Abstract

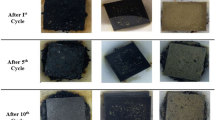

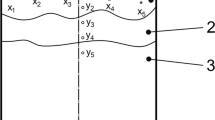

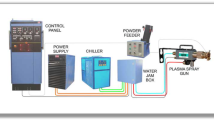

The aim of the study was to determine the effect of Ru additions to WC-Fe overlays when exposed to low pH slurry erosion conditions. These overlays were applied through Plasma Transferred Arc, and the original bulk Ru powder concentrations varied from 0.5 to 5 wt.%. A slurry jet impingement erosion–corrosion test rig was used to evaluate wear, and electrochemical measurements were performed to characterize the corrosion properties. The slurry mixtures contained silica sand and synthetic mine water. The pH was varied between 3 and 6.5 for the slurry erosion tests and lowered further for the corrosion characterization. Samples were examined optically and with a scanning electron microscope using energy-dispersive x-ray spectroscopy. X-ray diffraction analysis was used to determine the phases present. For the slurry erosion–corrosion results at the pH of 6.5, addition of Ru did not show a decrease in erosion–corrosion rates. However, when the pH was decreased to 3, by the addition of HCl, Ru improved the resistance. From the electrochemistry, it was also clear that Ru additions improved the corrosion resistance, but more than 1 wt.% Ru was required. At very low pH levels, the presence of Ru was not able to prevent corrosion.

Similar content being viewed by others

References

J.H. Potgieter, N. Thanjekwayo, P. Olubambi, N. Maledi, and S.S. Potgieter-Vermaak, Influence of Ru Additions on the Corrosion Behaviour of WC-Co Cemented Carbide Alloys in Sulphuric Acid, Int. J. Refract. Met. Hard Mater., 2011, 29, p 478-487

J.H. Potgieter, Alloys Cathodically Modified with Noble Metals, J. Appl. Electrochem., 1991, 21, p 471-482

J.H. Potgieter, W.O. Barnard, G. Myburg, K. Varga, P. Baradlai, and L. Tomcsanyi, Corrosion Behaviour of Duplex Stainless Steels Containing Minor Ruthenium Additions in Reducing Acid Media, J. Appl. Electrochem., 1996, 26, p 1103-1110

A.M. Human and H.E. Exner, The Relationship Between Electrochemical Behaviour and In-service Corrosion of WC Based Cemented Carbides, Int. J. Refract. Met. Hard Mater., 1997, 15, p 65-71

Z.B. Zheng, Y.G. Zheng, W.H. Sun, and J.Q. Wang, Erosion–Corrosion of HVOF-Sprayed Fe-Based Amorphous Metallic Coating Under Impingement by a Sand-Containing NaCl Solution, Corros. Sci., 2013, 76, p 337-347

E.J. Wentzel and C. Allen, The Erosion–Corrosion Resistance of Tungsten Carbide Hard Metals, Int. J. Refract. Met. Hard Mater., 1997, 15, p 81-87

B.W. Madsen, Measurement of Erosion–Corrosion Synergism with a Slurry Wear Test Apparatus, Wear, 1988, 123, p 127-142

B. Bozzini, G.P. De Gaudenzi, A. Fanigliulo, and C. Mele, Anodic Behaviour of WC-Co Type Hardmetal, Mater. Corros., 2003, 54, p 295-303

V.A. De Souza and A. Neville, Corrosion and Erosion Damage Mechanisms During Erosion–Corrosion of WC-Co-Cr Cermet Coatings, Wear, 2003, 255, p 146-156

A. Neville, F. Reza, S. Chiovelli, and T. Revega, Erosion–Corrosion Behaviour of WC-Based MMCs in Liquid–Solid Slurries, Wear, 2005, 259, p 181-195

M.M. Stack and T.M. Abd El-Badia, Some Comments on Mapping the Combined Effects of Slurry Concentration, Impact Velocity and Electrochemical Potential on the Erosion–Corrosion of WC/Co-Cr Coatings, Wear, 2008, 264, p 826-837

Z.B. Zheng, Y.G. Zheng, W.H. Sun, and J.Q. Wang, Erosion–Corrosion of HVOF-Sprayed Fe-Based Amorphous Metallic Coating Under Impingement by a Sand-Containing NaCl Solution, Corros. Sci., 2013, 76, p 337-347

U. Morkramer, R. Moll, and M. Oechsle, Wear-Resistant Coatings Using Tungsten Carbide Effective Protection for Demanding Applications, Finishing, 2005, 29(6), p 20-23

D. Harper, M. Gill, K.W.D. Hart, and M. Anderson, Plasma Transferred Arc Overlays Reduce Operating Costs in Oil Sands Processing, in International Thermal Spray Conference Proceedings (ASM International, Materials Park, 2002), pp. 278-283

M. Jones and R.J. Llewellyn, Erosion-Corrosion Assessment of Tungsten Carbide-Based Plasma-Tranferred Arc-Welded Overlays, Corrosion, 2012, 68(2), p 026003-1-026003-14

C.N. Machio, G.A. Akdogan, M.J. Witcomb, and S. Luyckx, Performance of WC-VC-Co Thermal Spray Coatings in Abrasion and Slurry Erosion Tests, Wear, 2005, 258, p 434-442

T.L. Shing, S. Luyckx, I.T. Northrop, and I. Wolff, The Effect of Ruthenium Addition on the Hardness, Toughness, and Grain Size of WC-Co, Int. J. Refract. Met. Hard Mater., 2001, 19, p 41-44

S.C. Tjong, J.S. Ku, and N.J. Ho, Laser Surface Alloying of Ferritic Fe-40Cr Alloy with Ruthenium, Surf. Coat. Technol., 1997, 90(2), p 203-209

N.P. Thanjekwayo, The Influence of Ru Additions on the Corrosion Behaviour of WC-Co Cemented Carbide in Corrosive Media. M.Sc. Dissertation, University of the Witwatersrand, Johannesburg (2009)

J.H. Potgieter, P. Olubambi, and S.S. Potgieter-Vermaak, The Corrosion Behaviour of WC-Co-Ru Alloys in Aggressive Chloride Media, Int. J. Electrochem., 2014, 2014, p 11. https://doi.org/10.1155/2014/594871

J.H. Potgieter, W. Skinner, and A.M. Heyns, Cathodic Modification as a Means of Improving the Corrosion Resistance of Alloys, J. Appl. Electrochem., 1990, 20, p 711-715

J.F. Flores, A. Neville, N. Kapur, and A. Gnanavelu, Erosion–Corrosion Degradation Mechanisms of Fe-Cr-C and WC-Fe-Cr-C PTA Overlays in Concentrated Slurries, Wear, 2009, 267, p 1811-1820

Acknowledgments

The authors gratefully acknowledge the financial assistance from the DST-NRF Centre of Excellence in Strong Materials and the University of the Witwatersrand. Anglo Platinum is acknowledged for the provision of Ru powder.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Nelwalani, N.B., van der Merwe, J.W. The Effect of pH on Slurry Erosion–Corrosion of Tungsten Carbide Overlays Alloyed with Ru. J Therm Spray Tech 27, 483–499 (2018). https://doi.org/10.1007/s11666-017-0676-9

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-017-0676-9