Abstract

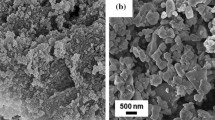

Plasma spraying of fine particles promises uniform microstructure and improved properties for ceramic coatings due to the formation of small splats with reduced residual stress and pore size. Although spraying fine particles is challenging due to the poor rheological properties of particles (e.g., low flowability and agglomeration), the potential improvements to the coatings make it an attractive option. In this study, we discussed the feasibility of fine particle spraying via three different spraying techniques, namely low-power direct current (DC) plasma spraying, axial suspension plasma spraying (ASPS), and plasma-assisted aerosol deposition or hybrid aerosol deposition (HAD). Low-power DC plasma was sufficient to melt and deposit fine particles in an ambient atmosphere without using a liquid carrier. The fabricated coatings had similar features to those of ASPS coatings of small splats (5–8 µm in diameter without internal cracks). The fabricated coatings by the low-power DC plasma showed almost equivalent properties to that of the conventional plasma-sprayed coating while providing low energy consumption. Fine particles deposited via the HAD process led to the coatings with improved microstructure without pores or cracks. During the HAD process, particle melting was not required for deposition, and using the plasma assisted the surface activation and improved the deposition efficiency of the aerosol deposition process. The fabricated HAD coating revealed improved microstructure with the highest hardness, Young’s modulus, and adhesion strength and lack of pores or cracks compared to the coatings fabricated by other plasma spray techniques. In addition, similarities and differences among the techniques for spraying fine ceramic particles were investigated.

Similar content being viewed by others

References

P. Fauchais, A. Vardelle, and B. Dussoubs, Quo Vadis Thermal Spraying?, J. Therm. Spray Technol., 2001, 10, p 44-66

A.J. Allen, G.G. Long, H. Boukari, J. Ilavsky, A. Kulkarni, S. Sampath, H. Herman, and A.N. Goland, Microstructural Characterization Studies to Relate the Properties of Thermal-Spray Coatings to Feedstock and Spray Conditions, Surf. Coat. Technol., 2001, 146–147, p 544-552

M. Vardelle, A. Vardelle, P. Fauchais, K.-I. Li, B. Dussoubs, and N.J. Themelis, Controlling Particle Injection in Plasma Spraying, J. Therm. Spray Technol., 2001, 10(2), p 267-284

M. Shahien, M. Yamada, T. Yasui, and M. Fukumoto, Reactive Plasma Spraying of Fine Al2O3/AlN Feedstock Powder, J. Therm. Spray Technol., 2013, 22(8), p 1283-1293

M. Shahien, M. Yamada, and M. Fukumoto, Influence of Transient Liquid Phase Promoting Additives Upon Reactive Plasma Spraying of AlN Coatings and Its Properties, Adv. Eng. Mater., 2018, 20(6), p 1700917. https://doi.org/10.1002/adem.201700917

M. Gell, Application Opportunities for Nanostructured Materials and Coatings, Mater. Sci. Eng., 1995, 204(1), p 246-251

J. Karthikeyan, C.C. Berndt, J. Tikkanen, J.Y. Wang, A.H. King, and H. Herman, Preparation of Nanophase Materials by Thermal Spray Processing of Liquid Precursors, Nanostruct. Mater., 1997, 8(1), p 61-74

R. Fauchais, V. Etchart-Salas, J.-F. Rat, N. Coudert, K. Caron, and Wittmann-Ténèze, Parameters Controlling Liquid Plasma Spraying: Solutions, Sols, or Suspensions, J. Therm. Spray Technol., 2008, 17(1), p 31-59

M. Gell, E.H. Jordan, Y.H. Sohn, D. Goberman, L. Shaw, and T.D. Xiao, Development and Implementation of Plasma Sprayed Nanostructured Ceramic Coatings, Surf. Coat. Technol., 2001, 146–147, p 48-54

O. Racek, C.C. Berndt, D.N. Guru, and J. Heberlein, Nanostructured and Conventional YSZ Coatings Deposited Using APS and TTPR Techniques, Surf. Coat. Technol., 2006, 201, p 338-346

R.S. Lima and B.R. Marple, Thermal Spray Coatings Engineered from Nano-structured Ceramic Agglomerated Powders for Structural, Thermal Barrier and Biomedical Applications: A Review, J. Therm. Spray Technol., 2007, 16(1), p 40-63

F. Gitzhofer, E. Bouyer, and M.I. Boulos, Suspension plasma spraying. US Patent 5 609 921, 3 November 1997

L. Pawlowski, Suspension and Solution Thermal Spray Coatings, Surf. Coat. Technol., 2009, 203, p 2807-2829

A. Killinger, R. Gadow, G. Mauer, A. Guignard, R. Vaßen, and D. Stöver, Review of New Developments in Suspension and Solution Precursor Thermal Spray Processes, J. Therm. Spray Technol., 2011, 20(4), p 677-695

M. Shahien and M. Suzuki, Low Power Consumption Suspension Plasma Spray System for Ceramic Coating Deposition, Surf. Coat. Technol., 2017, 318, p 11-17

M. Shahien, M. Suzuki, and Y. Tsutai, Controlling the Coating Microstructure on Axial Suspension Plasma Spray Process, Surf. Coat. Technol., 2018, 356, p 96-107

J. Akedo and M. Lebedev, Microstructure and Electrical Properties of Lead Zirconate Titanate (Pb (Zr52/Ti48)O3) Thick Films Deposited by Aerosol Deposition Method, Jpn. J. Appl. Phys. Part 1, 1999, 38(9B), p 5397-5401

J. Akedo, Aerosol Deposition of Ceramic Thick Films at Room Temperature: Densification Mechanism of Ceramic Layers, J. Am. Ceram. Soc., 2006, 89(6), p 1834-1839

J. Akedo, Room Temperature Impact Consolidation (RTIC) of Fine Ceramic Powder by Aerosol Deposition Method and Applications to Microdevices, J. Therm. Spray Technol., 2008, 17(2), p 181-198

M. Mori, T. Ustunomiya, S. Miyake, J. Akedo, Characteristics of PZT films fabricated by inductively coupled plasma-assisted aerosol deposition method, in 2007 Sixteenth IEEE Int. Symp. Appl. Ferroelectrics, May 2007 (Nara, Japan), p. 454–456

A. Vardelle, C. Moreau, J. Akedo, H. Ashrafizadeh, C.C. Berndt, J.O. Berghaus, M. Boulos, J. Brogan, A.C. Bourtsalas, A. Dolatabadi, M. Dorfman, T.J. Eden, P. Fauchais, G. Fisher, F. Gaertner, M. Gindrat, R. Henne, M. Hyland, E. Irissou, E.H. Jordan, K.A. Khor, A. Killinger, Y.C. Lau, C.J. Li, L. Li, J. Longtin, N. Markocsan, P.-J. Masset, J. Matejicek, G. Mauer, A. McDonald, J. Mostaghimi, S. Sampath, G. Schiller, K. Shinoda, M.F. Smith, A.A. Syed, N.J. Themelis, F.-L. Toma, J.P. Trelles, R. Vassen, P. Vuoristo, The Thermal Spray Roadmap. J. Therm. Spray Technol., 2016, 25(8), p. 1376–1440 (J. Akedo and K. Shinoda, Section 2.2 Aerosol Deposition Method, p. 1379–1383)

K. Shinoda, H. Noda, K. Ohtomi, T. Yamada, and J. Akedo, Promotion of Knowledge and Technology Transfer Towards Innovative Manufacturing Process: Case Study of New Hybrid Coating Process, Int. J. Automat. Technol., 2019, 13(3), p 419-431

T. Saeki, K. Shinoda, M. Mori, J. Akedo, Dense Crack-Free Alpha-Alumina Coatings with Three-Dimensional Coverage Capability by Fine Solid Powder Spraying with the Assistance of Mesoplasma (to be submitted)

M. Shahien, M. Suzuki, K. Shinoda J. Akedo, Direct spraying of fine ceramic particles in thermal spray, in Proceedings Thermal Spray Conference 2018 (ASM International), p. 515–520

M. Suzuki, M. Shahien, K. Shinoda and J. Akedo, State-of-the-art ceramic coating processes via fine particle spraying, in Proceedings of International Gas Turbine Congress 2019, Tokyo, IGTC-2019-179

M. Vardelle, A. Vardelle, and P. Fauchais, Spray parameter and particle behavior relationships during plasma spraying, J. Therm. Spray Technol., 1993, 2(1), p 79-91

W.C. Oliver and G.M. Pharr, An Improved Technique for Determining Hardness and Elastic Modulus Using Load and Displacement Sensing Indentation Experiments, J. Mater. Res., 1992, 7(6), p 1564-1583

W.C. Oliver and G.M. Pharr, Measurement of Hardness and Elastic Modulus by Instrumented Indentation: Advances in Understanding and Refinements to Methodology, J. Mater. Res., 2004, 19(1), p 3-20

K. Remesh, H.W. Ng, and S.C.M. Yu, Influence of Process Parameters on the Deposition Footprint in Plasma-Spray Coating, J. Therm. Spray Technol., 2003, 12(3), p 377-392

M. Shahien, M. Yamada, T. Yasui, and M. Fukumoto, Reactive Atmospheric Plasma Spraying of AlN Coatings: Influence of Aluminum Feedstock Particle Size, J. Therm. Spray Technol., 2011, 20(3), p 580-589

M. Boulos, P. Fauchais, and E. Pfender, Thermal plasmas, fundamentals and applications, Plenum Press, London, 1994

J.O. Berghaus, S. Bouaricha, J.-G. Legoux, C. Moreau, and T. Chraska, Suspension plasma spraying of nano-ceramics using an axial injection torch, in Proceedings of Int’l Thermal Spray Conference, C. Berndt and E. Lugsheider, Eds., May 2–4 (ASM International, Basel, Switzerland, 2005)

Acknowledgments

This work was conducted under “High-value Added Ceramic Products Manufacturing Technologies Project” supported by Innovative Design/Manufacturing Technologies (a part of Cross-Ministerial Strategic Innovation Promotion (SIP) Program managed by NEDO, Council for Science, Technology, and Innovation (CSTI)), and Japan Society for the Promotion of Science (JSPS) KAKENHI Grants-in-Aid (Grant number 14F03917).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Shahien, M., Suzuki, M., Shinoda, K. et al. Ceramic Coatings Deposited from Fine Particles by Different Spraying Processes. J Therm Spray Tech 29, 2033–2047 (2020). https://doi.org/10.1007/s11666-020-01095-6

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-020-01095-6