Abstract

The current work investigated effects of Fe3O4 addition on the oxide scale of the stream generator (SG) tube in high-temperature water by using different surface analysis methods. It is found that the oxide scale of the SG tube presents a three-layer structure no matter the addition of Fe3O4 or not, namely: the outmost dispersedly deposited particle, the outer layer which is rich in Ni and Fe, and the inner layer which is rich in Cr. The addition of Fe3O4 does not affect the growth dynamics of the Cr enriched inner layer, but can enhance the deposition of NiFe2O4 on the tube surface. Moreover, the deposition of NiFe2O4 on the surface of Fe3O4 is much faster than the one on SG tube surface. The related mechanisms and the implications on the SG tube service performance are also discussed.

Similar content being viewed by others

References

D.X. Chen, M.N. Liu, X.H. Liu, Y.W. Zhou, X. Wang, and Y.T. Zhou, Oxidation Behavior of 304 Stainless Steel With Modified Layer by Plasma Nitriding in High Temperature And Pressurized Water. Corros. Sci., 2021, 186.

K.J. Choi, S.C. Yoo, H.H. Jin, J. Kwon, M.J. Choi, S.S. Hwang and J.H. Kim, Crack Growth Behavior of Warm-Rolled 316L Austenitic Stainless Steel in High-Temperature Hydrogenated Water, J Nucl Mater, 2016, 476, p 243–254.

F.J. Meng, J.Q. Wang, E.H. Han and W. Ke, The Role of TiN Inclusions in Stress Corrosion Crack Initiation for Alloy 690TT in High-Temperature and High-Pressure Water, Corros. Sci., 2010, 52, p 927–932.

Z. Que, H.P. Seifert, P. Spatig, J. Holzer, A. Zhang, G.S. Rao and S. Ritter, Environmental Degradation of Fracture Resistance in High-Temperature Water Environments of Low-Alloy Reactor Pressure Vessel Steels with High Sulphur Or Phosphorus Contents, Corros Sci, 2019, 154, p 191–207.

J.B. Tan, X.Q. Wu, E.H. Han, W. Ke, X. Wang and H.T. Sun, Strain-rate Dependent Fatigue Behavior of 316LN Stainless Steel in High-Temperature Water, J Nucl Mater, 2017, 489, p 33–41.

J.Z. Wang, X.H. Li, J.Q. Wang and E.H. Han, Development of a Scratch Electrode System in High Temperature High Pressure Water, Corros Sci, 2015, 95, p 125–132.

W.Q. Zhang, X.L. Wang, S.Y. Wang, H.C. Wu, C.W. Yang, Y.J. Hu, K.W. Fang, and H. Jiang, Combined Effects of Machining-Induced Residual Stress and External Load on SCC Initiation and Early Propagation of 316 Stainless Steel in High Temperature High Pressure Water. Corros. Sci., 2021, 190

D. Bouskela, V. Chip, B. El Hefni, J.M. Favennec, M. Midou and J. Ninet, New Method to Assess Tube Support Plate Clogging Phenomena in Steam Generators of Nuclear Power Plants, Math Comp Model Dyn, 2010, 16, p 257–267.

G.Z. Yang, V. Pointeau, E. Tevissen and A. Chagnes, A Review on Clogging of Recirculating Steam Generators in Pressurized-Water Reactors, Prog Nucl Energ, 2017, 97, p 182–196.

S. Girard, T. Romary, J.M. Favennec, P. Stabat and H. Wackernagel, Sensitivity Analysis and Dimension Reduction of a Steam Generator Model for Clogging Diagnosis, Reliab Eng Syst Safe, 2013, 113, p 143–153.

L. Ren, S.W. Wang, J. Xu, T. Zhang, Q. Guo, D.Y. Zhang, J.J. Si, X.H. Zhang, H.Y. Yu, T. Shoji and D.B. Sun, Fouling on the Secondary Side of Nuclear Steam Generator Tube: Experimental and Simulated Study, Appl. Surf. Sci., 2022, 590, 153143.

L. Ren, G.H. Qiu, H.Y. Yu, P. Zhou, T. Shoji, N.N. Li and J. Xu, Correlation Between the Fouling of Different Crystal Calcium Carbonate and Fe2O3 Corrosion On Heat Exchanger Surface, Mol Simulat, 2021, 47, p 748–761.

C. Henry, J.P. Minier and G. Lefevre, Towards a Description of Particulate Fouling: From Single Particle Deposition To Clogging, Adv Colloid Interfac, 2012, 185, p 34–76.

Y. Xie and J.S. Zhang, Corrosion and Deposition on the Secondary Circuit of Steam Generators, J Nucl Sci Technol, 2016, 53, p 1455–1466.

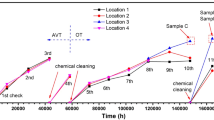

T. Zhang, G.H. Qiu, H.Y. Yu, P. Zhou, S.C. Wang, K.G. Zhang, Q. Guo, L. Ren, J. Xu, The Fouling Behavior of Steam Generator Tube at Different Positions in the High-Temperature Water. Metals-Basel, 2021, 11

Y. Lee, Y.J. Cho and I. Ryu, Preliminary Analyses on Decontamination Factors During Pool Scrubbing with Bubble Size Distributions Obtained from EPRI Experiments, Nucl. Eng. Technol., 2021, 53, p 509–521.

D. Qiao, Z. Changyu, P. Jian and H. Xiaohua, Experiment, Finite Element Analysis and EPRI Solution for J-integral of Commercially Pure Titanium, Rare Metal Mater. Eng., 2014, 43, p 257–263.

J. Nelson, A. Saunders, L. Poirier, F. Lopez-Linares, Analysis of Gold Nanoparticles in a Hydrocarbon Solvent By Single Particle-Inductively Coupled Plasma Mass Spectrometry (spICP-MS) and TEM, Sn Appl Sci, 3 (2021).

P.E. Peyneau, Poisson Process Modelling of Spike Occurrence in Single Particle Inductively Coupled Plasma Mass Spectrometry Time Scans For Very Dilute Nanoparticle Dispersions. Spectrochim Acta B, 2021, 178.

H.E. Pace, N.J. Rogers, C. Jarolimek, V.A. Coleman, E.P. Gray, C.P. Higgins and J.F. Ranville, Single Particle Inductively Coupled Plasma-Mass Spectrometry: A Performance Evaluation and Method Comparison in the Determination of Nanoparticle Size, Environ Sci Technol, 2012, 46, p 12272–12280.

L. Ren, S.C. Wang, J. Xu, T. Zhang, Q. Guo, D.Y. Zhang, J.J. Si, X.H. Zhang, H.Y. Yu, T. Shoji, and D.B. Sun, y Fouling on the Secondary Side of Nuclear Steam Generator Tube: Experimental and Simulated Study. Appl. Surface Sci. 2022, 590.

Z.M. Zhang, J.Q. Wang, E.-H. Han and W. Ke, Influence of Dissolved Oxygen on Oxide Films of Alloy 690TT with Different Surface Status in Simulated Primary Water, Corros. Sci., 2011, 53, p 3623–3635.

F. Huang, J.Q. Wang, E.-H. Han and W. Ke, Microstructural Characteristics of the Oxide Films Formed on Alloy 690 TT in Pure and Primary Water at 325°C, Corros. Sci., 2013, 76, p 52–59.

Z.H. Wang, Y. Takeda, Roles of Permeated Hydrogen in the Oxidation Process of Ni-Based Alloy in High Temperature Water Environment, Corros. Sci. 2021, 179

Z.H. Wang and Y. Takeda, Mechanistic Understanding of the Roles of Hydrogen in Modification of Oxide Film of Alloy 600 in High Temperature High Pressure Water Environment. Corros Sci, 2020, 170

J.J. Chen, Z.P. Lu, F.J. Meng, X.L. Xu, Q. Xiao, H.S. Kim and C. Jang, The Corrosion Behaviour of Alloy 690 Tube in Simulated PWR Secondary Water with the Effect of Solid Diffusing Hydrogen, J Nucl Mater, 2019, 517, p 179–191.

Z.M. Zhang, J.Q. Wang, E.H. Han and W. Ke, Analysis of Surface Oxide Films Formed in Hydrogenated Primary Water on Alloy 690TT Samples With Different Surface States, J Mater Sci Technol, 2014, 30, p 1181–1192.

F. Huang, J.Q. Wang, E.H. Han and W. Ke, Microstructural Characteristics of the Oxide Films Formed on Alloy 690 TT in Pure and Primary Water at 325 Degrees C, Corros. Sci., 2013, 76, p 52–59.

D.Y. Zhang, H.Y. Yu, W.R. Wang, A.Z. Wang, L. Ren, P. Hu, X.H. Zhang and D.B. Sun, Achieving Synergy of Load-Carrying Capability and Damage Tolerance in a ZrB2-SiC Composite Reinforced Through Discontinuous Carbon Fiber, J Eur Ceram Soc, 2021, 41, p 7404–7411.

W.Y. Jia, L. Ren, J. Xu, S.C. Wang, T. Shoji, Q. Guo, T. Zhang, D.Y. Zhang, H.Y. Yu, and D.B. Sun, Study on the Relationship Between Fe3O4 Fouling and NiFe2O4 Oxide Layer in the Secondary Circuit of Nuclear Steam Generator. Surf Sci., 2022, 717

S.C. Pan, L. Ren, J. Xu, T. Shoji, N.N. Li, T. Zhang, H.Y. Yu, and D.B. Sun, DFT study of the Fouling Deposition Process in the Steam Generator by Simulating the Adsorption of Fe2+ on Fe3O4 (001). J. Mol. Model, 2021, 27

L. Ren, J. Xu, W.Y. Jia, H.Y. Yu, T. Shoji, T. Zhang, N.N. Li, D.Y. Zhang, and D.B. Sun, Computational Study of Fe3O4 Adsorption Behaviour on the Secondary Side of the Heat Exchange Tube in the Steam Generator. Comp Mater Sci. 2021, 195

L. Ren, J. Xu, S.C. Pan, H.Y. Yu, T. Zhang, T. Shoji, N.N. Li, D.Y. Zhang and D.B. Sun, DFT Studies on the Interaction of Fe2+/Fe3O4(1 1 1) and OH-/Fe3O4(1 1 1) During the Adsorption Process in the Steam Generators of Nuclear Power Plants, Colloids Surf., A, 2021, 617, 126393.

M. Bojinova, A. Galtayries, P. Kinnunen, A. Machet and P. Marcus, Estimation of the Parameters of Oxide Film Growth on Nickel-Based Alloys in High-Temperature Water Electrolytes, Electrochim. Acta, 2007, 52, p 7475–7483.

M. Bojinov, P. Kinnunen and G. Sundholm, Electrochemical Behaviour of Nickel-Chromium Alloy in a High-Temperature Aqueous Electrolyte, Corrosion, 2003, 59, p 91–103.

Q. Guo, J. Nong, Y.L. Wu, F.R. Liang, L. Ren, J. Xu, and T. Shoji, Effects of In-Situ Hydrogen Charging on the Oxide Film of Iron in High-Temperature Water: Experiments and DFT Calculations. Scripta Mater. 2022, 221

Z.H. Wang and Y. Takeda, Amorphization and Structural Modification of the Oxide Film of Ni-Based Alloy by In-Situ H Charging in High Temperature High Pressure Water Environment. Corros Sci., 2020, 166

J. Xu, J. Nong, F. Liang, S. Yuan, L. Ren, Q. Guo, and T. Shoji, Hydrogen Charging Effects on the Alternation of Oxide Film Formed on Ni, Cr and Alloy 690 in High-Temperature Water. Corros. Sci., 2022, 209

Acknowledgments

This work has been supported by the National Key R&D project of China (2019YFB1900904), the National Natural Science Foundation of China (51901254, 52001336), Guangdong Natural Science Foundation (2020A1515110449, 2020A1515011033), China Postdoctoral Science Foundation (2021M693591).

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Zhang, T., Shan, H., Pu, Y. et al. Effects of Fe3O4 Addition on the Oxide Scale of a Steam Generator Tube in High-Temperature Water. J. of Materi Eng and Perform 33, 2768–2781 (2024). https://doi.org/10.1007/s11665-023-08160-5

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-023-08160-5