Abstract

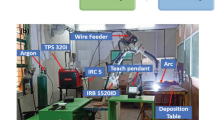

Laser shock peening (LSP) is a novel non-contact surface modification technique to enhance the corrosion and compression behavior of stainless steel 308L (SS308L) material for a cryogenic application. SS308L is commonly used as a weld filler, weld electrode and cryogenic environment due to its low carbon content and good mechanical and high corrosion resistance properties. In this present study, wire-arc additive manufacturing (WAAM) has been utilized to manufactured SS308L material and studied the compression, corrosion, wettability and surface properties of the material. Further, the nanosecond laser shock peening has been utilized to modify the additive-manufactured SS308L surface and mechanical properties. From the experimental results, it has been observed that the uni-directional flow path (UDFP) deposition has better corrosion resistance wettability and surface finish than the bi-directional flow path (BDFP) deposition on wire-arc additive-manufactured SS308L material due to its more uniform microstructure and smoother surface finish. In addition, the post-processing treatment (LSP) of SS308L materials has improved the compressive strength of additive-manufactured SS308L material with 20.6 and 15.9% as compared to UDFP and BDFP due to grain surface refinement and increases in dislocation density. The corrosion rate of LSP-treated materials was reduced by 20.7% compared to the UDFP materials due to the higher corrosion potential and lower corrosion current density. The higher surface roughness has produced better passive film formation to enhanced corrosion resistance in the UDFP with LSP. Finally, the microstructure and chemical composition have been analyzed using scanning electron microscope and energy-dispersive x-ray spectroscopy.

Graphical Abstract

Similar content being viewed by others

Change history

09 November 2023

A Correction to this paper has been published: https://doi.org/10.1007/s11665-023-08921-2

Abbreviations

- GMAW:

-

Gas metal arc welding

- WAAM:

-

Wire-arc additive manufacturing

- LSP:

-

Laser shock peening

- SS308L:

-

Stainless steel 308L

- UDFP:

-

Uni-directional flow path

- BDFP:

-

Bi-directional flow path

- Icorr:

-

Corrosion current

- Ecorr:

-

Corrosion potential

- W-EDM:

-

Wire-cut electrical discharge machining

- OM:

-

Optical microscope

- SEM:

-

Scanning electron microscope

- FESEM:

-

Field emission scanning electron microscope

- EDX/EDS:

-

Energy-dispersive x-ray spectroscopy

References

S.W. Williams, F. Martina, A.C. Addison, J. Ding, G. Pardal, and P. Colegrove, Wire + Arc Additive Manufacturing, Mater. Sci. Technol., 2016, 32(7), p 641–647.

T.E. Abioye, A. Medrano-Tellez, P.K. Farayibi, and P.K. Oke, Laser Metal Deposition of Multi-Track Walls of 308LSi Stainless Steel, Mater. Manuf. Process., 2017, 32(14), p 1660–1666.

Y. Ke and J. Xiong, Microstructure and Mechanical Properties of Double-Wire Feed GTA Additive Manufactured 308L Stainless Steel, Rapid Prototyp. J., 2020, 26(9), p 1503–1513.

Y. Yehorov, L.J. da Silva, and A. Scotti, Exploring the Use of Switchback for Mitigating Homoepitaxial Unidirectional Grain Growth and Porosity in WAAM of Aluminium Alloys, Int. J. Adv. Manuf. Technol., 2019, 104(1-4), p 1581–1592.

D. Ding, Z. Pan, D. Cuiuri, and H. Li, A Tool-Path Generation Strategy for Wire and Arc Additive Manufacturing, Int. J. Adv. Manuf. Technol., 2014, 73(1-4), p 173–183.

M. Abbaszadeh, V. Ventzke, L. Neto, S. Riekehr, F. Martina, N. Kashaev, J. Hönnige, S. Williams, and B. Klusemann, Compression Behaviour of Wire + Arc Additive Manufactured Structures, Metals (Basel), 2021, 11(6), p 877.

M.P. Sealy, H. Hadidi, L.D. Sotelo, W.L. Li, J.A. Turner, and J.A. McGeough, Compressive Behavior of 420 Stainless Steel After Asynchronous Laser Processing, CIRP Ann., 2020, 69(1), p 169–172.

E. Sert, L. Hitzler, S. Hafenstein, M. Merkel, E. Werner, and A. Öchsner, Tensile and Compressive Behaviour of Additively Manufactured AlSi10Mg Samples, Progr. Addit. Manuf, 2020, 5(3), p 305–313.

G. Ko, W. Kim, K. Kwon, and T.K. Lee, The Corrosion of Stainless Steel Made by Additive Manufacturing: A Review, Metals, 2021 https://doi.org/10.3390/met11030516

A. Hemmasian Ettefagh, S. Guo, and J. Raush, Corrosion Performance of Additively Manufactured Stainless Steel Parts: A Review, Addit. Manuf., 2021 https://doi.org/10.1016/j.addma.2020.101689

M.V. Popa, E. Vasilescu, P. Drob, C. Vasilescu, J. Mirza-Rosca, and A.S. Lopez, Corrosion Behavior of Some Titanium Base Alloys in Acid Solutions, Mater. Manuf. Process., 2005, 20(1), p 35–45.

E.R. Moldovan, C.C. Doria, J.L. Ocaña, L.S. Baltes, E.M. Stanciu, C. Croitoru, A. Pascu, I.C. Roata, and M.H. Tierean, Wettability and Surface Roughness Analysis of Laser Surface Texturing of AISI 430 Stainless Steel, Materials, 2022, 15(8), p 2955.

D.H. Kam, S. Bhattacharya, and J. Mazumder, Control of the Wetting Properties of an AISI 316L Stainless Steel Surface by Femtosecond Laser-Induced Surface Modification, J. Micromech Microeng, 2012, 22(10), p 105019.

D. Karthik and S. Swaroop, Laser Peening Without Coating—An Advanced Surface Treatment: A Review, Mater. Manuf. Process., 2017, 32(14), p 1565–1572.

V.T. Le, D.S. Mai, T.K. Doan, and H. Paris, Wire and Arc Additive Manufacturing of 308L Stainless Steel Components: Optimization of Processing Parameters and Material Properties, Eng Sci Technol Int J, 2021, 24(4), p 1015–1026.

C. Sudha, P. Parameswaran, R. Krishnan, S. Dash, and M. Vijayalakshmi, Effect of Laser Shock Processing on the Microstructure of 304(L) Austenitic Stainless Steel, Mater. Manuf. Processes, 2010, 25(9), p 956–964.

S. Qu, C.X. Huang, Y.L. Gao, G. Yang, S.D. Wu, Q.S. Zang, and Z.F. Zhang, Tensile and Compressive Properties of AISI 304L Stainless Steel Subjected to Equal Channel Angular Pressing, Mater. Sci. Eng., A, 2008, 475(1–2), p 207–216.

S. Singh, A.N. Jinoop, G.T.A. Tarun Kumar, I.A. Palani, C.P. Paul, and K.G. Prashanth, Effect of Interlayer Delay on the Microstructure and Mechanical Properties of Wire Arc Additive Manufactured Wall Structures, Materials, 2021, 14(15), p 4187.

C. Zhou, J. Wang, S. Hu, H. Tao, B. Fang, L. Li, J. Zheng, and L. Zhan, Enhanced Corrosion Resistance of Additively Manufactured 316L Stainless Steel After Heat Treatment, J. Electrochem. Soc., 2020, 167(14), p 141504.

J.R. Trelewicz, G.P. Halada, O.K. Donaldson, and G. Manogharan, Microstructure and Corrosion Resistance of Laser Additively Manufactured 316L Stainless Steel, JOM, Miner. Metals Mater. Soci., 2016, 68(3), p 850–859.

Y.R. Yoo, S.H. Choi, and Y.S. Kim, Effect of Laser Peening on the Corrosion Properties of 304L Stainless Steel, Materials, 2023, 16(2), p 804.

M.A. Attolico, C. Barile, C. Casavola, V. Moramarco, D. Furfari, and D.O. Busse, Effects of Laser Shock Peening on Surface Roughness and Residual Stress of AA 7050–T7451, J. Mater. Eng. Perform., 2022, 31(10), p 7973–7988.

A. Žemaitis, A. Mimidis, A. Papadopoulos, P. Gečys, G. Račiukaitis, E. Stratakis, and M. Gedvilas, Controlling the Wettability of Stainless Steel from Highly-Hydrophilic to Super-Hydrophobic by Femtosecond Laser-Induced Ripples and Nanospikes, RSC Adv., 2020, 10(62), p 37956–37961.

K. Praveenkumar, S. Swaroop, and G. Manivasagam, Residual Stress Distribution Phase Transformation, and Wettability Characteristics of Laser Peened Austenitic Stainless Steel, J. Mater. Eng. Perform, 2022, 31(8), p 6846–6857.

X. Ren, C. Yu, and W. Zhang, The Microstructure and Mechanical Properties of 308L Alloy Fabricated by Micro-Plasma Arc Additive Manufacturing, J. Phys. Conf. Series, 2019 https://doi.org/10.1088/1742-6596/1347/1/012070

M. Raja, Y. Tiwari, M. Mukherjee, B. Maji, and A. Chatterjee, Effect of Bidirectional and Switchback Deposition Strategies on Microstructure and Mechanical Properties of Wire Arc Additive Manufactured Inconel 625, Int. J. Adv. Manuf. Technol, 2022, 119(7–8), p 4845–4861.

Acknowledgments

The authors thank SERB (PDF/2021/002326) for funding or providing financial support for carrying out the research work under the National-Post Doctoral Fellowship scheme. We also thank the sophisticated instrumentation center of IIT Indore for their continuous support in providing characterization facilities. The authors gratefully acknowledge the characterization facilities provided by the Department of Metallurgy Engineering and Materials Science, IIT Indore.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

The authors declare that they have no conflict of interest.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

The original online version of this article was revised: In the originally published PDF version of the article, the list of author affiliations was incomplete and has now been corrected.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Geethapriyan, T., Palani, I.A., Singh, M.K. et al. Post-processing of Wire Arc Additive Manufactured Stainless Steel 308L to Enhance Compression and Corrosion Behavior using Laser Shock Peening Process. J. of Materi Eng and Perform (2023). https://doi.org/10.1007/s11665-023-08592-z

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-023-08592-z