Abstract

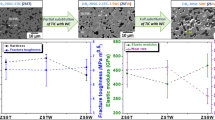

Nowadays, much attention has been paid to reactive composites due to their superior mechanical properties and sintering ability compared to conventional composites. In this study, a comparative evaluation of mechanical and microstructural properties of ZrB2-SiC composites fabricated by in situ reaction of ZrO2 + B4C + SiC (ZBS) and non-reactive sintering of ZrB2-SiC (ZS) powders via the spark plasma sintering (SPS) method is investigated. The SPS process was conducted in a vacuum atmosphere and sintering temperatures of 1900 and 2000 °C for 10 min. XRD and FESEM/EDS analysis were carried out for phase characterization and microstructural studies. Bulk density, microhardness, bending strength, and K1C of the fabricated composites were compared. A high shrinkage of the ZBS sample is observed due to the reaction of raw materials, while the ZS1 and ZS2 samples indicated lower shrinkage. This reaction is confirmed by vacuum changes above 1250 °C due to the formation of B2O3 and CO gases. XRD characterizations showed the complete formation of the ZrB2-SiC composite in the ZBS sample. Microstructural studies revealed complete densification of the ZBS composite, while the presence of porosities is observed in the ZS1 sample. A high relative density of 99.8 ± 0.6%, bending strength of 983 ± 36 MPa, hardness of 23.2 ± 2 GPa, and K1C of 5.18 ± 0.63 MPa.m 0.5 were obtained for the ZBS composite, while lower values of relative density (90.5 ± 0.9%), bending strength (554 ± 28 MPa), hardness (17.3 ± 1 GPa) and K1C (3.92 ± 0.15 MPa.m 0.5) are obtained for ZS1 specimen. Increasing the sintering temperature in the ZS2 sample gave a relative density of 99.9%. But it still had weaker bending strength (703 ± 26 MPa), hardness (18.11 ± 1 GPa), and K1C (4.21 ± 0.23 MPa.m 0.5).

Similar content being viewed by others

Abbreviations

- K1C:

-

Fracture toughness

- ΔG:

-

The change in Gibbs free energy

References

Z.Y.D. Guo-Jun Zhang, N. Kondo, J.F. Yang, and T. Ohji, Reactive Hot Pressing of ZrB2-SiC Composites, J. Am. Ceram. Soc., 2000, 9, p 2330–2332.

T.G. Aguirre, B.W. Lamm, C.L. Cramer, and D.J. Mitchell, Zirconium-Diboride Silicon-Carbide Composites: A review, Ceramics International (2021).

B. Kübra Gürcan, Densification and Properties of In-Situ Synthesized ZrB2-SiC Composities from ZrO2, B4C and SiC System, J. Ceram. Process. Res., 2017, 18(4), p 280–284.

M. Shirani, M. Rahimipour, M. Zakeri, S. Safi, and T. Ebadzadeh, ZrB2-SiC-WC Coating with SiC Diffusion Bond Coat on Graphite by Spark Plasma Sintering Process, Ceram. Int., 2017, 43(16), p 14517–14520.

G.H. Jeremy Watts, and W.G. Fahrenholtz, Mechanical Characterization of ZrB2-SiC Composites with Varying SiC Particle Sizes, J. Am. Ceram. Soc., 2011, 94(12), p 4410–4418.

S.C. Zhang, G.E. Hilmas, and W.G. Fahrenholtz, Mechanical Properties of Sintered ZrB2-SiC Ceramics, J. Eur. Ceram. Soc., 2011, 31(5), p 893–901.

S. Oguntuyi, O. Johnson, and M. Shongwe, Spark Plasma Sintering of Ceramic Matrix Composite of ZrB2 and TiB2: Microstructure, Densification, and Mechanical Properties—A Review, Met. Mater. Int., 2021, 27(7), p 2146–2159.

M.S.A. B. Nayebi, M. Ghassemi Kakroudi, and M. Shokouhimehr, Int. J. Refract. Met. Hard Mater, 54 (Temperature Dependence of Microstructure Evolution During Hot Pressing of ZrB2–30 vol.% SiC Composites) (2016)

M.R. Derakhshandeh, A. Fazili, R.B. Golenji, F. Alipour, M.J. Eshraghi, and L. Nikzad, Fabrication of (TixZr1− x) B2-(ZrxTi1− x) N Composites by Reactive Spark Plasma Sintering of ZrB2-TiN, J. Alloy. Compd., 2021, 887, p 161403.

B. Mohammadpour, Z. Ahmadi, M. Shokouhimehr, and M.S. Asl, Spark Plasma Sintering of Al-Doped ZrB2-SiC Composite, Ceram. Int., 2019, 45(4), p 4262–4267.

K. Shirvanimoghaddam, E. Ghasali, A. Pakseresht, S. Derakhshandeh, M. Alizadeh, T. Ebadzadeh, and M. Naebe, Super Hard Carbon Microtubes Derived from Natural Cotton for Development of High Performance Titanium Composites, J. Alloy. Compd., 2019, 775, p 601–616.

S. Derakhshandeh, M.S. Gohari, E.K. Saeidabadi, A. Jam, A. Fazili, M. Alizadeh, E. Ghasali, A. Pakseresht, and T. Ebadzadeh, Comparison of Spark Plasma and Microwave Sintering of Mullite Based Composite: Mullite/Ta2O5 Reaction, Ceram. Int., 2018, 44(11), p 13176–13181.

Y. Orooji, M.R. Derakhshandeh, E. Ghasali, M. Alizadeh, M.S. Asl, and T. Ebadzadeh, Effects of ZrB2 Reinforcement on Microstructure and Mechanical Properties of a Spark Plasma Sintered Mullite-CNT Composite, Ceram. Int., 2019, 45(13), p 16015–16021.

Y. Orooji, E. Ghasali, M. Moradi, M.R. Derakhshandeh, M. Alizadeh, M.S. Asl, and T. Ebadzadeh, Preparation of mullite-TiB2-CNTs Hybrid Composite Through Spark Plasma Sintering, Ceram. Int., 2019, 45(13), p 16288–16296.

Y. Orooji, A.A. Alizadeh, E. Ghasali, M.R. Derakhshandeh, M. Alizadeh, M.S. Asl, and T. Ebadzadeh, Co-Reinforcing of Mullite-TiN-CNT Composites with ZrB2 and TiB2 Compounds, Ceram. Int., 2019, 45(16), p 20844–20854.

A. Fazili, L. Nikzad, M. RahimiPour, M. Razavi, and E. Salahi, Effect of Al2O3 Ceramic Binder on Mechanical and Microstructure Properties of Spark Plasma Sintered WC-Co Cermets, Int. J. Refract Metal Hard Mater., 2017, 69, p 189–195.

M. Derakhshandeh, M.S. Naeini, E. Ghasali, A. Jam, A. Fazili, M. Alizadeh, A. Kazemzadeh, and T. Ebadzadeh, Preparation of In-Situ Formed TiN0. 3-Ti5Si3-TiN Composites Through Reactive Spark Plasma Sintering of Ti and Si3N4, Ceram. Int., 2019, 45(5), p 6477–6483.

N. Hosseini, A. Fazili, M.R. Derakhshandeh, L. Nikzad, M. Bahamirian, and M. Razavi, Effect of Co Addition on Microstructural and Mechanical Properties of WC-B4C-SiC Composites, Ceram. Int., 2021, 47(11), p 15771–15782.

E. Ghasali, M.R. Derakhshandeh, Y. Orooji, M. Alizadeh, and T. Ebadzadeh, Effects of 211 and 413 Ordering on the Corrosion Behavior of V-Al-C MAX Phases Prepared by Spark Plasma Sintering, J. Eur. Ceram. Soc., 2021, 41(9), p 4774–4787.

A. Fazili, M.R. Derakhshandeh, S. Nejadshamsi, L. Nikzad, M. Razavi, and E. Ghasali, Improved Electrochemical and Mechanical Performance of WC-Co Cemented Carbide by Replacing a Part of Co with Al2O3, J. Alloy. Compd., 2020, 823, p 153857.

R.L.P.E.V. Clougherty and L. Kaufman, Synthesis of Oxidation Resistant Metal Biboride Composites, Tran. Metal. Soc. AIME, 1968, 242(6), p 1077–1082.

Z.H.Y. Yan, S. Dong, and D. Jiang, Pressureless Sintering of High-Density ZrB2-SiC Ceramic Composites, J. Am. Ceram. Soc., 2006, 89, p 11.

R.M.A. Purwar, K. Ravikumar, S. Ariharan, N.K. Gopinath, and B. Basu, Development of ZrB2-SiC-Ti by Multi Stage Spark Plasma Sintering at 1600°C, J. Ceram. Soc. Japan, 2016, 124(4), p 393–402.

J.-H. Yuan, Q.-Y. Liu, Y. You, L.-Y. Zeng, M.-W. Bai, L.R. Blackburn, W.-M. Guo, and H.-T. Lin, Effect of ZrB2 Powders on Densification, Microstructure, Mechanical Properties and Thermal Conductivity of ZrB2-SiC Ceramics, Ceram. Int., 2021, 47(11), p 15843–15848.

L. Xu, Y. Yang, S. Wang, M. Li, J. Xu, Y. Qian, J. Zuo, and D. Zhang, Improved Both Mechanical and Anti-Oxidation Performances of ZrB2-SiC Ceramics with Molybdenum Disilicide Addition, Mater. Chem. Phys., 2019, 223, p 53–59.

C.L.C. Trevor, G. Aguirre, E. Cakmak, M.J. Lance, and R.A. Lowden, Processing and Microstructure of ZrB2-SiC Composite Prepared by Reactive Spark Plasma Sintering, Res. Mater., 2021, 11, p 100217.

L.J.W.Y. Zhao, G.J. Zhang, W. Jiang, and L.-D. Chen, Effect of Holding Time and Pressure on Properties of ZrB2-SiC Composite Fabricated by the Spark Plasma Sintering Reactive Synthesis Method, Int. J. Refract. Metals Hard Mater., 2009, 27(1), p 177–180.

E.A.M. Xiang, Reactive Spark Plasma Sintering and Mechanical Properties of ZrB2-SiC-ZrC Composites from ZrC-B4C-Si System, Ceram. Int., 2018, 44(7), p 8417–8422.

Z. Balak, Open Porosity and Grain Size Effect on the Mechanical Property of ZrB2-30SiC Containing HfB2, Mater. Res. Express, 2019, 6(9), p 095607.

J. Marschall, D.A. Pejaković, W.G. Fahrenholtz, G.E. Hilmas, F. Panerai, and O. Chazot, Temperature Jump Phenomenon During Plasmatron Testing of ZrB2-SiC Ultrahigh-Temperature Ceramics, J. Thermophys. Heat Trans., 2012, 26(4), p 559–572.

M. Playez, D.G. Fletcher, J. Marschall, W.G. Fahrenholtz, G.E. Hilmas, and S. Zhu, Optical Emission Spectroscopy During Plasmatron Testing of ZrB2-SiC Ultrahigh-Temperature Ceramic Composites, J. Thermophys. Heat Trans., 2009, 23(2), p 279–285.

J. Marschall, D.A. Pejakovic, W.G. Fahrenholtz, G.E. Hilmas, S. Zhu, J. Ridge, D.G. Fletcher, C.O. Asma, and J. Thömel, Oxidation of ZrB2-SiC Ultrahigh-Temperature Ceramic Composites in Dissociated Air, J. Thermophys. Heat Transfer, 2009, 23(2), p 267–278.

ISO 28079, Hardmetals–Palmqvist Toughness Test, 2009., 2009.

S. Sun, Y. Liu, Z. Ma, F. Wang, S. Zhu, J. Guo, and C. Hong, Effect of Powder Pre-Oxidation on the Microstructure and Ablation Resistance of ZrB2-SiC Coating, J. Alloy. Compd., 2020, 832, p 154881.

Y. Xiong, X. Du, M. Xiang, H. Wang, W. Wang, and Z. Fu, Densification Mechanism During Reactive Hot Pressing of B4C-ZrO2 Mixtures, J. Eur. Ceram. Soc., 2018, 38(12), p 4167–4172.

J.R. Rumble, CRC Handbook of Chemistry and Physics, (Internet Version 2018), CRC Press/Taylor & Francis, Boca Raton, FL, 2018.

O. Popov, J. Vleugels, E. Zeynalov, and V. Vishnyakov, Reactive Hot Pressing Route for Dense ZrB2-SiC and ZrB2-SiC-CNT Ultra-High Temperature Ceramics, J. Eur. Ceram. Soc., 2020, 40(15), p 5012–5019.

Z. Zhang, J. Sha, Y. Zu, J. Dai, and Y. Liu, Fabrication and Mechanical Properties of self-Toughening ZrB 2-SiC Composites from In-Situ Reaction, J. Adv. Ceram., 2019, 8(4), p 527–536.

M.D. Alvari, M.G. Kakroudi, B. Salahimehr, R. Alaghmandfard, M.S. Asl, and M. Mohammadi, Microstructure, Mechanical Properties, and Oxidation Behavior of Hot-Pressed ZrB2-SiC-B4C Composites, Ceram. Int., 2021, 47(7), p 9627–9634.

N.P. Vafa, M.G. Kakroudi, and M.S. Asl, Role of h-BN Content on Microstructure and Mechanical Properties Of Hot-Pressed ZrB2-SiC Composites, Ceram. Int., 2020, 46(13), p 21533–21541.

Author information

Authors and Affiliations

Corresponding author

Additional information

Publisher's Note

Springer Nature remains neutral with regard to jurisdictional claims in published maps and institutional affiliations.

Rights and permissions

Springer Nature or its licensor (e.g. a society or other partner) holds exclusive rights to this article under a publishing agreement with the author(s) or other rightsholder(s); author self-archiving of the accepted manuscript version of this article is solely governed by the terms of such publishing agreement and applicable law.

About this article

Cite this article

Fazili, A., Irankhah, R., Shirani, M. et al. Comparison of ZrB2-SiC Composites Fabricated Through Reactive and Non-reactive Methods. J. of Materi Eng and Perform 32, 10728–10739 (2023). https://doi.org/10.1007/s11665-023-07909-2

Received:

Revised:

Accepted:

Published:

Issue Date:

DOI: https://doi.org/10.1007/s11665-023-07909-2