Abstract

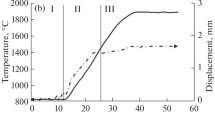

The influence of Y2O3 addition on densification, physical, mechanical, thermal, and oxidation properties of ZrB2-20 vol.%SiC- (0-15 vol.%Y2O3) composites was investigated in the present study. Powders of ZrB2-SiC-Y2O3 were cold compacted uniaxially, and green compacts were densified by pressure-less sintering. Results indicate that Y2O3 addition improves the sinterability and mechanical properties, whereas it diminishes the electrical and thermal conductivities of the investigated composites. Removal of surface oxides by the additives and segregation of Y2O3 particles at the triple junction of the ZrB2 grains enhances densification. Reduction in porosity (9.5-4.2%) through Y2O3 addition (0-15 vol.%) improves hardness (up to 52%), relative elastic modulus (up to 9%), and fracture toughness (up to 26%) of the investigated composites. The electrical conductivity has been observed to vary in the range of 2.67-1.92 106 S/m, and thermal diffusivity values decrease with an increase in Y2O3 content and temperature. Oxidation studies indicate that the ZrB2-SiC composite shows better oxidation resistance than other investigated composites. Characterization of oxidized scales confirms the formation of a thicker oxide layer over the samples containing Y2O3.

Similar content being viewed by others

References

B.R. Golla, A. Mukhopadhyay, B. Basu, and S.K. Thimmapp, Review on Ultra-High Temperature Boride Ceramics, Prog. Mater. Sci.. Mater. Sci., 2020, 111, 100651. (in English)

A.L. Chamberlain and J.W. Zimmermann, Processing and Characterization of ZrB2- Based Ultra-High Temperature Monolithic and Fibrous Monolithic Ceramics, J. Mater. Sci., 2004, 39(19), p 5951–5957. (in English)

E.W. Neuman, G.E. Hilmas, and W.G. Fahrenholtz, Processing, Microstructure, and Mechanical Properties of Large Grained Zirconium Diboride Ceramics, Mater. Sci. Eng. A, 2016, 670, p 196–204. (in English)

M. Mallik, K.K. Ray, and R. Mitra, Oxidation Behavior of Hot Pressed ZrB2-SiC and HfB2-SiC Composites, J. Eur. Ceram. Soc., 2011, 31(1–2), p 199–215. (in English)

R.A. Cutler. Engineering properties of borides. Ceramics and Glasses, Engineered Materials Handbook, ASM International, Materials Park, OH, 1991, p.787–803

M.J. Gasch, D.T. Ellerby, and S.M. Johnson, Ultra High Temperature Ceramic Composites, Handbook of Ceramic Composites. N.P. Bansal Ed., Springer US, 2005, p 197–224. (in English)

K. Upadhya, J.M. Yang and W.P. Hoffmann, Materials for Ultrahigh Temperature Structural Applications, Am. Ceram. Soc. Bull., 1997, 76(12), p 51–56. (in English)

W.G. Fahrenholtz, G.E. Hilmas, I. Talmy, and J.A. Zaykoski, Refractory Diborides of Zirconium and Hafnium, J. Am. Ceram. Soc., 2007, 90(5), p 1347–1364. (in English)

S.R. Levine, E.J. Opila, M.C. Halbig, J.D. Kiser, M. Singh, and J.A. Salem, Evaluation of Ultra High Temperature Ceramics for Aeropropulsion Use, J. Eur. Ceram. Soc., 2002, 22, p 2757–3276. (in English)

M.M. Opeka, I.G. Talmy, E.J. Wuchina, J.A. Zaykoski, and S.J. Causey, Mechanical, Thermal, and Oxidation Properties of Refractory Hafnium and Zirconium Compounds, J. Eur. Ceram. Soc., 1999, 19(13–14), p 2405–2414. (in English)

A.K. Kuriakose and J.L. Margrave, The Oxidation Kinetics of Zirconium Diboride and Zirconium Carbide at High Temperatures, J. Electrochem. Soc.Electrochem. Soc., 1964, 111(7), p 827–831. (in English)

J.B. Berkowitz-Mattuck, High-Temperature Oxidation III. Zirconium and Hafnium Diboride, J. Electrochem. Soc.Electrochem. Soc., 1966, 113(9), p 908–994. (in English)

W.C. Tripp and H.C. Graham, Thermogravimetric Study of the Oxidation of ZrB2 in the Temperature Range of 800–1500°C, J. Electrochem. Soc.Electrochem. Soc., 1971, 118(7), p 1195–1199. (in English)

D. Sciti, S. Guicciardi, A. Bellosi, and G. Pezzotti, Properties of a Pressureless-Sintered ZrB2-MoSi2 Ceramic Composite, J. Am. Ceram. Soc., 2006, 89(7), p 2320–2322. (in English)

Y. Yan, Z. Huang, S. Dong, and D. Jiang, Pressureless Sintering of High Density ZrB2-SiC Ceramic Composites, J. Am. Ceram. Soc., 2006, 89(11), p 3589–3592. (in English)

S.C. Zhang, G.E. Hilmas, and W.G. Fahrenholtz, Pressureless Densification of Zirconium Diboride with Boron Carbide Additives, J. Am. Ceram. Soc., 2006, 89(5), p 1544–1550. (in English)

S. Zhu, W.G. Fahrenholtz, G.E. Hilmas, and S.C. Zhang, Pressureless Sintering of Zirconium Diboride Using Boron Carbide and Carbon Additions, J. Am. Ceram. Soc., 2007, 90(11), p 3660–3663. (in English)

W.G. Fahrenholtz, G.E. Hilmas, S.C. Zhang, and S. Zhu, Pressureless Sintering of Zirconium Diboride: Particle Size and Additive Effects, J. Am. Ceram. Soc., 2008, 91(5), p 1398–1404. (in English)

S. Zhu, W.G. Fahrenholtz, G.E. Hilmas, and S.C. Zhang, Pressureless Sintering of Carbon-Coated Zirconium Diboride Powders, Mater. Sci. Eng. A, 2007, A459(1–2), p 167–171. (in English)

A.L. Chamberlain, W.G. Fahrenholtz, and G.E. Hilmas, Pressureless Sintering of Zirconium Diboride, J. Am. Ceram. Soc., 2006, 89(2), p 450–456. (in English)

M. Mallik, S. Upender, R. Mitra, and K.K. Ray, Thermal Shock and Ablation Resistance of ZrB2 Based Ultra-high Temperature Ceramic Composites. In: K.K. Kar, K. Muralidhar, J. Ramkumar editors. Proceeding in International Conference on Future Trends in Composite Materials and Processing INCCOM-6, Anamaya Publications, IIT Kanpur, 12-14 December 2007, p. 670-675, in English.

T.R. Paul, M.K. Mondal, and M. Mallik, Thermal Shock Behavior of ZrB2-MoSi2-SiCw Composites, J. Alloy. Compd., 2022, 924, 166443. (in English)

M. Mallik, A.J. Kailath, K.K. Ray, and R. Mitra, Electrical and Thermophysical Properties of ZrB2 and HfB2 Based Composites, J. Eur. Ceram. Soc., 2012, 32(10), p 2545–2555. (in English)

S. Guo and Y. Kagawa, Thermal and Electric Properties in Hot-Pressed ZrB2-MoSi2-SiC Composites, J. Am. Ceram. Soc., 2007, 90(7), p 2255–2258. (in English)

G.V. Samsonov and I.M. Vinitskii, Handbook of Refractory Compounds, FI/PLENUM, New York, 1980. (in English)

M. Mallik, A.J. Kailath, K.K. Ray, and R. Mitra, Effect of SiC Content on Electrical, Thermal and Ablative Properties of Pressureless Sintered ZrB2-Based Ultra-High Temperature Ceramic Composites, J. Eur. Ceram. Soc., 2017, 37(2), p 559–572. (in English)

M. Mallik, P. Mitra, N. Srivastava, A. Narain, S.G. Dastidar, A. Singh, and T.R. Paul, Abrasive Wear Performance of Zirconium Diboride Based Ceramic Composite, Int. J. Refract. Metals Hard Mater., 2019, 79, p 224–232. (in English)

T.R. Paul, M.K. Mondal, and M. Mallik, Dry Sliding Wear Response of ZrB2-20vol.% MoSi2 Composite, Mater. Today Proc., 2018, 5(2), p 7174–7183. (in English)

T.R. Paul, M.K. Mondal, and M. Mallik, Abrasive Wear Performance and Wear Map of ZrB2-MoSi2-SiCw Composites, J. Eur. Ceram. Soc., 2021, 41(6), p 3227–3251. (in English)

D. Kalish, E.V. Clougherty, and K. Kreder, Strength, Fracture Mode, and Thermal Stress Resistance of HfB2 and ZrB2, J. Am. Ceram. Soc., 1969, 52(1), p 30–36. (in English)

S.Q. Guo, Densification of ZrB2-Based Composites and their Mechanical and Physical Properties: A Review, J. Am. Ceram. Soc., 2009, 29(6), p 995–1011. (in English)

D. Sciti, F. Monteverde, S. Guicciardi, G. Pezzotti, and A. Bellosi, Microstructure and Mechanical Properties of ZrB2-MoSi2 Ceramic Composites Produced by Different Sintering Techniques, Mater. Sci. Eng. A, 2006, 434(1–2), p 303–309. (in English)

W. Li, X. Zhang, C. Hong, W. Han, and J. Han, Microstructure and Mechanical Properties of Zirconia-Toughened ZrB2-MoSi2 Composites Prepared by Hot-Pressing, Scr. Mater., 2009, 60(2), p 100–103. (in English)

F. Monteverde, The Addition of SiC Particles into a MoSi2-Doped ZrB2 Matrix: Effects on Densification, Microstructure and Thermo-Physical Properties, Mater. Chem. Phys., 2009, 113(2–3), p 626–633. (in English)

M. Mallik, S. Roy, K.K. Ray, and R. Mitra, Effect of SiC Content, Additives and Process Parameters on Densification and Structure-Property Relations of Pressureless Sintered ZrB2-SiC Composites, Ceram. Int., 2013, 39(3), p 2915–2932. (in English)

M. Mallik, R. Mitra, and K.K. Ray, Effect of Particulate Volume Fraction on Mechanical Properties of Pressure-Less Sintered ZrB2-SiC Ultra-High Temperature Ceramic Composites, Processing and Properties of Advanced Ceramics and Composites II: Ceram Trans: Wiley. N.P. Bansal, J.P. Singh, J. Lamon, S.R. Choi, M.M. Mahmoud Ed., Hoboken, 2010, p 77–90. (in English)

S. Pan and H. Roy, Fracture Toughness Measurement of Hot Pressed ZrB2-MoSi2 Composite, Int. J. Curr. Eng. Tech., 2013, 3(5), p 1647–1652. (in English)

T.R. Paul, M.K. Mondal, and M. Mallik, Microstructure Dependent Physical and Mechanical Properties of Spark Plasma Sintered ZrB2-MoSi2-SiCw Composites, Int. J. Refract. Metals Hard Mater., 2019, 79, p 131–137. (in English)

M. Mallik, K.K. Ray, and R. Mitra, Effect of Si3N4 Addition on Compressive Creep Behavior of Hot Pressed ZrB2-SiC Composites, J. Am. Ceram. Soc., 2014, 97(9), p 2957–2964. (in English)

E. Ringdalen and M. Tangstad, Softening and Melting of SiO2, an Important Parameter for Reactions with Quartz in Si Production, Advances in Molten Slags, Fluxes, and Salts: Proceedings of the 10th International Conference on Molten Slags, Fluxes and Salts 2016. R.G. Reddy, P. PinakinChaubal, C. Pistorius, U. Pal Ed., Springer International Publishing, Cham, 2016, p 43–51. (in English)

M. Mallik, K.K. Ray, and R. Mitra, Effect of Si3N4 Addition on Oxidation Resistance of ZrB2-SiC Composites, Coatings, 2017, 7(7), p 92. (in English)

M. Mallik, R. Mitra, K.K. Ray, Oxidation Behavior of Three ZrB2 based Ultra High Temperature Ceramic Composites, in: Proceeding in SEICO 09 SAMPE EUROPE 30th International Jubilee Conference and Forum in March, Paris, 2009, pp. 467–474, in English.

R. Mitra, M. Mallik, and S. Kashyap, High-Temperature Environmental Degradation Behavior of Ultrahigh-Temperature Ceramic Composites: Case Examples of Zirconium and Hafnium Diboride, Handbook of Advanced Ceramics and Composites: Defense, Security, Aerospace and Energy Applications. Y.R. Mahajan, R. Johnson Ed., Springer International Publishing, Cham, 2020, p 1221–1256. (in English)

A.L. Chamberlain, W.G. Fahrenholtz, G.E. Hilmas, and D.T. Ellerby, High Strength Zirconium Diboride-Based Ceramics, J. Am. Ceram. Soc., 2004, 87(6), p 1170–1172. (in English)

F. Monteverde, Beneficial Effects of an Ultra-Fine α–SiC Incorporation on the Sinterability and Mechanical Properties of ZrB2, Appl. Phys. A, 2006, 82(2), p 329–337. (in English)

D. Sciti, S. Guicciardi, A. Bellosi, and G. Pezzotti, Properties of a Pressureless Sintered ZrB2-MoSi2 Ceramic Composite, J. Am. Ceram. Soc., 2006, 89(7), p 2320–2322. (in English)

S.C. Zhang, G.E. Hilmas, and W.G. Fahrenholtz, Mechanical Properties of Sintered ZrB2-SiC Ceramics, J. Euro. Ceram. Soc., 2011, 31(5), p 893–901. (in English)

J. Han, Hu. Ping, X. Zhang, S. Meng, and W. Han, Oxidation Resistant ZrB2-SiC Composites at 2200°C, Compos. Sci. Technol., 2008, 68(3–4), p 799–806. (in English)

W.M. Guo and G.J. Zhang, Oxidation Resistance and Strength Retention of ZrB2-SiC Ceramics, J. Eur. Ceram. Soc., 2010, 30(11), p 2387–2395. (in English)

X. Zhang, X. Li , J. Han, W. Han, and C. Hong, Effects of Y2O3 on Microstructure and Mechanical Properties of ZrB2-SiC Ceramics, J. Alloy. Compd., 2008, 465(1–2), p 506–511. (in English)

C. Zhi-qiang, Z. Chang-ling, T. Ting-yan, S. Cheng-gong, S. Zhi-hong, and F. Jie, Pressureless Sintering of Ultra-high Temperature ZrB2-SiC Ceramics, Key Eng. Mater., 2008, 368, p 1746–1749. (in English)

ASTME1461-01, Standard Test Method for Thermal Diffusivity of Solids by the Flash Method, 2008 (July21) http://www.astm.org/DATABASE.CART/ HISTORICAL/E1461-01.htm. in English.

I. Barin, Thermochemical Data of Pure Substance, Wiley, Weinheim, 1989. (in English)

G.R. Anstis, P. Chantikul, B.R. Lawn, and D.B. Marshall, A Critical Evaluation of Indentation Techniques for Measuring Fracture Toughness: I, Direct Crack Measurements, J. Am. Ceram. Soc., 1981, 64, p 533–538. (in English)

B. Marappa, V. Pattar and M.S. Rudresha, Investigations of Structural, Optical and Electrical Properties of Cu2+ Doped Y2O3 Nanosheets, Chem. Phys. Lett.Lett., 2019, 728, p 57–61. (in English)

D.S. Smith, S. Fayette, S. Grandjean, and C. Martin, Thermal Resistance of Grain Boundaries in Alumina Ceramics and Refractories, J. Am. Ceram. Soc., 2003, 86(1), p 105–111. (in English)

L. Zhang, D.A. Pejakovic, J. Marschall, and M. Gasch, Thermal and Electrical Transport Properties of Spark Plasma- Sintered HfB2 and ZrB2 Ceramics, J. Am. Ceram. Soc., 2011, 94(8), p 2562–2570. (in English)

G. Grimvall Ed., Thermophysical Properties of Materials, 1st ed. Elsevier, North-Holland, 1999 (in English)

H. Kinoshita, S. Otani, S. Kamiyama, H. Amano, I. Akasaki, J. Suda, and H. Matsunami, Zirconium Diboride (0001) as an Electrically Conductive Lattice-Matched Substrate for Gallium Nitride, Jpn. J. Appl. Phys.. J. Appl. Phys., 2001, 40(12A), p L1280–L1282. (in English)

M. Nakabayashi, T. Fujimoto, M. Sawamura, N. Ohtani, (2010) Silicon Carbide Single Crystal, Silicon Carbide Single Crystal Wafer, and Method of Production of Same, U.S. Patent 7,794,842, in English.

J.W. Zimmermann, G.E. Hilmas, W.G. Fahrenholtz, R.B. Dinwiddie, W.D. Porter, and H. Wang, Thermophysical Properties of ZrB2 and ZrB2-SiC Ceramics, J. Am. Ceram. Soc., 2008, 91(5), p 1405–1411. (in English)

C.K. Jun and P.T.B. Shaffer, Elastic Modulus of Dense Silicon Carbide, Mater. Res. Bull., 1972, 7(1), p 63–70.

W.R. Manning, O. Hunter Jr., and B.R. Powell Jr., Elastic Properties of Polycrystalline Yttrium Oxide, Dysprosium Oxide, Holmium Oxide, and Erbium Oxide: Room Temperature Measurements, J. Am. Ceram. Soc., 1969, 52(8), p 436–442. (in English)

P.F. Becher, C.H. Hsueh, P. Angelini, and T.N. Tiegs, Toughening Behavior in Whisker Reinforced Ceramic Matrix Composites, J. Am. Ceram. Soc., 1988, 71(12), p 1050–1061. (in English)

H. Lin, Y. Liu, W. Liang, Q. Miao, S. Zhou, J. Sun, Y. Qi, X. Gao, Y. Song ,and K. Ogawa, Effect of the Y2O3 Amount on the Oxidation Behavior of ZrB2-SiC-Based Coatings for Carbon/Carbon Composites, J. Eur. Ceram. Soc., 2022, 42, p 4770–4782. (in English)

Acknowledgments

The project's financial support [DST, SERB, CRG/2019/004057] is gratefully acknowledged. The authors would like to express their appreciation to Dr. Lokesh C. Pathak, Chief Scientist, CSIR-National Metallurgical Laboratory, Jamshedpur, for permitting us to use their laboratory facilities. The authors acknowledge Dr. Gayatri Paul of Department of Production and Industrial Engineering, Birla Institute of Technology Mesra, Ranchi, Jharkhand, India for providing experimental facility for the thermal diffusivity measurement of the composites. The Field Emission Scanning Electron Microscope (Zeiss-SIGMA) facility at NIT Durgapur's Centre of Excellence in Advanced Materials has been recognized. The authors would also like to thank Mr. Shambhu Sarkar of COE NIT Durgapur for gathering FESEM and EDX data. We'd also like to thank Mr. Hiranmay Bairagya, of the XRD lab, for the XRD studies.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

This article is an invited submission to the Journal of Materials Engineering and Performance selected from presentations at the 4th International Conference on Processing & Characterization of Materials (ICPCM 2022) held December 9–11, 2022, at the National Institute of Technology, Rourkela, Odisha, India. It has been expanded from the original presentation. The issue was organized by Prof. Joao Pedro Oliveira, Universidade NOVA de Lisboa, Portugal; Prof. B. Venkata Manoj Kumar, Indian Institute of Technology Roorkee, India; Dr. D. Arvindha Babu, DMRL, DRDO, Hyderabad, India; Prof. Kumud Kant Mehta and Prof. Anshuman Patra, National Institute of Technology Rourkela, Odisha, India; and Prof. Manab Mallik, National Institute of Technology Durgapur, India.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Sarkar, S., Mondal, M.K. & Mallik, M. Correlation Between Pressureless Sintering, Microstructure, and Properties of ZrB2-SiC-Y2O3 Composites. J. of Materi Eng and Perform (2024). https://doi.org/10.1007/s11665-024-09417-3

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-024-09417-3