Abstract

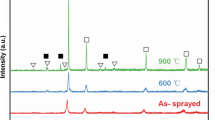

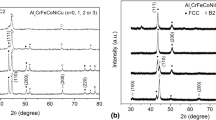

High entropy alloys (HEAs) are characterized as alloys containing five or more principal elements in equal or close to equal atomic percentage. HEAs as bulk materials and coatings are considered a potential candidate for high-temperature applications owing to their superior combination of mechanical and thermal properties. In the present study, the CrMnFeCoNi HEA coatings were developed using high-velocity oxygen fuel (HVOF) and annealed at 800 °C for 2 h. The microstructure and wear behavior of the as sprayed and annealed HEA coatings were systematically evaluated on rough and polished surfaces. The wear behavior of these HEA coatings against an alumina (Al2O3) ball was tested at room temperature. Ex situ characterization was performed using XRD and Raman spectroscopy for phase analysis, SEM-EDS for cross-section microscopy and phase compositions of the HEA coatings. Both the as sprayed and annealed coatings comprised the FCC solid solution phase with the formation of oxides. The tribological results showed equivalent behavior of as sprayed and heat-treated coatings on the polished surfaces. Rough surfaces, on the other hand, revealed significantly higher wear rates compared to the polished surfaces due to third body abrasion during sliding. A strong emphasis was placed on correlating the interfacial processes to the tribological behavior.

Similar content being viewed by others

Data Availability

The raw/processed data required to reproduce these findings cannot be shared due to legal or ethical reasons.

References

J. Yeh, S. Chen, S. Lin, J. Gan, T. Chin, T. Shun, C. Tsau and S. Chang, Nanostructured High-entropy Alloys with Multiple Principal Elements: Novel Alloy Design Concepts and Outcomes, Adv. Eng. Mater., 2004, 6, p 299–303.

B. Cantor, I.T.H. Chang, P. Knight and A.J.B. Vincent, Microstructural Development in Equiatomic Multicomponent Alloys, Mater. Sci. Eng. A, 2004, 375, p 213–218.

S. Ranganathan, Alloyed Pleasures: Multimetallic Cocktails, Curr. Sci., 2003, 85, p 1404–1406.

P. Stoyanov, K.M. Harrington and A. Frye, Insights into the Tribological Characteristic of Cu-Based Coatings Under Extreme Contact Conditions, JOM, 2020, 72, p 2191–2197.

S. Aouadi, E. Broitman, C.A. Figueroa, G. Greczynski, J.A. Zapien and M. Stüber, ICMCTF 2018—Preface, Surf Coatings Technol., 2019, 357, p 1014.

M.-H. Tsai and J.-W. Yeh, High-entropy Alloys: A Critical Review, Mater. Res. Lett., 2014, 2, p 107–123.

ZhangC, Gao M C, Yeh J W, Liaw P K and Zhang Y 2016 High-Entropy alloys: fundamentals and applications

Taylor P, Tsai M and Yeh J (2014) High-Entropy Alloys : A Critical Review High-Entropy Alloys : A Critical Review 37–41

J. Li, Y. Huang, X. Meng and Y. Xie, A Review on High Entropy Alloys Coatings: Fabrication Processes and Property Assessment, Adv. Eng. Mater., 2019, 1900343, p 1–27.

F. Otto, A. Dlouhý, C. Somsen, H. Bei, G. Eggeler and E.P. George, The Influences of Temperature and Microstructure on the Tensile Properties of a CoCrFeMnNi High-entropy Alloy, Acta Mater., 2013, 61, p 5743–5755.

O.N. Senkov, G.B. Wilks, J.M. Scott and D.B. Miracle, Mechanical Properties of Nb25Mo25Ta25W25 and V20Nb20Mo20Ta20W20 Refractory High Entropy Alloys, Intermetallics, 2011, 19, p 698–706.

M.T. Wall, M.V. Pantawane, S. Joshi, F. Gantz, N.A. Ley, R. Mayer, A. Spires, M.L. Young and N. Dahotre, Laser-coated CoFeNiCrAlTi High Entropy Alloy onto a H13 Steel Die Head, Surf Coat. Technol, 2020, 387, p 125473.

A.S.M. Ang, C.C. Berndt, M.L. Sesso, A.S.P. Anupam, R.S. Kottada and B.S. Murty, Plasma-Sprayed High Entropy Alloys: Microstructure and Properties of AlCoCrFeNi and MnCoCrFeNi, Metall Mater Trans. A Phys. Metall Mater Sci., 2015, 46, p 791–800.

S.-T. Chen, W.-Y. Tang, Y.-F. Kuo, S.-Y. Chen, C.-H. Tsau, T.-T. Shun and J.-W. Yeh, Microstructure and Properties of Age-hardenable AlxCrFe1. 5MnNi0. 5 Alloys, Mater. Sci. Eng. A, 2010, 527, p 5818–5825.

C.M. Liu, H.M. Wang, S.Q. Zhang, H.B. Tang and A.L. Zhang, Microstructure and Oxidation Behavior of New Refractory High Entropy Alloys, J. Alloys Compd., 2014, 583, p 162–169.

Z.S. Nong, Y.N. Lei and J.C. Zhu, Wear and Oxidation Resistances of AlCrFeNiTi-based High Entropy Alloys, Intermetallics, 2018, 101, p 144–151.

C. Huang, Y. Zhang, J. Shen and R. Vilar, Thermal Stability and Oxidation Resistance of Laser Clad TiVCrAlSi High Entropy Alloy Coatings on Ti-6Al-4V Alloy, Surf. Coat. Technol., 2011, 206, p 1389–1395.

Y.Y. Chen, T. Duval, U.D. Hung, J.W. Yeh and H.C. Shih, Microstructure and Electrochemical Properties of High Entropy Alloys—A Comparison with Type-304 Stainless Steel, Corros. Sci., 2005, 47, p 2257–2279.

Y.-J. Hsu, W.-C. Chiang and J.-K. Wu, Corrosion Behavior of FeCoNiCrCux High-entropy Alloys in 3.5% Sodium Chloride Solution, Mater Chem. Phys., 2005, 92, p 112–117.

P. Shi, Y. Yu, N. Xiong, M. Liu, Z. Qiao, G. Yi, Q. Yao, G. Zhao, E. Xie and Q. Wang, Microstructure and Tribological Behavior of a Novel Atmospheric Plasma Sprayed AlCoCrFeNi High Entropy Alloy Matrix Self-lubricating Composite Coatings, Tribol Int, 2020, 151, p 106470.

X. Qiu, Microstructure, Hardness and Corrosion Resistance of Al2CoCrCuFeNiTix High-entropy Alloy Coatings Prepared by Rapid Solidification, J. Alloys Compd., 2018, 735, p 359–364.

Y. Zhang, B. Zhang, K. Li, G.-L. Zhao and S.M. Guo, Electromagnetic Interference Shielding Effectiveness of High Entropy AlCoCrFeNi Alloy Powder Laden Composites, J. Alloys Compd., 2018, 734, p 220–228.

L. Tian, Microstructure and Wear Behavior of Atmospheric Plasma-Sprayed AlCoCrFeNiTi High-Entropy Alloy Coating, J. Mater. Eng. Perform, 2016, 25, p 5513.

Qiu X 2017 AC J. Alloys Compd.

Li Z 2018 Designing and understanding novel high- entropy alloys towards superior properties

Jin G, Cai Z, Guan Y, Cui X, Liu Z and Li Y 2018 Institute of Surface / Interface Science and Technology , Key Laboratory of College of Material Science and Chemical Engineering, Harbin

W. Hsu, Y. Yang, C. Chen and J. Yeh, Intermetallics Improved Mechanical Properties and Oxidation Resistance, Intermetallics, 2017, 89, p 105–110.

M. Löbel, T. Lindner, T. Mehner and T. Lampke, Microstructure and Wear Resistance of AlCoCrFeNiTi High-entropy Alloy Coatings Produced by HVOF, Coatings, 2017, 7, p 144.

L. Chen, K. Bobzin, Z. Zhou, L. Zhao, M. Öte, T. Königstein, Z. Tan and D. He, Surface & Coatings Technology Wear Behavior of HVOF-sprayed Al 0. 6 TiCrFeCoNi High Entropy Alloy Coatings at Different Temperatures, Surf Coat. Technol., 2019, 358, p 215–222.

J.K. Xiao, H. Tan, Y.Q. Wu, J. Chen and C. Zhang, Microstructure and Wear Behavior of FeCoNiCrMn High Entropy Alloy Coating Deposited by Plasma Spraying, Surf Coatings Technol., 2020, 385, p 125430.

Y.-F. Kao, S.-K. Chen, T.-J. Chen, P.-C. Chu, J.-W. Yeh and S.-J. Lin, Electrical, Magnetic, and Hall Properties of AlxCoCrFeNi High-entropy Alloys, J. Alloys Compd., 2011, 509, p 1607–1614.

P. Yang, Y. Liu, X. Zhao, J. Cheng and H. Li, Electromagnetic Wave Absorption Properties of Mechanically Alloyed FeCoNiCrAl High Entropy Alloy Powders, Adv. Powder Technol., 2016, 27, p 1128–1133.

C.C. Berndt, F. Hasan, U. Tietz and K.P. Schmitz, A review of hydroxyapatite coatings manufactured by thermal spray, Advances in calcium phosphate biomaterials Springer, Berlin, 2014.

K. Alagarsamy, A. Fortier, M. Komarasamy, N. Kumar, A. Mohammad, S. Banerjee, H.C. Han and R.S. Mishra, Mechanical Properties of High Entropy Alloy al 0.1 Cocrfeni for Peripheral Vascular Stent Application, Cardiovasc. Eng. Technol., 2016, 7, p 448–54.

G. Popescu, B. Ghiban, C.A. Popescu, L. Rosu, R. Trusca, I. Carcea, V. Soare, D. Dumitrescu, I. Constantin and M.T. Olaru, New TiZrNbTaFe High Entropy Alloy used for Medical Applications, IOP Conf Ser. Mater. Sci. Eng., 2018, 400, p 22049.

A. Vladescu, I. Titorencu, Y. Dekhtyar, V. Jinga, V. Pruna, M. Balaceanu, M. Dinu, I. Pana, V. Vendina and M. Braic, In vitro Biocompatibility of Si Alloyed Multi-Principal Element Carbide Coatings, PLoS One, 2016, 11, p e0161151.

A. Meghwal, A. Anupam, B.S. Murty, C.C. Berndt, R.S. Kottada and A.S.M. Ang, Thermal Spray High-Entropy Alloy Coatings: A Review, Springer, US, 2020.

Geant V, Voiculescu I, Mitrica D, Tudor A and Bobzin K 2017 Processing of AlCoCrFeNiTi high entropy alloy by atmospheric plasma spraying Processing of AlCoCrFeNiTi high entropy alloy by atmospheric plasma spraying 0–9

T. Li, Y. Liu, B. Liu, W. Guo and L. Xu, Microstructure and Wear Behavior of FeCoCrNiMo0.2 High Entropy Coatings Prepared by Air Plasma Spray and the High Velocity Oxy-fuel Spray Processes, Coatings, 2017, 7, p 5–8.

L. Chen, K. Bobzin, Z. Zhou, L. Zhao, M. Öte, T. Königstein, Z. Tan and D. He, Wear Behavior of HVOF-sprayed Al0. 6TiCrFeCoNi High Entropy Alloy Coatings at Different Temperatures, Surf Coatings Technol., 2019, 358, p 215–222.

L.H. Tian, W. Xiong, C. Liu, S. Lu and M. Fu, Microstructure and Wear Behavior of Atmospheric Plasma-Sprayed AlCoCrFeNiTi High-Entropy Alloy Coating, J. Mater. Eng. Perform., 2016, 25, p 5513–5521.

G. Laplanche, P. Gadaud, O. Horst, F. Otto, G. Eggeler and E.P. George, Temperature Dependencies of the Elastic Moduli and Thermal Expansion Coefficient of an Equiatomic, Single-Phase CoCrFeMnNi High-Entropy Alloy, J. Alloys Compd., 2015, 623, p 348–353.

A. Haglund, M. Koehler, D. Catoor, E.P. George and V. Keppens, Polycrystalline Elastic Moduli of a High-Entropy Alloy at Cryogenic Temperatures, Intermetallics, 2015, 58, p 62–64.

Y.Z. Xia, H. Bei, Y.F. Gao, D. Catoor and E.P. George, Synthesis, Characterization, and Nanoindentation Response of Single Crystal Fe–Cr–Ni Alloys with FCC and BCC Structures, Mater Sci. Eng. A, 2014, 611, p 177–187.

B. Gludovatz, A. Hohenwarter, D. Catoor, E.H. Chang, E.P. George and R.O. Ritchie, A Fracture-resistant High-entropy Alloy for Cryogenic Applications, Science, 2014, 345, p 1153.

Z.G. Zhu, Q.B. Nguyen, F.L. Ng, X.H. An, X.Z. Liao, P.K. Liaw, S.M.L. Nai and J. Wei, Hierarchical Microstructure and Strengthening Mechanisms of a CoCrFeNiMn High Entropy Alloy Additively Manufactured by Selective Laser Melting, Scr. Mater., 2018, 154, p 20–24.

S.J. Sun, Y.Z. Tian, H.R. Lin, X.G. Dong, Y.H. Wang, Z.J. Zhang and Z.F. Zhang, Enhanced Strength and Ductility of Bulk CoCrFeMnNi High Entropy Alloy Having Fully Recrystallized Ultrafine-Grained Structure, Mater Des., 2017, 133, p 122–127.

Q. Ye, K. Feng, Z. Li, F. Lu, R. Li, J. Huang and Y. Wu, Microstructure and Corrosion Properties of CrMnFeCoNi High Entropy Alloy Coating, Appl. Surf. Sci., 2017, 396, p 1420–1426.

Z. Wang, Y. Huang, Y. Yang, J. Wang and C.T. Liu, Atomic-size Effect and Solid Solubility of Multicomponent Alloys, Scr Mater., 2015, 94, p 28–31.

F. Otto, Y. Yang, H. Bei and E.P. George, Relative Effects of Enthalpy and Entropy on the Phase Stability of Equiatomic High-entropy Alloys, Acta Mater., 2013, 61, p 2628–2638.

X. Ji, H. Duan, H. Zhang and J. Ma, Slurry Erosion Resistance of Laser Clad NiCoCrFeAl3 High-entropy Alloy Coatings, Tribol Trans., 2015, 58, p 1119–1123.

H. Zhang, W. Wu, Y. He, M. Li and S. Guo, Formation of Core–shell Structure in High Entropy Alloy Coating by Laser Cladding, Appl Surf. Sci., 2016, 363, p 543–547.

L. Chen, K. Bobzin, Z. Zhou, L. Zhao, M. Öte, T. Königstein, Z. Tan and D. He, Wear Behavior of HVOF-sprayed Al0.6TiCrFeCoNi High Entropy Alloy Coatings at Different Temperatures, Surf. Coatings Technol., 2019, 358, p 215–222.

W.L. Hsu, H. Murakami, J.W. Yeh, A.C. Yeh and K. Shimoda, On the Study of Thermal- sprayed Ni0.2Co0.6Fe0.2CrSi0.2AlTi0.2 HEA Overlay Coating, Surf Coatings Technol., 2017, 316, p 71–74.

J.A. Picas, M. Punset, M.T. Baile, E. Martín and A. Forn, Effect of Oxygen/fuel Ratio on the In-flight Particle Parameters and Properties of HVOF WC-CoCr Coatings, Surf Coatings Technol., 2011, 205, p S364–S368.

T.Y. Cho, J.H. Yoon, K.S. Kim, K.O. Song, Y.K. Joo, W. Fang, S.H. Zhang, S.J. Youn, H.G. Chun and S.Y. Hwang, A Study on HVOF Coatings of Micron and Nano WC–Co Powders, Surf Coatings Technol., 2008, 202, p 5556–5559.

Heberlein J V R Thermal Spray Fundamentals

Gao, Yu R C 2020 Characterization and Mechanical Properties for Diamalloy 3001 and Diamalloy 3002NS Thermally Sprayed Coatings

J. Chen, J. Xiao, H. Tan, Y. Wu, J. Chen and C. Zhang, Microstructure and Wear Behavior of FeCoNiCrMn High Entropy Alloy Coating Deposited by Plasma Spraying Surface & Coatings Technology Microstructure and Wear Behavior of FeCoNiCrMn High Entropy Alloy Coating Deposited by Plasma Spraying, Surf. Coat. Technol., 2020, 385, p 125430.

M. Löbel, T. Lindner, S. Clauß, R. Pippig, D. Dietrich and T. Lampke, Microstructure and Wear Behavior of the High-Velocity- Oxygen-Fuel Sprayed and Spark Plasma Sintered High-Entropy Alloy AlCrFeCoNi, Adv. Eng. Mater, 2021, 23, p 2001253.

B.C.N.M. de Castilho, N. Sharifi, S.A. Alidokht, K. Harrington, P. Stoyanov, C. Moreau and R.R. Chromik, Short-time Exposure Oxidation Studies on Multi-component Coatings and their Influence on Tribological Behavior, Wear, 2021, 477, p 203892.

C. Coating, H. Li, J. Li, C. Yan, X. Zhang and D. Xiong, Microstructure and Tribological Properties of Plasma-Sprayed Al0.2Co1.5CrFeNi1.5Ti-Ag Composite Coating from 25 to 750_C, J. Mater. Eng. Perform., 2020, 29, p 1640.

M.V. Tran, A.T. Ha and P.M.L. Le, Nanoflake Manganese Oxide and Nickel- Manganese Oxide Synthesized by Electrodeposition for Electrochemical Capacitor, J Nanomater, 2015, 2015, p 609273.

Id Q L, Huang M, Zhang S, Deng S and Gong F 2018 Effects of Annealing on Residual Stress in Ta 2 O 5 Films Deposited by Dual Ion Beam Sputtering 1–10

L. Aihaiti, K. Tuokedaerhan, B. Sadeh, M. Zhang, X. Shen and A. Mijiti, Effect of Annealing Temperature on Microstructure and Resistivity of TiC Thin Films, Coatings, 2021, 11, p 457.

Coatings S, Savoie S, Schulz R and Moreau C 2019 Electrochemical Behavior, Microstructure, and Surface Chemistry of Thermal-Sprayed Stainless-Steel Coatings

Davis J R 2004 Handbook of thermal spray technology (ASM international)

L. Zhao, M. Maurer, F. Fischer, R. Dicks and E. Lugscheider, Influence of Spray Parameters on the Particle In-flight Properties and the Properties of HVOF Coating of WC-CoCr, Wear, 2004, 257, p 41–46.

Kuroda S, Kawakita J, Watanabe M and Katanoda H 2008 Warm spraying—a novel coating process based on high-velocity impact of solid particles Sci. Technol. Adv. Mater.

S. Alvi and F. Akhtar, High Temperature Tribology of CuMoTaWV High Entropy Alloy, Wear, 2019, 426, p 412–419.

M. Mohammadtaheri, Q. Yang, Y. Li and J. Corona-Gomez, The Effect of Deposition Parameters on the Structure and Mechanical Properties of Chromium Oxide Coatings Deposited by Reactive Magnetron Sputtering, Coatings, 2018, 8, p 111.

Soler MAG, Qu F (2012) Raman Spectroscopy of Iron Oxide Nanoparticles BT - Raman Spectroscopy for Nanomaterials Characterization ed C S S R Kumar (Berlin, Heidelberg: Springer Berlin Heidelberg) pp 379–416

J.H. Kim and I.S. Hwang, Development of an In situ Raman Spectroscopic System for Surface Oxide Films on Metals and Alloys in High Temperature Water, Nucl Eng. Des., 2005, 235, p 1029–1040.

Acknowledgment

The work was conducted in collaboration between two groups of Concordia University and McGill University, Canada. The authors sincerely acknowledge the support of Dr. Fadhel Ben Ettouil and Mr. Saeed Garmeh in experiments of the reported work. The authors express their sincere gratitude to Dr. Vamsi Mungala for his support during experimental work and Dr. Sadegh Mahdipoor for helping in procurement of powders. The authors would also like to acknowledge the financial support from Natural Sciences and Engineering Research Council (NSERC) Project Number CRDPJ 530409-18 and the Consortium for Research and Innovation in Aerospace in Québec (CRIAQ) Project Number MANU-1719.

Author information

Authors and Affiliations

Corresponding authors

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This article is part of a special topical focus in the Journal of Thermal Spray Technology on High Entropy Alloy and Bulk Metallic Glass Coatings. The issue was organized by Dr. Andrew S.M. Ang, Swinburne University of Technology; Prof. B.S. Murty, Indian Institute of Technology Hyderabad; Distinguished Prof. Jien-Wei Yeh, National Tsing Hua University; Prof. Paul Munroe, University of New South Wales; Distinguished Prof. Christopher C. Berndt, Swinburne University of Technology. The issue organizers were mentored by Emeritus Prof. S. Ranganathan, Indian Institute of Sciences.

Rights and permissions

About this article

Cite this article

Patel, P., Alidokht, S.A., Sharifi, N. et al. Microstructural and Tribological Behavior of Thermal Spray CrMnFeCoNi High Entropy Alloy Coatings. J Therm Spray Tech 31, 1285–1301 (2022). https://doi.org/10.1007/s11666-022-01350-y

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-022-01350-y