Abstract

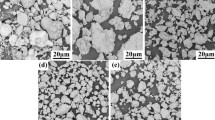

In this study, the effects of Al2O3 addition on microstructural and mechanical properties of TiB2-3 wt.% Fe composites were investigated. At first, TiB2 was synthesized via carbothermal reduction method. Then, four batches of TiB2-3 wt.%Fe-x wt.%Al2O3 (x = 0, 10, 20, 30) were prepared and consolidated by spark plasma sintering method at 1700 °C. Phase evaluation and microstructural observation of the prepared composites were studied through x-ray diffraction and field-emission scanning electron microscopy (FESEM) analysis, respectively. Vickers indentation and three point bending tests were used to evaluate the hardness, fracture toughness and flexural strength of the composites. Results showed that the addition of Al2O3 improved the densification and mechanical properties of the composites, however, the grain growth occurred. In other words, the results showed that the sample containing 10 wt.% Al2O3, exhibited the optimal mechanical properties, relative density (97 ± 1.8 g/cm3), hardness (18.70 ± 0.6 GPa), flexural strength (479.2 ± 34.2 MPa) and fracture toughness (6.84 ± 0.36 MPa m1/2).

Similar content being viewed by others

References

A. Twardowska, M. Podsiadło, I. Sulima, K. Bryła, and P. Hyjek, Microstructure and Properties of TiB2 Composites Produced by Spark Plasma Sintering with the Addition of Ti5Si3, Materials, 2021, 14, p 3812–3823.

X. Li, T. Zhang, Ch. Chen, Sh. Song, S. Shen, G. He, Zh. Li, R. Li, Q. Zhen, S. Bashir, and J.L. Liu, Preparation of TiB2-SiC Composites Toughened with Interlocking Microstructure by Self-assembled TiB2 Plates, Ceram. Int., 2022, 48, p 5119–5129.

N.S. Karthiselva, B.S. Murty, and S.R. Bakshi, Graphene Nanoplatelets Induce Crystallographic Texturing During Reactive Spark Plasma Sintering of TiB2, Carbon, 2018, 133, p 323–334.

S. Nekahi, F.S. Moghanlou, M. Vajdi, Z. Ahmadi, A. Motallebzadeh, and M.S. Asl, Microstructural, Thermal and Mechanical Characterization of TiB2-SiC Composites Doped with Short Carbon Fibers, Int. J. Refract. Met. Hard Mater., 2019, 82, p 129–135.

S. Sahoo and S.K. Singh, Synthesis of TiB2 by Extended Arc Thermal Plasma, Ceram. Int., 2017, 43(17), p 15561–15566.

V. Moradi, L. Nikzad, I. Mobasherpour, and M. Razavi, Low Temperature Synthesis of TiB2 by Carbothermal Method, Ceram. Int., 2018, 44, p 19421–19426.

M. Fattahi, Y. Pazhouhanfar, S.A. Delbari, and S. Shaddel, Influence of TiB2 Content on the Properties of TiC-SiCw Composites, Ceram. Int., 2020, 46, p 7403–7412.

J.H. Zhu, H.M. Zhou, B. Qin, and Z.Y. Zhao, Design, Fabrication, and Properties of TiB2/TiN/WC Gradient Ceramic Tool Materials, Ceram. Int., 2020, 46, p 6497–6506.

I. Smid and E. Kny, Evaluation of Binder Phases for Hard Metal Systems Based on TiB2, Int. J. Refract. Met. Hard Mater., 1988, 7(3), p 135–138.

L. Shuo and Z. Weiping, Research on Microstructure of in Situ Synthesized TiB2/Ni Metal–Ceramics Composite Coating, J. Mater. Sci. Poland, 2005, 391, p 146–150.

M. Hu, N. Bi, M. Liu, G. Gao, Sh. Li, and T. Su, Rapid Sintering of TiB2 Ceramics Using Co as Sintering Aid Under High Pressure Condition, J. Mater. Sci., 2020, 38(3), p 502–507.

L. Pecanha Jr., S.N. Monteiro, Í. Vale Tomaz, M. Oliveira, A. Ramalho, N. Simonassi, and F. Braga, Characterization of TiB2-AlN Composites for Application as Cutting Tool, J. Mater. Res. Technol., 2018, 7(4), p 403–616.

M. Shahedi Asla, S.A. Delbaria, F. Shayesteha, Z. Ahmadia, and A. Motallebzadehb, Reactive Spark Plasma Sintering of TiB2-SiC-TiN Novel Composite, Int. J. Refract. Met. Hard Mater., 2019, 81, p 119–126.

V. Nguyen, M. Shahedi Asl, Z. Hamidzadeh Mahaseni, M. Dashti Germi, Q. Van Le, Z. Ahmadi, M.R. Shokouhimehr, A. Sabahi Namini, and M. Mohammadi, Role of Co-Addition of BN and SiC on Microstructure of TiB2-Based Composites Densified by SPS Method, Ceram. Int., 2020, 46(16), p 25341–25350.

S. Yan, Z. Lyu, and L. KokFoong, Effects of SiC Amount and Morphology on the Properties of TiB2-Based Composites Sintered by Hot-Pressing, Ceram. Int., 2020, 46(11), p 18813–18825.

Z. Jinyong, T. Wenjun, F. Zhengyi, W. Weiming, and Z. Qingjie, Fabrication of Homogenous Dispersion TiB2-Al2O3 Composites, J. Wuhan Univ. Technol. Mater Sci. Ed., 2011, 26, p 681–683.

T. Watanahe and A.N.D.K. Shoubu, Mechanical Properties of Hot-Pressed TiB2-ZrO2 Composite, J. Am. Ceram. Soc., 1985, 68, p C34–C36.

A.Y. Popov, A.A. Sivak, H.Y. Borodianska, and I.L. Shabalin, High Toughness TiB2-Al2O3 Composite Ceramics Produced by Reactive Hot Pressing with Fusible Component, Adv. Appl. Ceram., 2015, 114(3), p 178–182.

A. Rabiezadeh, A. Ataie, and A.M. Hadian, Sintering of Al2O3-TiB2 Nano-Composite Derived from Milling Assisted Sol–Gel Method, Int. J. Refract. Met. Hard Mater., 2012, 33, p 58–64.

H.-W. Kim, Y.-H. Koh, and H.-E. Kim, Densification and Mechanical Properties of B4C with Al2O3 as a Sintering Aid, J. Am. Ceram. Soc., 2000, 83(11), p 2863–2865.

J. Pyzik and D.R. Beaman, Microstructure and Properties of Self-reinforced Silicon Nitride, J. Am. Ceram. Soc., 1993, 76(11), p 2737–2744.

M.S. Heidari and H.R. Baharvandi, Comparing the Effects of Different Sintering Methods for Ceramics on the Physical and Mechanical Properties of B4C-TiB2 Nanocomposites, Int. J. Refract. Met. Hard Mater., 2015, 51, p 61.

A.N. Azar, L. Nikzad, and A. Moosavi, Spark Plasma Sintering and Mechanical Properties of Tungsten Carbide in Presence of Ni and Al2O3 Binders, Mater. Sci. Eng. A, 2021, 826, p 141968.

L. Zhaog, C.Z. Huang, N. He, H.L. Liu, and B. Zou, Preparation and Cutting Performance of Reactively Hot Pressed TiB2-SiC Ceramic Tool When Machining Invar36 Alloy, Int. J. Refract. Met. Hard Mater., 2016, 86, p 2679–2688.

M. Gu, C. Huang, S. Xiao, and H. Liu, Improvements in Mechanical Properties of TiB2 Ceramics Tool Materials by the Dispersion of Al2O3 Particles, Mater. Sci. Eng., A, 2008, 486, p 167–170.

G.D. Quinn, Fracture Toughness of Ceramics by the Vickers Indentation Crack Length Method: A Critical Review, Ceram. Eng. Sci. Proc., 2007, 27, p 45.

N. Wu, F. Xue, H. Yang, G. Li, F. Luo, and J. Ruan, Effects of TiB2 Particle Size on the Microstructure and Mechanical Properties of TiB2-Based Composites, Ceram. Int., 2019, 45, p 1370–1378.

Acknowledgments

The authors would like to acknowledge the Materials and Energy Research Center (MERC) for providing the financial support throughout the research grant (No. 99391001).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Habibzadeh, S., Nikzad, L. & Majidian, H. Al2O3-Reinforced TiB2-Fe Composites: Microstructural and Mechanical Properties. J. of Materi Eng and Perform (2023). https://doi.org/10.1007/s11665-023-08308-3

Received:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-023-08308-3