Abstract

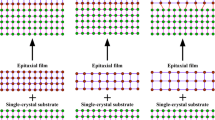

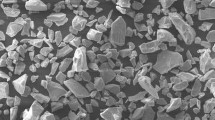

In the present study, the epitaxial growth and cracking mechanisms of thermally sprayed ceramic splats were explored. We report, for the first time, the epitaxial growth of various splat/substrate combinations at low substrate temperatures (100 °C) and large lattice mismatch (− 11.26%). Our results suggest that thermal spray deposition was essentially a liquid-phase epitaxy, readily forming chemical bonding. The interface temperature was also estimated. The results convincingly demonstrated that atoms only need to diffuse and rearrange over a sufficiently short range during extremely rapid solidification. Concurrently, severe cracking occurred in the epitaxial splat/substrate systems, which indicated high tensile stress was produced during splat deposition. The origin of the tensile stress was attributed to the strong constraint of the locally heated substrate by its cold surroundings.

Similar content being viewed by others

References

N.P. Padture, M. Gell, and E.H. Jordan, Materials Science—Thermal Barrier Coatings for Gas-Turbine Engine Applications, Science, 2002, 296(5566), p 280-284

N.P. Padture, Advanced Structural Ceramics in Aerospace Propulsion, Nat. Mater., 2016, 15(8), p 804-809

R. Hui, J.O. Berghaus, C. Deces-Petit, W. Qu, S. Yick, J.G. Legoux, and C. Moreau, High Performance Metal-supported Solid Oxide Fuel Cells Fabricated by Thermal Spray, J. Power Sources, 2009, 191(2), p 371-376

R. Vassen, D. Hathiramani, J. Mertens, V.A.C. Haanappel, and I.C. Vinke, Manufacturing of High Performance Solid Oxide Fuel Cells (SOFCs) with Atmospheric Plasma Spraying (APS), Surf. Coat Technol., 2007, 202(3), p 499-508

G. Bolelli, V. Cannillo, L. Lusvarghi, and T. Manfredini, Wear behaviour of thermally sprayed ceramic oxide coatings, Wear, 2006, 261(11–12), p 1298-1315

S. Wilson, Thermally Sprayed Abradable Coating Technology for Sealing in Gas Turbines, in 6th International Conference on the Future of Gas Turbine Technology, 2012

E. Irissou, A. Dadouche, and R.S. Lima, Tribological Characterization of Plasma-Sprayed CoNiCrAlY-BN Abradable Coatings, J Therm. Spray Technol., 2014, 23(1–2), p 252-261

D. Sporer, M. Dorfman, L. Xie, A. Refke, I. Giovannetti, and M. Giannozzi, Processing and Properties of Advanced Ceramic Abradable Coatings, Therm. Spray 2007 Global Coat. Solut., 2007, 2007, p 14-16

A. Ohmori and C.J. Li, Quantitative Characterization of the Structure of Plasma-Sprayed Al2O3 Coating by Using Copper Electroplating, Thin Solid Films, 1991, 201(2), p 241-252

S. Rangarajan and A.H. King, Non-destructive Evaluation of Delamination in Ceramic Thin Films on Metal Substrates by Scanning Electron Microscopy, Thin Solid Films, 2001, 385(1–2), p 22-28

T. Chraska and A.H. King, Effect of Different Substrate Conditions upon Interface with Plasma Sprayed Zirconia—A TEM Study, Surf. Coat Technol., 2002, 157(2–3), p 238-246

T. Chraska and A.H. King, Transmission Electron Microscopy Study of Rapid Solidification of Plasma Sprayed Zirconia—Part I. First Splat Solidification, Thin Solid Films, 2001, 397(1–2), p 30-39

T. Chraska and A.H. King, Transmission Electron Microscopy Study of Rapid Solidification of Plasma Sprayed Zirconia—Part II. Interfaces and Subsequent Splat Solidification, Thin Solid Films, 2001, 397(1–2), p 40-48

A.G. Evans, M. Ruhle, B.J. Dalgleish, and P.G. Charalambides, The Fracture Energy of Bimaterial Interfaces, Metall. Trans. A, 1990, 21(9), p 2419-2429

C.J. Li and A. Ohmori, Relationships Between the Microstructure and Properties of Thermally Sprayed Deposits, J Therm. Spray Technol., 2002, 11(3), p 365-374

C.J. Li, G.J. Yang, and C.X. Li, Development of Particle Interface Bonding in Thermal Spray Coatings: A Review, J. Therm. Spray Technol., 2013, 22(2–3), p 192-206

L. Chen, G.J. Yang, and C.X. Li, Formation of Lamellar Pores for Splats via Interfacial or Sub-interfacial Delamination at Chemically Bonded Region, J. Therm. Spray Technol., 2017, 26, p 315-326

V.V. Sobolev, J.M. Guilemany, J. Nutting, and J.R. Miquel, Development of Substrate-coating Adhesion in Thermal Spraying, Int. Mater. Rev., 1997, 42(3), p 117-136

C.J. Li and J.L. Li, Transient Contact Pressure During Flattening of Thermal Spray Droplet and its Effect on Splat Formation, J. Therm. Spray Technol., 2004, 13(2), p 229-238

X.Y. Jiang, Y.P. Wan, H. Herman, and S. Sampath, Role of Condensates and Adsorbates on Substrate Surface on Fragmentation of Impinging Molten Droplets During Thermal Spray, Thin Solid Films, 2001, 385(1–2), p 132-141

M.X. Xue, S. Chandra, and J. Mostaghimi, Investigation of Splat Curling up in Thermal Spray Coatings, J. Therm. Spray Technol., 2006, 15(4), p 531-536

L. Chen, G.-J. Yang, C.-X. Li, and C.-J. Li, Edge Effect on Crack Patterns in Thermally Sprayed Ceramic Splats, J. Therm. Spray Technol., 2017, 26, p 302-314

L. Chen, G.J. Yang, C.X. Li, and C.J. Li, Hierarchical Formation of Intrasplat Cracks in Thermal Spray Ceramic Coatings, J. Therm. Spray Technol., 2016, 25(5), p 959-970

S.A. Campbell, The Science and Engineering of Microelectronic Fabrication, 2nd edn, Chapter 3. Oxford University Press, Oxford, 2001

L.B. Freund and S. Suresh, Thin Film Materials: Stress, Defect Formation, and Surface Evolution, Cambridge University Press, Cambridge, 2003

J. Robertson and M.I. Manning, Limits to Adherence of Oxide Scales, Mater. Sci. Technol., 1990, 6(1), p 81-92

V.B. Shenoy, A.F. Schwartzman, and L.B. Freund, Crack Patterns in Brittle Thin Films, Int. J. Fract., 2001, 109(1), p 29-45

M.D. Thouless, Crack Spacing in Brittle Films on Elastic Substrates, J. Am. Ceram. Soc., 1990, 73(7), p 2144-2146

M.D. Thouless, E. Olsson, and A. Gupta, Cracking of Brittle Films on Elastic Substrates, Acta Metall. Mater., 1992, 40(6), p 1287-1292

X. Cao, R. Vassen, W. Fischer, F. Tietz, W. Jungen, and D. Stöver, Lanthanum-Cerium Oxide as a Thermal Barrier-Coating Material for High-temperature Applications, Adv. Mater., 2003, 15(17), p 1438-1442

W. Ma, S. Gong, H. Li, and H. Xu, Novel Thermal Barrier Coatings Based on La2Ce2O7/8YSZ Double-Ceramic-Layer Systems Deposited by Electron Beam Physical Vapor Deposition, Surf. Coat Technol., 2008, 202(12), p 2704-2708

S. Kaiser, H. Preis, W. Gebhardt, O. Ambacher, H. Angerer, M. Stutzmann, A. Rosenauer, and D. Gerthsen, Quantitative Transmission Electron Microscopy Investigation of the Relaxation by Misfit Dislocations Confined at the Interface of GaN/Al2O3 (0001), Jpn. J. Appl. Phys., 1998, 37(1), p 84-89

A.F. Schwartzman and R. Sinclair, Metastable and Equilibrium Defect Structure of II–VI/GaAs Interfaces, J. Electron. Mater., 1991, 20(7), p 805-814

J.H. Joo, K.J. Greenberg, M. Baram, D.R. Clarke, and E.L. Hu, Aqueous Epitaxial Growth of ZnO on Single Crystalline Au Microplates, Cryst. Growth Des., 2013, 13(3), p 986-991

M. Vardelle, A. Vardelle, A.C. Leger, P. Fauchais, and D. Gobin, Influence of Particle Parameters at Impact on Splat Formation and Solidification in Plasma Spraying Processes, J. Therm. Spray Technol., 1995, 4(1), p 50-58

H. Jones, Cooling, Freezing and Substrate Impact of Droplets Formed by Rotary Atomization, J. Phys. D Appl. Phys., 1971, 4(11), p 1657-1660

R. Mcpherson, A Review of Microstructure and Properties of Plasma Sprayed Ceramic Coatings, Surf. Coat Technol., 1989, 39(1–3), p 173-181

C. Moreau, P. Cielo, M. Lamontagne, S. Dallaire, J.C. Krapez, and M. Vardelle, Temperature Evolution of Plasma-Sprayed Niobium Particles Impacting on a Substrate, Surf. Coat Technol., 1991, 46(2), p 173-187

T.L. Bergman, A.S. Lavine, F.P. Incropera, and D.P. Dewitt, Fundamentals of Heat and Mass Transfer, 7th ed., Wiley, New York, 2012

Q.M. Tan, Dimensional Analysis. With Case Studies in Mechanics, Springer, Berlin, Heidelberg, 2011

M.W. Chase, NIST-JANAF thermochemical tables. J. Phys. Chem. Reference Data, 1998, 9

L. Chen and G.-J. Yang, Anomalous Epitaxial Growth in Thermally Sprayed YSZ and LZ Splats, J Therm Spray Techn, 2017, 26(5566), p 1168-1182

J.W. Hutchinson and Z. Suo, Mixed-Mode Cracking in Layered Materials, Adv. Appl. Mech., 1992, 29, p 63-191

J.W. Hutchinson, Stresses and Failure Modes in Thin Films and Multilayers, in Lecture Notes, 1996

A. Bagchi and A.G. Evans, The Mechanics and Physics of Thin Film Decohesion and its Measurement, Interface Sci., 1996, 3(3), p 169-193

A.G. Evans and J.W. Hutchinson, The Thermomechanical Integrity of Thin Films and Multilayers, Acta Metall. Mater., 1995, 43(7), p 2507-2530

Z. Suo and J.W. Hutchinson, Steady-State Cracking in Brittle Substrates Beneath Adherent Films, Int. J. Solids Struct., 1989, 25(11), p 1337-1353

Acknowledgments

The present project is supported by National Basic Research Program (Nos. 2013CB035701), the Fundamental Research Funds for the Central Universities, and the National Program for Support of Top-notch Young Professionals.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Chen, L., Yang, Gj. Epitaxial Growth and Cracking Mechanisms of Thermally Sprayed Ceramic Splats. J Therm Spray Tech 27, 255–268 (2018). https://doi.org/10.1007/s11666-018-0692-4

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-018-0692-4