Abstract

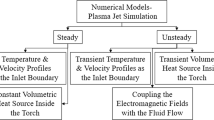

Suspension plasma spray is a promising technology for surface coatings. In this work, a comprehensive numerical model was developed to investigate the multiphase flow of suspension droplets and nanoparticles in direct-current (DC) plasma spraying. A three-dimensional computational model was developed to describe the plasma jet flow fields coupled with the axial injection of suspension droplets in which the zirconia micro- and nanoparticles were dispersed. The suspension droplets were tracked using Lagrangian coordinates, considering particle heating, melting, and evaporation. After evaporation of the solvent surrounding the particle, the nanoparticles were discharged into the plasma flow. In addition to the viscous force exerted by the flow on the micrometer-sized particles, the Brownian force and the Saffman lift force were taken into account. The effects of the noncontinuum on particle momentum transfer and evaporation on heat transfer were also considered. The numerical predictions of gas flow temperature were compared with experimental data and numerical data obtained with a different computational fluid dynamics code. The agreement was reasonable. The trajectories, velocity, and temperature of nanoparticles were calculated, and compared with those of microparticles. The results showed that the Brownian force plays a major role in acceleration and heating of nanoparticles. Compared with the conventional plasma spray process with micrometer-sized feedstock, the nanoparticles in suspension plasma spraying were found to have a wider spatial distribution and higher temperature. The effects of operating parameters, such as the power input to the plasma gas and plasma gas composition, on the gas velocity and temperature were investigated. The parameters that have a significant effect on the heat and momentum transfer to the particles injected in the plasma jet were identified.

Similar content being viewed by others

Abbreviations

- C p :

-

Specific heat (J/kg/K)

- C D :

-

Drag coefficient

- D :

-

Diffusion coefficients (m2 s−1)

- h :

-

Heat transfer coefficient (W/m2/K)

- k :

-

Thermal conductivity (W/m/K)

- L m :

-

Latent heat of fusion (J/kg)

- L v :

-

Latent heat of evaporation (J/kg)

- Nu:

-

Nusselt number, Nu = 2 h/k

- Pr:

-

Prandtl number, Pr = μC p/k

- Q conv :

-

Convective heat rate (W)

- Q rad :

-

Radiative heat rate (W)

- Q vap :

-

Vaporization heat rate (W)

- Sc:

-

Schmidt number, \({\text{Sc}} = \mu /\rho D\)

- r :

-

Radial coordinate (m)

- R :

-

Particle radius (m)

- t :

-

Time (s)

- T p :

-

Particle temperature (K)

- T m,d :

-

Droplet evaporation temperature (K)

- V :

-

Velocity (m/s)

- Y :

-

Mass fraction of vapor in the gas phase

- α :

-

Weight fraction

- μ :

-

Viscosity (kg/s/m)

- d:

-

Suspension droplet embedded with nanoparticles

- f:

-

Film temperature around the particle

- g:

-

Plasma gas

- p:

-

Solid nanoparticles or agglomerates

- sl:

-

Solvent

- ∞:

-

Ambient condition of spray

References

P. Fauchais, G. Montavon, R.S. Lima, and B.R. Marple, Engineering A New Class of Thermal Spray Nano-Based Microstructures from Agglomerated Nanostructured Particles, Suspensions and Solutions: An Invited Review, J. Phys. D Appl. Phys., 2011, 44(9), p 1-52

J. Karthikeyan, C.C. Berndt, J. Tikkanen, J.Y. Wang, A.H. King, and H. Herman, Preparation of Nanophase Materials by Thermal Spray Processing of Liquid Precursors, Nanostruct. Mater., 1997, 9, p 137-140

P. Fauchais and G. Montavon, Latest Developments in Suspension and Liquid Precursor Thermal Spraying, J. Therm. Spray Technol., 2010, 19, p 226-239

U. Kogelschatz, Atmospheric-Pressure Plasma Technology, Plasma Phys. Control. Fus., 2004, 46, p B63-B75

E.H. Jordan, M. Gell, Y.H. Sohn, D. Goberman, L. Shaw, S. Jiang, M. Wang, T.D. Xiao, Y. Wang, and P. Strutt, Fabrication and Evaluation of Plasma Sprayed Nanostructured Alumina-Titania Coatings with Superior Properties, Mater. Sci. Eng. A, 2001, 301, p 80-89

P. Fauchais, R. Etchart-Salas, C. Delbos, M. Tognovi, V. Rat, J.F. Coudert, and T. Chartier, Suspension and Solution Plasma Spraying of Finely Structured Coatings, J. Phys. D Appl. Phys., 2007, 40, p 2394-2406

R.S. Lima, A. Kucuk, and C.C. Berndt, Integrity of Nanostructured Partially Stabilized Zirconia after Plasma Spray Processing, Mater. Sci. Eng. A, 2001, 313, p 75-82

F. Tarasi, M. Medraj, A. Dolatabadi, J. Oberste-Berghaus, and C. Moreau, Effective Parameters in Axial Injection Suspension Plasma Spray Process of Alumina-Zirconia Ceramics, J. Therm. Spray Technol., 2008, 17(5-6), p 685-691

E. Meillot, S. Vincent, C. Caruyer, J.-P. Caltagirone, and D. Damiani, From DC Time-Dependent Thermal Plasma Generation to Suspension Plasma-Spraying Interactions, J. Therm. Spray Technol., 2009, 18, p 875-886

D. Chen, E.H. Jordan, and M. Gell, The Solution Precursor Plasma Spray Coatings: Influence of Solvent Type, Plasma Chem. Plasma Process., 2010, 30, p 111-119

P. Fauchais, R. Etchart-Salas, V. Rat, J.F. Coudert, N. Caron, and K. Wittmann-Teneze, Parameters Controlling Liquid Plasma Spraying: Solutions, Sols, or Suspensions, J. Therm. Spray Technol., 2008, 17(1), p 31-59

A. Ozturk and B.M. Cetegen, Modeling of Axially and Transversely Injected Precursor Droplets into a Plasma Environment, Int. J. Heat Mass Transf., 2005, 48, p 4367-4383

C. Marchand, C. Chazelas, G. Mariaux, and A. Vardelle, Liquid Precursor Plasma Spraying: Modeling the Interactions Between the Transient Plasma Jet and the Droplets, J. Therm. Spray Technol., 2007, 16(5-6), p 705-711

A.M. Ahmed, R.H. Rangel, V.V. Sobolev, and J.M. Guilemany, In-Flight Oxidation of Composite Powder Particles During Thermal Spraying, Int. J. Heat Mass Transf., 2001, 44, p 4667-4677

S. Basu, E.H. Jordan, and B.M. Cetegen, Fluid Mechanics and Heat Transfer of Liquid Precursor Droplets Injected into High-Temperature Plasmas, J. Therm. Spray Technol., 2008, 17, p 60-72

Y. Shan and Y. Hu, Heat and Mass Transfer within an Evaporating Solution Droplet in a Plasma Jet, J. Therm. Spray Technol., 2012, 21(3-4), p 676-688

F. Jabbari, M. Jadidi, R. Wuthrich, and A. Dolatabadi, A Numerical Study of Suspension Injection in Plasma-Spraying Process, J. Therm. Spray Technol., 2014, 23, p 3-13

J.D. Ramshaw and C.H. Chang, Computational Fluid Dynamics Modeling of Multi-Component Thermal Plasmas, Plasma Chem. Plasma Process., 1992, 12, p 299-325

Y.C. Lee, K.C. Hsu, and E. Pfender, Modeling of Particles Injected into a D.C. Plasma Jet, 5th International Symposium on Plasma Chemistry, Edinburgh, Scotland, 1981

X. Chen and E. Pfender, Behavior of Small Particles in a Thermal Plasma Flow, Plasma Chem. Plasma Process., 1983, 3(3), p 351-366

X. Chen and E. Pfender, Effect of the Knudsen Number on Heat Transfer to a Particle Immersed into a Thermal Plasma, Plasma Chem. Plasma Process., 1983, 3, p 97-113

H.B. Xiong and J.Z. Lin, Nanoparticles Modeling in Axially Injection Suspension Plasma Spray of Zirconia and Alumina Ceramics, J. Therm. Spray Technol., 2009, 18(5), p 887-895

H.B. Xiong, L.L. Zheng, S. Sampath, R.L. Williamson, and J.R. Fricke, Three-Dimensional Simulation of Plasma Spray: Effects of Carrier Gas Flow and Particle Injection on Plasma Jet and Entrained Particle Behavior, Int. J. Heat Mass Transf., 2004, 47, p 5189-5200

P.G. Saffman, The Lift on a Small Sphere in a Slow Shear Flow, J. Fluid Mech., 1965, 22(2), p 385-400

K.C. Chung, Three-Dimensional Analysis of Airflow and Contaminant Particle Transport in a Partitioned Enclosure, Build. Environ., 1999, 34, p 7-17

F. Peng and S.K. Aggarwal, A Review of Droplet Dynamics and Vaporization Modeling for Engineering Calculations, J. Eng. Gas Turb. Power, 1995, 117, p 453-461

Y.P. Wan, V. Prasad, G.-X. Wang, S. Sampath, and J.R. Fincke, Model and Powder Particle Heating, Melting, Resolidification, and Evaporation in Plasma Spraying Processes, J. Heat Transf., 1999, 121, p 691-699

X. Chen and E. Pfender, Heat Transfer to a Single Particle Exposed to a Thermal Plasma, Plasma Chem. Plasma Process., 1982, 2(2), p 185-212

M. Brossa and E. Pfender, Probe Measurements in Thermal Plasma Jets, Plasma Chem. Plasma Process., 1988, 8, p 75-90

Acknowledgments

The work was supported by the National Natural Science Foundation of China (nos. 11472245, 11072216, and 10602052) and the Fundamental Research Funds for the Central Universities (nos. 2012FZA4027).

Author information

Authors and Affiliations

Corresponding author

Rights and permissions

About this article

Cite this article

Shao, Xm., Zhang, K. & Xiong, Hb. Modeling of Micro- and Nanoparticle Characteristics in DC Suspension Plasma Spray. J Therm Spray Tech 24, 309–317 (2015). https://doi.org/10.1007/s11666-014-0182-2

Received:

Revised:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11666-014-0182-2