Abstract

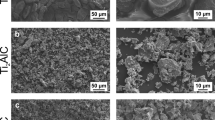

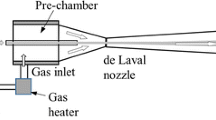

Cold gas spray technology has been used to build up coatings of Fe-base metallic glass onto different metallic substrates. In this work, the effect of the substrate properties on the viscoplastic response of metallic glass particles during their impact has been studied. Thick coatings with high deposition efficiencies have been built-up in conditions of homogeneous flow on substrates such as Mild Steel AISI 1040, Stainless Steel 316L, Inconel 625, Aluminum 7075-T6, and Copper (99.9%). Properties of the substrate have been identified to play an important role in the viscoplastic response of the metallic glass particles at impact. Depending on the process gas conditions, the impact morphologies show not only inhomogeneous deformation but also homogeneous plastic flow despite the high strain rates, 108 to 109 s−1, involved in the technique. Interestingly, homogenous deformation of metallic glass particles is promoted depending on the hardness and the thermal diffusivity of the substrate and it is not exclusively a function of the kinetic energy and the temperature of the particle at impact. Coating formation is discussed in terms of fundamentals of dynamics of undercooled liquids, viscoplastic flow mechanisms of metallic glasses, and substrate properties. The findings presented in this work have been used to build up a detailed scheme of the deposition mechanism of metallic glass coatings by the cold gas spraying technology.

Similar content being viewed by others

References

E. Axinte, Metallic Glasses from “Alchemy” to Pure Science: Present and Future of Design, Processing and Applications of Glassy Metals, Mater. Des., 2012, 35, p 518-556

J.Q. Wang, Y.H. Liu, M.W. Chen, G.Q. Xie, D.V. Louzguine-Luzgin, A. Inoue, and J.H. Perepezko, Rapid Degradation of Azo Dye by Fe-Based Metallic Glass Powder, Adv. Funct. Mater., 2012, 22, p 2567-2570

A. Inoue, Stabilization of Metallic Supercooled Liquid and Bulk Amorphous Alloys, Acta Mater., 2000, 48(1), p 279-306

A.T. Patel and A. Pratap, Study of Kinetics of Glass Transition of Metallic Glasses, J. Therm. Anal. Calorim., 2012, 110(2), p 567-571

G. Pookat, H. Thomas, S. Thomas, S.H. Al-Harthi, L. Raghavan, I. Al-Omari, and M.R. Anantharaman, Evolution of Structural and Magnetic Properties of Co-Fe Based Metallic Glass Thin Films with Thermal Annealing, Surf. Coat. Technol., 2013, 236, p 246-251

W.H. Wang, C. Dong, and C.H. Shek, Bulk Metallic Glasses, Mater. Sci. Eng., 2004, 44(2), p 45-89

W.L. Johnson, Bulk Glass-Forming Metallic Alloys: Science and Technology, Mrs Bull., 1999, 24, p 42-56

A. Concustell, G. Alcala, S. Mato, T.G. Woodcock, A. Gebert, J. Eckert, and M.D. Baró, Effect of Relaxation and Primary Nanocrystallization on the Mechanical Properties of Cu 60 Zr 22 Ti 18 Bulk Metallic Glass, Intermetallics, 2005, 13(11), p 1214-1219

A.L. Greer, Y.Q. Cheng, and E. Ma, Shear Bands in Metallic Glasses, Mater. Sci. Eng., 2013, 74(4), p 71-132

D.B. Miracle, A. Concustell, Y. Zhang, A.R. Yavari, and A.L. Greer, Shear Bands in Metallic Glasses: Size Effects on Thermal Profiles, Acta Mater., 2011, 59(7), p 2831-2840

S. Ding, Y. Liu, Y. Li, Z. Liu, S. Sohn, F.J. Walker, and J. Schroers, Combinatorial Development of Bulk Metallic Glasses, Nat Mater., 2014, 13(5), p 494-500

T. Schmidt, H. Assadi, F. Gärtner, H. Richter, T. Stoltenhoff, H. Kreye, and T. Klassen, From Particle Acceleration to Impact and Bonding in Cold Spraying, J. Therm. Spray Technol., 2009, 18(5-6), p 794-808

W.Y. Li and C.J. Li, Optimal Design of a Novel Cold Spray Gun Nozzle at a Limited Space, J. Therm. Spray Technol., 2005, 14(3), p 391-396

W.Y. Li, H. Liao, G. Douchy, and C. Coddet, Optimal Design of a Cold Spray Nozzle by Numerical Analysis of Particle Velocity and Experimental Validation with 316l Stainless Steel Powder, Mater. Des., 2007, 28(7), p 2129-2137

S. Grigoriev, A. Okunkova, A. Sova, P. Bertrand, and I. Smurov, Cold Spraying: From Process Fundamentals Towards Advanced Applications, Surf. Coat. Technol., 2005, 268, p 77-84

H. Tabbara, S. Gu, D. McCartney, T. Price, and P. Shipway, Study on Process Optimization of Cold Gas Spraying, J. Therm. Spray Technol., 2011, 20(3), p 608-620

T. Klassen, F. Gärtner, T. Schmidt, J.O. Kliemann, K. Onizawa, K.R. Donner, and H. Kreye, Basic Principles and Application Potentials of Cold Gas Spraying, Materialwissenschaft und Werkstofftechnik, 2010, 41(7), p 575-584

J. Villafuerte, Current and Future Applications of Cold Spray Technology, Metal Finish., 2010, 108(1), p 37-39

H. Assadi, T. Schmidt, H. Richter, J.O. Kliemann, K. Binder, F. Gärtner, and H. Kreye, On Parameter Selection in Cold Spraying, J. Therm. Spray Technol., 2011, 20(6), p 1161-1176

H. Assadi, F. Gärtner, T. Stoltenhoff, and H. Kreye, Bonding Mechanism in Cold Gas Spraying, Acta Mater., 2003, 51(15), p 4379-4394

G. Bae, Y. Xiong, S. Kumar, K. Kang, and C. Lee, General Aspects of Interface Bonding in Kinetic Sprayed Coatings, Acta Mater., 2008, 56(17), p 4858-4868

M. Chen, Mechanical Behavior of Metallic Glasses: Microscopic Understanding of Strength and Ductility, Annu. Rev. Mater. Res., 2008, 38, p 445-469

T.G. Nieh and J. Wadsworth, Homogeneous Deformation of Bulk Metallic Glasses, Scr. Mater., 2006, 54(3), p 387-392

S. Yoon, H.J. Kim, G. Bae, B. Kim, and C. Lee, Formation of Coating and Tribological Behavior of Kinetic Sprayed Fe-Based Bulk Metallic Glass, J. Alloys. Compd, 2011, 509(2), p 347-353

S. Yoon, G. Bae, Y. Xiong, S. Kumar, K. Kang, J.J. Kim, and C. Lee, Strain-Enhanced Nanocrystallization of a CuNiTiZr Bulk Metallic Glass Coating by a Kinetic Spraying Process, Acta Mater., 2009, 57(20), p 6191-6199

A. List, F. Gärtner, T. Schmidt, and T. Klassen, Impact Conditions for Cold Spraying of Hard Metallic Glasses, J. Therm. Spray Technol., 2012, 21(3-4), p 531-540

P.D. Olmsted, Perspectives on Shear Banding in Complex Fluids, Rheol Acta, 2008, 47(3), p 283-300

A. Concustell, J. Henao, S. Dosta, N. Cinca, I.G. Cano, and J.M. Guilemany, On the Formation of Metallic Glass Coatings by Means of Cold Gas Spray Technology, J. Alloys Compd, 2015, 651, p 764-772

J. Henao, A. Concustell, I.G. Cano, N. Cinca, S. Dosta, and J.M. Guilemany, Influence of Cold Gas Spray Process Conditions on the Microstructure of Fe-Based Amorphous Coatings, J. Alloys Compd, 2015, 622, p 995-999

J.W. Christian, The Theory of Transformations in Metals and Alloys, 2nd ed., Pergamon, Oxford, 1975

K. Kim, M. Watanabe, and S. Kuroda, Bonding Mechanisms of Thermally Softened Metallic Powder Particles and Substrates Impacted at High Velocity, Surf. Coat. Technol., 2010, 204(14), p 2175-2180

S. Yin, X.F. Wang, W.Y. Li, and X.P. Guo, Examination on Substrate Preheating Process in Cold Gas Dynamic Spraying, J. Therm. Spray Technol., 2011, 20(4), p 852-859

K. Yokoyama, M. Watanabe, S. Kuroda, Y. Gotoh, T. Schmidt, and F. Gärtner, Simulation of Solid Particle Impact Behavior for Spray Processes, Mater. Trans., 2006, 47(7), p 1697-1702

M. Grujicic, J.R. Saylor, D.E. Beasley, W.S. DeRosset, and D. Helfritch, Computational Analysis of the Interfacial Bonding Between Feed-Powder Particles and the Substrate in the Cold-Gas Dynamic-Spray Process, Appl. Surf. Sci., 2003, 219(3), p 211-227

D. Zhang, P.H. Shipway, and D.G. McCartney, Cold Gas Dynamic Spraying of Aluminum: the Role of Substrate Characteristics In Deposit Formation, J. Therm. Spray Technol., 2005, 14(1), p 109-116

P.C. King, G. Bae, S.H. Zahiri, M. Jahedi, and C. Lee, An Experimental and Finite Element Study of Cold Spray Copper Impact onto Two Aluminum Substrates, J. Therm. Spray Technol., 2010, 19(3), p 620-634

T. Marrocco, D.G. McCartney, P.H. Shipway, and A.J. Sturgeon, Production of Titanium Deposits by Cold-Gas Dynamic Spray: Numerical Modeling and Experimental Characterization, J. Therm. Spray Technol., 2006, 15(2), p 263-272

X.K. Suo, M. Yu, W.Y. Li, M.P. Planche, and H.L. Liao, Effect of Substrate Preheating on Bonding Strength of Cold-Sprayed Mg Coatings, J. Therm. Spray Technol., 2012, 21(5), p 1091-1098

M. Grujicic, C.L. Zhao, W.S. DeRosset, and D. Helfritch, Adiabatic Shear Instability Based Mechanism for Particles/Substrate Bonding in the Cold-Gas Dynamic-Spray Process, Mater. Des., 2004, 25(8), p 681-688

L. Ajdelsztajn, E.J. Lavernia, B. Jodoin, P. Richer, and E. Sansoucy, Cold Gas Dynamic Spraying of Iron-Base Amorphous Alloy, J. Therm. Spray Technol., 2006, 15(4), p 495-500

S. Yoon, C. Lee, H. Choi, H. Kim, and J. Bae, Impacting Behavior of Bulk Metallic Glass Powder at an Abnormally High Strain Rate During Kinetic Spraying, Mater. Sci. Eng., 2007, 449, p 911-915

http://rsbweb.nih.gov/ij/index.html Accessed 04 Feb 2016.

U. Prisco, Size-Dependent Distributions of Particle Velocity and Temperature at Impact in the Cold-Gas Dynamic-Spray Process, J. Mater. Process. Technol., 2015, 216, p 302-314

http://www.matweb.com/. Accessed 04 February 2016.

M.A. Munoz-Morris, S. Surinach, M. Gich, M.D. Baró, and D.G. Morris, Crystallization of a Al-4Ni-6Ce Glass and its Influence on Mechanical Properties, Acta Mater., 2003, 51(4), p 1067-1077

J. Wu, H. Fang, S. Yoon, H. Kim, and C. Lee, The Rebound Phenomenon in Kinetic Spraying Deposition, Scr. Mater., 2006, 54(4), p 665-669

A. List, F. Gärtner, T. Mori, M. Schulze, H. Assadi, S. Kuroda, and T. Klassen, Cold Spraying of Amorphous Cu50Zr50 Alloys, J. Therm. Spray Technol., 2015, 24(1-2), p 108-118

S. Yoon, C. Lee, H. Choi, and H. Jo, Kinetic Spraying Deposition Behavior of Bulk Amorphous Nitizrsisn Feedstock, Mater. Sci. Eng., 2006, 415(1), p 45-52

A.L. Yarin, Drop Impact Dynamics: Splashing, Spreading, Receding, Bouncing, Annu. Rev. Fluid Mech., 2006, 38, p 159-192

X. Zhou, X. Wu, S. Mou, J. Liu, and J. Zhang, Simulation of Deposition Behavior of Bulk Amorphous Particles in Cold Spraying, Mater. Trans., 2010, 51(10), p 1977-1980

S.H. Kang, J.H. Lee, J.S. Cheon, and Y.T. Im, The Effect of Strain-Hardening on Frictional Behavior in Tip Test, Int. J. Mech. Sci., 2004, 46(6), p 855-869

J.R. Davis, Tensile testing, chapter 7, 2nd ed., ASM interantional, Ohio, 2004

A. McDonald and S. Chandra, Kinematic Viscosities of High-Temperature Materials Used in Plasma Spraying, J. Am. Ceram. Soc., 2011, 94(6), p 1865-1871

H. Chiriac, M. Tomut, C. Naum, F. Necula, and V. Nagacevschi, On the Measurement of Surface Tension for Liquid Fesib Glass-Forming Alloys by Sessile Drop Method, Mater. Sci. Eng., 1997, 226, p 341-343

X. Chen and J.W. Hutchinson, Particle Impact on Metal Substrates with Application to Foreign Object Damage to Aircraft Engines, J. Mech. Phys. Solids, 2002, 50(12), p 2669-2690

R. Probstein, Physicochemical Hydrodynamics: An Introduction, Chapter 9, Wiley, New York, 2005, p 286

P. Gould, Introduction to Linear Elasticity, Chapter 3, Springer Science & Business Media, Berlin, 2013, p 64-65

M. Fukumoto, H. Wada, K. Tanabe, M. Yamada, E. Yamaguchi, A. Niwa, and M. Izawa, Effect of Substrate Temperature on Deposition Behavior of Copper Particles on Substrate Surfaces in the Cold Spray Process, J. Therm. Spray Technol., 2007, 16(5-6), p 643-650

M.D. Demetriou and W.L. Johnson, Shear Flow Characteristics and Crystallization Kinetics During Steady Non-Isothermal Flow of Vitreloy-1, Acta Mater., 2004, 52(12), p 3403-3412

M.A. Meyers, V.F. Nesterenko, J.C. LaSalvia, and Q. Xue, Shear Localization in Dynamic Deformation of Materials: Microstructural Evolution and Self-Organization, Mater. Sci. Eng, 2001, 317(1), p 204-225

F. Spaepen, A Microscopic Mechanism for Steady State Inhomogeneous Flow in Metallic Glasses, Acta Metall., 1977, 25(4), p 407-415

Acknowledgments

The authors would like to thank IMPACT INNOVATIONS GmbH for their collaboration in coating deposition, EPSON-ATMIX for providing the powder used in this work, and the Generalitat de Catalunya through 2014 SGR 1558 for the financial support. The authors also acknowledge the CPT grant for supporting “John Henao” in his PhD program at the Universitat de Barcelona.

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Henao, J., Concustell, A., Dosta, S. et al. Influence of the Substrate on the Formation of Metallic Glass Coatings by Cold Gas Spraying. J Therm Spray Tech 25, 992–1008 (2016). https://doi.org/10.1007/s11666-016-0419-3

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-016-0419-3