Abstract

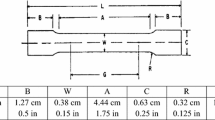

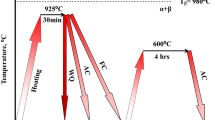

The Ti-6Al-4 V alloy emphasizes its suitability for application in the chemical, aerospace, and automotive industries due to its exceptional mechanical, physical, and chemical qualities. However, the poor tribological properties of these alloys make them unsuitable for interacting environments where wear and friction are encountered. Consequently, this study was conducted to evaluate the impact of thermal treatment settings to tailor the mechanical and tribological properties of Ti-6Al-4 V alloys using duplex heat treatment. The Ti-6Al-4 V alloy was heat treated for 10 to 30 min at a solution temperature of 850 to 913 °C, followed by 60 to 120 min of ageing at a temperature of 450 to 550 °C. The impacts of heat treatment parameters on modifications in microstructure and mechanical characteristics like hardness, tensile properties, impact strength, and wear resistance have been investigated. According to the findings, the mechanical qualities have significantly improved. The impact fracture toughness of the as-received samples is around 36% lower than the heat-treated alloy in the SAT2 (ST@850 °C/30 min-WQ-ageing@550 °C/120 min-FC) conditions. Ti-6Al-4 V alloy's heat treated on SAT 6 (ST@913 °C/10 min-WQ-ageing@550 °C/90 min-FC) condition has the maximum hardness, which is around 16.62% higher than the as-received alloy. The greatest tensile strength for an alloy is achieved under SAT5 (ST @913 °C/20 min-WQ-ageing @450 °C/120 min-FC) conditions. The specimens thermally treated at SAT4 (ST@882 °C/30 min-WQ-ageing@450 °C/90 min-FC) and SAT6 (ST@913 °C/10 min-WQ-ageing@550 °C/90 min-FC) exhibit the greatest reduction in wear rate. The improved mechanical and wear properties of the specimens were attributed to the equiaxed small grains and bimodal lamellar structure of the alloy’s microstructure, which was altered by heat treatment.

Similar content being viewed by others

References

M.J. Donachie Jr., Titanium and Titanium Alloys Source Book, ASM international Metals, Park, Ohio, OH, 1982, p 12–105

S. Kalpakjian, Manufacturing Engineering and Technology, Addison-Wesley Publishing Company, Inc, USA, 1995.

A. Banerjee, S. Dhar, S. Acharyya, D. Datta, and N. Nayak, Determination of Johnson Cook Material and Failure Model Constants and Numerical Modelling of Charpy Impact Test of Armour Steel, Mater. Sci. Eng. A., 2015, 2015(640), p 200–209. https://doi.org/10.1016/j.msea.2015.05.073

J. Barry, G. Byrne, and D. Lennon, Observations on Chip Formation and Acoustic Emission in Machining Ti-6Al-4V Alloy, Int. J. Machine. Tools. Manuf., 2001, 41(7), p 1055–1070. https://doi.org/10.1016/S0890-6955(00)00096-1

K.G. Budinski, Tribological Properties of Titanium Alloys, Wear, 1991, 151(2), p 203–217.

N.S.M. El-Tayeb, T.C. Yap, and P.V. Brevern, Wear Characteristics of Titanium Alloy Ti54 for Cryogenic Sliding Applications, Tribol. Inter., 2010, 439(12), p 2345–2354.

S. Yerramareddy and S. Bahadur, Effect of Operational Variables, Microstructure and Mechanical Properties on the Erosion of Ti-6Al-4V, Wear, 1991, 142(2), p 253–263.

G. Perumal, M. Geetha, R. Asokamani, and N. Alagumurthi, A Comparative Study on the Wear Behaviour of Al2O3 and SiC Coated Ti-6Al-4V Alloy Developed Using Plasma Spraying Technique, Trans. Ind. Inst. Met., 2013, 66, p 109–115.

L. Ceschini, E. Lanzoni, C. Martini, D. Prandstraller, and G. Sambogna, Comparison of Dry Sliding Friction and Wear of Ti6Al4V Alloy Treated by Plasma Electrolytic Oxidation and PVD coating, Wear, 2008, 264(1–2), p 86–95.

G. Perumal, M. Geetha, R. Asokamani, and N. Alagumurthi, Wear Studies on Plasma Sprayed Al2O3-40 wt.% 8YSZ Composite Ceramic Coating on Ti-6Al-4V Alloy used for Biomedical Applications, Wear, 2014, 311(1–2), p 101–113. https://doi.org/10.1016/j.wear.2013.12.027

S. Krol, W. Grzesik, Z. Zalisz, and M. Hepner, “Frictional Behaviour of Oxygen Diffusion Hardened Titaniumin Dry Sliding Against Co-28Cr-5W-4Fe-3Ni-1Si Cobalt Alloy, Tribol. Inter., 2004, 37(8), p 633–643.

C. Met, L. Vandenbulcke, and M.C. Sainte Catherine, Friction and Wear Characteristics of Various Prosthetic Materials Sliding Against Smooth Diamond-Coated Titanium Alloy, Wear, 2003, 255(7–12), p 1022–1029.

H. Dong and T. Bell, Enhanced Wear Resistance of Titanium Surfaces by a New Thermal Oxidation Treatment, Wear, 2000, 238(2), p 131–137.

L.J. Hunter, M. Strangwood, and P. Bowen, Effect of Microstructure on the Fracture Behaviour of the α & β Titanium Alloy Ti-4Al-4Mo-2Sn-0.5Si wt.% (IMI 550), Titanium’95: Science and Technology. P.A. Blenkinsop, W.J. Evans, H.M. Flower Ed., The Inst. Mat, London, 1996, p 925

P. Burad, C. Gullipalli, and N. Thawari, Direct Laser-Deposited IN718 Alloy: Effect of Heat Treatment Route on Microstructural Evolution and Mechanical Properties, J. Mater. Eng. Perform., 2022 https://doi.org/10.1007/s11665-022-07744-x

G. Lutjering, Influence of Processing on Microstructure and Mechanical Properties of (α+β) Titanium Alloys, Mater. Sci. Eng. A., 1998, 243, p 32–45.

A. ElJersifi, K. Aouadi, and M. Ali, The Effect of Heat Treatments on the Properties of a Ferritic High-Chromium Cast Iron, J. Mater. Eng. Perform., 2022 https://doi.org/10.1007/s11665-022-07700-9

L.H. Zhou, H.Y. Bi, and F.L. Sui, Influence of Finish Rolling Temperature on Microstructure and Properties of Hot-Rolled SUS436L Stainless Steel, J. Mater. Eng. Perform., 2022 https://doi.org/10.1007/s11665-022-07719-y

E.W. Collings, The physical metallurgy of titanium alloys, ASM, Ohio, OH, 1989, p 1–130

J. Nakahigashi and H. Yoshimura, Superplasticity and Its Application of Ultra-Fine-Grained Ti-6Al-4V Alloy Obtained through Protium Treatment, Trans. Met., 2002, 43–11, p 2768–2772.

J.I. Qazi, O.N. Senkov, J. Rahim, and F.H. Froes, Phase Transformations in Ti-6Al-4V–xH Alloy, Mater. Sci. Eng. A., 2003, 359, p 137–149.

T. Morita, Y. Misaka, K. Kawasaki, and T. Iizuka, Strengthening of Ti-6A1-4V Alloy by Short-Time 2-Stage Induction Heat Treatment, J. Jpn. Inst. Met., 2004, 68–10, p 862–867.

J.C. Chesnutt, C.G. Rhodes, and J.C. Williams, ASTM-STP, 1976, 600, p 99–138.

S. Sastry, T.C. Peng, P.J. Mechter, and J.E. O’Neal, The Effect of Microstructure on the Mechanical Properties of Two-Phase Titanium Alloys, J. Met., 1984, 36(5), p 21–28.

S. Seo, H. Choi, and G. Lee, Effect of Cooling Rate on Microstructure and Hardness during Solution Treatment and Aging Process of Ti-6Al-4V Alloy for Aerospace Components, J. Mater. Eng. Perform., 2021, 30, p 3406–3415. https://doi.org/10.1007/s11665-021-05618-2

R. Sahoo, S. Mantry, T.K. Sahoo, S. Mishra, and B.B. Jha, Effect of Microstructural Variation on Erosion Wear Behavior of Ti-6Al-4V Alloy, Tribol. Trans., 2013, 56(4), p 555–560.

D.J. Mceldowney, S. Tamirisakandala, and D.B. Miracle, Heat-Treatment Effects on the Microstructure and Tensile Properties of Powder Metallurgy Ti-6Al-4V Alloys Modified with Boron, Metall. Mater. Trans. A., 2010, 41, p 1003–1015.

C. Leyens and M. Peters, Titanium and Titanium Alloys: Fundamentals and Applications, Wiley-VCH, Berlin, 2003.

N.P. Suh, An Overview of the Delamination Theory of Wear, Wear, 1977, 44, p 1–16.

A.S. Canbolat, A.H. Bademlioglu, N. Arslanoglu, and O. Kaynakli, Performance Optimization of Absorption Refrigeration Systems Using Taguchi, ANOVA and Grey Relational Analysis Methods, J. Clean. Prod., 2019, 229, p 874–888.

Acknowledgments

The author (G.P.) wishes to express his heartfelt appreciation to the chief executive officer PMJF, Ln. M. Saravanan, of VRS College of Engineering and Technology for his kind assistance and for approving the current work.

Funding

No funding was received for this research.

Author information

Authors and Affiliations

Corresponding author

Ethics declarations

Conflict of interest

There is no conflict of interest, the authors claim.

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Perumal, G., Senthilkumar, N., Subramaniyan, C. et al. Tailoring the Mechanical and Tribological Properties of Ti-6Al-4 V Alloy through Duplex Heat Treatment. J. of Materi Eng and Perform (2023). https://doi.org/10.1007/s11665-023-08586-x

Received:

Revised:

Accepted:

Published:

DOI: https://doi.org/10.1007/s11665-023-08586-x