Abstract

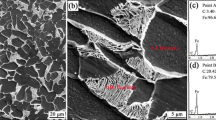

In this study, the corrosion behavior of carbon steel in crude oil–water–CO2/H2S multiphase environments simulating the service conditions of a production well and ground gathering pipeline of a carbonate oilfield was explored by weight loss tests and surface analysis techniques. The results show that the presence of crude oil significantly reduces the corrosion rate of 80SS casing and L245 pipeline steels, but it favors the occurrence of localized corrosion at middle-high water cuts. The corrosion of 80SS steel with the variation in the water cut obeys a similar pattern under different environmental conditions. When the water cut is higher than 50%, the corrosion rate obviously enhanced, and the corrosion form changes from uniform corrosion to localized corrosion due to the inhomogeneous wetting of crude oil and water under the test conditions. Benefiting from the synergistic corrosion inhibition of crude oil and a protective sulfur-rich film, the steel demonstrates a relatively low corrosion rate at a high water cut of 80%, however, this is higher than that at middle-low water cuts.

Similar content being viewed by others

Data Availability

The raw/processed data required to reproduce these findings cannot be shared at this time due to technical and time limitations. Concurrently, the data also form part of an ongoing study.

References

P. Bai, H. Zhao, S. Zheng and C. Chen, Initiation and Developmental Stages of Steel Corrosion in Wet H2S Environments, Corros. Sci., 2015, 93, p 109–119.

J. Li, C. Sun, S. Shuang, M. Roostaei, V. Fattahpour, M. Mahmoudi, H. Zeng and J.-L. Luo, Investigation on the Flow-Induced Corrosion and Degradation Behavior of Underground J55 Pipe in a Water Production Well in the Athabasca Oil Sands Reservoir, J. Petrol. Sci. Eng., 2019, 148, p 106325.

R. Elgaddafi, R. Ahmed and S. Shah, Modeling and Experimental Studies on CO2-H2S Corrosion of API Carbon Steels Under High-Pressure, J. Petrol. Sci. Eng., 2017, 156, p 682–696.

R.C. Souza, B.A.F. Santos, M.C. Goncalves, E.P. Mendes Junior, T.A. Simoes, J.R. Oliveira, G.L. Vaz, L. Caldeira, J.A.C.P. Gomes and A.H. Bueno, The Role of Temperature and H2S (thiosulfate) on the Corrosion Products of API X65 Carbon Steel Exposed to Sweet Environment, J. Petrol. Sci. Eng., 2019, 180, p 78–88.

D.-H. Xia, S. Song, Y. Behnamian, W. Hu, Y.F. Cheng, J.-L. Luo and F. Huet, Review-Electrochemical Noise Applied in Corrosion Science: Theoretical and Mathematical Models Towards Quantitative Analysis, J. Electrochem. Soc., 2020, 167, p 081507.

D.-H. Xia, S. Song, L. Tao, Z. Qin, Z. Wu, Z. Gao, J. Wang, W. Hu, Y. Behnamian and J.-L. Luo, Review-Material Degradation Assessed by Digital Image Processing: Fundamentals, Progresses, and Challenges, J. Mater. Sci. Technol., 2020, 53, p 146–162.

P.C. Okonkwo, R.A. Shakoor, A. Benamor, A.M.A. Mohamed and M.J.F.A. Al-Marri, Corrosion Behavior of API X100 Steel Material in a Hydrogen Sulfide Environment, Metals, 2017, 7, p 109.

Z. Liu, X. Gao, L. Du, J. Li, P. Li, C. Yu, R.D.K. Misra and Y. Wang, Comparison of Corrosion Behavior of Low-Alloy Pipeline Steel Exposed to H2S/CO2-Saturated Brine and Vapor-Saturated H2S/CO2 Environments, Electrochim. Acta, 2017, 232, p 528–541.

L. Wei, X. Pang and K. Gao, Effect of Small Amount of H2S on the Corrosion Behavior of Carbon Steel in the Dynamic Supercritical CO2 Environments, Corros. Sci., 2016, 103, p 132–144.

C. Yu, X. Gao and H. Wang, Corrosion Characteristics of Low Alloy Steel Under H2S/CO2 Environment: Experimental Analysis and Theoretical Research, Mater. Lett., 2017, 209, p 459–462.

F.F. Eliyan, F. Mohammadi and A. Alfantazi, An Electrochemical Investigation on the Effect of the Chloride Content on CO2 Corrosion of API-X100 Steel, Corros. Sci., 2012, 64, p 37–43.

H.-Q. Fan, D.-D. Shi, M.-M. Ding, M.-C. Li, Y.F. Cheng and Q. Li, Preparation of (3-Mercaptopropyl) Trimethoxylsilane Film on Brass and Its Corrosion Resistance in Natural Seawater, Prog. Org. Coat., 2020, 138, p 105392.

S. Gao, B. Brown, D. Young and M. Singer, Formation of Iron Oxide and Iron Sulfide at High Temperature and Their Effects on Corrosion, Corros. Sci., 2018, 135, p 167–176.

S. Navabzadeh, W. Zhang, B. Brown, M. Singer and S. Nesic, Localized Corrosion of Mild Steel in Marginally Sour Environments, Corrosion, 2017, 73, p 1097–1106.

P. Sui, J. Sun, Y. Hua, H. Liu, M. Zhou, Y. Zhang, J. Liu and Y. Wang, Effect of Temperature and Pressure on Corrosion Behavior of X65 Carbon Steel in Water-Saturated CO2 Transport Environments Mixed with H2S, Int. J. Greenh. Gas Control, 2018, 73, p 60–69.

J. Tang, Y. Shao, J. Guo, T. Zhang, G. Meng and F. Wang, The Effect of H2S Concentration on the Corrosion Behavior of Carbon Steel at 90 °C, Corros. Sci., 2010, 52, p 2050–2058.

B. Sun, Z. Liu, Y. He, F. Gao and X. Li, A New Study for Healing Pitting Defects of 316L Stainless Steel Based on Microarc Technology, Corros. Sci., 2021, 187, p 109505.

L. Wei, X. Pang and K. Gao, Effect of Flow Rate on Localized Corrosion of X70 steel in Supercritical CO2 Environments, Corros. Sci., 2018, 136, p 339–351.

A. Benamor, A.G. Talkman, M. Nasser, I. Hussein and P.C. Okonkwo, Effect of Temperature and Fluid Speed on the Corrosion Behavior of Carbon Steel Pipeline in Qatari Oilfield Produced Water, J. Electroanal. Chem., 2018, 808, p 218–227.

P.C. Okonkwo, M.H. Sliem, R.A. Shakoor, A.M.A. Mohamed and A.M. Abdullah, Effect of Temperature on the Corrosion Behavior of API X120 Pipeline Steel in H2S Environment, J. Mater. Eng. Perform., 2017, 26, p 3775–3783.

Y. Cheng, Y. Bai, Z. Li and J.G. Liu, The Corrosion Behavior of X65 steel in CO2/Oil/Water Environment of Gathering Pipeline, Anti-Corros. Method. M., 2019, 66, p 174–187.

Z.M. Wang and J. Zhang, Corrosion of Multiphase Flow Pipelines: the Impact of Crude Oil, Corros. Rev., 2016, 34, p 17–40.

Y. Cheng, Z. Li, Y. Zhao, Y. Xu, Q. Liu and Y. Bai, Effect of Main Controlling Factor on the Corrosion Behavior of API X65 Pipeline Steel in the CO2/Oil/Water Environment, Anti-Corros. Method. M., 2017, 64, p 371–379.

M.N. Zafar, R. Rihan and L. Al-Hadhrami, Evaluation of the Corrosion Resistance of SA-543 and X65 Steels in Emulsions Containing H2S and CO2 Using a Novel Emulsion Flow Loop, Corros. Sci., 2015, 94, p 275–287.

M.N. Zafar, R. Rihan and L. Al-Hadhrami, Effect of H2S and CO2 in Oil/Water Emulsions on the Corrosion Resistance of SA-543 Steel, J. Mater. Eng. Perform., 2015, 24, p 683–693.

C. Sun, J. Sun, Y. Wang, S. Wang and J. Liu, Corrosion Mechanism of OCTG Carbon Steel in Supercritical CO2/Oil/Water System, Acta Metall. Sin., 2014, 50, p 811–820.

J. Sun, C. Sun, G. Zhang, W. Zhao and Y. Wang, Effect of Water Cut on the Localized Corrosion Behavior of P100 Tube Steel in Supercritical CO2/Oil/Water Environment, Corrosion, 2016, 72, p 1470–1482.

L. Wei, X. Pang, and K. Gao, Effects of Crude Oil on Corrosion Behavior of Pipeline Steel Under Wet CO2 Condition, paper no. 3846, NACE, Houston, TX, 2014

F. Ayello, W. Robbins, S. Richter, S. Nesic, Crude Oil Chemistry Effects on Inhibition of Corrosion and Phase Wetting. paper no. 11060, NACE, Houston, TX, 2011

B.D. Craig, Corrosion in Oil/Water Systems, Mater. Perform., 1996, 35, p 61–62.

K.D. Efird, Predicting Corrosion of Steel in Crude Oil Production, Mater. Perform., 1991, 30, p 63–66.

K.D. Efird, Oil Characteristics, Water/Oil Wetting and Flow Influence on the Metal Loss Corrosion – Part II: Chemistry, Wettability and Experimental Evaluation, Paper No. 06114, NACE, Houston, TX, 2006

K.E. Kee, S. Richter, M. Babic and S. Nesic, Experimental Study of Oil-Water Flow Patterns in a Large Diameter Flow Loop—The Effects on Water Wetting and Corrosion, Corrosion, 2016, 72, p 569–582.

U. Lotz, L. Bodegom and C. Ouwehand, Problems of Corrosion in Multiphase Flows-Influence of Flow on Corrosion, Corrosion, 1991, 44, p 155–158.

Z.L. Wang, J. Zhang, Z.M. Wang, L. Zhou, X. Han, Q.F. Li and S. Gao, Emulsification Reducing the Corrosion Risk of Mild Steel in Oil–Brine Mixtures, Corros. Sci., 2014, 86, p 310–317.

Z.M. Wang, Q.Y. Liu, J. Wang, X. Han, W. Zhu, J. Zhang and G.-L. Song, Corrosion Mitigation Behavior of an Alternately Wetted Steel Electrode in Oil/Water Media, Corros. Sci., 2019, 152, p 140–152.

G.A. Zhang and Y.F. Cheng, Corrosion of X65 Steel in CO2-Saturated Oilfield Formation Water in the Absence and Presence of Acetic Acid, Corros. Sci., 2009, 51, p 1589–1595.

M. Castillo, H. Rincon, S. Duplat, J.R. Vera, and E. Baron, Protective Properties of Crude Oils in CO2 and H2S Corrosion, Paper No. 00005, NACE, Houston, TX, 2000

D.-P. Li, L. Zhang, J.-W. Yang, M.-X. Lu, J.-H. Ding and M.-L. Liu, Effect of H2S Concentration on the Corrosion Behavior of Pipeline Steel Under the Coexistence of H2S and CO2, Int. J. Miner. Metall. Mater., 2014, 21, p 388–394.

P.R.P. Viana, F.V.V. Sousa, O.E. Barcia, B. Tribollet and O.R. Mattos, Hydrogen Reaction Analysis in Aqueous Solutions Containing H2S/CO2 at Different Pressures, Corros. Sci., 2020, 2020(176), p 108938.

ASTM Standard G1–03, Standard Practice for Preparing, Cleaning, and Evaluating Corrosion Test Specimens, ASTM International, West Conshohocken, PA, 2011

ASTM Standard G46-94, Standard Guide for Examination and Evaluation of Pitting Corrosion, ASTM International, West Conshohocken, PA, 2005

NACE Standard RP0775-2005, Standard Recommended Practice: Preparation, Installation, Analysis, and Interpretation of Corrosion Coupons in Oilfield Operations, 2005

G.X. Zhao, Physical Chemistry of Surfactants, 2nd ed. Peking University Press, Beijing, 1991.

M. Foss, E. Gulbrandsen and J. Sjöblom, Effect of Corrosion Inhibitors and Oil on Carbon Dioxide Corrosion and Wetting of Carbon Steel with Ferrous Carbonate Deposits, Corrosion, 2009, 65, p 1–14.

J. Banaś, U. Lelek-Borkowska, B. Mazurkiewicz and W. Solarski, Effect of CO2 and H2S on the Composition and Stability of Passive Film on Iron Alloys in Geothermal Water, Electrochim. Acta, 2007, 52, p 5704–5714.

P. Marcus, Corrosion Mechanisms in Theory and Practice, 3rd ed. CRC Press, Boca Raton, 2012.

C. Sun, J. Liu, J. Sun, X. Lin and Y. Wang, Probing the Initial Corrosion Behavior of X65 Steel in CCUS-EOR Environments with Impure Supercritical CO2 Fluids, Corros. Sci., 2021, 189, p 109585.

M. Ueda, Effect of Alloying Elements and Microstructure on Stability of Corrosion Product in CO2 and/or H2S Environments, Chem. Eng. Oil Gas, 2005, 34, p 43–52.

J. Cai, S. Nesic, and C. De Waard, Modeling of Water Wetting in Oil–Water Pipe Flow, Paper No. 04663, NACE, Houston, TX, 2004

S. Nesic, Key Issues Related to Modelling of Internal Corrosion of Oil and Gas Pipelines—A Review, Corros. Sci., 2007, 49, p 4308–4338.

M. Stroe, N. Passade-Boupat, M. Bonis, B. Admas, Inhibitive Properties of Crude Oils: Can We Count on Them? Paper No. 11061, NACE, Houston, TX, 2011

Acknowledgments

This work is supported by the National Science and Technology Major Project of China (No. 2016ZX05016-004) and the Fundamental Research Funds for the Central Universities (No. 20CX06075A).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

About this article

Cite this article

Ye, Z., Ding, T., Zhou, X. et al. Corrosion Behavior of Carbon Steel in Crude Oil–Water–Gas Multiphase Environments with CO2 and H2S. J. of Materi Eng and Perform 31, 7673–7685 (2022). https://doi.org/10.1007/s11665-022-06790-9

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-022-06790-9