Abstract

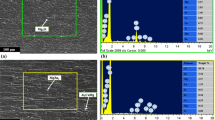

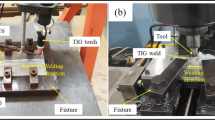

The current study explored the combined influence of tool rotation speed (TRS), traverse speed (TS), and tool tilt angle (TA) on the response variables, namely ultimate tensile strength (UTS), impact toughness (IT), microhardness (MH), and residual stress (RS). A TIG + FSP welding technique was utilized to fabricate the distinct aluminum alloys AA6061-T6 and AA7075-T6 butt welds as per the face-cantered central composite design. The response surface methodology-based desirability function technique was employed to obtain optimum conditions. A validation test was also performed at optimum conditions, and it was observed that the predicted and measured values were in good agreement. Analysis of variance results displayed that the TRS exerts the greatest influence on the response variables, while the TS and TA exert relatively less influence. Increased TRS values improved joint UTS, IT, and MH while decreasing weld RS magnitude. The TIG + FSP welded joint exhibited an optimized UTS of 277.62 MPa, an IT of 15.82 J, an MH of 124.52 HV, and an RS of 26.89 MPa at a TRS of 1400 rpm, a TS of 50.64 mm/min, and a TA of 1.77 degrees. Electron backscatter diffraction (EBSD) demonstrated that the FZ of TIG joints featured coarse dendritic grain structures, whereas the SZ of TIG + FSP joints possessed ultrafine equiaxed morphology. Pole figures (PFs) exhibited that the fusion region of the TIG joint had notable recrystallization \({\text{A}}_{1}^{*}\)/\({\text{A}}_{2}^{*}\) and A/\(\stackrel{\mathrm{-}}{\text{A}}\) textures, while the stir region of the TIG + FSP joint had significant shear deformation B/\(\overline{\text{B}}\) and C textures.

Similar content being viewed by others

References

X. Wang, S. Mao, P. Chen, Y. Liu, J. Ning, H. Li et al., Evolution of Microstructure and Mechanical Properties of a Dissimilar Aluminium Alloy Weldment, Mater. Des., 2016, 90, p 230–237. https://doi.org/10.1016/j.matdes.2015.10.134

S. Jain and R.S. Mishra, Microstructural and Mechanical Behavior of Micro-Sized SiC Particles Reinforced Friction Stir Processed/Welded AA7075 and AA6061, SILICON, 2022, 14, p 10741–10753. https://doi.org/10.1007/s12633-022-01716-5

M.S. Bin Reyaz and A.N. Sinha, An Experimental Investigation on Mechanical Characteristics and Wear Behaviour of TIG Welded Dissimilar Aluminum Alloys, J. Adhes. Sci. Technol., 2023, 2023, p 1–36. https://doi.org/10.1080/01694243.2023.2251782

J. Luo, S. Liu, M. Paidar, R.V. Vignesh and S. Mehrez, Enhanced Mechanical and Tribological Properties of AA6061/CeO2 Composite Fabricated by Friction Stir Processing, Mater. Lett., 2022, 318, p 132210. https://doi.org/10.1016/j.matlet.2022.132210

S. Liu, M. Paidar, S. Mehrez, O.O. Ojo, I. Mahariq and I. Elbadawy, Development of AA6061/316 Stainless Steel Surface Composites via Friction Stir Processing: Effect of Tool Rotational Speed, Mater Charact, 2022, 192, p 112215. https://doi.org/10.1016/j.matchar.2022.112215

H. Mehdi and R.S. Mishra, Influence of Friction Stir Processing on Weld Temperature Distribution and Mechanical Properties of TIG-Welded Joint of AA6061 and AA7075, Trans. Indian Inst. Met., 2020, 73, p 1773–1788. https://doi.org/10.1007/s12666-020-01994-w

R. Palanivel, P. Koshy Mathews, N. Murugan and I. Dinaharan, Effect of Tool Rotational Speed and Pin Profile on Microstructure and Tensile Strength of Dissimilar Friction Stir Welded AA5083-H111 and AA6351-T6 Aluminum Alloys, Mater. Des., 2012, 40, p 7–16. https://doi.org/10.1016/j.matdes.2012.03.027

N. Shanmuga Sundaram and N. Murugan, Tensile Behavior of Dissimilar Friction Stir Welded Joints of Aluminium Alloys, Mater. Des., 2010, 31, p 4184–4193. https://doi.org/10.1016/j.matdes.2010.04.035

K. Elangovan and V. Balasubramanian, Influences of Tool Pin Profile and Welding Speed on the Formation of Friction Stir Processing Zone in AA2219 Aluminium Alloy, J. Mater. Process. Technol., 2008, 200, p 163–175. https://doi.org/10.1016/j.jmatprotec.2007.09.019

H. Mehdi and R.S. Mishra, An Experimental Analysis and Optimization of Process Parameters of AA6061 and AA7075 Welded Joint by TIG+FSP Welding Using RSM, Adv. Mater. Process. Technol., 2022, 8, p 598–620. https://doi.org/10.1080/2374068X.2020.1829952

N.A. Liyakat and D. Veeman, Improvement of Mechanical and Microstructural Properties of AA 5052–H32 TIG Weldment Using Friction Stir Processing Approach, J. Market. Res., 2022, 19, p 332–344. https://doi.org/10.1016/j.jmrt.2022.05.015

W. Safeen, S. Hussain, A. Wasim, M. Jahanzaib, H. Aziz and H. Abdalla, Predicting the Tensile Strength, Impact Toughness, and Hardness of Friction Stir-Welded AA6061-T6 Using Response Surface Methodology, Int. J. Adv. Manuf. Technol., 2016, 87, p 1765–1781. https://doi.org/10.1007/s00170-016-8565-9

K. Devireddy, V. Devuri, M. Cheepu and K.B. Kranthi, Analysis of the Influence of Friction Stir Processing on Gas Tungsten Arc Welding of 2024 Aluminum Alloy Weld Zone, Int. J. Mech. Prod. Eng. Res. Develop., 2018, 8, p 243–252. https://doi.org/10.24247/ijmperdfeb20182

M.S. Bin Reyaz and A.N. Sinha, Analysis of Mechanical Properties and Optimization of Tungsten Inert Gas Welding Parameters on Dissimilar AA6061-T6 and AA7075-T6 by a Response Surface Methodology-Based Desirability Function Approach, Eng. Optimiz., 2023, 2023, p 1–32. https://doi.org/10.1080/0305215X.2023.2230133

N. Kiaee and M. Aghaie-Khafri, Optimization of Gas Tungsten Arc Welding Process by Response Surface Methodology, Mater. Des., 2014, 54, p 25–31. https://doi.org/10.1016/j.matdes.2013.08.032

A. Equbal, M.I. Equbal and A.K. Sood, An Investigation on the Feasibility of Fused Deposition Modelling Process in EDM Electrode Manufacturing, CIRP J. Manuf. Sci. Technol., 2019, 26, p 10–25. https://doi.org/10.1016/j.cirpj.2019.07.001

D.S. Correia, C.V. Gonçalves, S.S. Da Cunha and V.A. Ferraresi, Comparison Between Genetic Algorithms and Response Surface Methodology in GMAW Welding Optimization, J. Mater. Process. Technol., 2005, 160, p 70–76. https://doi.org/10.1016/j.jmatprotec.2004.04.243

S. Kumar, S. Kumar and A. Kumar, Optimization of Process Parameters for Friction Stir Welding of Joining A6061 and A6082 Alloys by Taguchi Method, Proc. Inst. Mech. Eng. C J. Mech. Eng. Sci., 2013, 227, p 1150–1163. https://doi.org/10.1177/0954406212459448

A. Nait Salah, H. Mehdi, A. Mehmood, A. Wahab Hashmi, C. Malla and R. Kumar, Optimization of Process Parameters of Friction Stir Welded Joints of Dissimilar Aluminum Alloys AA3003 and AA6061 by RSM, Mater. Today Proc., 2022, 56, p 1675–1683. https://doi.org/10.1016/j.matpr.2021.10.288

R.S. Mishra and S. Jain, Parametric Optimization of FSWed Dissimilar Composite Joints of AA7075 and AA6061 Using RSM, Trans. Indian Inst. Met., 2023 https://doi.org/10.1007/s12666-023-02996-0

N. Abdul Hammied Saad and H.D. Abass, Using Friction STIR Process (FSP) to Improve the Properties of AA7020 Aluminum Alloy Weldments Welded by Tungsten Inert Gas (TIG), J. Kerbala Univ., 2015, 11, p 50–60.

C.B. Fuller and M.W. Mahoney, The Effect of Friction Stir Processing on 5083–H321/5356 Al Arc Welds: Microstructural And Mechanical Analysis, Metall. and Mater. Trans. A., 2006, 37, p 3605–3615. https://doi.org/10.1007/s11661-006-1055-1

Ş Kasman, Multi-Response Optimization Using the Taguchi-Based Grey Relational Analysis: A Case Study for Dissimilar Friction Stir Butt Welding of AA6082-T6/AA5754-H111, Int. J. Adv. Manuf. Technol., 2013, 68, p 795–804. https://doi.org/10.1007/s00170-012-4720-0

S. Mabuwa and V. Msomi, The Effect of FSP Conditions Towards Microstructure and Mechanical Properties of the AA6082/AA8011 TIG-Welded Joint, Mater. Res. Express, 2021, 8, p 066514. https://doi.org/10.1088/2053-1591/ac0735

K. Prasad Rao, G.D. Janaki Ram and B.E. Stucker, Effect of Friction Stir Processing on Corrosion Resistance of Aluminum-Copper Alloy Gas Tungsten Arc Welds, Mater. Des., 2010, 31, p 1576–1580. https://doi.org/10.1016/j.matdes.2009.09.029

G.A. Roeen, S.G. Yousefi, R. Emadi, M. Shooshtari and S. Lotfian, Remanufacturing the AA5052 GTAW Welds Using Friction Stir Processing, Metals (Basel), 2021, 11, p 749. https://doi.org/10.3390/met11050749

H. Mehdi and R.S. Mishra, Microstructure and Mechanical Characterization of Tungsten Inert Gas-Welded Joint of AA6061 and AA7075 by Friction Stir Processing, Proc. Institut. Mech. Eng. Part L: J. Mater. Design Appl., 2021, 235, p 2531–2546. https://doi.org/10.1177/14644207211007882

M. Ishak, N.F.M. Noordin and L.H.A. Shah, Feasibility Study on Joining Dissimilar Aluminum Alloys AA6061 and AA7075 by Tungsten Inert Gas (TIG), Jurnal Teknologi, 2015 https://doi.org/10.11113/jt.v75.5177

S.S. Kumar and G. Godwin, An Enhancement of Properties on Al7075 and Al6061 Dissimilar Materials Welded by TIG Process, Int. Res. J. Adv. Sci. Hub, 2020, 2, p 115–121. https://doi.org/10.47392/irjash.2020.47

A.K. Sood, R.K. Ohdar and S.S. Mahapatra, Parametric Appraisal of Mechanical Property of Fused Deposition Modelling Processed Parts, Mater. Des., 2010, 31, p 287–295. https://doi.org/10.1016/j.matdes.2009.06.016

A.H. Jamshidi, Influences of Pin Profile on the Mechanical and Microstructural Behaviors in Dissimilar Friction Stir Welded AA6082-AA7075 Butt Joint, Mater. Des., 2015, 67, p 413–421. https://doi.org/10.1016/j.matdes.2014.11.055

J. Lin, N. Ma, Y. Lei and H. Murakawa, Measurement of residual stress in arc welded lap joints by cosα x-ray diffraction method, J. Mater. Process. Technol., 2017, 243(387), p 394. https://doi.org/10.1016/j.jmatprotec.2016.12.021

R.S. Vidyarthy, D.K. Dwivedi and V. Muthukumaran, Optimization of A-TIG Process Parameters Using Response Surface Methodology, Mater. Manuf. Processes, 2018, 33, p 709–717. https://doi.org/10.1080/10426914.2017.1303154

Y. Koli, N. Yuvaraj and S. Aravindan, Multi-Response Mathematical Model for Optimization of Process Parameters in CMT Welding of dissimilar thickness AA6061-T6 and AA6082-T6 Alloys Using RSM-GRA Coupled with PCA, Adv. Ind. Manuf. Eng., 2021, 2, p 100050. https://doi.org/10.1016/j.aime.2021.100050

H. Mehdi and R.S. Mishra, Effect of Friction Stir Processing on Mechanical Properties and Wear Resistance of Tungsten Inert Gas Welded Joint of Dissimilar Aluminum Alloys, J. Mater. Eng. Perform., 2021, 30, p 1926–1937. https://doi.org/10.1007/s11665-021-05549-y

M. Karthikeyan, Effect of Tool Travel Speed on Tensile Strength of Friction Stir Welded Dissimilar Joint of Aluminium AA6061 T6 Alloy and Maraging M250 Steel, Mater. Res. Express, 2021, 2021(8), p 026502. https://doi.org/10.1088/2053-1591/abde57

C. Rajendran, K. Srinivasan, V. Balasubramanian, H. Balaji and P. Selvaraj, Identifying the Combination of Friction Stir Welding Parameters to Attain Maximum Strength of AA2014-T6 Aluminum Alloy Joints, Adv. Mater. Process. Technol., 2018, 4, p 100–119. https://doi.org/10.1080/2374068X.2017.1410687

M. Shamanian, H. Mostaan, M. Safari and J.A. Szpunar, Friction stir Modification of GTA 7075–T6 Al Alloy Weld Joints: EBSD Study and Microstructural Evolutions, Arch. Civil Mech. Eng., 2017, 17, p 574–585. https://doi.org/10.1016/j.acme.2017.01.002

M. Verma and P. Saha, Effect of Micro-Grooves Featured Tool and Their Depths on Dissimilar Micro-Friction Stir Welding (μFSW) of Aluminum Alloys: A Study of Process Responses and Weld Characteristics, Mater Charact, 2023, 196, p 112614. https://doi.org/10.1016/j.matchar.2022.112614

D. Peng, J. Shen, Q. Tang, C.P. Wu and Y.B. Zhou, Effects of Aging Treatment and Heat Input on the Microstructures and Mechanical Properties of TIG-Welded 6061–T6 Alloy Joints, Int. J. Miner. Metall. Mater., 2013, 20, p 259–265. https://doi.org/10.1007/s12613-013-0721-8

Q. Qin, H. Zhao, J. Li, Y. Zhang, B. Zhang and X. Su, Microstructures and Mechanical Properties of TIG Welded Al-Mg2Si Alloy Joints, J. Manuf. Process., 2020, 56, p 941–949. https://doi.org/10.1016/j.jmapro.2020.05.058

G.A. Roeen, S.G. Yousefi, R. Emadi, M. Shooshtari and S. Lotfian, Remanufacturing the aa5052 gtaw Welds Using Friction Stir Processing, Metals, 2021, 11, p 749. https://doi.org/10.3390/met11050749

A.N. Salah, S. Mabuwa, H. Mehdi, V. Msomi, M. Kaddami and P. Mohapatra, Effect of Multipass FSP on Si-rich TIG Welded Joint of Dissimilar Aluminum Alloys AA8011-H14 and AA5083-H321: EBSD and Microstructural Evolutions, SILICON, 2022, 14, p 9925–9941. https://doi.org/10.1007/s12633-022-01717-4

M. Tariq, I. Khan, G. Hussain and U. Farooq, Microstructure and Micro-Hardness Analysis of Friction Stir Welded bi-Layered Laminated Aluminum Sheets, Int. J. Lightweight Mater. Manuf., 2019, 2, p 123–130. https://doi.org/10.1016/j.ijlmm.2019.04.010

M. Karthikeyan, Effect of Tool Travel Speed on Tensile Strength of Friction Stir Welded Dissimilar Joint of Aluminium AA6061 T6 Alloy and Maraging M250 steel, Mater. Res. Express, 2021, 8, p 026502. https://doi.org/10.1088/2053-1591/abde57

D.K. Dwivedi, Welding Metallurgy: Metallurgical aspect of Metal Joining Processes, Fundamentals of Metal Joining: Processes, Mechanism and Performance. D.K. Dwivedi Ed., Springer Singapore, Singapore, 2022, p 261–272. https://doi.org/10.1007/978-981-16-4819-9_20

D.H. Lee, I.J. Jeong and K.J. Kim, A Desirability Function Method for Optimizing Mean and Variability of Multiple Responses Using a Posterior Preference Articulation Approach, Qual. Reliab. Eng. Int., 2018, 34, p 360–376. https://doi.org/10.1002/qre.2258

M. Bhattacharyya, T. Gnaupel-Herold, K.S. Raja, J. Darsell, S. Jana and I. Charit, Evaluation of Residual Stresses in Isothermal Friction Stir Welded 304L Stainless Steel Plates, Mater. Sci. Eng. A, 2021, 826, p 141982. https://doi.org/10.1016/j.msea.2021.141982

S. Madhavan, M. Kamaraj, L. Vijayaraghavan and R.K. Srinivasa, Microstructure and Mechanical Properties of Aluminium/Steel Dissimilar Weldments: Effect of Heat Input, Mater. Sci. Technol., 2017, 33, p 200–209. https://doi.org/10.1080/02670836.2016.1176716

J.G. Roy and N. Yuvaraj, Effect of Welding Parameters on Mechanical Properties of Cold Metal Transfer Welded Thin AISI 304 Stainless-Steel Sheets, Trans. Indian Inst. Metals, 2021, 74, p 2397–2408. https://doi.org/10.1007/s12666-021-02326-2

T.R. McNelley, S. Swaminathan and J.Q. Su, Recrystallization Mechanisms During Friction Stir Welding/Processing of Aluminum Alloys, Scr. Mater., 2008, 58, p 349–354. https://doi.org/10.1016/j.scriptamat.2007.09.064

S. Li, H. Dong, X. Wang, Z. Liu, Z. Tan, L. Shangguan et al., Effect of Repair Welding on Microstructure and Mechanical Properties of 7N01 Aluminum Alloy MIG Welded Joint, J. Manuf. Process., 2020, 54, p 80–88. https://doi.org/10.1016/j.jmapro.2020.03.009

R.W. Fonda and J.F. Bingert, Texture Variations in an Aluminum Friction Stir Weld, Scr. Mater., 2007, 57, p 1052–1055. https://doi.org/10.1016/j.scriptamat.2007.06.068

M. Raturi and A. Bhattacharya, Microstructure and Texture Correlation of Secondary Heating Assisted Dissimilar Friction Stir Welds of Aluminum Alloys, Mater. Sci. Eng. A, 2021, 825, p 141891. https://doi.org/10.1016/j.msea.2021.141891

A. Garg, M. Raturi, A. Garg and A. Bhattacharya, Microstructure Evolution and Mechanical Properties of Double-Sided Friction Stir Welding Between AA6061-T6 and AA7075-T651, CIRP J. Manuf. Sci. Technol., 2020, 31, p 431–438. https://doi.org/10.1016/j.cirpj.2020.07.005

O.G. Rivera, P.G. Allison, L.N. Brewer, O.L. Rodriguez, J.B. Jordon, T. Liu et al., Influence of Texture and Grain Refinement on the Mechanical Behavior of AA2219 Fabricated by High Shear Solid State Material Deposition, Mater. Sci. Eng. A, 2018, 724, p 547–558. https://doi.org/10.1016/j.msea.2018.03.088

Acknowledgment

The authors would like to thank the OIM & Texture Lab, Indian Institute of Technology, Bombay, for facilitating the EBSD characterization and the Precision Manufacturing Lab, Delhi Technological University, Delhi, for assisting with the residual stress characterization of the welded samples.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no known competing financial interests or personal relationships that could have appeared to influence the work reported in this paper.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Reyaz, M.S.B., Sinha, A.N. Parametric Optimization and Characterization of AA6061-T6 and AA7075-T6 Tungsten Inert Gas Welding Joints Subjected to Friction Stir Processing. J. of Materi Eng and Perform (2024). https://doi.org/10.1007/s11665-023-09111-w

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-023-09111-w