Abstract

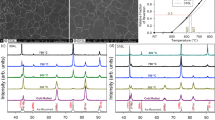

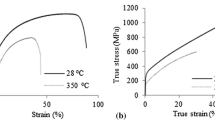

In the present investigation, grain size and dislocation density in SS 304 metastable austenitic stainless steel were varied by annealing the as-received steel at 1025 °C for 120 and 360 min. Effect of dislocation density and grain size on the work hardening behavior, evolution of deformation-induced martensite, and kinetics of deformation-induced transformation has been systematically studied with x-ray diffraction and microscopic examination of steels when subjected to the interrupted tensile deformation. As-rolled stainless steels exhibited rapid work hardening at low strains due to high initial dislocation density, while annealed steel rapidly work-hardened at higher strains due to the formation of large fraction of deformation-induced martensite and generation of large number of geometrically necessary dislocations. Differences in the initial dislocation density influenced the rate of deformation-induced transformation. Further, in this study, from first principles, it has been found that due to relatively high apparent stacking fault energy, in as-rolled fine grain stainless steels, deformation of austenite primarily takes place with the formation of twins. In contrast, annealed coarse-grained stainless steels with low apparent stacking fault energy, deformation-induced transformation of austenite into \(\epsilon \)-martensite is the dominant deformation path, rendering annealed steel to undergo deformation-induced transformation rapidly as compared to the as-received stainless steel.

Similar content being viewed by others

Data Availability

Data will be made available on a reasonable request.

References

H. Zhang, C. Li, Y. Shi, G. Yao, and Y. Zhang, Fatigue and Tensile Deformation Behaviors of Laser Powder Bed Fused 304L Austenitic Stainless Steel, Mater. Sci. Eng. A, 2022, 849, 143503.

M. Soleimani, A. Kalhor, and H. Mirzadeh, Transformation-Induced Plasticity (TRIP) in Advanced Steels: A Review, Mater. Sci. Eng. A, 2020, 795, 140023.

M.J. Sohrabi, M. Naghizadeh, and H. Mirzadeh, Deformation-Induced Martensite in Austenitic Stainless Steels: A Review, Arch. Civ. Mech. Eng.neering, 2020, 20, p 1–24.

W. Bleck, X. Guo, and Y. Ma, The TRIP Effect and Its Application in Cold Formable Sheet Steels, Steel Res. Int., 2017, 88(10), p 1700218.

Q. Lai, H. Yang, Y. Wei, H. Zhou, L. Xiao, H. Ying, S. Lan, Z. You, Z. Kou, and T. Feng, Transformation Plasticity in High Strength, Ductile Ultrafine-Grained FeMn Alloy Processed by Heavy Ausforming, Int. J. Plast., 2022, 148, 103151.

M.J. Sohrabi, H. Mirzadeh, S. Sadeghpour, and R. Mahmudi, Explaining the Drop of Work-Hardening Rate and Limitation of Transformation-Induced Plasticity Effect in Metastable Stainless Steels during Tensile Deformation, Scr. Mater., 2023, 231, 115465.

K. Spencer, J.D. Embury, K.T. Conlon, M. Véron, and Y. Bréchet, Strengthening via the Formation of Strain-Induced Martensite in Stainless Steels, Mater. Sci. Eng. Ag. A, 2004, 387, p 873–881.

P.M. Ahmedabadi, V. Kain, and A. Agrawal, Modelling Kinetics of Strain-Induced Martensite Transformation during Plastic Deformation of Austenitic Stainless Steel, Mater. Des., 2016, 109, p 466–475.

G. Fargas, J.J. Roa, and A. Mateo, Effect of Shot Peening on Metastable Austenitic Stainless Steels, Mater. Sci. Eng. A, 2015, 641, p 290–296.

S. Kheiri, H. Mirzadeh, and M. Naghizadeh, Tailoring the Microstructure and Mechanical Properties of AISI 316L Austenitic Stainless Steel via Cold Rolling and Reversion Annealing, Mater. Sci. Eng. A, 2019, 759, p 90–96.

Y. He, J. Zhang, Y. Wang, Y. Wang, and T. Wang, The Expansion Behavior Caused by Deformation-Induced Martensite to Austenite Transformation in Heavily Cold-Rolled Metastable Austenitic Stainless Steel, Mater. Sci. Eng. A, 2019, 739, p 343–347.

A. Järvenpää, M. Jaskari, A. Kisko, and P. Karjalainen, Processing and Properties of Reversion-Treated Austenitic Stainless Steels, Metals (Basel), 2020, 10(2), p 281.

T. Shintani and Y. Murata, Evaluation of the Dislocation Density and Dislocation Character in Cold Rolled Type 304 Steel Determined by Profile Analysis of X-Ray Diffraction, Acta Mater., 2011, 59(11), p 4314–4322.

J. Liu and D. Kaoumi, Use of In-Situ TEM to Characterize the Deformation-Induced Martensitic Transformation in 304 Stainless Steel at Cryogenic Temperature, Mater Charact, 2018, 136, p 331–336.

T. Suzuki, H. Kojima, K. Suzuki, T. Hashimoto, S. Koike, and M. Ichihara, Plastic Deformation and Martensitic Transformation in an Iron-Base Alloy, Scr. Metall., 1976, 10(4), p 353–358.

H.C. Shin, T.K. Ha, and Y.W. Chang, Kinetics of Deformation Induced Martensitic Transformation in a 304 Stainless Steel, Scr. Mater., 2001, 45(7), p 823–829.

T. Kikuchi and S. Kajiwara, HVEM in Situ Observation of Isothermal Martensitic Transformation under Applied Stress, Trans. Jpn. Inst. Met., 1985, 26(12), p 861–868.

X.F. Fang and W. Dahl, Strain Hardening and Transformation Mechanism of Deformation-Induced Martensite Transformation in Metastable Austenitic Stainless Steels, Mater. Sci. Eng. A, 1991, 141(2), p 189–198.

J. Liu, C. Chen, Q. Feng, X. Fang, H. Wang, F. Liu, J. Lu, and D. Raabe, Dislocation Activities at the Martensite Phase Transformation Interface in Metastable Austenitic Stainless Steel: An in-Situ TEM Study, Mater. Sci. Eng. A, 2017, 703, p 236–243.

S. Chatterjee, H.-S. Wang, J.R. Yang, and H. Bhadeshia, Mechanical Stabilisation of Austenite, Mater. Sci. Technol., 2006, 22(6), p 641–644.

D. Qi-Xun, W. An-Dong, C. Xiao-Nong, and L. Xin-Min, Stacking Fault Energy of Cryogenic Austenitic Steels, Chin. Phys., 2002, 11(6), p 596.

M.R. da Rocha and C.A.S. de Oliveira, Evaluation of the Martensitic Transformations in Austenitic Stainless Steels, Mater. Sci. Eng. A, 2009, 517(1–2), p 281–285.

K. Nohara, Y. Ono, and N. Ohashi, Composition and Grain Size Dependencies of Strain-Induced Martensitic Transformation in Metastable Austenitic Stainless Steels, Tetsu-to-Hagané, 1977, 63(5), p 772–782.

D.C. Ludwigson, Modified Stress–Strain Relation for FCC Metals and Alloys, Metall. Trans., 1971, 2(10), p 2825–2828.

E.-96 ASTM, Standard Test Methods for Determining Average Grain Size, ASTM International: West Conshohocken, PA, USA, 2004.

R. Abbaschian and R.E. Reed-Hill, Physical Metallurgy Principles-SI Version, Cengage Learning, Stamford, USA, 2009.

P. Tiwari and A. Varshney, A Review on Measurement Techniques of Deformation-Induced Transformation Kinetics in Transformation-Induced Plasticity and Transformation-Induced Plasticity-Assisted Steels, Steel Res. Int., 2023, 95(1), p 2300341.

W.A. Rachinger, A Correction for the Α1 Α2 Doublet in the Measurement of Widths of X-Ray Diffraction Lines, J. Sci. Instrum., 1948, 25(7), p 254.

T.H. De Keijser, J.I. Langford, E.J. Mittemeijer, and A.B.P. Vogels, Use of the Voigt Function in a Single-Line Method for the Analysis of X-Ray Diffraction Line Broadening, J. Appl. Crystallogr., 1982, 15(3), p 308–314.

T. Narutani, Effect of Deformation-Induced Martensitic Transformation on the Plastic Behavior of Metastable Austenitic Stainless Steel, Mater. Trans. JIM, 1989, 30(1), p 33–45.

M. Naghizadeh and H. Mirzadeh, Effects of Grain Size on Mechanical Properties and Work-hardening Behavior of AISI 304 Austenitic Stainless Steel, Steel Res. Int., 2019, 90(10), p 1900153.

M.J. Sohrabi, H. Mirzadeh, S. Sadeghpour, and R. Mahmudi, Grain Size Dependent Mechanical Behavior and TRIP Effect in a Metastable Austenitic Stainless Steel, Int. J. Plast., 2023, 160, 103502.

S. Rajasekhara, P.J. Ferreira, L.P. Karjalainen, and A. Kyröläinen, Hall-Petch Behavior in Ultra-Fine-Grained AISI 301LN Stainless Steel, Metall. Mater. Trans. A, 2007, 38, p 1202–1210.

G.E. Dieter and D. Bacon, Mechanical Metallurgy, McGraw-hill, New York, 1976.

D. Hull and D.J. Bacon, Introduction to Dislocations, Elsevier, Burlington, USA, 2011.

J. Talonen and H. Hänninen, Formation of Shear Bands and Strain-Induced Martensite during Plastic Deformation of Metastable Austenitic Stainless Steels, Acta Mater., 2007, 55(18), p 6108–6118.

A. Heinz and P. Neumann, Crack Initiation during High Cycle Fatigue of an Austenitic Steel, Acta Metall. Mater., 1990, 38(10), p 1933–1940.

C. Blochwitz and W. Tirschler, Influence of Texture on Twin Boundary Cracks in Fatigued Austenitic Stainless Steel, Mater. Sci. Eng. A, 2003, 339(1–2), p 318–327.

O. Grässel and G. Frommeyer, Effect of Martensitic Phase Transformation and Deformation Twinning on Mechanical Properties of Fe–Mn–Si–AI Steels, Mater. Sci. Technol., 1998, 14(12), p 1213–1217.

G.B. Olson and M. Cohen, Kinetics of Strain-Induced Martensitic Nucleation, Metall. Trans. A, 1975, 6, p 791–795.

A. Jain and A. Varshney, A Critical Review on Deformation-Induced Transformation Kinetics of Austenitic Stainless Steels, Mater. Sci. Technol., 2024, 40(2), p 75–106. https://doi.org/10.1177/02670836231212618

A. Kundu and D.P. Field, Influence of Microstructural Heterogeneity and Plastic Strain on Geometrically Necessary Dislocation Structure Evolution in Single-Phase and Two-Phase Alloys, Mater Charact, 2020, 170, 110690.

S. Furukane and S. Torizuka, Effect of Grain Size and Dislocation Density on Strain-Induced Martensitic Transformation in Austenitic Stainless Steels, Tetsu To Hagane (Online), 2019, 105(8), p 827–836.

B.L. Ennis, E. Jimenez-Melero, E.H. Atzema, M. Krugla, M.A. Azeem, D. Rowley, D. Daisenberger, D.N. Hanlon, and P.D. Lee, Metastable Austenite Driven Work-Hardening Behaviour in a TRIP-Assisted Dual Phase Steel, Int. J. Plast., 2017, 88, p 126–139.

Y.K. Lee, J.E. Jin, and Y.Q. Ma, Transformation-Induced Extraordinary Ductility in an Ultrafine-Grained Alloy with Nanosized Precipitates, Scr. Mater., 2007, 57(8), p 707–710.

A. Kisko, R.D.K. Misra, J. Talonen, and L.P. Karjalainen, The Influence of Grain Size on the Strain-Induced Martensite Formation in Tensile Straining of an Austenitic 15Cr-9Mn-Ni-Cu Stainless Steel, Mater. Sci. Eng. A, 2013, 578, p 408–416.

R.G. Stringfellow, D.M. Parks, and G.B. Olson, A Constitutive Model for Transformation Plasticity Accompanying Strain-Induced Martensitic Transformations in Metastable Austenitic Steels, Acta Metall. Mater., 1992, 40(7), p 1703–1716.

M.F. Ashby, The Deformation of Plastically Non-Homogeneous Materials, Philos. Mag. A J. Theor. Exp. Appl. Phys., 1970, 21(170), p 399–424.

Y.-K. Lee and C. Choi, Driving Force for Γ→ ε Martensitic Transformation and Stacking Fault Energy of γ in Fe-Mn Binary System, Metall. Mater. Trans. A, 2000, 31, p 355–360.

A. Saeed-Akbari, J. Imlau, U. Prahl, and W. Bleck, Derivation and Variation in Composition-Dependent Stacking Fault Energy Maps Based on Subregular Solution Model in High-Manganese Steels, Metall. Mater. Trans. A, 2009, 40, p 3076–3090.

M. Huang, L. Wang, C. Wang, A. Mogucheva, and W. Xu, Characterization of Deformation-Induced Martensite with Various AGSs upon Charpy Impact Loading and Correlation with Transformation Mechanisms, Mater Charact, 2022, 184, 111704.

D. Geissler, J. Freudenberger, A. Kauffmann, S. Martin, and D. Rafaja, Assessment of the Thermodynamic Dimension of the Stacking Fault Energy, Philos. Mag., 2014, 94(26), p 2967–2979.

D.T. Pierce, J.A. Jiménez, J. Bentley, D. Raabe, C. Oskay, and J.E. Wittig, The Influence of Manganese Content on the Stacking Fault and Austenite/ε-Martensite Interfacial Energies in Fe–Mn–(Al–Si) Steels Investigated by Experiment and Theory, Acta Mater., 2014, 68, p 238–253.

E.I. Galindo-Nava and P.E.J. Rivera-Díaz-del-Castillo, Understanding Martensite and Twin Formation in Austenitic Steels: A Model Describing TRIP and TWIP Effects, Acta Mater., 2017, 128, p 120–134.

J.S. Aristeidakis and G.N. Haidemenopoulos, Constitutive and Transformation Kinetics Modeling of ε-, Α′-Martensite and Mechanical Twinning in Steels Containing Austenite, Acta Mater., 2022, 228, 117757.

Y.F. Shen, X.X. Li, X. Sun, Y.D. Wang, and L. Zuo, Twinning and Martensite in a 304 Austenitic Stainless Steel, Mater. Sci. Eng. A, 2012, 552, p 514–522.

P. Peralta, L. Llanes, J. Bassani, and C. Laird, Deformation from Twin-Boundary Stresses and the Role of Texture: Application to Fatigue, Philos. Mag. A, 1994, 70(1), p 219–232.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

It is certified that they have NO affiliations with or involvement in any organization or entity with any financial interest (such as honoraria; educational grants; participation in speakers’ bureaus; membership, employment, consultancies, stock ownership, or other equity interest; and expert testimony or patent-licensing arrangements), or non-financial interest (such as personal or professional relationships, affiliations, knowledge or beliefs) in the subject matter or materials discussed in this manuscript.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Jain, A., Varshney, A. Effect of Grain Size and Dislocation Density on the Work Hardening Behavior of SS 304. J. of Materi Eng and Perform (2024). https://doi.org/10.1007/s11665-024-09358-x

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-024-09358-x