diffusion dedicated to the memory of Thaddeus B. “Ted” Massalski. The issue was organized by David E. Laughlin, Carnegie Mellon University; John H. Perepezko, University of Wisconsin–Madison; Wei Xiong, University of Pittsburgh; and JPED Editor-in-Chief Ursula Kattner, National Institute of Standards and Technology (NIST).

Supplementary Information

Below is the link to the electronic supplementary material.

Heating-rate dependence of the DTA onset temperatures of the C15-C36 and C36-C14 transformations of Ti-rich samples.

Supplementary file1 (TIF 5440 kb)

Laves phase region of present assessment compared with experimental data.

Supplementary file2 (TIF 975 kb)

Rietveld refinement of 24 at.% Ti alloy treated at 1300°C. Identified phases: bcc.

Supplementary file3 (TIF 649 kb)

Rietveld refinement of 24 at.% Ti alloy treated at 1150°C. Identified phases: bcc + C15.

Supplementary file4 (TIF 672 kb)

Rietveld refinement of 48 at.% Ti alloy treated at 1100°C. Identified phases: bcc + C15.

Supplementary file5 (TIF 705 kb)

Rietveld refinement of 48 at.% Ti alloy treated at 1150°C. Identified phases: bcc + C36.

Supplementary file6 (TIF 716 kb)

Parameters of the thermodynamic database of the Cr–Ti system.

Supplementary file6 (TXT 7 kb)

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Flores, A., Chatain, S., Fossati, P. et al. Experimental Investigation and Thermodynamic Assessment of the Cr–Ti System. J. Phase Equilib. Diffus. (2024). https://doi.org/10.1007/s11669-024-01090-2

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11669-024-01090-2