Abstract

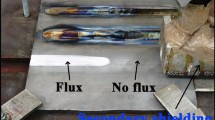

Gas tungsten arc welding (GTAW) and its variants are esteemed as economically efficient welding methods for welding titanium alloys in the aerospace and nuclear industries. In the present work, the influence of electrode tip angle on weld geometrical elements, distortion, and hardness was investigated in commercially pure titanium (CP-Ti) sheets welded through pulsed-GTAW. Bead-on-plate (BOP) welding was performed on 2 mm thick CP-Ti sheets using electrode tip angles of 30, 45, 60, 75, and 90°. Defect-free welds were obtained by utilizing an indigenously developed shielding setup assembled with p-GTAW machine. The weld geometrical elements were evaluated using metallographic samples of weldment cross section under the stereomicroscope. The findings revealed that as the electrode tip angle increased from 30 to 60°, weld bead width decreased from 6.84 to 5.32 mm. Additionally, the weld penetration initially increased from 1.59 to 1.75 mm up to 60°, but subsequently decreased to 1.51 mm at 90°. Furthermore, increasing the electrode tip angle led to reduction in weld distortion. Microhardness measurements demonstrated an increase in hardness from the base (141 HV0.2) to the weld region (151 HV0.2), with a slight decrease observed in the HAZ (134 HV0.2). This hardness trend across the weldment remained consistent with each electrode tip angle, and higher hardness was observed using large electrode tip angle.

Similar content being viewed by others

Data Availability

The data that support the findings of this study are available from the corresponding author upon reasonable request.

References

C. Leyens and M. Peters, Titanium and Titanium Alloys: Fundamentals and Applications, Wiley Online Library, New York, 2006.

T.S. Balasubramanian, M. Balakrishnan, and V. Balasubramanian et al., Effect of Welding Processes on Joint Characteristics of Ti-6Al-4V Alloy, Sci. Technol. Weld. Join., 2011, 16(8), p 702–708.

A. Karpagaraj, N. Siva Shanmugam, and K. Sankaranarayanasamy, Some Studies on Mechanical Properties and Microstructural Characterization of Automated TIG Welding of Thin Commercially Pure Titanium Sheets, Mater. Sci. Eng. A, 2015, 640, p 180–189.

N. Kashaev, V. Ventzke, and V. Fomichev et al., Effect of Nd:YAG Laser Beam Welding on Weld Morphology and Mechanical Properties of Ti-6Al-4V Butt Joints and T-Joints, Opt. Lasers Eng., 2016, 86, p 172–180.

Q. Yunlian, D. Ju, and H. Quan et al., Electron Beam Welding, Laser Beam Welding and Gas Tungsten Arc Welding of Titanium Sheet, Mater. Sci. Eng. A, 2000, 280(1), p 177–181.

S.K. Sahoo, B. Bishoyi, and U.K. Mohanty et al., Effect of Laser Beam Welding on Microstructure and Mechanical Properties of Commercially Pure Titanium, Trans. Indian Inst. Met., 2017, 70(7), p 1817–1825.

S.T. Auwal, S. Ramesh, and F. Yusof et al., A Review on Laser Beam Welding of Titanium Alloys, Int. J. Adv. Manuf. Technol., 2018, 97(1–4), p 1071–1098.

F. Gao, Y. Cui, and H. Shi et al., Fracture Toughness of Ti-6Al-4V Titanium Alloy Welded by Keyhole Gas Tungsten Arc Welding Based on High Current, J. Mater. Eng. Perform., 2023, 32(23), p 10556–10566.

A.R. Pavan, T. Sakthivel, and B. Arivazhagan et al., A Comparative Study on the Microstructural Evolution and Mechanical Behavior of 316LN Stainless Steel Welds Made Using Hot-Wire Tungsten Inert Gas and Activated Tungsten Inert Gas Process, J. Mater. Eng. Perform., 2023 https://doi.org/10.1007/s11665-023-08881-7

W. Lucas, TIG and Plasma Welding: Process Techniques, Recommended Practices and Applications, Abington Publishing, Nashville, 1990.

A. Iltaf, F.N. Khan, and T. Shehbaz et al., Influence of Filler Material on the Microstructure, Mechanical Properties, and Residual Stresses in Tungsten inert Gas Welded Ti-5Al-2.5Sn Alloy Joints, Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl., 2021, 235(8), p 1952–1966.

K. Anbalagan, S. Ramasubramanian, and C. David et al., Importance of Shielding and Mechanical Characterization of Gtaw on Ti-6AL-4V Alloy Sheet, Weld. Int., 2023, 37(6), p 1–11.

S. Kumar, K.E.K. Vimal, and M.A. Khan et al., A Hybrid Learning Approach for Modelling the Fabrication of Super Duplex Stainless Steel Thin Joints Using GTAW Process, Int. J. Interact. Des. Manuf. (IJIDeM), 2023 https://doi.org/10.1007/s12008-023-01413-6

T.V. da Cunha, Roadmap Proposal for Determining the Variables of Pulsed TIG Welding Process Applied to Welding of Thin Plates, Weld. Int., 2015, 29(5), p 356–362.

M. Darivandpour, R. Dehmolaei, and K. Ranjbar et al., Selecting the Appropriate Filler Metal to Join HSLA-100 Steel by Gas Tungsten Arc Welding Process, J. Mater. Eng. Perform., 2023, 32(23), p 10503–10513.

N. Liu, Z. Lan, and L. Liu et al., Optimizing 304 Stainless Steel Surface Performance with CoCrFeMoNi High-Entropy Alloy Coating via Gas Tungsten Arc Cladding, J. Mater. Eng. Perform., 2023, 32(20), p 9114–9120.

S. Lathabai, B.L. Jarvis, and K.J. Barton, Comparison of Keyhole and Conventional Gas Tungsten Arc Welds in Commercially Pure Titanium, Mater. Sci. Eng. A, 2001, 299(1–2), p 81–93.

G. Dak, S.M. Pandey, and C. Pandey, Residual Stress Analysis, Microstructural Characterization, and Mechanical Properties of Tungsten Inert Gas-Welded P92/AISI 304L Dissimilar Steel Joints, Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl., 2023, 237(4), p 767–790.

S. Ukita, K. Kokubo, and T. Masuko, Effects of Electrode Tip Shape and Torch Angle on High-Speed DCEN TIG Welding, Weld. Int., 2002, 16(10), p 778–783.

S. Sundaresan, G.D. Janaki Ram, and R.G. Madhusudhan, Microstructural Refinement of Weld Fusion Zones in α–β Titanium Alloys Using Pulsed Current welding, Mater. Sci. Eng. A, 1999, 262(1–2), p 88–100.

H. Lin and C. Chou, Optimisation of the GTA Welding Process Using the Taguchi Method and a Neural Network, Sci. Technol. Weld. Joining, 2006, 11(1), p 120–126.

D.T. Cicic, C. Rontescu, and V. Savulescu et al., The Processing Method of the Tungsten Electrodes and the Current Type Choice Influence on the Shape of the Welding arc in Tungsten Inert Gas Welding (TIG), IOP Conf. Ser. Mater. Sci. Eng., 2018, 400(2), p 022016. https://doi.org/10.1088/1757-899X/400/2/022016

X. Hong, B. Huang, and T. Li et al., Effects of Welding Speed and Welding Current on the Residual Stress and Deformation of SAF 2507/316L Dissimilar Plasma Arc Welding, J. Mater. Eng. Perform., 2023 https://doi.org/10.1007/s11665-023-08969-0

M. Goodarzi, R. Choo, and J.M. Toguri, The Effect of the Cathode Tip Angle on the GTAW Arc and Weld Pool: I. Mathematical Model of the Arc, J. Phys. D Appl. Phys., 1997, 30(19), p 2744.

H.-L. Lin and T.-M. Wu, Effects of Activating Flux on Weld Bead Geometry of Inconel 718 Alloy TIG Welds, Mater. Manuf. Process., 2012, 27(12), p 1457–1461.

R. Singh and Y. Kumar, Tribological Analysis of Cooling Tank Assisted Hybrid Friction Stir Welded 6061 Aluminium Alloy, Weld. Int., 2023, 37(9), p 507–518.

R. Singh and Y. Kumar, Microstructural Analysis of Cooling Tank-Assisted Hybrid Friction Stir Welded Aluminium Alloys: A Novel Approach, Weld. Int., 2023, 37(8), p 445–456.

R. Singh and Y. Kumar, Effect of Cooling Tank Embedded Fixture Design on the Thermal Analysis of Friction Stir Welded Aluminum Alloy, J. Mater. Eng. Perform., 2023, 32(16), p 7215–7224.

A. Kumar, M.K. Mahto, and V.S. Rana et al., Investigation of Microstructure Evolution and Mechanical Properties of Gas Tungsten Arc Welded Dissimilar Titanium (CP-Ti/Ti-6Al-4V) Alloys, Proc. Inst. Mech. Eng. Part E J. Process Mech. Eng., 2022, 237(5), p 1819–1831. https://doi.org/10.1177/095440892211264

A. Kumar, N. Kumar, and M.K. Mahto et al., Impression Creep Behaviour of Different Zones of Pulsed Gas Tungsten Arc Welded Ti-6Al-4V Alloy, Mater. Today Commun., 2023, 36, p 106722.

M. Balasubramanian, V. Jayabalan, and V. Balasubramanian, Effect of Process Parameters of Pulsed Current Tungsten Inert Gas Welding on Weld Pool Geometry of Titanium Welds, Acta Metall. Sin. (English Letters), 2010, 23(4), p 312.

B. Mehdi, R. Badji, and V. Ji et al., Microstructure and Residual Stresses in Ti-6Al-4V Alloy Pulsed and Unpulsed TIG Welds, J. Mater. Process. Technol., 2016, 231, p 441–448.

K. Herrmann, Hardness Testing: Principles and Applications, ASM International, Novelty, OH, 2011.

G. Mathers, Welding of Titanium and its Alloys–Part 2, TWI Global, Cambridge, 2017, p 2–4

M. Junaid, K. Rahman, and F.N. Khan et al., Comparison of Microstructure, Mechanical Properties, and Residual Stresses in Tungsten Inert Gas, Laser, and Electron Beam Welding of Ti-5Al-2.5Sn Titanium Alloy, Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl., 2019, 233(7), p 1336–1351.

M. Junaid, M.N. Baig, and M. Shamir et al., A comparative Study of Pulsed Laser and Pulsed TIG Welding of Ti-5Al-2.5Sn Titanium Alloy Sheet, J. Mater. Process. Technol., 2017, 242, p 24–38.

M. Inoue and I. Hirasawa, The Relationship Between Crystal Morphology and XRD Peak Intensity on CaSO4·2H2O, J. Cryst. Growth, 2013, 380, p 169–175.

M. Junaid, F.N. Khan, and M.R. Mirza et al., Microstructure, Mechanical Properties and Residual Stress Distribution in Pulsed Tungsten Inert Gas Welding of Ti-5Al-2.5 Sn Alloy, Proc. Inst. Mech. Eng. Part L J. Mater. Des. Appl., 2019, 233(10), p 2030–2044.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The author(s) declared no potential conflict of interest with respect to the research, authorship, and/or publication of this article.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Kumar, A., Mahto, M.K., Vashista, M. et al. Analysis of Electrode Tip Angle Variation on Weld Geometry, Distortion, and Hardness in Commercially Pure Titanium Welded Using Pulsed-Gas Tungsten Arc Welding. J. of Materi Eng and Perform (2024). https://doi.org/10.1007/s11665-024-09387-6

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-024-09387-6