Abstract

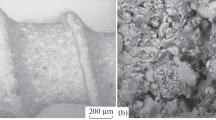

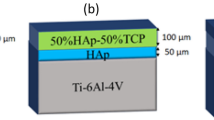

This study focuses on the role of residual stress in the tribological behavior of calcium-phosphate (CaP) coating on titanium (Ti) substrate. The CaP coating was applied using an integrated electrospinning and rapid heating and cooling (EMRHC) process. The residual stress over half and full done EMRHC process was measured by x-ray method. The substrate and coatings were characterized using a field emission scanning electron microscope equipped with the energy-dispersive spectroscope, Vicker's microhardness, atomic force microscopy, and x-ray diffractometer techniques. It was found that the preliminary hydroxyapatite on the Ti substrate was exchanged with α-TCP, CaO, TiO2, CaTiO3, and Ti5P3 over the EMRHC process. The results also showed that the tensile + 591 ± 89 and compressive − 189 ± 42 MPa residual stress remained on the surface over the half and full done EMRHC process, respectively. The hardness, Young module, and ultimate tensile strength of both samples were enhanced significantly by the EMRHC process. The tribology of samples was comprehensibly evaluated in a dry and simulated body fluid solution. The CaP coating prepared by the full-EMRHC process showed the lowest wear rates in comparison with the others due to the compressive residual stress. The coefficient of friction of CPTi coated by EMRHC was significantly reduced when exposed to the SBF solution. Our findings revealed that EMRHC is a promising method to fabricate the Ti implant with higher mechanical properties.

Similar content being viewed by others

Data availability

The raw/processed data required to reproduce these findings cannot be shared at this time as the data also forms part of an ongoing study.

References

Z. Jing, Q. Cao, and H. Jun, Corrosion, Wear and Biocompatibility of Hydroxyapatite Bio-functionally Graded Coating on Titanium Alloy Surface Prepared by Laser Cladding, Ceram. Int., 2021, 47, p 24641–24651. https://doi.org/10.1016/j.ceramint.2021.05.186

P.K. Rai, D. Naidu, S.K. Vajpai, B. Sharma, K. Ameyama, and K. Mondal, Effect of Cold Rolling and Heat Treatment on Corrosion and Wear Behavior of β-Titanium Ti-25Nb-25Zr Alloy, J. Mater. Eng. Perform., 2021, 30, p 4174–4182. https://doi.org/10.1007/s11665-021-05739-8

Y. Zhang, S. Luo, Q. Wang, and C. Seshadri Ramachandran, Effect of Hydrothermal Treatment on the Surface Characteristics and Bioactivity of HAP based MAO Coating on Ti-6Al-4V Alloy, Surf. Coat. Technol., 2023, 464, p 129566. https://doi.org/10.1016/j.surfcoat.2023.129566

S. Hussain, Z.A. Shah, K. Sabiruddin, and A.K. Keshri, Characterization and Tribological Behaviour of Indian Clam Seashell-derived Hydroxyapatite Coating Applied on Titanium Alloy by Plasma Spray Technique, J. Mech. Behave. Biomed. Mater., 2023, 137, p 105550. https://doi.org/10.1016/j.jmbbm.2022.105550

Z.Y. Zhang, T.Y. Huang, D.J. Zhai, H.B. Wang, K.Q. Feng, and L. Xiang, Study on Strontium Doped Bioactive Coatings on Titanium Alloys Surfaces by Micro-arc Oxidation, Surf. Coat. Technol., 2022, 451, p 129045. https://doi.org/10.1016/j.surfcoat.2022.129045

M. Madhusmita and N. Arunachalam, Effects of Electrophoretic Deposited Graphene Coating Thickness on the Corrosion and Wear Behaviors of Commercially Pure Titanium, Surf. Coat. Technol., 2022, 450, p 128946. https://doi.org/10.1016/j.surfcoat.2022.128946

Y. Wu, A.H. Wang, Z. Zhang, H.B. Xia, and Y.N. Wang, Wear Resistance of in Situ Synthesized Titanium Compound Coatings Produced by Laser Alloying Technique, Surf. Coat. Technol., 2014, 258, p 711–715. https://doi.org/10.1016/j.surfcoat.2014.08.012

M. Kheradmandfard, O.V. Penkov, S.F. Kashani-Bozorg, J.S. Lee, C.L. Kim, M. Khadem, S.W. Cho, A.Z. Hanzaki, and D.E. Kim, Exceptional Improvement in The Wear Resistance of Biomedical β-type Titanium Alloy with the use of a Biocompatible Multilayer Si/DLC Nanocomposite Coating, Ceram. Int., 2022, 48, p 17376–17384. https://doi.org/10.1016/j.ceramint.2022.03.002

T. Sun, N. Xue, C. Liu, C. Wang, and J. He, Bioactive (Si, O, N)/(Ti, O, N)/Ti Composite Coating on NiTi Shape Memory Alloy for Enhanced Wear and Corrosion Performance, Appl. Surf. Sci., 2015, 356, p 599–609. https://doi.org/10.1016/j.apsusc.2015.07.185

R.C. Costa, J.G.S. Souza, J.M. Cordeiro, M. Bertolini, E.D. de Avila, R. Landers, E.C. Rangel, C.A. Fortulan, B. Retamal-Valdes, N.C. da Cruz, M. Feres, and V.A.R. Barão, Synthesis of Bioactive Glass-based Coating by Plasma Electrolytic Oxidation: Untangling a New Deposition Pathway Toward Titanium Implant Surfaces, J. Colloid Interface Sci., 2020, 579, p 680–698. https://doi.org/10.1016/j.jcis.2020.06.102

D. Kuczyńska-Zemła, J. Pura, B. Przybyszewski, M. Pisarek, and H. Garbacz, A Comparative Study of Apatite Growth and Adhesion on a Laser-Functionalized Titanium Surface, Tribol. Int., 2023, 182, p 108338. https://doi.org/10.1016/j.triboint.2023.108338

A. Błoniarz, K. Cholewa-Kowalska, M. Gajewska, B. Grysakowski, and T. Moskalewicz, Electrophoretic Deposition, Microstructure and Selected Properties of Nanocrystalline SnO2/Sr Enriched Bioactive Glass/Chitosan Composite Coatings Titanium, Surf. Coat. Technol., 2020, 450, p 129004. https://doi.org/10.1016/j.surfcoat.2022.129004

H. Shaygani, S. Seifi, A. Shamloo, M. Golizadeh, S.Y. Rahnamaee, M. Alishiri, and S. Ebrahimi, Novel Bilayer Coating on Gentamicin-loaded Titanium Nanotube for Orthopedic Implants Applications, Int. J. Pharm., 2023, 636, p 122764. https://doi.org/10.1016/j.ijpharm.2023.122764

C. Skjoldebrand, J.L. Tipper, P. Hatto, M. Bryant, and R.M. Hall, Cecilia Persson Current Status and Future Potential of Wear-resistant Coatings and Articulating Surfaces for Hip and Knee Implants, Mater. Today Bio., 2020, 15, p 100270. https://doi.org/10.1016/j.mtbio.2022.100270

Y. Fang, Simulation and Experiment of Impact Effects of Nanosecond Pulse Laser-Generated Processing Ti-6Al-4V Alloy, J. Mater. Eng. Perform., 2021, 30, p 5515–5523. https://doi.org/10.1007/s11665-021-05551-4

A. Ghailane, E.Y. Maadane, A. Barchid, S. Berchane, S. Badre-Eddine, H. Larhlimi, C.B. Fischer, J. Alami, and M. Makha, Influence of Annealing Temperature on the Microstructure and Hardness of TiN Coatings Deposited by High-Power Impulse Magnetron Sputtering, J. Mater. Eng. Perform., 2022, 31, p 5593–5601. https://doi.org/10.1007/s11665-022-06689-5

E.Z. Nahum, S. Lugovskoy, A. Lugovskoy, B. Kazanski, and A. Sobolev, The Study of Hydroxyapatite Growth Kinetics on CP e Ti and Ti65Zr Treated by Plasma Electrolytic Oxidation Process, J. Market. Res., 2023, 24, p 2169–2186. https://doi.org/10.1016/j.jmrt.2023.03.128

O.V. Tkachuk, I.M. Pohrelyuk, R.V. Proskurnyak, J. Morgiel, M. Faryna, and A. Goral, Morphology and Corrosion Resistance of Hydroxyapatite Coatings Formed on Commercially Pure Titanium, J. Mater. Eng. Perform., 2023 https://doi.org/10.1007/s11665-023-07910-9

M. Samiksha, R. Gnanamoorthy, and Y. Otsuka, Fretting Wear Characteristics of Suspension Plasma-Sprayed Hydroxyapatite Coating on Titanium Substrate for Orthopedic Applications, J. Mater. Eng. Perform., 2022, 31, p 7290–7301. https://doi.org/10.1007/s11665-022-06753-0

A. Alcantara-Garcia, A. Garcia-Casas, and A. Jimenez-Morales, Electrochemical study of the synergic effect of phosphorus and cerium additions on a sol-gel coating for Titanium manufactured by powder metallurgy, Prog. Org. Coat., 2018, 124, p 267–274. https://doi.org/10.1016/j.porgcoat.2018.01.026

U. Rokkala, G. Suresh, and M.R. Ramesh, Comparative Study of Plasma Spray and Friction Stir Processing on Wear Properties of Mg-Zn-Dy Alloy, J. Mater. Eng. Perform., 2023 https://doi.org/10.1007/s11665-023-08087-x

M. Yadi, H. Esfahani, M. Sheikhi, and M. Mohammadi, CaTiO3/α-TCP Coatings on CP-Ti Prepared via Electrospinning and Pulsed Laser Treatment for in-vitro Bone Tissue Engineering, Surf. Coat. Technol., 2020, 401, p 126256. https://doi.org/10.1016/j.surfcoat.2020.126256

R. Gorejov, R. Oriňaková, Z.O. Králová, T. Sopčák, I. Šišoláková, M. Schnitzer, M. Kohan, and R. Hudák, Electrochemical Deposition of a Hydroxyapatite Layer onto the Surface of Porous Additively Manufactured Ti6Al4V Scaffolds, Surf. Coat. Technol., 2023, 455(25), p 129207. https://doi.org/10.1016/j.surfcoat.2022.129207

H. Esfahani, R. Jose, and S. Ramakrishna, Electrospun Ceramic Nanofiber Mats Today: Synthesis, Properties, and Applications, Materials, 2017, 10(11), p 1238. https://doi.org/10.3390/ma10111238

H. Esfahani, E. Salahi, A. Tayebifard, M.R. Rahimipour, and M. Keyanpour-Rad, Influence of Zinc Incorporation on Microstructure of Hydroxyapatite to Characterize the Effect of pH and Calcination Temperatures, J. Asian Ceramic Soc., 2014, 2, p 248–252. https://doi.org/10.1016/j.jascer.2014.05.001

H. Esfahani, M. Darvishghanbar, and B. Farshid, Enhanced Bone Regeneration of Zirconia-toughened Alumina Nanocomposites Using PA6/HA Nanofiber Coating via Electrospinning, J. Mater. Res., 2018, 33(24), p 4287–4295. https://doi.org/10.1557/jmr.2018.391

V. Rattan, T.S. Sidhu, and M. Mittal, Wear Studies on Plasma-Sprayed Pure and Reinforced Hydroxyapatite Coatings, Mater. Today Proc., 2022, 60, p 1731–1735. https://doi.org/10.1016/j.matpr.2021.12.306

F. Musharavati, F. Jaber, M. Nasor, M. Sarraf, E.Z. Nezhad, K. Uzun, Y. Ma, S. Bae, R. Singh, and M.E. Chowdhury, Micromechanical Properties of Hydroxyapatite Nanocomposites Reinforced with CNTs and ZrO2, Ceram. Int., 2023, 49(5), p 7466–7475. https://doi.org/10.1016/j.ceramint.2022.10.218

M. Yadi, H. Esfahani, A. Nourian, S.H. Navard, and A. Fattahalhosseini, Surface Modification of CP-Ti by Calcium-Phosphate via an Integrated Electrospinning and Rapid Heating and Cooling (EMRHC) process: Essential in-vitro Studies for Bone Regeneration, Surf. Int., 2021, 27, p 101480. https://doi.org/10.1016/j.surfin.2021.101480

V. Baranauskas, H.J. Ceragioli, A.C. Peterlevitz, and M. Fontana, Low Residual Stress Diamond Coatings on Titanium, Surf. Coat. Technol., 2005, 200, p 2343–2347. https://doi.org/10.1016/j.surfcoat.2005.04.020

Y.C. Yang, E. Chang, B.H. Hwang, and S.Y. Lee, Biaxial Residual Stress States of Plasma-sprayed Hydroxyapatite Coatings on Titanium Alloy Substrate, Biomaterials, 2000, 21, p 1327–1337.

C.L. Chang, J.I. Jao, W.Y. Ho, and D.Y. Wang, Effects of Titanium-Implanted Pre-Treatments on the Residual Stress of TiN Coatings on High-speed Steel Substrates, Surf. Coat. Technol., 2007, 201, p 6702–6706. https://doi.org/10.1016/j.surfcoat.2006.09.035

A.R. Nimkerdphol, Y. Otsuka, and Y. Mutoh, Effect of Dissolution/precipitation on the Residual Stress Redistribution of Plasma-sprayed Hydroxyapatite Coating on Titanium Substrate in Simulated Body Fluid (SBF), J. Mech. Behav. Biomed. Mater., 2014, 36, p 98–108. https://doi.org/10.1016/j.jmbbm.2014.04.007

Y.C. Yang and E. Chang, Measurements of Residual Stresses in Plasma-sprayed Hydroxyapatite Coatings on Titanium Alloy, Surf. Coat. Technol., 2005, 190, p 122–131. https://doi.org/10.1016/j.surfcoat.2004.02.038

C.H. Huang and M. Yoshimura, Biocompatible Hydroxyapatite Ceramic Coating on Titanium Alloys by Electrochemical Methods via Growing Integration Layers [GIL] Strategy: A Review, Ceramics Int., 2023 https://doi.org/10.1016/j.ceramint.2022.12.248

A. Umapathi and S. Swaroop, Measurement of Residual Stresses in Titanium Alloys using Synchrotron Radiation, Measurement, 2019, 140, p 518–525. https://doi.org/10.1016/j.measurement.2019.04.021

V. Koshuro, E. Osipova, O. Markelova, M. Fomina, A. Zakharevich, S. Pichkhidze, and A. Fomin, Titanium Oxide Coatings Formed by Plasma Spraying Followed by Induction Heat Treatment, Ceramics Int., 2023, 49, p 2034–2043. https://doi.org/10.1016/j.ceramint.2022.09.169

S. Park, J. Choi, S. Mondal, T.M.T. Vo, V.H. Pham, H. Lee, S.Y. Nam, C.-S. Kim, and O. Junghwan, The Impact of Cu(II) Ions Doping in Nanostructured Hydroxyapatite Powder: A Finite Element Modelling Study for Physico-mechanical and Biological Property Evaluation, Adv. Powder Technol., 2022, 33(2), p 103405. https://doi.org/10.1016/j.apt.2021.103405

A. Ebrahimi, H. Esfahani, A. Fattah-alhosseini, and O. Imantalab, Electrochemical Properties of Commercially Pure Ti with TiB/TiB2 Coatings in Hanks Balanced Salt Solution, J. Mater. Eng. Perform., 2019, 28, p 1456–1468. https://doi.org/10.1007/s11665-019-03930-6

T. Kokubo and H. Takadama, How useful is SBF in Predicting in vivo Bone Bioactivity?, Biomaterials, 2006, 27(15), p 2907–2915. https://doi.org/10.1016/j.biomaterials.2006.01.017

Cullity, Bernard Dennis. Elements of x-ray Diffraction. Addison-Wesley Publishing, (1956) Chapter 17.

S. Panda, B. Prasad Behera, S. Kumar Bhutia, C. Kumar Biswas, and S. Paul, Rare Transition Metal Doped Hydroxyapatite Coating Prepared via Microwave Irradiation Improved Corrosion Resistance, Biocompatibility and Anti-biofilm Property of Titanium Alloy, J. Alloys Compd., 2022, 918, p 165662. https://doi.org/10.1016/j.jallcom.2022.165662

H. Shi, X. Wu, S. Sun, C. Wang, Z. Vangelatos, A. Ash-Shakoor, C.P. Grigoropoulos, P.T. Mather, J.H. Henderson, and Z. Ma, Profiling the Responsiveness of Focal Adhesions of Human Cardiomyocytes to Extracellular Dynamic Nano-topography, Bioactive Mater., 2022, 10, p 367–377. https://doi.org/10.1016/j.bioactmat.2021.08.028

Q. Zan, C. Wang, L. Dong, P. Cheng, and J. Tian, Effect of Surface Roughness of Chitosan-based Microspheres on Cell Adhesion, Appl. Surf. Sci., 2008, 255(2), p 401–403. https://doi.org/10.1016/j.apsusc.2008.06.074

S. Balcı and F. Tomu, Catalytic Wet Peroxide Oxidation of Phenol Through Mesoporous Silica-pillared Clays Supported Iron and/or Titanium Incorporated Catalysts, J. Environ. Manag., 2023, 326(Part B), p 116835. https://doi.org/10.1016/j.jenvman.2022.116835

J.C. Sánchez-López, M. Rodríguez-Albelo, M. Sánchez-Pérez, V. Godinho, C. López-Santos, and Y. Torres, Ti6Al4V Coatings on Titanium Samples by Sputtering Techniques: Microstructural and Mechanical Characterization, J. Alloy. Compd., 2023, 953, p 170018. https://doi.org/10.1016/j.jallcom.2023.170018

W.O.S. Seeram Ramakrishna, M. Ramalingam, and T.S. Sampath Kumar, Biomaterials A Nano Approach, 1st ed. CRC Press, Florida, 2010.

S. Kumar and A. Kumar Das, Wear Resistance and Hardness Properties of TiB2– Fe Coating Developed on AISI 1020 Steel by Tungsten Inert Gas (TIG) Cladding, Ceramics Int., 2022, 48(20), p 30052–30065. https://doi.org/10.1016/j.ceramint.2022.06.274

S.P. Chodisetti and B.V.M. Kumar, Tailoring Friction and Wear Properties of Titanium Boride Reinforced Silicon Carbide Composites, Wear, 2023, 526–527, p 204886. https://doi.org/10.1016/j.wear.2023.204886

A. Shenhar, I. Gotmana, S. Radinb, P. Ducheyne, and E.Y. Gutmanas, Titanium Nitride Coatings on Surgical Titanium Alloys Produced by a Powder Immersion Reaction Assisted Coating Method: Residual Stresses and Fretting Behavior, Surface Coat. Technology, 2000, 126, p 210–218. https://doi.org/10.1016/S0257-8972(00)00524-7

Y. Fu, H. Du, and Ch.Q. Sun, Interfacial Structure, Residual Stress and Adhesion of Diamond Coatings Deposited on Titanium, Thin Solid Films, 2003, 424, p 107–114. https://doi.org/10.1016/S0040-6090(02)00908-2

G. Singh, S. Sharma, M. Mittal, G. Singh, J. Singh, L. Changhe, A.M. Khan, S.P. Dwivedi, R.T. Mushtaq, and S. Singh, Impact of Post-heat-treatment on the Surfaceroughness, Residual Stresses, and Micromorphology Characteristics of Plasmasprayed Pure Hydroxyapatite and 7%-Aloxite Reinforced Hydroxyapatite Coatings Deposited on Titanium Alloy-based Biomedical Implants, J. Mater. Res. Technol., 2022, 18, p 1358–1380. https://doi.org/10.1016/j.jmrt.2022.03.065

R. Singh, S. Schruefer, S. Wilson, J. Gibmeier, and R. Vassen, Influence of Coating Thickness on Residual Stress and Adhesion-strength of Cold-sprayed Inconel 718 Coatings, Surf. Coat. Technol., 2018, 350, p 64–73. https://doi.org/10.1016/j.surfcoat.2018.06.080

A. Vereschaka, M. Volosova, A. Chigarev, N. Sitnikov, A. Ashmarin, C. Sotova, J. Bublikov, and D. Lytkin, Influence of the Thickness of a Nanolayer Composite Coating on Values of Residual Stress and the Nature of Coating Wear, Coatings, 2020, 10, p 63. https://doi.org/10.3390/coatings10010063

K. Khlifi, H. Dhiflaoui, Z. Lassaad, and A.B.C. Larbi, Mechanical Characterization of CrN/CrAlN Multilayer Coatings Deposited by Magnetron Sputtering System, J. Mater. Eng. Perform., 2015, 24, p 4077–4082. https://doi.org/10.1007/s11665-015-1692-x

M. Bielawski, Residual Stress Control in TiN/Si Coatings Deposited by Unbalanced Magnetron Sputtering, Surf. Coat. Technol., 2006, 200, p 3987–3995. https://doi.org/10.1016/j.surfcoat.2005.06.004

A. Ghasemi and S.A. Sadough Vanini, A Comprehensive Investigation on the Effect of Controlling Parameters of Ultrasonic Peening Treatment on Residual Stress and Surface Roughness: Experiments, Numerical Simulations and Optimization, Surf. Coat. Technol., 2023, 464, p 129515. https://doi.org/10.1016/j.surfcoat.2023.129515

F. Ahmed, M. Zain-ul-abdein, I.A. Channa, M.K. Yaseen, S.J. Gilani, M.A. Makhdoom, M. Mansoor, U. Shahzad, and M.N.B. Jumah, Effect of Ultrasonic Surface Mechanical Attrition Treatment-Induced Nanograins on the Mechanical Properties and Biocompatibility of Pure Titanium, Materials, 2022, 15, p 5097. https://doi.org/10.3390/ma15155097

S. Zhao, Y. Wang, L. Peng, Y.X. Zhang, R. Ran, and G. Yuan, Effect of Annealing Temperature on Microstructure and Mechanical Properties of Cold-rolled Commercially Pure Titanium Sheets, Trans. Nonferrous Metals Soc. China, 2022, 32(8), p 2587–2597. https://doi.org/10.1016/S1003-6326(22)65968-5

R. Liu, S. Yuan, N. Lin, Z. Liu, Y. Yu, Z. Wang, Q. Zeng, W. Chen, L. Tian, L. Qin, B. Li, H. Zhang, Z. Wang, B. Tang, and Y. Wu, Tailoring Tribological Performance of Pure Titanium by a Duplex Treatment of Laser Surface Texturing-Thermal Oxidation, J. Mater. Eng. Perform., 2020, 29, p 4047–4062. https://doi.org/10.1007/s11665-020-04875-x

A.K. Pandey, A. Kumar, R. Kumar, R.K. Gautam, and C.K. Behera, Tribological Performance of SS 316L, Commercially Pure Titanium, and Ti6Al4V in Different Solutions for Biomedical Applications, Mater. Today Proc., 2023, 78(4), p A1–A8. https://doi.org/10.1016/j.matpr.2023.03.736

S. Wang, Q. An, W. Liu, R. Zhang, Z. Ma, L. Huang, and L. Geng, Towards Strength-ductility Enhancement of Titanium Matrix Composites through Heterogeneous Grain Structured Ti Matrix Design, J. Alloy. Compd., 2022, 927, p 167022. https://doi.org/10.1016/j.jallcom.2022.167022

S. Bajda, Y. Liu, R. Tosi, K. Cholewa-Kowalska, M. Krzyzanowski, M. Dziadek, M. Kopyscianski, S. Dymek, A.V. Polyakov, I.P. Semenova, and T. Tokarski, Laser Cladding of Bioactive Glass Coating on Pure Titanium Substrate with Highly Refined Grain Structure, J. Mech. Behav. Biomed. Mater., 2021, 119, p 104519. https://doi.org/10.1016/j.jmbbm.2021.104519

L. Morejón-Alonso, C. Mochales, L. Nascimento, and W.D. Müller, Electrochemical Deposition of Sr and Sr/Mg-co-substituted Hydroxyapatite on Ti-40Nb Alloy, Mater. Lett., 2019, 248, p 65–68. https://doi.org/10.1016/j.matlet.2019.03.141

Author information

Authors and Affiliations

Contributions

KSH was involved in writing—original draft preparation, formal analysis, and investigation. MY took part in writing—original draft preparation, formal analysis, and investigation. HE contributed to conceptualization, writing—original draft preparation, validation, writing—review and editing, and supervision.

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This invited article is part of a special topical issue of the Journal of Materials Engineering and Performance on Residual Stress Analysis: Measurement, Effects, and Control. The issue was organized by Rajan Bhambroo, Tenneco, Inc.; Lesley Frame, University of Connecticut; Andrew Payzant, Oak Ridge National Laboratory; and James Pineault, Proto Manufacturing on behalf of the ASM Residual Stress Technical Committee.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Hamedani, K.S., Yadi, M. & Esfahani, H. Influence of Residual Stress on Mechanical and Tribology Behaviors of Calcium-Phosphate Coating on Commercially Pure Titanium via Integrated Electrospinning and Rapid Heating and Cooling Process. J. of Materi Eng and Perform (2024). https://doi.org/10.1007/s11665-024-09534-z

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-024-09534-z