Abstract

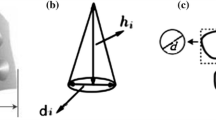

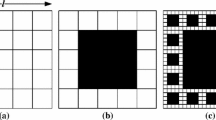

Since the internal structure of actual porous media has irregularity and complexity and is rough on the surface, it cannot be characterized accurately by traditional theoretical analytical methods. In this paper, the mathematical formalism of the effective diffusion coefficient of gas on rough porous surfaces is established by employing fractal geometry theory, utilizing the rough capillary tube bundle model, and introducing the penetration correction factor. The effective gas diffusion coefficient is investigated as a function relation of the rough porous media structural parameters and gas parameters. The results show that the effective diffusion coefficient of gas is positively correlated to the porosity, maximum pore diameter, and area fractal dimension of porous media and negatively correlated to the relative roughness, tortuous fractal dimension, the molar mass of gas, and gas density. The correctness and reliability of the present model have been confirmed, by the comparative analysis of the model predictive values in this paper and the available experimental data.

Similar content being viewed by others

References

A. Zoeir, M. Riazi, Y. Kazemzadeh, and E. Khodapanah, To Optimize Well Pattern During Miscible Gas Injection Process via Heuristic Techniques, J. Pet. Sci. Eng., 2022, 208, p 109786.

M. Zhang, H. Yang, S. Wu, and S. Sun, Parallel multilevel domain decomposition preconditioners for monolithic solution of non-isothermal flow in reservoir simulation, Comput. Fluids, 2022, 232, p 105183.

Z. Ye, T. Ding, X. Zhou, M. Ju, R. Yi, W. Jiang, X. Cui, X. Lin, C. Sun, and J. Sun, Corrosion Behavior of Carbon Steel in Crude Oil–Water–Gas Multiphase Environments with CO2 and H2S, J. Mater. Eng. Perform., 2022, 31, p 7673–7685.

B. Sheikh and T. Qiu, Pore-Scale Simulation and Statistical Investigation of Velocity and Drag Force Distribution Of Flow Through Randomly-Packed Porous Media Under Low and Intermediate Reynolds Numbers, Comput. Fluids, 2018, 171, p 15–28.

X. Zhang, J. Wang, H. Yang, J. Li, Y. Li, and Q. Wu, Formation and Storage Characteristics of CO2 Hydrate in Porous Media: Effect of Liquefaction Amount on the Formation Rate, Accumulation Amount, Appl. Therm. Eng., 2022, 214, p 118747.

Y. Takeuchi, J. Takeuchi, and M. Fujihara, Numerical Investigation of Inertial, Viscous, and Capillary Effects on the Drainage Process in Porous Media, Comput. Fluids, 2022, 237, p 105324.

B. Kabdenova, L.R. Rojas-Solórzano, and E. Monaco, Lattice Boltzmann Simulation of Near/Supercritical CO2 Flow Featuring a Crossover Formulation of the Equation of State, Comput. Fluids, 2021, 216, p 104820.

Y. Zhang, Y. Tao, H. Ren, M. Wu, G. Li, Z. Wan, and J. Shao, A Metallic Gas Diffusion Layer and Porous Media Flow Field for Proton Exchange Membrane Fuel Cells, J. Power Sources, 2022, 543, p 231847.

M. Peng, L. Chen, R. Zhang, W. Xu, and W.Q. Tao, Improvement of Thermal and Water Management of Air-Cooled Polymer Electrolyte Membrane Fuel Cells by Adding Porous Media into the Cathode Gas Channel, Electrochim. Acta, 2022, 412, p 140154.

G. Kolb, V. Hessel, V. Cominos, H. Pennemann, J. Schürer, R. Zapf, and H. Löwe, Microstructured Fuel Processors for Fuel-Cell Application, J. Mater. Eng. Perform., 2006, 15, p 389–393.

B.K. Chang and B.J. Tatarchuk, Microfibrous Entrapment of Small Catalyst Particulates for High Contacting Efficiency Removal of Trace CO from Practical Reformates for PEM H2–O2 Fuel Cells, J. Mater. Eng. Perform., 2006, 15, p 453–456.

M. Liang, Y. Liu, B. Xiao, S. Yang, Z. Wang, and H. Han, An Analytical Model for the Transverse Permeability of Gas Diffusion Layer with Electrical Double Layer Effects in Proton Exchange Membrane Fuel Cells, Int. J. Hydrog. Energy, 2018, 43, p 17880–17888.

B. Xiao, H. Zhu, F. Chen, G. Long, and Y. Li, A Fractal Analytical Model for Kozeny-Carman Constant and Permeability of Roughened Porous Media Composed of Particles and Converging-Diverging Capillaries, Powder Technol., 2023, 420, p 118256.

Y. Zhang, B. Xiao, B. Tu, G. Zhang, Y. Wang, and G. Long, Fractal Analysis for Thermal Conductivity of Dual Porous Media Embedded with Asymmetric Tree-Like Bifurcation Networks, Fractals, 2023, 31, p 2350046.

J. Gao, B. Xiao, B. Tu, F. Chen, and Y.H. Liu, A Fractal Model for Gas Diffusion in Dry and Wet Fibrous Media with Tortuous Converging-Diverging Capillary Bundle, Fractals, 2022, 30, p 2250176.

Q. Zheng, J. Fan, and C. Xu, Fractal Model of Gas Diffusion Through Porous Fibrous Materials with Rough Surfaces, Fractals, 2018, 26(05), p 1850065.

J.A. Currie, Gaseous Diffusion in Porous Media. Part 2.-Dry Granular Materials, Br. J. Appl. Phys., 1960, 11(8), p 318–324.

S. Roy, R. Raju, H.F. Chuang, B.A. Cruden, and M. Meyyappan, Modeling Gas Flow Through Microchannels and Nanopores, J. Appl. Phys., 2003, 93(8), p 4870–4879.

H. Sheikha, M. Pooladi-Darvish, and A.K. Mehrotra, Development of Graphical Methods for Estimating the Diffusivity Coefficient of Gases in Bitumen from Pressure-Decay Data, Energy Fuels, 2005, 19(5), p 2041–2049.

X. He, Y. Guo, M. Li, N. Pan, and M. Wang, Effective Gas Diffusion Coefficient in Fibrous Materials by Mesoscopic Modeling, Int. J. Heat Mass Transf., 2017, 107, p 736–746.

T. Zhao, H. Zhao, Z. Ning, X. Li, and Q. Wang, Permeability Prediction of Numerical Reconstructed Multiscale Tight Porous Media Using the Representative Elementary Volume SCALE LATTICE BOLTZMANN METHOD, Int. J. Heat Mass Transf., 2018, 118, p 368–377.

L.P. Wang and B. Afsharpoya, Modeling Fluid Flow in Fuel Cells Using the Lattice-Boltzmann Approach, Math. Comput. Simul., 2006, 72(2–6), p 242–248.

B. Yu, M. Zou, and Y. Feng, Permeability of Fractal Porous Media by Monte Carlo Simulations, Int. J. Heat Mass Transf., 2005, 48(13), p 787–2794.

Q. Zheng, B. Yu, S. Wang, and L. Luo, A Diffusivity Model for Gas Diffusion Through Fractal Porous Media, Chem. Eng. Sci., 2012, 68(1), p 650–655.

J. Cai, X. Hu, B. Xiao, Y. Zhou, and W. Wei, Recent Developments on Fractal-Based Approaches to Nanofluids and Nanoparticle Aggregation, Int. J. Heat Mass Transf., 2017, 105, p 623–637.

M. Liang, C. Fu, B. Xiao, L. Luo, and Z. Wang, A Fractal Study for the Effective Electrolyte Diffusion Through Charged Porous Media, Int. J. Heat Mass Transf., 2019, 137, p 365–371.

S. Mao, A. Kan, Z. Huang, and W. Zhu, Prediction of Thermal Performance of Vacuum Insulation Panels (VIPs) with Micro-Fiber Core Materials, Mater. Today Commun., 2020, 22, p 100786.

B. Yu and P. Cheng, A Fractal Permeability Model for bi-Dispersed Porous Media, Int. J. Heat Mass Transf., 2002, 45(14), p 2983–2993.

P. Xu, A Discussion on Fractal Models for Transport Physics of Porous Media, Fractals, 2015, 23(03), p 1530001.

B. Xiao, H. Yan, S. Xiao, W. Ren, J. Fan, and Z. Pan, An Analytical Model for Gas Diffusion Through Fractal Nanofibers in Complex Resources, J. Nat. Gas Sci. Eng., 2016, 33, p 1324–1329.

A. Das, R.P. Yadav, V. Chawla, S. Kumar, Ş Ţălu, E.P. Pinto, and R.S. Matos, Analyzing the Surface Dynamics of Titanium Thin Films Using Fractal and Multifractal Geometry, Mater. Today Commun., 2021, 27, p 102385.

S. Yang, M. Wang, S. Zheng, S. Zeng, and L. Gao, Fractal Permeability Model of Newtonian Fluids in Rough Fractured Dual Porous Media, Mater., 2022, 15(13), p 4662.

B. Yu, Analysis of Flow in Fractal Porous Media, ASME Appl. Mech. Rev., 2008, 61(5), p 050801.

L.Z. Zhang, A Fractal Model for Gas Permeation Through Porous Membranes, Int. J. Heat Mass Transf., 2008, 51(21–22), p 5288–5295.

C. Li, P. Xu, S. Qiu, and Y. Zhou, The Gas Effective Permeability of Porous Media with Klinkenberg Effect, J. Nat. Gas Sci. Eng., 2016, 34, p 534–540.

C. Wang, S. Zhang, and J. Xu, Fractal Model of Effective Gas Diffusion Coefficient Based on Permeability Correction Factor, Lithol. Reserv., 2021, 33, p 162–168. (in Chinese)

A. Majumdar and B. Bhushan, Fractal Model of Elastic-Plastic Contact Between Rough Surfaces, ASME. J. Tribol., 1991, 113, p 1–11.

B. Xiao, Y. Liu, H. Chen, X. Chen, and G. Long, A Novel Fractal Solution for Laminar Flow Resistance in Roughened Cylindrical Microchannels, Fractals, 2020, 28(06), p 2050097.

B. Yu and J. Li, Some Fractal Characters of Porous Media, Fractals, 2001, 9(03), p 365–372.

Y. Feng, B. Yu, M. Zou, and D. Zhang, A Generalized Model for the Effective Thermal Conductivity of Porous Media Based on Self-similarity, J. Phys. D Appl. Phys., 2004, 37(21), p 3030.

B. Xiao, W. Wang, X. Zhang, G. Long, J. Fan, H. Chen, and L. Deng, A Novel Fractal Solution for Permeability and Kozeny-Carman Constant of Fibrous Porous Media Made up of Solid Particles and Porous Fibers, Powder Technol., 2019, 349, p 92–98.

B. Xiao, S. Wang, Y. Wang, G. Jiang, Y. Zhang, and H. Chen, Effective Thermal Conductivity of Porous Media with Roughened Surfaces by Fractal-Monte Carlo Simulations, Fractals, 2020, 28(02), p 2050029.

W. Wei, J. Cai, J. Xiao, Q. Meng, B. Xiao, and Q. Han, Kozeny-Carman Constant of Porous Media: Insights from Fractal-Capillary Imbibition Theory, Fuel, 2018, 234, p 1373–1379.

P. Xu and B. Yu, Developing a New Form of Permeability and Kozeny-Carman Constant for Homogeneous Porous Media by Means of Fractal Geometry, Adv. Water Resour., 2008, 31(1), p 74–81.

M. Yun, B. Yu, and J. Cai, Analysis of Seepage Characters in Fractal Porous Media, Int. J. Heat Mass Transf., 2009, 52(13–14), p 3272–3278.

B. Yu and J. Li, A Geometry Model for Tortuosity of Flow Path in Porous Media, Chin. Phys. Lett., 2004, 21(8), p 1569.

J. Comiti and M. Renaud, A New Model for Determining Mean Structure Parameters of Fixed Beds from Pressure Drop Measurements: Application to Beds Packed with Parallelepipedal Particles, Chem. Eng. Sci., 1989, 44(7), p 1539–1545.

B. Xiao, Y. Zhang, Y. Wang, W. Wang, H. Chen, X. Chen, and G. Long, An Investigation on Effective Thermal Conductivity of Unsaturated Fractal Porous Media with Roughened Surfaces, Fractals, 2020, 28(05), p 2050080.

A. Beskok and G.E. Karniadakis, Report: A Model for Flows in Channels, Pipes, and Ducts at Micro and Nano Scales, Microscale Thermophys. Eng., 1999, 3(1), p 43–77.

S. Yang, B. Yu, M. Zou, and M. Liang, A Fractal Analysis of Laminar Flow Resistance in Roughened Microchannels, Int. J. Heat Mass Transf., 2014, 77, p 208–217.

S. Yang, M. Liang, B. Yu, and M. Zou, Permeability Model for Fractal Porous Media with Rough Surfaces, Microfluid Nanofluid, 2015, 18, p 1085–1093.

B. Xiao, Q. Huang, H. Chen, X. Chen, and G. Long, A Fractal Model for Capillary Flow Through a Single Tortuous Capillary with Roughened Surfaces in Fibrous Porous Media, Fractals, 2021, 29(01), p 2150017.

Acknowledgments

This study was supported by the National Natural Science Foundation of China (Grant Nos. 51641606) and the Key Project of Science and Technology Research Program of Hubei Provincial Education Department (Grant No. D20221201).

Author information

Authors and Affiliations

Corresponding authors

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, X., Yang, S., Zheng, S. et al. Fractal Study on the Effective Diffusion Coefficient of Gases in Rough Porous Media. J. of Materi Eng and Perform (2023). https://doi.org/10.1007/s11665-023-08731-6

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-023-08731-6