Abstract

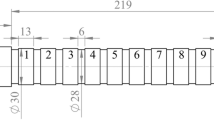

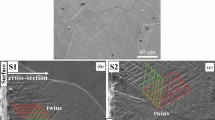

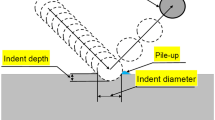

The present article addresses the influence of surface mechanical attrition treatment (SMAT) parameters such as a size of the balls (2, 5 and 8 mm ∅ 316L stainless steel (SS) balls) and treatment time (15, 30, 45 and 60 min) on the microstructural features, deformation characteristics, surface roughness and compressive residual stress induced on EN 8 steel. The effective deformation is ~ 25 μm from the top surface along with elongated grains in the near subsurface region. The decrease in crystallite size and an increase in micro-strain become more pronounced during SMAT using balls with a larger diameter and for a longer treatment time. A similar trend is observed in surface roughness. This is mainly attributed to the involvement of higher kinetic energy imposed by SMAT on EN 8 steel. The residual stress induced during SMAT of EN 8 steel measured by x-ray diffraction (XRD) measurements is higher when treated using 2 mm ∅ SS balls when compared to those treated using 5 and 8 mm ∅ SS balls for a similar time duration. Irrespective of the size of the balls, an increase in treatment time has led to a decrease in the residual stress of EN8 steel. Over working of EN8 steel that creates surface cracking has been considered responsible for the decrease in residual stress of EN8 steel treated using 5 and 8 mm ∅ SS balls for any given time duration as well as with an increase in treatment time for a given size of the balls. The development surface cone cracks and material removal from the surface evidenced from the microstructure validates such as an occurrence. When the duration of SMAT is limited to 15 min, a large difference in residual stress values is observed for the EN8 steel treated using 2, 5 and 8 mm ∅ balls, whereas with a further increase in treatment time, the difference between them becomes marginal. Hence, in order to achieve better mechanical properties, the treatment time employed for SMAT of carbon steels should be carefully optimized. The other option available is to choose lower size balls for SMAT. The change in residual stress of EN8 steel as a function of process parameters employed for SMAT and the correlation between the ball size and treatment time with the residual stress are discussed.

Similar content being viewed by others

Data Availability

The raw data of residual stress can be made available upon request.

References

X. Li, L. Lu, J. Li, X. Zhang, and H. Gao, Mechanical Properties and Deformation Mechanisms of Gradient Nanostructured Metals and Alloys, Nat. Rev., 2020, 5, p 706–723.

S.C. Cao, X. Zhang, J. Lu, Y. Wang, S.Q. Shi, and R.O. Ritchie, Predicting Surface Deformation During Mechanical Attrition of Metallic Alloys, Npj Comput. Mater., 2019, 5, p 36.

X. Chen, Z. Han, X. Li, and K. Lu, Lowering Coefficient of Friction in Cu Alloys with Stable Gradient Nanostructures, Sci. Adv., 2016, 2, e1601942.

T. Balusamy, T. S. N. Sankara Narayanan, and H. W. Park, Surface Nanostructuring of Metallic Materials for Implant Applications. In: T. S. Santra, L. Mohan, (eds) Nanomaterials and Their Biomedical Applications. Springer Series in Biomaterials Science and Engineering, Springer, Singapore, 16, 465-511. (2021)

T. Balusamy, Sivakumar Bose, T. S. N. Sankara Narayanan, K. Ravichandran, Surface Nanostructuring of Ti Based Alloys for Biomedical Applications—Role of Surface Mechanical Attrition Treatment. In: Savaş Kaya, Sasikumar Yesudass., (eds), Materials Development and Processing for Biomedical Applications. 1st Edition, CRC Press, p 241-254. (2022)

H. Zhang, S. Wu, N. Ao, J. Zhang, H. Li, L. Zhou, P. Xu, and Y. Su, Fatigue Crack Non-Propagation Behavior of a Gradient Steel Structure from Induction Hardened Railway Axles, Int. J. Fatigue, 2023, 166, 107296.

Z. Wang, X. Wang, H. Huang, J. Gan, Y. Yang, J. He, and M. Shi, Effect of High-Energy Shot Peening on Surface Nanocrystallization and Integrity of AISI 4140 Steel: A Numerical and Experimental Investigation, J. Mater. Eng. Perform., 2021, 30, p 5579–5592.

J. Ding, Z. Shang, J. Li, H. Wang, and X. Zhang, Microstructure and Tensile Behavior of Nanostructured Gradient TWIP steel, J. Mater. Sci. Eng. A, 2020, 785, 139346.

N. Kumar, G.P. Chaudhari, and S.R. Meka, Influence of Ultrasonic Shot Peening on Microstructure, Mechanical, and Electrochemical Behaviour 316 of Stainless Steel, J. Mater. Eng. Perform., 2021, 31, p 2364–2380.

R. Zhang, R. Chiang, Z. Ren, H. Zhang, W. Zhao, G.-X. Wang, V.K. Vasudevan, Y. Dong, and C. Ye, Fatigue Performance Improvement of 7075-T651 Aluminum Alloy by Ultrasonic Nanocrystal Surface Modification, J. Mater. Eng. Perform., 2022, 31, p 2354–2363.

Y. Yang, K. Zhou, and G. Li, Surface gradient microstructural characteristics and evolution mechanism of 2195 aluminum lithium alloy induced by laser shock peening, Opt. Laser Technol., 2019, 109, p 1–7.

S. Anand Kumar, P. Satish Kumar, S. Ganesh Sundara Raman, and T.S. Sankara Narayanan, Influence of SMAT Parameters on Microstructural and Mechanical Properties of Al-Mg-Si Alloy AA 6061, J. Mater. Eng. Perform., 2017, 26, p 1947–1957.

T. Balusamy, T.S. Narayanan, K. Ravichandran, M.H. Lee, and T. Nishimura, Surface Nanocrystallization of EN8 Steel: Correlation of Change in Material Characteristics with Corrosion Behavior, J. Electrochem. Soc., 2015, 162(6), p C285.

T. Balusamy, T.S.N. Sankara Narayanan, K. Ravichandran, M.H. Lee, and T. Nishimura, A Facile Method to Modify the Characteristics and Corrosion Behavior of 304 Stainless Steel by Surface Nanostructuring Toward Biomedical Applications, ACS Appl. Mater. Interfaces, 2015, 32, p 17731–17747.

X. Wang, C. Xu, D. Hu, C. Li, C. Liu, and Z. Tang, Effect of Ultrasonic Shot Peening on Surface Integrity And Fatigue Performance of Single-Crystal Superalloy, J. Mater. Process. Technol., 2021, 296, 117209.

T. Balusamy, T.S. Narayanan, K. Ravichandran, I.S. Park, and M.H. Lee, Plasma Nitriding of AISI 304 Stainless Steel: Role of Surface Mechanical Attrition Treatment, Mater Charact, 2013, 1(85), p 38–47.

T. Balusamy, T.S. Narayanan, and K. Ravichandran, Effect of Surface Mechanical Attrition Treatment (SMAT) on Boronizing of EN8 Steel, Surf. Coat. Technol., 2012, 1(213), p 221–228.

V. Kumar, M.D. Joshi, C. Pruncu, I. Singh, and S.S. Hosmani, Microstructure and Tribological Response of Selective Laser Melted AISI 316L Stainless Steel: the Role of Severe Surface Deformation, J. Mater. Eng. Perform., 2021, 30, p 5170–5183.

S. Ghosh, N. Bibhanshu, S. Suwas, and K. Chatterjee, Surface Mechanical Attrition Treatment of Additively Manufactured 316L Stainless Steel Yields Gradient Nanostructure with Superior Strength and Ductility, J. Mater. Sci. Eng. A., 2021, 820, 141540.

T. Wegener, T. Wu, F. Sun, C. Wang, J. Lu, and T. Niendorf, Influence of Surface Mechanical Attrition Treatment (SMAT) on Microstructure, Tensile and Low-Cycle Fatigue Behavior of Additively Manufactured Stainless Steel 316L, Metals, 2022, 12, p 1425.

T. Gao, Z. Sun, H. Xue, and D. Retraint, Effect of Surface Mechanical Attrition Treatment on High Cycle and Very High Cycle Fatigue of a 7075-T6 Aluminium Alloy, Int. J. Fatigue, 2020, 139, 105798.

S.A. Kumar, S.G. Raman, and T.S. Narayanan, Influence of Surface Mechanical Attrition Treatment Duration On Fatigue Lives of Ti-6Al-4V, Trans. Indian Inst. Metals., 2014, 67, p 137–141.

Y. Wang, L. Yuan, S. Zhang, C. Sun, W. Wang, G. Yang, Q. Li, and Y. Wei, The Influence of Combined Gradient Structure with Residual Stress on Crack-Growth Behavior in Medium Carbon Steel, Eng. Fract. Mech., 2019, 209, p 369–381.

Z. Li, P. La, and F. Wei, TEM Observation and Strengthening Mechanism of Cementite Nanoparticles of Heterogeneous Structure 1045 Steel, Mater. Res. Express, 2021, 8(8), 086502.

D.A. Lesyk, B.N. Mordyuk, S. Martinez, M.O. Iefimov, V.V. Dzhemelinskyi, and A. Lamikiz, Influence of Combined Laser Heat Treatment and Ultrasonic Impact Treatment on Microstructure and Corrosion Behavior of AISI 1045 Steel, Surf. Coat. Technol., 2020, 401, 126275.

D.A. Lesyk, S. Martinez, B.N. Mordyuk, V.V. Dzhemelinskyi, A. Lamikiz, G.I. Prokopenko, M.O. Iefimov, and K.E. Grinkevych, Combining Laser Transformation Hardening and Ultrasonic Impact Strain Hardening for Enhanced Wear Resistance of AISI 1045 Steel, Wear, 2020, 462, 203494.

H. Nykyforchyn, V. Kyryliv, and O. Maksymiv, Wear Resistance of Steels with Surface Nanocrystalline Structure Generated by Mechanical-Pulse Treatment, Nanoscale Res. Lett., 2017, 12, p 150.

S. Vives, E. Gaffet, and C. Meunier, X-ray Diffraction Line Profile Analysis of Iron Ball Milled Powder, Mater. Sci. Eng. A, 2004, 366, p 229–238.

S.A. Kumar, S.G. Raman, T.S. Narayanan, and R. Gnanamoorthy, Influence of Counterbody Material on Fretting Wear Behaviour of Surface Mechanical Attrition Treated Ti-6Al-4V, Tribol. Int., 2013, 1(57), p 107–114.

T. Lorentzen and T. Leffers, Measurement of Residual and Applied Stress Using Neutron Diffraction, NATO ASI series E, Vol 216, M.T. Hutchings, A.D. Krawitz Ed., Kluwer, Dordrecht, 1992, p 253–261

M. Franxois, J.M. Sprauel, C.F. Dehan, M.R. James, F. Convert, and J. Lu, Handbook of Measurement of Residual Stresses. J. Lu Ed., Society for Experimental Mechanics, Lilburn, 1996, p 71–131

C.C. Huang, Y.C. Pan, and T.H. Chuang, Effects of Post-Weld Heat Treatments on the Residual Stress and Mechanical Properties of Electron Beam Welded SAE 4130 Steel Plates, J. Mater. Eng. Perform., 1997, 6, p 61–68.

W.R. Calado and R. Barbosa, Influence of Carbon Content and Deformation Temperature on Ultra-Grain Refinement of Plain Carbon Steels by Means of Torsion Test, ISIJ Int., 2013, 53, p 909–914.

L. Zhou, G. Liu, X.L. Ma, and K. Lu, Strain-Induced Refinement ina Steel with Spheroidal Cementite Subjected to Surface Mechanical Attrition Treatment, Acta Mater., 2008, 56, p 78–87.

N.A. Prakash, R. Gnanamoorthy, and M. Kamaraj, Surface Nanocrystallization of Aluminium Alloy by Controlled Ball Impact Technique, Surf. Coat. Technol., 2012, 15(210), p 78–89.

M.R. Belbasi and M. Ramezani, The Effect of Sandblasting Time on Producing Nanocrystalline Surface of PO733 Steel (DIN: 1.8509), Mater. Phys. Mech., 2013, 17(1), p 33–37.

X. Yong, G. Liu, K. Lu, and J. Lu, Characterization and Properties Of Nanostructured Surface Layer in a Low Carbon Steel Subjected to Surface Mechanical Attrition Treatment, J. Mater. Sci. Technol., 2003, 19, p 1–4.

Z.B. Wang, N.R. Tao, S. Li, W. Wang, G. Liu, J. Lu, and K. Lu, Effect of Surface Nanocrystallization on Friction and Wear Properties in Low Carbon Steel, Mater. Sci. Eng. A, 2003, 352, p 144–149.

T. Balusamy, T.S. Narayanan, K. Ravichandran, I.S. Park, and M.H. Lee, Pack Boronizing of AISI H11 Tool Steel: Role of Surface Mechanical Attrition Treatment, Vacuum, 2013, 1(97), p 36–43.

K. Dai and L. Shaw, Comparison Between Shot Peening and Surface Nanocrystallization and Hardening Processes, Mater. Sci. Eng. A, 2007, 463, p 46–53.

W. Pfeiffer and J. Wenzel, Shot Peening of Brittle Materials—Status and Outlook, Mater. Sci. Forum, 2010, 638–642, p 799–804.

W.Y. Tsai, J.C. Huang, Y.J. Gao, Y.L. Chung, and G.R. Huang, Relationship Between Microstructure and Properties For Ultrasonic Surface Mechanical Attrition Treatment, Scr. Mater., 2015, 103, p 45–48.

H.L. Chan, H.H. Ruan, A.Y. Chen and J. Lu, Optimization of the Strain Rate to Achieve Exceptional Mechanical Properties of 304 Stainless Steel Using High Speed Ultrasonic Surface Mechanical Attrition Treatment, Acta Mater., 2010, 58, p 5086–5096.

G. Chen, J. Gao, Y. Cui, H. Gao, X. Guo, and S. Wu, Effects of Strain Rate on the Low Cycle Fatigue Behavior of AZ31B Magnesium Alloy Processed by SMAT, J. Alloys Compd., 2018, 735, p 536–546.

Q. Lin, H. Liu, C. Zhu, D. Chen, and S. Zhou, Effects of Different Shot Peening Parameters on Residual Stress, Surface Roughness and Cell Size, Surf. Coat. Technol., 2020, 398, 126054.

Acknowledgments

TB and TSNSN thank the Council of Scientific and Industrial Research (CSIR), New Delhi, for providing the financial support in the form a SUPRA Institutional Project and Director, CSIR-National Metallurgical Laboratory, Jamshedpur, for his constant encouragement and support.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This invited article is part of a special topical issue of the Journal of Materials Engineering and Performance on Residual Stress Ana lysis: Measurement, Effects, and Control. The issue was organized by Rajan Bhambroo, Tenneco, Inc.; Lesley Frame, University of Connecticut; Andrew Payzant, Oak Ridge National Laboratory; and James Pineault, Proto Manufacturing on behalf of the ASM Residual Stress Technical Committee.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Balusamy, T., Sathyaraj, P.M., Ravichandran, K. et al. Influence of Surface Mechanical Attrition Treatment Parameters on the Residual Stress of EN8 Steel. J. of Materi Eng and Perform (2024). https://doi.org/10.1007/s11665-024-09521-4

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-024-09521-4