Abstract

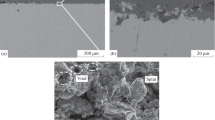

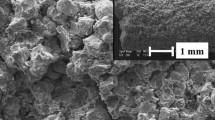

The present work focuses on exploring the effect of thermal treatment on HVOF thermally sprayed rGO-reinforced alumina-based coatings on 17-4 PH steel. Based on the previous study, an optimized coating composition (Al2O3-0.8CeO2-0.2 rGO) is selected for exploring the effect of flame heat treatment in terms of physical, tribological, mechanical, and electrochemical properties. The hardness (Vickers and scratch) and tribological responses are recorded using a CETR-UMT tribometer. The as-coated, treated, and worn surfaces are analyzed using Goniometer, Scanning electron microscope (SEM), Energy dispersive spectroscopy (EDS), Raman spectroscopy, and 3-D optical profilometer. Corrosive degradation is studied using Potentiodynamic polarization and Electrical impedance spectroscopy (EIS). The results revealed that the thermal treatment severely deteriorates the coating properties. The Vickers hardness and scratch hardness of the as-sprayed coating were reduced to one-third and one-ninth respectively, after the post-treatment process. The specific wear rate and corrosion rate increased by ≈165 times and ≈1500 times, respectively. Furthermore, the Raman, SEM, and EDS analysis of the corroded region of the heat-treated coating confirmed the formation of iron oxides. This deterioration in the heat-treated coating properties is attributed to the evaporation of the reinforced rGO from the as-sprayed coating making the coating highly porous. So, it is not advisable to heat treat the above-mentioned coating composition above 400 °C.

Similar content being viewed by others

Data Availability

Data will be made available on request.

References

M.A. Zavareh, A.A.D.M. Sarhan, B.B.A. Razak, and W.J. Basirun, Plasma Thermal Spray of Ceramic Oxide Coating on Carbon Steel with Enhanced Wear and Corrosion Resistance for Oil and Gas Applications, Ceram. Int., 2014, 40, p 14267–14277. https://doi.org/10.1016/j.ceramint.2014.06.017

H. Hu, L. Mao, S. Yin, H. Liao, and C. Zhang, Wear-Resistant Ceramic Coatings Deposited by Liquid Thermal Spraying, Ceram. Int., 2022, 48, p 33245–33255. https://doi.org/10.1016/j.ceramint.2022.07.267

E. Sadeghi, N. Markocsan, S. Joshi, Advances in Corrosion-Resistant Thermal Spray Coatings for Renewable Energy Power Plants. Part I: Effect of Composition and Microstructure, Springer US, 2019. DOI: https://doi.org/10.1007/s11666-019-00938-1.

A.V. Pinzón, K.J. Urrego, A. González-Hernández, M. Rincón Ortiz, and F. Vargas Galvis, Corrosion Protection of Carbon Steel by Alumina-Titania Ceramic Coatings Used for Industrial Applications, Ceram. Int., 2018, 44, p 21765–21773. https://doi.org/10.1016/j.ceramint.2018.08.273

T. Lampke, D. Meyer, G. Alisch, D. Nickel, I. Scharf, L. Wagner, and U. Raab, Alumina Coatings Obtained by Thermal Spraying and Plasma Anodising - A Comparison, Surf. Coat. Technol., 2011, 206, p 2012–2016. https://doi.org/10.1016/j.surfcoat.2011.09.006

J. Huang, Y. Liu, J. Yuan, and H. Li, Al/Al2O3 Composite Coating Deposited by Flame Spraying for Marine Applications: Alumina Skeleton Enhances Anti-corrosion and Wear Performances, J. Therm. Spray Technol., 2014, 23, p 676–683. https://doi.org/10.1007/s11666-014-0056-7

S. Singh, C.C. Berndt, R.K. Singh Raman, H. Singh, and A.S.M. Ang, Applications and Developments of Thermal Spray Coatings for the Iron and Steel Industry, Materials (Basel)., 2023, 16, p 1–27. https://doi.org/10.3390/ma16020516

S. Amin, H. Panchal, and A. Professor, A Review on Thermal Spray Coating Processes, Int. J. Curr. Trends Eng Res. Sci. J. Impact Factor., 2016, 2, p 556–563.

A. Woźniak, M. Staszuk, Ł Reimann, O. Bialas, Z. Brytan, S. Voinarovych, O. Kyslytsia, S. Kaliuzhnyi, M. Basiaga, and M. Admiak, The Influence of Plasma-Sprayed Coatings on Surface Properties and Corrosion Resistance of 316L Stainless Steel for Possible Implant Application, Arch. Civ. Mech. Eng., 2021, 21, p 1–21. https://doi.org/10.1007/s43452-021-00297-1

S. Shen, X. Li, P. Zhang, Y. Nan, G. Yang, and X. Song, Effect of Solution-Treated Temperature on Hydrogen Embrittlement of 17-4 PH Stainless Steel, Mater. Sci. Eng. A, 2017, 703, p 413–421. https://doi.org/10.1016/j.msea.2017.06.078

C.J. Li, X.T. Luo, X.Y. Dong, L. Zhang, and C.X. Li, Recent Research Advances in Plasma Spraying of Bulk-Like Dense Metal Coatings with Metallurgically Bonded Lamellae, J. Therm. Spray Technol., 2022, 31, p 5–27. https://doi.org/10.1007/s11666-022-01327-x

G. Sundararajan, D.S. Rao, G. Sivakumar, S. V Joshi, Detonation Spray Coatings, in: Q.J. Wang, Y.-W. Chung (Eds.), Encycl. Tribol., Springer US, Boston, MA, 2013: pp. 736–742. https://doi.org/10.1007/978-0-387-92897-5_704.

L. Singh, V. Chawla, and J.S. Grewal, A Review on Detonation Gun Sprayed Coatings, J. Miner. Mater. Charact. Eng., 2012, 11, p 243–265. https://doi.org/10.4236/jmmce.2012.113019

J. Mehta, J.S. Grewal, and P. Gupta, Analysis of D-gun Sprayed Coating on Medium Carbon Steel, Mater. Today Proc., 2020, 21, p 1403–1406. https://doi.org/10.1016/j.matpr.2019.07.699

P. Vuoristo, 4.10 - Thermal Spray Coating Processes, in: S. Hashmi, G.F. Batalha, C.J. Van Tyne, B. Yilbas (Eds.), Compr. Mater. Process., Elsevier, Oxford, 2014: pp. 229–276. https://doi.org/10.1016/B978-0-08-096532-1.00407-6.

P. Poza and M.Á. Garrido-Maneiro, Cold-Sprayed Coatings: Microstructure, Mechanical Properties, and Wear Behaviour, Prog. Mater. Sci., 2022 https://doi.org/10.1016/j.pmatsci.2021.100839

X.T. Luo, C.X. Li, F.L. Shang, G.J. Yang, Y.Y. Wang, and C.J. Li, High Velocity Impact Induced Microstructure Evolution During Deposition of Cold Spray Coatings: A Review, Surf. Coat. Technol., 2014, 254, p 11–20. https://doi.org/10.1016/j.surfcoat.2014.06.006

M. Saleh, V. Luzin, and K. Spencer, Analysis of the Residual Stress and Bonding Mechanism in the Cold Spray Technique Using Experimental and Numerical Methods, Surf. Coat. Technol., 2014, 252, p 15–28. https://doi.org/10.1016/j.surfcoat.2014.04.059

A. Gupta, A. Pattnayak, N.V. Abhijith, D. Kumar, V. Chaudhry, and S. Mohan, Development of Alumina-Based Hybrid Composite Coatings for High Temperature Erosive and Corrosive Environments, Ceram. Int., 2022 https://doi.org/10.1016/j.ceramint.2022.09.059

A. Gupta and D. Kumar, Development of Al2O3-based hybrid ceramic matrix composite coating to mitigate the erosive wear of advanced steel, Proc. Inst. Mech Eng. Part L J. Mater. Des. Appl., 2021, 235, p 752–762. https://doi.org/10.1177/1464420720978676

N.V. Abhijith, D. Kumar, and D. Kalyansundaram, Development of Single-Stage TiNbMoMnFe High-Entropy Alloy Coating on 304L Stainless Steel Using HVOF Thermal Spray, J. Therm. Spray Technol., 2022, 31, p 1032–1044. https://doi.org/10.1007/s11666-021-01294-9

M. Oksa, E. Turunen, T. Suhonen, T. Varis, and S.-P. Hannula, Optimization and Characterization of High Velocity Oxy-fuel Sprayed Coatings: Techniques, Mater. Appl. Coat., 2011, 1, p 17–52. https://doi.org/10.3390/coatings1010017

M. Rani, G. Perumal, M. Roy, H.S. Grewal, H. Singh, and H.S. Arora, Post-processing of Ni-Cr-Al2O3 Thermal Spray Coatings Through Friction Stir Processing for Enhanced Erosion-Corrosion Performance, J. Therm. Spray Technol., 2019, 28, p 1466–1477. https://doi.org/10.1007/s11666-019-00891-z

S. Kumar, D. Kumar, and J. Jain, Surface and Interface Characteristics of CeO2 Doped Al2O3 Coating on Solution Treated and Peak Aged AZ91 Mg Alloy, Surf. Coat. Technol., 2017, 332, p 511–521. https://doi.org/10.1016/j.surfcoat.2017.07.082

S. Kumar and D. Kumar, Role of CeO2 Doping on Tribological Behavior of Al2O3 Coated AZ91 Alloy, Surf. Coat. Technol., 2018, 349, p 462–469. https://doi.org/10.1016/j.surfcoat.2018.06.025

A. Gupta, A. Pattnayak, N.V. Abhijith, D. Kumar, V. Chaudhry, and S. Mohan, Development of Alumina-Based Hybrid Composite Coatings for High Temperature Erosive and Corrosive Environments, Ceram. Int., 2023, 49, p 862–874. https://doi.org/10.1016/j.ceramint.2022.09.059

A. Srikanth and V. Bolleddu, High Velocity Oxy-Fuel (HVOF) Sprayed Coating Nanoarchitectonics: Influence of Reduced Graphene Oxide (rGO) on Tribological Characteristics, Appl. Phys. A Mater. Sci. Process., 2023 https://doi.org/10.1007/s00339-023-06607-z

A. Srikanth and V. Bolleddu, Influence of Reduced Graphene Oxide (rGO) on Plasma Sprayed Nanostructured Coatings, J. Therm. Spray Technol., 2023, 32, p 1260–1272. https://doi.org/10.1007/s11666-023-01556-8

V. Bolleddu, V. Racherla, and P.P. Bandyopadhyay, Comparative Study of Air Plasma Sprayed and High Velocity Oxy-Fuel Sprayed Nanostructured WC-17wt.% Co Coatings, Int. J. Adv. Manuf. Technol., 2016, 84, p 1601–1613. https://doi.org/10.1007/s00170-015-7824-5

C. Kalangi and V. Bolleddu, Microstructural Characteristics and Mechanical Properties of Thermally Sprayed Conventional Ceramic Coatings Reinforced with Multiwalled Carbon Nanotubes, J. Reinf. Plast. Compos., 2022 https://doi.org/10.1177/07316844221099926

G. Li, J. Wang, C. Li, Q. Peng, J. Gao, and B. Shen, Microstructure and dry-sliding wear properties of DC plasma nitrided 17-4 PH stainless steel, Nucl. Instruments Methods Phys Res. Sect. B Beam Interact. Mater. Atoms, 2008, 266, p 1964–1970. https://doi.org/10.1016/j.nimb.2008.02.073

A. Pattnayak, A. Gupta, N.V. Abhijith, D. Kumar, J. Jain, and V. Chaudhry, Development of rGO Doped Alumina-Based Wear and Corrosion Resistant Ceramic Coatings on Steel Using HVOF Thermal Spray, Ceram. Int., 2023 https://doi.org/10.1016/j.ceramint.2023.02.124

G. Bolelli and L. Lusvarghi, Heat Treatment Effects on the Tribological Performance of HVOF Sprayed Co-Mo-Cr-Si Coatings, Proc. Int. Therm. Spray Conf., 2006, 15, p 802–810. https://doi.org/10.1361/105996306X146721

Y. Morisada, H. Fujii, T. Mizuno, G. Abe, T. Nagaoka, and M. Fukusumi, Modification of Thermally Sprayed Cemented Carbide Layer by Friction Stir Processing, Surf. Coat. Technol., 2010, 204, p 2459–2464. https://doi.org/10.1016/j.surfcoat.2010.01.021

X.M. Meng, J.B. Zhang, W. Han, J. Zhao, and Y.L. Liang, Influence of Annealing Treatment on the Microstructure and Mechanical Performance of Cold Sprayed 304 Stainless Steel Coating, Appl. Surf. Sci., 2011, 258, p 700–704. https://doi.org/10.1016/j.apsusc.2011.07.107

K.J. Hodder, H. Izadi, A.G. McDonald, and A.P. Gerlich, Fabrication of Aluminum-Alumina Metal Matrix Composites via Cold Gas Dynamic Spraying at Low Pressure Followed by Friction Stir Processing, Mater. Sci. Eng. A, 2012, 556, p 114–121. https://doi.org/10.1016/j.msea.2012.06.066

C.D. Prasad, S. Joladarashi, M.R. Ramesh, M.S. Srinath, and B.H. Channabasappa, Influence of Microwave Hybrid Heating on the Sliding wear Behaviour of HVOF Sprayed CoMoCrSi Coating, Mater. Res. Express., 2018, 5, p 86519. https://doi.org/10.1088/2053-1591/aad44e

R.R. Mishra and A.K. Sharma, Microwave-Material Interaction Phenomena: Heating Mechanisms, Challenges and Opportunities in Material Processing, Compos. Part A Appl. Sci. Manuf., 2016, 81, p 78–97. https://doi.org/10.1016/j.compositesa.2015.10.035

W.Y. Li, C.J. Li, and H. Liao, Effect of Annealing Treatment on the Microstructure and Properties of Cold-Sprayed Cu Coating, J. Therm. Spray Technol., 2006, 15, p 206–211. https://doi.org/10.1361/105996306X108066

H. Li, K.A. Khor, and P. Cheang, Properties of Heat-Treated Calcium Phosphate Coatings Deposited by High-Velocity Oxy-Fuel (HVOF) Spray, Biomaterials, 2002, 23, p 2105–2112. https://doi.org/10.1016/S0142-9612(01)00326-X

K. Wang, H. Peng, H. Guo, and S. Gong, Effect of Sintering on Thermal Conductivity and Thermal Barrier Effects of Thermal Barrier Coatings, Chin. J. Aeronaut., 2012, 25, p 811–816. https://doi.org/10.1016/S1000-9361(11)60449-4

B. Siebert, C. Funke, R. Vaben, and D. Stöver, Changes in Porosity and Young’s Modulus Due to Sintering of Plasma Sprayed Thermal Barrier Coatings, J. Mater. Process. Technol., 1999, 92–93, p 217–223. https://doi.org/10.1016/S0924-0136(99)00243-5

M.M. Verdian, Finishing and Post-treatment of Thermal Spray Coatings, Elsevier Ltd., 2017 https://doi.org/10.1016/B978-0-12-803581-8.09200-6

R. Pötzl, Laser Remelting of HVOF Coatings, in: ASM Heat Treat. Surf. Eng. Conf. II, Trans Tech Publications Ltd, 1994: pp. 595–602. https://doi.org/10.4028/www.scientific.net/MSF.163-165.595.

B.S. Yilbas, I.H. Toor, F. Patel, and M.A. Baig, Effects of Laser Re-melting on the Corrosion Properties of HVOF Coatings, J. Mater. Eng. Perform., 2013, 22, p 1505–1511. https://doi.org/10.1007/s11665-012-0428-4

A. Coatings, M. Grimm, T. Lindner, T. Lampke, Effects of Laser-Remelting on the Microstructure , Hardness (2022).

L. Chen, D. He, B. Han, Z. Guo, L. Zhang, L. Lu, X. Wang, Z. Tan, and Z. Zhou, Effect of Laser Remelting on Wear Behavior of hvof-Sprayed Fecrconitial 0.6 High Entropy Alloy Coating, Appl. Sci., 2020, 10, p 1–9. https://doi.org/10.3390/app10207211

B. Das, A. Nath, and P.P. Bandyopadhyay, Scratch Resistance and Damage Mechanism of Laser Remelted Thermally Sprayed Ceramic Coating, Surf. Coat. Technol., 2019, 364, p 157–169. https://doi.org/10.1016/j.surfcoat.2019.02.078

R. de Medeiros Castro, E.I. Mercado Curi, L.F. Feltrim Inacio, A. da Silva Rocha, M. Pereira, R. Gomes Nunes Silva, and A. de Souza Pinto Pereira, Laser Remelting of WC-CoCr Surface Coated by HVOF: Effect on the Tribological Properties and Energy Efficiency, Surf. Coat. Technol., 2021, 427, p 127841. https://doi.org/10.1016/j.surfcoat.2021.127841

I.D. Utu and G. Marginean, Effect of Electron Beam Remelting on the Characteristics of HVOF Sprayed Al2O3-TiO2 Coatings Deposited on Titanium Substrate, Colloids Surfaces A Physicochem. Eng. Asp., 2017, 526, p 70–75. https://doi.org/10.1016/j.colsurfa.2016.10.034

G. Marginean and D. Utu, Cyclic Oxidation Behaviour of Different Treated CoNiCrAlY Coatings, Appl. Surf. Sci., 2012, 258, p 8307–8311. https://doi.org/10.1016/j.apsusc.2012.05.050

G. Li, Y. Li, T. Dong, H. Wang, X. Zheng, and X. Zhou, Microstructure and Wear Resistance of TIG Remelted NiCrBSi Thick Coatings, Adv. Mater. Sci. Eng., 2018, 2018, p 1–10. https://doi.org/10.1155/2018/8979678

F. Ghadami, M. Heydarzadeh Sohi, and S. Ghadami, Effect of TIG Surface Melting on Structure and Wear Properties of Air Plasma-Sprayed WC-Co Coatings, Surf. Coat. Technol., 2015, 261, p 108–113. https://doi.org/10.1016/j.surfcoat.2014.11.050

A. Pattnayak, N.V. Abhijith, D. Kumar, J. Jain, and V. Chaudhry, Tribological and Corrosive Degradation of Differently Surface Engineered 17–4 PH Steel, Tribol. Int., 2024, 192, p 109294. https://doi.org/10.1016/j.triboint.2024.109294

H. Wu, F. Dave, M. Mokhtari, M.M. Ali, R. Sherlock, A. McIlhagger, D. Tormey, and S. McFadden, On the Application of Vickers Micro Hardness Testing to Isotactic Polypropylene, Polymers (Basel)., 2022 https://doi.org/10.3390/polym14091804

Nanovea, Scratch Hardness Measurement Using Mechanical Tester (2014). https://doi.org/10.13140/RG.2.1.3120.0164.

S. Krainer and U. Hirn, Contact Angle Measurement on Porous Substrates: Effect of Liquid Absorption and Drop Size, Colloids Surfaces A Physicochem. Eng. Asp., 2021, 619, p 126503. https://doi.org/10.1016/j.colsurfa.2021.126503

A. Shalaby, V. Yaneva, A. Staneva, L. Aleksandrov, R. Iordanova, Y. Dimitriev, Thermal Stability of RGO and RGO/SiO2 Nanocomposite Prepared by Sol-Gel Technique, Researchgate.Net. (2014). https://www.researchgate.net/profile/Ahmed_Shalaby17/post/How_does_graphene_behave_when_heated_fast_and_cooled_down_fast/attachment/59d61de779197b807797c254/AS%3A273842201661441%401442300476938/download/THERMAL+STABILITY+OF+RGO+AND+RGOSiO2+2014.pdf.

S.D. Zhang, J. Wu, W.B. Qi, and J.Q. Wang, Effect of Porosity Defects on the Long-Term Corrosion Behaviour of Fe-Based Amorphous Alloy Coated Mild Steel, Corros. Sci., 2016, 110, p 57–70. https://doi.org/10.1016/j.corsci.2016.04.021

N. Basavegowda, K. Mishra, and Y.R. Lee, Synthesis, Characterization, and Catalytic Applications of Hematite (α-Fe2O3) Nanoparticles as Reusable Nanocatalyst, Adv. Nat. Sci. Nanosci. Nanotechnol., 2017 https://doi.org/10.1088/2043-6254/aa6885

A.S. Hamdy, E. El-Shenaw, and T. El-Bitar, Electrochemical Impedance Spectroscopy Study of the Corrosion Behavior of Some Niobium Bearing Stainless Steels in 3.5% NaCl, Int. J. Electrochem. Sci., 2006, 1, p 171–180. https://doi.org/10.1016/s1452-3981(23)17147-1

Acknowledgments

The authors are thankful to the technical staff of the Centre for Automotive Research and Tribology (CART), SERB DST, Nano Research Facility (NRF), and Central Research Facility (CRF) of the Indian Institute of Technology Delhi.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Competing interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Pattnayak, A., Kumar, D. High Velocity Oxy-Fuel Thermally Sprayed rGO Reinforced Alumina-Based Coatings on 17-4 PH Steel: Exploring the Effect of Flame Heat Treatment. J. of Materi Eng and Perform (2024). https://doi.org/10.1007/s11665-024-09515-2

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-024-09515-2