Abstract

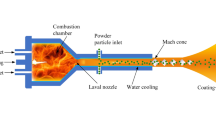

HVOF has unique advantages as spraying metal carbides and alloys and is widely used in the aerospace, national defense industry, iron and steel metallurgy, petrochemical industry and other fields. The WC-Co coating prepared by HVOF has the characteristics of low oxide content, high bonding strength, low porosity and high temperature resistance and is the most ideal surface strengthening technology to replace surface chrome plating. In this study, a three-dimensional model of HVOF spraying was established and the flame flow characteristics in the spraying were analyzed. Combined with the discrete phase model (DPM), the influence of spraying distance, particle size and O/F ratio on temperature and velocity for particle flight were revealed. Based on the birth and death unit method, a three-dimensional thermodynamic coupling model of multi-layer coating growth was established. The stress-strain law of each coating unit in the growth process of WC-12Co coating was explored. The optimal particle parameters were obtained by calculating the flow field. The calculation shows that the optimal temperature and velocity of the sprayed particles are 1402 K and 535 m/s, respectively. The temperature of each coating unit gradually increases from the center to the outer ring and decreases under the action of air cooling with the spread time. The difference of temperature is obvious between the coating and the substrate, resulting in a relatively large stress value at the junction of the two and a relatively concentrated stress between adjacent elements. The maximum tensile stress in the X-axis direction reaches 1908 MPa and distributes in an elliptical shape at the center position of the coating unit. The shear stress in the XY direction is concentrated at the edge of each element for the coating, and the maximum reaches 1285 MPa.

Similar content being viewed by others

References

M. Li and P.D. Christofides, Computational Study of Particle in-Flight Behavior in the HVOF Thermal Spray Process, Chem. Eng. Sci., 2006, 61(19), p 6540-6552.

I. Baumann, W. Tillmann, C. Schaak, K. Schmidt, L. Hagen, J. Zajaczkowski, G. Schmidtmann, G. Matthäus, and W. Luo, Internal Diameter Coating by Warm Spraying of Fine WC-12Co Powders (− 10 + 2 µm) with Very Short Spray Distances up to 10 mm, J. Therm. Spray Technol., 2021, 30(5), p 1344-1364.

I. Baumann, L. Hagen, W. Tillmann, P. Hollingsworth, D. Stangier, G. Schmidtmann, M. Tolan, M. Paulus, and C. Sternemann, Process Characteristics, Particle Behavior and Coating Properties During HVOF Spraying of Conventional, Fine and Nanostructured WC-12Co Powders, Surf. Coat. Technol., 2021, 15(405), p 126716.

M. Oksa, E. Turunen, T. Suhonen, T. Varis, and S.-P. Hannula, Optimization and Characterization of High Velocity Oxy-fuel Sprayed Coatings: Techniques, Mater. Appl. Coat., 2011, 1(1), p 17-52.

M. Jadidi, S. Moghtadernejad, and A. Dolatabadi, A Comprehensive Review on Fluid Dynamics and Transport of Suspension/Liquid Droplets and Particles in High-Velocity Oxygen-Fuel (HVOF) Thermal Spray, Coatings, 2015, 5(4), p 576-645.

Y. Sun. Study on Combustion Characteristics and Spray Particle Behavior of Supersonic Flame Spraying, China University of Petroleum (Eastern China), (2011).

H. Tabbara, S. Gu, and D.G. McCartney, Computational Modelling of Titanium Particles in Warm Spray, Comput. Fluids, 2011, 44(1), p 358-368.

J.-S. Baik and Y.-J. Kim, Effect of Nozzle Shape on the Performance of High Velocity Oxygen-Fuel Thermal Spray System, Surf. Coat. Technol., 2008, 202(22-23), p 5457-5462.

H. Jafari, S. Emami, and Y. Mahmoudi, Numerical Investigation of Dual-Stage High Velocity Oxy-Fuel (HVOF) Thermal Spray Process: A Study on Nozzle Geometrical Parameters, Appl. Therm. Eng., 2017, 111, p 745-758.

J. Pan, S. Hu, L. Yang, K. Ding, and B. Ma, Numerical Analysis Of Flame and Particle Behavior in an HVOF Thermal Spray Process, Mater. Des., 2016, 96, p 370-376.

C. Li, X. Gao, D. Zhang, H. Gao, X. Han, and B. Zhang, Numerical Investigation on the Flame Characteristics and Particle Behaviors in a HVOF Spray Process Using Kerosene as Fuel, J. Therm. Spray Technol., 2021, 30(3), p 725-738.

C. Li, X. Gao, Y. Yang, X. Chen, and X. Han, Sensitivity Analysis of Process Parameters of Warm Spraying Process Based on Response Surface Method, J. Therm. Spray Technol., 2022, 31(3), p 585-597.

L. Qiao, Y. Wu, S. Hong, J. Cheng, and Z. Wei, Influence of the High-Velocity Oxygen-Fuel Spray Parameters on the Porosity and Corrosion Resistance of Iron-Based Amorphous Coatings, Surf. Coat. Technol., 2019, 366, p 296-302.

M.N. Khan and T. Shamim, Investigation of a Dual-Stage High Velocity Oxygen Fuel Thermal Spray System, Appl. Energy, 2014, 130, p 853-862.

M.N. Khan and T. Shamim, Effect of Particle and Injection Parameters on the Performance of a Dual-Stage High-Velocity Oxygen Fuel Thermal Spray System, J. Therm. Spray Technol., 2015, 24(5), p 807-816.

B.F. Magnussen and B.H. Hjertager, On Mathematical Modeling of Turbulent Combustion with Special Emphasis on Soot Formation and Combustion, Symp. Combust., 1977, 16(1), p 719-729.

R. Kamali and A.R. Binesh, The Importance of Sensitive Parameters Effect on the Combustion in a High Velocity Oxygen-Fuel Spray System, Int. Commun. Heat Mass Transfer, 2009, 36(9), p 978-983.

S. Gordon, B.J. Mcbride, Computer Program for Calculation of Complex Chemical Equilibrium Compositions and Applications. Part 1: Analysis. nasa reference publications, (1994)

X. Gao, C. Li, D. Zhang, H. Gao, and X. Han, Numerical Analysis of the Activated Combustion High-Velocity Air-Fuel (AC-HVAF) Thermal Spray Process: A Survey on the Parameters of Operation And Nozzle Geometry, Surf. Coat. Technol., 2021, 15(405), p 126588.

X. Gao, C. Li, Y. Xu, X. Chen, and X. Han, Effects of Fuel Types and Process Parameters on the Performance of an Activated Combustion High Velocity Air-Fuel (AC-HVAF) Thermal Spray System, J. Therm. Spray Technol., 2021, 30(7), p 1875-1890.

M. Xiao, X. Liu, S. Zeng, Z. Zheng, G. Wang, Z. Qiu, M. Liu, and D. Zeng, Effects of Particle Size on the Microstructure and Mechanical Properties of HVAF-Sprayed Al-Based Quasicrystalline Coatings, J. Therm. Spray Technol., 2021, 30(5), p 1380-1392.

H.-R. Jiang, M.-L. Li, X.-S. Wei, T.-C. Ma, Y. Dong, C.-X. Ying, Z.-Y. Liao, and J. Shen, Numerical Investigation of In-Flight Behavior of Fe-Based Amorphous Alloy Particles in AC-HVAF Thermal Spray Process, J. Therm. Spray Technol., 2019, 28(6), p 1146-1159.

H. Chen, M. Xiao, and W.F. Heng, Dynamic Simulation of Phased Excavation Based on ABAQUS Large Underground Cavern Group, J. Wuhan Univ. Eng. Edit., 2013, 46(03), p 321-327.

R.F. Leng and Y.F. Zhang, Simulation of Life and Death Method of Dynamic Construction Process Units of Foundation Pit Engineering, J. Guangzhou Univ. Nat. Sci. Edit., 2011, 10(02), p 64-67.

Y. Li, Residual stress analysis of steel structure welding, Wuhan Univ. Technol., (2007)

Acknowledgments

The authors thank the “Applied Basic Research Project of Liaoning Province (2023JH2/101300226)” and“Project for Graduate Education Reform and Technological Innovation and Entrepreneurship of University of Science and Technology Liaoning (2023YJSCX02).”

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no competing interests.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Li, C., Li, S. & Han, X. The Study on Flow Field Simulation and WC-12Co Multi-layer Coating Growth in High-Velocity Oxygen-Fuel (HVOF) Thermal Spraying. J Therm Spray Tech 33, 1135–1157 (2024). https://doi.org/10.1007/s11666-024-01724-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-024-01724-4