Abstract

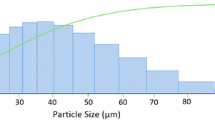

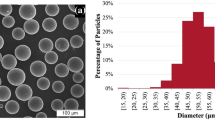

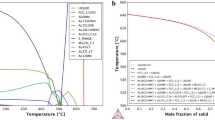

The lack of a comprehensive understanding of the role of heat treatments on microstructure and multiscale mechanical properties of powders and their interrelatedness with cold spray process parameters severely impedes the manufacturing of high-strength aluminum coatings. For the first time, this study develops customized heat treatment protocols for controlling microstructure homogenization and intermetallic precipitation in Al 6061 and Al 7075 powders for cold spray. Solution treatment at 505-545 °C, followed by precipitation hardening at 130-160 °C, enables controlled precipitation of hard intermetallic Mg2Si and MgZn2 phases in Al 6061 and Al 7075, respectively. Strengthening by these phases enhances powder nanohardness of Al 6061 and Al 7075 from 1.0 and 1.5 to 1.6 and 1.8 GPa, respectively. The cumulative response from multiple grains at the micrometer length scale carries the trend to improve microhardness to 131.2 and 177 HV. These characteristics of the precipitation-hardened powder encompass improvements of 13-60% above their pristine gas-atomized counterparts. Experimentally measured powder hardness was employed as input in a cold spray simulation tool to develop process maps for manufacturing high-quality coatings. The optimum temperature for deposition with 75-98% efficiencies was established to be 100-300 °C with helium and 500-600 °C with nitrogen and air. In this process window, the particle velocity and critical velocity range of the powders are 998 to 1237 ms−1 and 548 to 858 ms−1 for helium and 580 to 663 ms−1 and 400 to 594 ms−1 for air and nitrogen, respectively.

Similar content being viewed by others

References

Victor Kenneth Champagne and Ozan Cagatay Ozdemir Aaron. Nardi, Practical Cold Spray, Springer, Cham, 2021.

T.H.V. Steenkiste, J.R. Smith and R.E. Teets, Aluminum Coatings via Kinetic Spray with Relatively Large Powder Particles, Surf. Coat. Technol., 2002, 154(2-3), p 237-252.

R.N. Raoelison, Analytical Description of Solid Particles Kinematics Due to a Fluid Flow and Application to the Depiction of Characteristic Kinematics in Cold Spraying, Powder Technol., 2017, 319, p 191-203. https://doi.org/10.1016/j.powtec.2017.06.029

He. Shiwen, L. Yong and G. Sheng, Cooling Rate Calculation of Non-Equilibrium Aluminum Alloy Powders Prepared by Gas Atomization, Rare Met. Mater. Eng., 2009, 38(S1), p 353-356.

G. von Bradsky and R.A. Ricks, Solidification Microstructures in Rapidly Solidified, Gas Atomized Aluminium-Lithium Alloy Powders, J. Mater. Sci., 1987, 22(4), p 1469-1476.

S. Hariprasad, S.M.L. Sastry and S. Louis, Undercooling and Supersaturation of Alloying Elements in Rapidly Solidified AI-8.5% Fe-1.2% V-1.7% Si Alloy, J. Mater. Sci., 1996, 31(4), p 921-925. https://doi.org/10.1007/BF00352891.

M.R. Rokni, C.A. Widener and V.R. Champagne, Microstructural Evolution of 6061 Aluminum Gas-Atomized Powder and High-Pressure Cold-Sprayed Deposition, J. Therm. Spray Technol., 2014, 23(3), p 514-524.

C. Walde, K. Tsaknopoulos, V. Champagne and D. Cote, Phase Transformations in Thermally Treated Gas-Atomized Al 7075 Powder, Metallogr. Microstruct. Anal., 2020, 9(3), p 419-427. https://doi.org/10.1007/s13632-020-00641-6

A. Sabard, P. McNutt, H. Begg and T. Hussain, Cold Spray Deposition of Solution Heat Treated, Artificially Aged and Naturally Aged Al 7075 Powder, Surf. Coatings Technol., 2020, 385, p 125367. https://doi.org/10.1016/j.surfcoat.2020.125367

L.E. Randaccio, Pre-Heat Treatment of Gas Atomized Al 2024 Powder and Its Effects on the Properties of Cold Spray Coatings, Mater of Science Thesis, Northeastern University, December (2019)

K. Tsaknopoulos, J. Grubbs, M. Siopis, A. Nardi and D. Cote, Microstructure and Mechanical Property Evaluation of Aluminum F357 Powder for Cold Spray Applications, J. Therm. Spray Technol., 2021, 30(3), p 643-654. https://doi.org/10.1007/s11666-020-01140-4

M.R. Rokni, A.T. Nardi, V.K. Champagne and S.R. Nutt, Effects of Preprocessing on Multi-Direction Properties of Aluminum Alloy Cold-Spray Deposits, J. Therm. Spray Technol., 2018, 27(5), p 818-826. https://doi.org/10.1007/s11666-018-0723-1

S. Vijayan, B.A. Bedard, M.A. Gleason, H.R. Leonard, D.L. Cote and M. Aindow, Studies of Thermally Activated Processes in Gas-Atomized Al Alloy Powders: In Situ STEM Heating Experiments on FIB-Cut Cross Sections, J. Mater. Sci., 2019, 54(13), p 9921-9932. https://doi.org/10.1007/s10853-019-03562-0

K. Tsaknopoulos, C. Walde, D. Tsaknopoulos, V. Champagne and D. Cote, Characterization of Thermally Treated Gas-Atomized Al 5056 Powder, Materials (Basel), 2020, 13(18), p 1-11.

A. Sabard, H.L. de Villiers Lovelock and T. Hussain, Microstructural Evolution in Solution Heat Treatment of Gas-Atomized Al Alloy (7075) Powder for Cold Spray, J. Therm. Spray Technol., 2018, 27(1-2), p 145-158.

W.A. Story and L.N. Brewer, Heat Treatment of Gas-Atomized Powders for Cold Spray Deposition, Metall. Mater. Trans. A Phys. Metall. Mater. Sci., 2018, 49(2), p 446-449. https://doi.org/10.1007/s11661-017-4428-8

T. Liu, J.D. Leazer, S.K. Menon and L.N. Brewer, Microstructural Analysis of Gas Atomized Al-Cu Alloy Feedstock Powders for Cold Spray Deposition, Surf. Coatings Technol., 2018, 350, p 621-632. https://doi.org/10.1016/j.surfcoat.2018.07.006

A. Sabard and T. Hussain, Inter-Particle Bonding in Cold Spray Deposition of a Gas-Atomised and a Solution Heat-Treated Al 6061 Powder, J. Mater. Sci., 2019, 54(18), p 12061-12078.

C. Walde, D. Cote, V. Champagne and R. Sisson, Characterizing the Effect of Thermal Processing on Feedstock Al Alloy Powder for Additive Manufacturing Applications, J. Mater. Eng. Perform., 2019, 28(2), p 601-610. https://doi.org/10.1007/s11665-018-3550-0

B.A. Bedard, T.J. Flanagan, A.T. Ernst, A. Nardi, A.M. Dongare, H.D. Brody, V.K. Champagne, S.W. Lee and M. Aindow, Microstructure and Micromechanical Response in Gas-Atomized Al 6061 Alloy Powder and Cold-Sprayed Splats, J. Therm. Spray Technol., 2018, 27(8), p 1563-1578. https://doi.org/10.1007/s11666-018-0785-0

A.T. Ernst, P. Kerns, A. Nardi, H.D. Brody, A.M. Dongare, S.W. Lee, V.K. Champagne, S.L. Suib and M. Aindow, Surface States of Gas-Atomized Al 6061 Powders-Effects of Heat Treatment, Appl. Surf. Sci., 2020, 534, p 147643.

K. Tsaknopoulos, C. Walde, V. Champagne and D. Cote, Gas-Atomized Al 6061 Powder: Phase Identification and Evolution During Thermal Treatment, Jom, 2019, 71(1), p 435-443. https://doi.org/10.1007/s11837-018-3175-7

A. List, F. Gärtner, T. Mori, M. Schulze, H. Assadi, S. Kuroda and T. Klassen, Cold Spraying of Amorphous Cu50Zr50 Alloys, J. Therm. Spray Technol., 2014, 24(1-2), p 108-118.

T. Schmidt, H. Assadi, F. Gärtner, H. Richter, T. Stoltenhoff, H. Kreye and T. Klassen, Erratum: From Particle Acceleration to Impact and Bonding in Cold Spraying, J. Therm. Spray Technol., 2009, 18(5-6), p 1038. https://doi.org/10.1007/S11666-009-9357-7

T. Schmidt, H. Assadi, F. Gärtner, H. Richter, T. Stoltenhoff, H. Kreye and T. Klassen, From Particle Acceleration to Impact and Bonding in Cold Spraying, J. Therm. Spray Technol., 2009, 18(5-6), p 794-808.

H. Assadi, T. Schmidt, H. Richter, J.O. Kliemann, K. Binder, F. Gärtner, T. Klassen and H. Kreye, On Parameter Selection in Cold Spraying, J. Therm. Spray Technol., 2011, 20(6), p 1161-1176.

J. Cizek, M. Vilemova, F. Lukac, M. Koller, J. Kondas and R. Singh, Cold Sprayed Tungsten Armor for Tokamak First Wall, Coatings, 2019, 9(12), p 1-15.

S. Krebs, F. Gärtner and T. Klassen, Cold Spraying of Cu-Al-Bronze for Cavitation Protection in Marine Environments, J. Therm. Spray Technol., 2014, 24(1-2), p 126-135.

W. Sun, A.W.Y. Tan, A. Bhowmik, I. Marinescu, X. Song, W. Zhai, F. Li and E. Liu, Deposition Characteristics of Cold Sprayed Inconel 718 Particles on Inconel 718 Substrates with Different Surface Conditions, Mater. Sci. Eng. A, 2018, 720, p 75-84. https://doi.org/10.1016/j.msea.2018.02.059

G. Mauer, R. Singh, K.H. Rauwald, S. Schrüfer, S. Wilson and R. Vaßen, Diagnostics of Cold-Sprayed Particle Velocities Approaching Critical Deposition Conditions, J. Therm. Spray Technol., 2017, 26(7), p 1423-1433.

P. Coddet, C. Verdy, C. Coddet and F. Debray, Effect of Cold Work, Second Phase Precipitation and Heat Treatments on the Mechanical Properties of Copper-Silver Alloys Manufactured by Cold Spray, Mater. Sci. Eng. A, 2015, 637, p 40-47. https://doi.org/10.1016/j.msea.2015.04.008

R.G. Neo, K. Wu, S.C. Tan and W. Zhou, Effect of Spray Distance and Powder Feed Rate on Particle Velocity in Cold Spray Processes, Metals (Basel), 2022, 12(1), p 1-15.

A. Ardeshiri Lordejani, L. Vitali, M. Guagliano and S. Bagherifard, Estimating Deposition Efficiency and Chemical Composition Variation along Thickness for Cold Spraying of Composite Feedstocks, Surf. Coatings Technol., 2022, 436, p 128239. https://doi.org/10.1016/j.surfcoat.2022.128239

O. Stier, Fundamental Cost Analysis of Cold Spray, J. Therm. Spray Technol., 2014, 23(1-2), p 131-139.

M. Flores, Optimization of Cold-Sprayed Nickel Alloy 625 Thick Deposits by Cold Spray Using the KSS Software, IMedPub J., 2022, 8(2).

W. Sun, A. Bhowmik, A.W.Y. Tan, R. Li, F. Xue, I. Marinescu and E. Liu, Improving Microstructural and Mechanical Characteristics of Cold-Sprayed Inconel 718 Deposits via Local Induction Heat Treatment, J. Alloys Compd., 2019, 797, p 1268-1279. https://doi.org/10.1016/j.jallcom.2019.05.099

R. Singh, S. Schruefer, S. Wilson, J. Gibmeier and R. Vassen, Influence of Coating Thickness on Residual Stress and Adhesion-Strength of Cold-Sprayed Inconel 718 Coatings, Surf. Coatings Technol., 2018, 350, p 64-73. https://doi.org/10.1016/j.surfcoat.2018.06.080

A. Elsenberg, M. Busato, F. Gärtner, A. List, A. Bruera, G. Bolelli, L. Lusvarghi and T. Klassen, Influence of MAX-Phase Deformability on Coating Formation by Cold Spraying, J. Therm. Spray Technol., 2021, 30(3), p 617-642.

A.W.Y. Tan, J.Y. Lek, W. Sun, A. Bhowmik, I. Marinescu, X. Song, W. Zhai, F. Li, Z. Dong, C.B. Boothroyd and E. Liu, Influence of Particle Velocity When Propelled Using N2 or N2-He Mixed Gas on the Properties of Cold-Sprayed Ti6Al4V Coatings, Coatings, 2018, 8(9), p 327.

N. Cinca, A. List, F. Gärtner, J.M. Guilemany and T. Klassen, Influence of Spraying Parameters on Cold Gas Spraying of Iron Aluminide Intermetallics, Surf. Coatings Technol., 2015, 268, p 99-107. https://doi.org/10.1016/j.surfcoat.2014.07.070

Z. Arabgol, M. Villa Vidaller, H. Assadi, F. Gärtner and T. Klassen, Influence of Thermal Properties and Temperature of Substrate on the Quality of Cold-Sprayed Deposits, Acta Mater. Acta Materialia Inc., 2017, 127, p 287-301. https://doi.org/10.1016/j.actamat.2017.01.040

H. Che, P. Vo and S. Yue, Investigation of Cold Spray on Polymers by Single Particle Impact Experiments, J. Therm. Spray Technol., 2019, 28(1-2), p 135-143. https://doi.org/10.1007/s11666-018-0801-4

H. Che, S. Yue, and P. Vo, Investigation of Cold Spray on Polymers by Single Particle Impact Experiments, Proc. Int. Therm. Spray Conf., 173-178. May 2018

P. Coddet, C. Verdy, C. Coddet and F. Debray, Mechanical Properties of Cu-0.1Ag Alloys Deposited by Cold Spray with Various Powder Feed Rate and Heat Treatment, J. Therm. Spray Technol., 2014, 24(1-2), p 119-125.

H. Che, X. Chu, P. Vo and S. Yue, Metallization of Various Polymers by Cold Spray, J. Therm. Spray Technol., 2018, 27(1-2), p 169-178.

A.W.Y. Tan, J.Y. Lek, W. Sun, A. Bhowmik, I. Marinescu, P.J. Buenconsejo, Z. Dong and E. Liu, Microstructure, Mechanical and Tribological Properties of Cold Sprayed Ti6Al4V-CoCr Composite Coatings, Compos. Part B Eng., 2020, 202, p 108280. https://doi.org/10.1016/j.compositesb.2020.108280

P. Coddet, C. Verdy, C. Coddet and F. Debray, On the Mechanical and Electrical Properties of Copper-Silver and Copper-Silver-Zirconium Alloys Deposits Manufactured by Cold Spray, Mater. Sci. Eng. A, 2016, 662, p 72-79. https://doi.org/10.1016/j.msea.2016.03.049

L.I. Pérez-Andrade, F. Gärtner, M. Villa-Vidaller, T. Klassen, J. Muñoz-Saldaña and J.M. Alvarado-Orozco, Optimization of Inconel 718 Thick Deposits by Cold Spray Processing and Annealing, Surf. Coatings Technol., 2019, 378, p 124997. https://doi.org/10.1016/j.surfcoat.2019.124997

M. Hauer, F. Gärtner, S. Krebs, T. Klassen, M. Watanabe, S. Kuroda, W. Krömmer and K.M. Henkel, Process Selection for the Fabrication of Cavitation Erosion-Resistant Bronze Coatings by Thermal and Kinetic Spraying in Maritime Applications, J. Therm. Spray Technol., 2021, 30(5), p 1310-1328.

C. Huang, M. Arseenko, L. Zhao, Y. Xie, A. Elsenberg, W. Li, F. Gärtner, A. Simar and T. Klassen, Property Prediction and Crack Growth Behavior in Cold Sprayed Cu Deposits, Mater. Des., 2021, 206, p 109826. https://doi.org/10.1016/j.matdes.2021.109826

M.V. Vidaller, A. List, F. Gaertner, T. Klassen, S. Dosta and J.M. Guilemany, Single Impact Bonding of Cold Sprayed Ti-6Al-4V Powders on Different Substrates, J. Therm. Spray Technol., 2015, 24(4), p 644-658.

S. Bagherifard, J. Kondas, S. Monti, J. Cizek, F. Perego, O. Kovarik, F. Lukac, F. Gaertner and M. Guagliano, Tailoring Cold Spray Additive Manufacturing of Steel 316 L for Static and Cyclic Load-Bearing Applications, Mater. Des., 2021, 203, p 109575. https://doi.org/10.1016/j.matdes.2021.109575

C. Huang, A. List, J. Shen, B. Fu, S. Yin, T. Chen, B. Klusemann, F. Gärtner and T. Klassen, Tailoring Powder Strengths for Enhanced Quality of Cold Sprayed Al6061 Deposits, Mater. Des., 2022, 215, p 110494. https://doi.org/10.1016/j.matdes.2022.110494

N. Fan, J. Cizek, C. Huang, X. Xie, Z. Chlup, R. Jenkins, R. Lupoi and S. Yin, A New Strategy for Strengthening Additively Manufactured Cold Spray Deposits through In-Process Densification, Addit. Manuf., 2020, 36, p 101626. https://doi.org/10.1016/j.addma.2020.101626

M. Terrone, A. Ardeshiri Lordejani, J. Kondas and S. Bagherifard, A Numerical Approach to Design and Develop Freestanding Porous Structures through Cold Spray Multi-Material Deposition, Surf. Coatings Technol., 2021, 421, p 127423. https://doi.org/10.1016/j.surfcoat.2021.127423

K. Wu, W. Sun, A.W.Y. Tan, I. Marinescu, E. Liu and W. Zhou, An Investigation into Microstructure, Tribological and Mechanical Properties of Cold Sprayed Inconel 625 Coatings, Surf. Coatings Technol., 2021, 424, p 127660. https://doi.org/10.1016/j.surfcoat.2021.127660

G. Mauer, K.H. Rauwald, Y.J. Sohn and T.E. Weirich, Cold Gas Spraying of Nickel-Titanium Coatings for Protection Against Cavitation, J. Therm. Spray Technol., 2021, 30(1-2), p 131-144. https://doi.org/10.1007/s11666-020-01139-x

T. Lindner, M. Löbel, M. Grimm and J. Fiebig, Cold Gas Spraying of Solution-Hardened 316L Grade Stainless Steel Powder, Metals (Basel), 2022, 12(1), p 1-11.

C. Huang, A. List, F. Gartner and T. Klassen, Cold Spray Deposition of Functionally Graded Al-SiC Composites, Available at SSRN: https://ssrn.com/abstract=4097864 or https://doi.org/10.2139/ssrn.4097864.

B.C. Sousa, M.A. Gleason, B. Haddad, V.K. Champagne, A.T. Nardi and D.L. Cote, Nanomechanical Characterization for Cold Spray: From Feedstock to Consolidated Material Properties, Metals (Basel), 2020, 10(9), p 1-71.

J. Beddoes, Design of Solution Heat Treatments for Aerospace Alloys, Can. Metall. Q., 2011, 50(3), p 215-221.

C.W. Lin, F.Y. Hung and T.S. Lui, Microstructure Evolution and Microstructural Characteristics of Al-Mg-Si Aluminum Alloys Fabricated by a Modified Strain-Induced Melting Activation Process, Metals (Basel), 2018, 8(1), p 3.

X. Zhang and T. Chen, Solution Treatment Behaviors of 6061 Aluminum Alloy Prepared by Powder Thixoforming, Mater. Res., 2018, 21(4), p e20180057. https://doi.org/10.1590/1980-5373-mr-2018-0057.

T. Maeda, K. Kaneko, T. Namba, Y. Koshino, Y. Sato, R. Teranishi and Y. Aruga, Structural and Compositional Study of Precipitates in Under-Aged Cu-Added Al-Mg-Si Alloy, Sci. Rep., 2018, 8(1), p 1-5. https://doi.org/10.1038/s41598-018-35134-8

D.I. Richard and P.N. Adler, Calorimetric Studies of 7000 Series Aluminum Alloys: I. Matrix Precipitate Characterization of 7075, Metall. Trans. A, 1977, 8(7), p 1177-1183.

T.R. Prabhu, Effects of Ageing Time on the Mechanical and Conductivity Properties for Various Round Bar Diameters of AA 2219 Al Alloy, Eng. Sci. Technol. an Int. J., 2017, 20(1), p 133-142. https://doi.org/10.1016/j.jestch.2016.06.003

M.H. Farshidi, M. Kazeminezhad and H. Miyamoto, Severe Plastic Deformation of 6061 Aluminum Alloy Tube with Pre and Post Heat Treatments, Mater. Sci. Eng. A, 2013, 563, p 60-67. https://doi.org/10.1016/j.msea.2012.11.025

A.K. Keshri, R. Patel and A. Agarwal, Comprehensive Process Maps to Synthesize High Density Plasma Sprayed Aluminum Oxide Composite Coatings with Varying Carbon Nanotube Content, Surf. Coatings Technol., 2010, 205(3), p 690-702. https://doi.org/10.1016/j.surfcoat.2010.07.007

H. Assadi, H. Kreye, F. Gärtner and T. Klassen, Cold Spraying–A Materials Perspective, Acta Mater., 2016, 116, p 382-407. https://doi.org/10.1016/j.actamat.2016.06.034

Acknowledgments

The authors acknowledge the financial support of DEVCOM—Army Research Laboratory (ARL) grant W911NF2020256. The Advanced Materials Engineering Research Institute (AMERI) at FIU is greatly acknowledged for all the characterization facilities used in this study.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Supplementary Information

Below is the link to the electronic supplementary material.

Rights and permissions

About this article

Cite this article

John, D., Paul, T., Orikasa, K. et al. Engineered Aluminum Powder Microstructure and Mechanical Properties by Heat Treatment for Optimized Cold Spray Deposition of High-Strength Coatings. J Therm Spray Tech 31, 2537–2559 (2022). https://doi.org/10.1007/s11666-022-01455-4

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-022-01455-4