Abstract

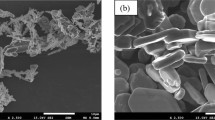

In order to get a homogenous mixture and compact of TiB2-Al2O3, hybridization as a surface modification method was used to prepare nano-scale Al2O3 coated TiB2 particles. PE-wax particles were first coated onto TiB2 particles by hybridization, and then the nano-scale Al2O3 particles were coated onto the surface of TiB2 coated by PE-wax particles again. SEM, TEM and EDS were used to characterize the microstructure of as-received core/shell particles and its compacts. The experimental results show that a particle-scale homogenous dispersion of TiB2 and Al2O3 can be formed not only in mixed powder but also in dewaxed compacts. The compacts then were sintered by gas-pressing sintering (GPS). Finial products show improved mechanic properties comparing with reference samples fabricated by normal ways.

Similar content being viewed by others

References

Davies T J, Ogwu A A. TiC Plus TiB2 Composite Shows Wear Promise[J]. Metal Powder Report, 1997, 52(6):31–34

Mroz C. Advanced Materials & Powders: Titanium Diboride (TiB2)[J]. Am. Ceram. Soc. Bull. 2000, 79(6):55–62

CH MURTHY T S R, BASU B, BALASUBRAMANIAM R. Processing and Properties of TiB2 with MoSi2 Sinteradditive: A First Report[J]. J. Am. Ceram. Soc., 2006, 89(1):131–138

XIANG Xin, QIN Yan. Development of Research on TiB2 and Its Composites[J]. Journal of Ceramic, 1999, 20(2):112–119

Smid I, Kny E. Evaluation of Binder Phases for Hard Metal Systems Based on TiB2[J]. Int. J. Refract. Met. Hard Mate., 1988,7(3): 135–138

Liu Shuo, Zhang Weiping. Research on Microstructure of in Situ Synthesized TiB2/Ni Metal-ceramics Composite Coating[J]. Journal of Alloys and Compounds, 2005, 391:146–150

GUO Jingkun, ZHU Peinan. The Design Principles of Multiphase Ceramic Materials[J]. J. Chin. Ceram. Soc., 1996, 24(1):7–13 (in Chinese)

Koishi M, Honda H, Matsuno T. Hybridization and Its Application[C]. In: Proc. Second World Congress Particle Technol., 1990: 361–365

Tang W J, Fu Z Y, Zhang J Y, Wang W M, Wang H, Wang Y C, Zhang Q J. Fabrication and Characteristics of TiB2/Al2O3 Core/shell Particles by Hybridization[J]. Powder Technology, 2006, 167: 117–123

Yuan R Z, Fu Z Y, Zhou X X, Yang Z L, Munir Z A. Synthesis TiB2 by Reductive SHS[J]. J. Mater. Synthesis Process, 1993, 1:153–157

WANG Weimin, FU Zhengyi, WANG Hao. Influence of Hot Pressing Sintering Temperature and Time on Microstructure and Mechanical Properties of TiB2 Ceramics[J]. J. Eur. Ceram. Soc., 2002, 22:1 045–1 049

Author information

Authors and Affiliations

Corresponding author

Additional information

Funded by the Foundation from the State Key Lab of Material and Processing of Wuhan University of Technology(2011-KF-7) and the Foundation of Ministry of Education of China(PCSIR70644)

Rights and permissions

About this article

Cite this article

Zhang, J., Tang, W., Fu, Z. et al. Fabrication of homogenous dispersion TiB2-Al2O3 composites. J. Wuhan Univ. Technol.-Mat. Sci. Edit. 26, 681–683 (2011). https://doi.org/10.1007/s11595-011-0291-4

Received:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11595-011-0291-4