Abstract

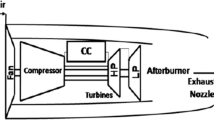

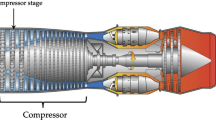

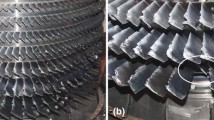

The compressor is an integral and an important part of an aero-engine. The blades of compressor fail because of several reasons. Failed blades of various aero-engines are subjected to investigations in this work. Results of these investigations are presented in detail. Compressor blade denoted as CB-1 failed because of formation of alpha casing and impact on the casing. Another compressor blade termed as CB-2 was damaged because of impact by foreign object. Sticking of the blade to the casing resulting in tearing of the blade is responsible for failing of third compressor blade referred as CB-3. Thermo-mechanical fatigue caused cracking on a different compressor blade designated as CB-4. Impact by foreign object containing Ca, Al, Zn and O is the reason for the damage of the leading and trailing edges of fifth compressor blade assigned as CB-5.

Similar content being viewed by others

References

V. Infante, J.M. Silva, M. de Freitas, L. Reis, Failures analysis of compressor blades of aeroengines due to service. Eng. Fail. Anal. 16, 1118–1125 (2009)

K.S. Song, S.G. Kim, Y.H. Hwang, Failure of the J79 engine compressor blade due to stall. J. Fail. Anal. Prev. 7, 212–217 (2007)

K. Mishra, K. Johney Thomas, S.S.I. Ahmed, Fatigue Failure of LP Compressor Blade in an Aero Gas. J. Fail. Anal. Prev. 14, 296–302 (2014)

R.K. Mishra, V. Nandi, R. Raghavendra Bhat, Failure analysis of high-pressure compressor blade in, an aero gas turbine engine. J. Fail. Anal. Prev. 18, 465–470 (2018)

E. Poursaeidi, A. Babaei, F. Behrouzshad, M.R. Mohammadi Arhani, Failure analysis of an axial compressor first row rotating blades. Eng. Fail. Anal. 28, 25–33 (2013)

L. Witek, Experimental crack propagation and failure analysis of the first stage compressor blade subjected to vibration. Eng. Fail. Anal. 16, 2163–2217 (2009)

M. Swamy, A.H.V. Kulvir Singh, M.C. Pavan Antony Harison, G. Jayaraman, Failure investigation of frame 6FA gas turbine compressor blades. Trans. Ind. Inst. Met. 69, 647–651 (2016)

M. Roy, Failure analysis of bearings of aero engine. J. Fail. Anal. Prev. 19, 1615–1629 (2019)

S. Madhav, M. Roy, Failure analysis of turbine stator vanes of aero-engine. Eng. Fail. Anal. 117, 104783 (2020)

S. Sung, Y. Kim, Alpha-case formation mechanism on titanium investment castings. Mater. Sci. Eng. A. 405, 173 (2005)

C. Tomastic, M. Lackner, A. Pauschitz, M. Roy, Structural, chemical and nanomechanical investigations of SiC/polymeric a-C: H films deposited by reactive RF unbalanced magnetron sputtering. Solid State Sci. 53, 1–8 (2016)

P. Cosemans, X. Zhu, J.P. Celis, M.V. Stappen, Development of low friction wear-resistant coatings. Surf. Coat. Technol. 174–175, 416–420 (2003)

M. Roy, S. Kvasnica, C. Eisenmenger-Stittner, G. Vorlaufer, A. Pauschitz, An analysis of nano tribological study of Ti-containing hard carbon film. Surf. Eng. 21(3), 257–264 (2005)

T. Sampath Kumar, S. Balasivanandha Prabu, S. Madhavan, K.A. Padmanabhan, Thermal stability of cathodic arc vapour deposited TiAlN/AlCrN and AlCrN/TiAlN coatings on tungsten carbide tool. Trans. Ind. Inst. Met. 71, 665–676 (2018)

A.K. Krella, Cavitation erosion of monolayer PVD coatings – An influence of deposition technique on the degradation process. Wear. 478–479, 203762 (2021)

M. Roy, S. Saha, K. Valleti, Microstructure and wear of cathodic arc physical vapor deposited TiAlN, TiCrN and n-TiAlN/α-Si3N4 films. Def. Sci. J. 70(6), 656–663 (2020)

H.A. Jehn, Multicomponent and multiphase hard coatings for tribological applications. Surf. Coat. Technol. 131, 433–440 (2000)

M. Palaniappa, M. Roy, Plating and Tribology, Surface Engineering for Enhanced Performance against Wear. (Springer Verlag, Austria, 2013)

S.N. Patankar, Y.T. Kwang, T.M. Jen, Alpha casing and super plastic behavior of Ti-6-4. J. Mater. Proces. Technol. 112, 24–28 (2001)

M. Roy, K.K. Ray, G. Sundararajan, An analysis of the transition from metal erosion to oxide erosion. Wear. 217, 312–320 (1998)

S. Sarkar, E. Badisch, R. Mitra, M. Roy, Impact abrasive wear response of carbon/carbon composites at elevated temperatures. Tribology Letter. 37, 445–451 (2010)

M. Roy, D. Subba Rao, S. Rao, G. Sundararajan, Abrasive wear behaviour of detonation sprayed WC-Co coatings on mild steel. Surf. Eng. 15, 129–136 (1999)

M. Roy, Y. Tirupataiah, G. Sundararajan, Effect of particle shape on the erosion of Cu and its alloys. Mater. Sci. Eng., A. 165, 51–63 (1993)

A. Kermanpur, H. Sepehri Amin, S. Ziaei-Rad, N. Nourbakhshnia, M. Mosaddeghfar, Failure analysis of Ti6Al4V gas turbine compressor blades. Eng. Fail. Anal. 15, 1052–1064 (2008)

W. Feifei, C. Yunyong, W. Zhiqing, C. Lulu, M. Jin, Failure analysis of rubbing of the fan tip and case of an engine. Proc. Eng. 99, 1289–1296 (2015)

D. Lao, W. Jia, S. Li, D. Heiand, R. Chen, Effect of residual compressive stress on thermal shock resistance and microstructure of Al2O3–ZrO2 reticulated porous ceramics. Mater. Res. Express. 6(10), 105209 (2019)

D. Senthilkumar, I. Rajendrana, M. Pellizzari, J. Siiriainen, Influence of shallow and deep cryogenic treatment on the residual state of stress of 4140 steel. J. Mater. Process. Technol. 211, 396–401 (2011)

I. Gunes, A. Cicek, K. Aslantas, F. Kara, Effect of deep cryogenic treatment on wear resistance of AISI 52100 bearing steel. Trans. Ind. Inst. Met. 67, 909–917 (2014)

N. Krishnaraj, M. Roy, Tribology of Diffusion Treated Surfaces, Surface Engineering for Enhanced Performance against Wear. (Springer Verlag, Austria, 2013)

E. Silveira, G. Atxaga, A.M. Irisarri, Failure analysis of a set of compressor blades. Eng. Fail. Anal. 15, 666–674 (2008)

R. Sharma, P. Manda, S. Singh, A.K. Singh, Failure analysis of variable inlet guide vane and compressor rotor blade of helicopter engine. Mater. Today Proc. 5, 5124–5130 (2018)

P. Mukhopadhyay, M. Srinivas, M. Roy, Microstructural development during erosion of tribological steel. Mater. Charact. 113, 43–51 (2016)

M. Roy, Dynamic hardness of detonation sprayed WC-Co coating. J. Therm. Spray Technol. 11, 393–399 (2002)

M. Roy, Y. Tirupataiah, G. Sundararajan, The influence of solid solution and dispersion strengthening mechanisms on the room temperature erosion behaviour of Nickel. Mater. Sci. Technol. 11, 791–797 (1995)

M. Roy, Approaches to enhance elevated temperature erosion resistance of Ni-base super alloys. Mater. High Temp. 36(2), 142–156 (2019)

Acknowledgment

Authors are grateful to the Director, DMRL for giving permission to publish the manuscript.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Madhav, S., Roy, M. Failure Analysis of Compressor Blades of Aero-Engine. J Fail. Anal. and Preven. 22, 968–982 (2022). https://doi.org/10.1007/s11668-022-01405-w

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11668-022-01405-w